A garbage incinerator and its construction method

A technology for a waste incinerator and a construction method, which is applied to the field of waste incinerators and their construction, can solve the problems of easy coking of furnace walls, and achieve the effects of reducing uneven heating, increasing temperature, and preventing coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is further described in detail through specific implementation methods:

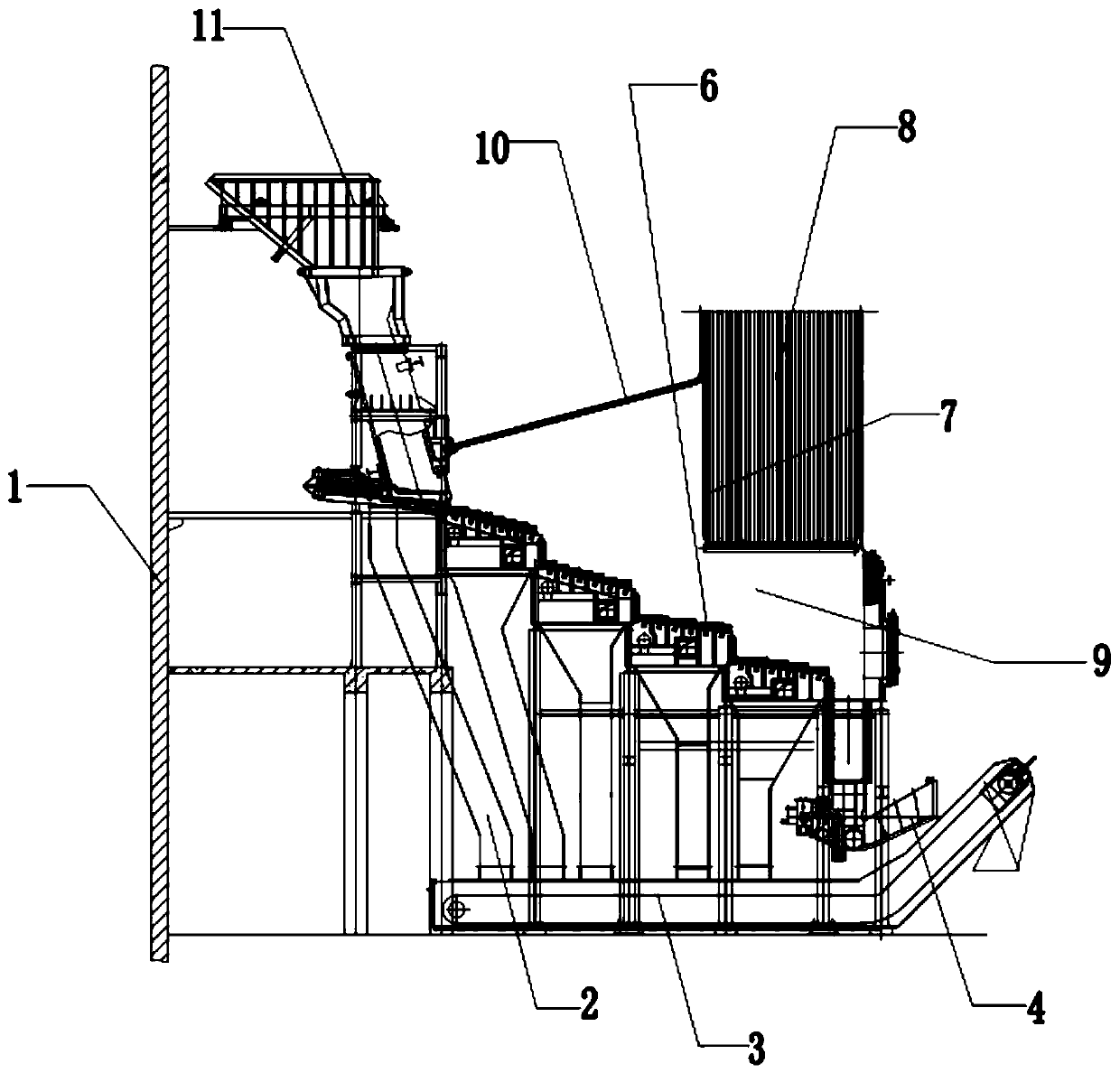

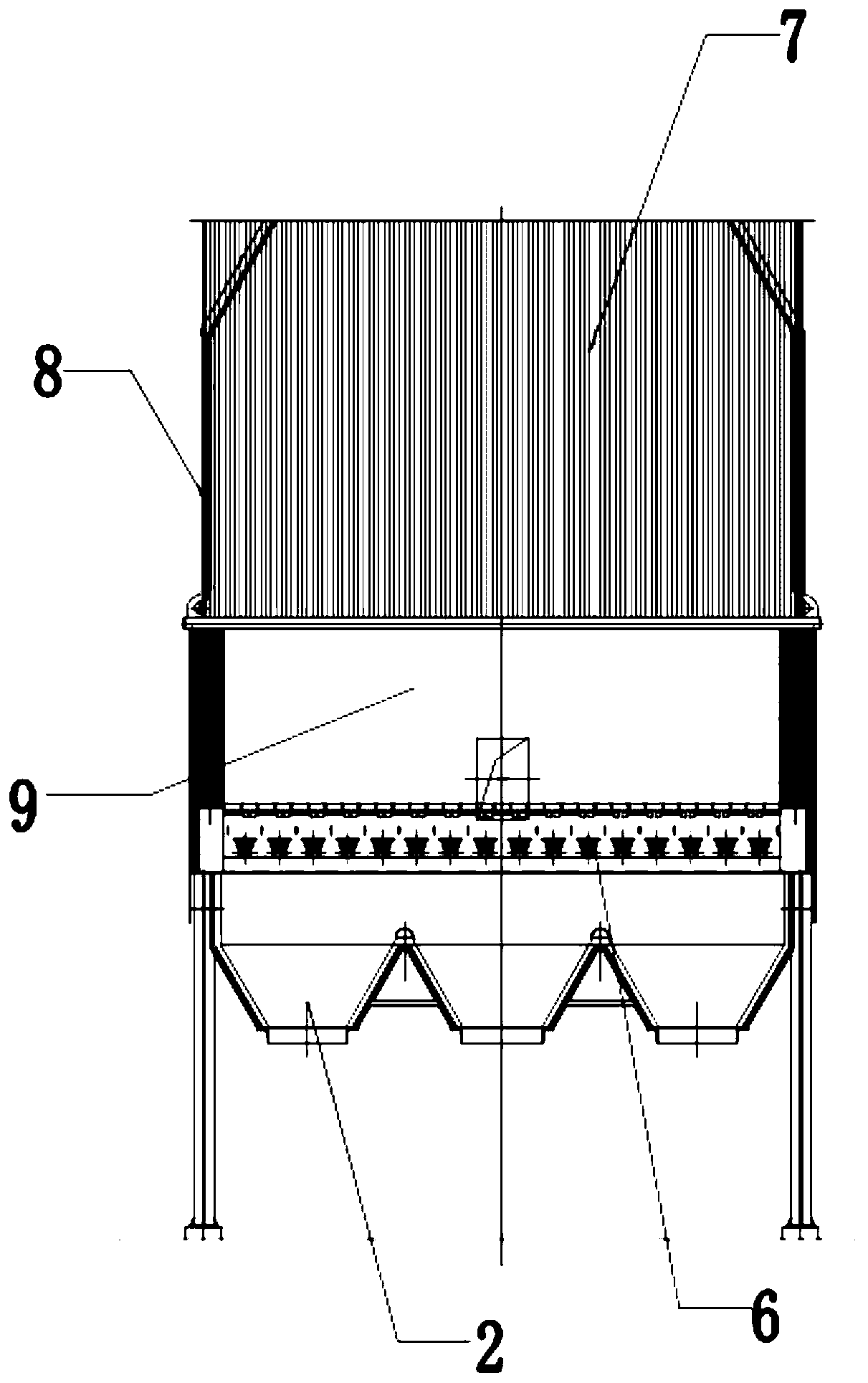

[0041] The reference signs in the accompanying drawings of the description include: garbage pit civil construction wall 1, ash bucket 2, ash conveyor 3, slag extractor 4, fire grate 6, rear wall water cooling wall 7, side wall water cooling wall 8, furnace 9, Front arch water wall 10, garbage feed port 11.

[0042] The embodiment is basically as attached figure 1 As shown: the garbage incinerator in this embodiment includes a drying zone, a main combustion zone and a burnout zone which are connected in sequence.

[0043] Among them, the drying area includes a garbage pit for fermenting and dehydrating garbage, and a manipulator for grabbing out the dehydrated garbage in the garbage pit. The garbage pit has a garbage pit civil wall 1 for surrounding and forming a garbage pit for stacking garbage.

[0044] The main combustion zone includes a garbage feed port 11 for putting the ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com