Oil-gas composite cooling type flame stabilizer and combustion chamber

A technology of flame stabilizer and composite cooling, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of easy coking, clogging and ablation of fuel injection rods, and achieve enhanced flame stability, high-efficiency cooling, and increased The effect of dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and effect of the present invention more clear and definite, the technical solution of the present invention will be further described in conjunction with the accompanying drawings and embodiments. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

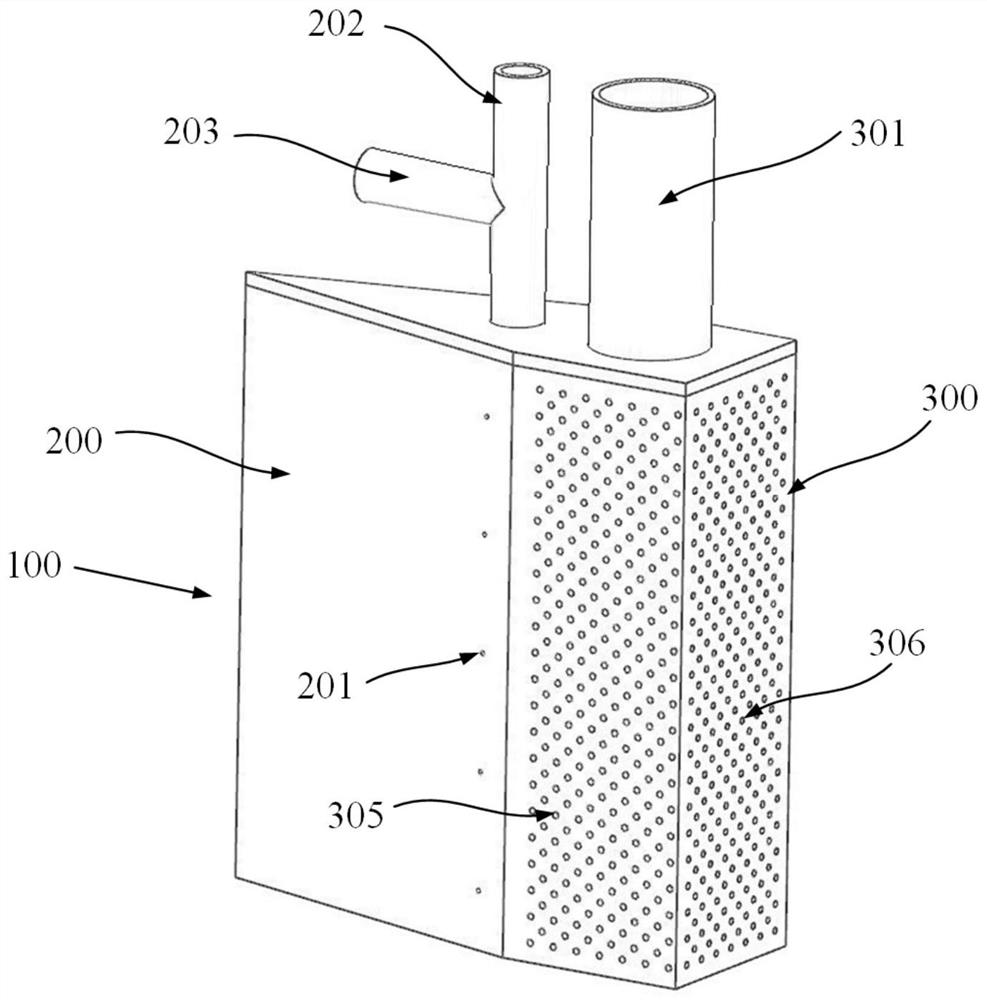

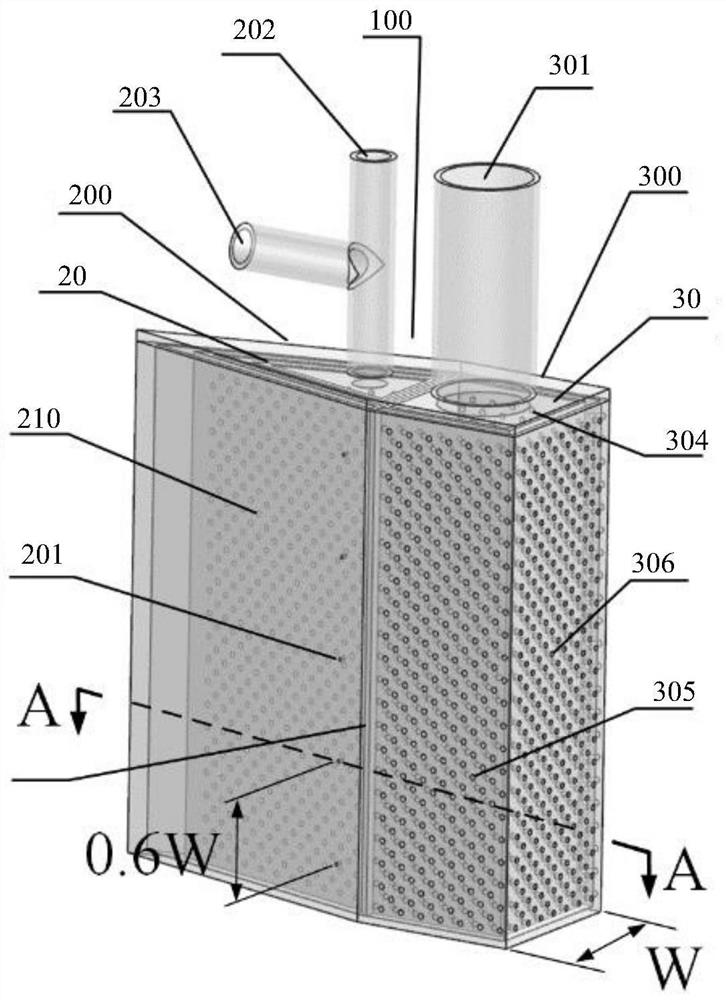

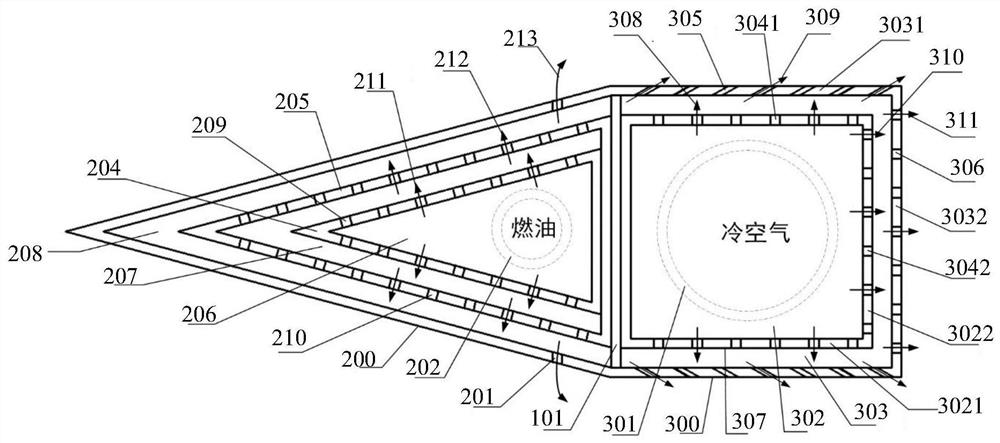

[0021] Such as figure 1 As shown, the oil-air composite cooling flame stabilizer of the present invention includes a flame stabilizer main body 100 , the hollow flame stabilizer main body 100 is divided into a V-shaped section 200 and a straight section 300 downstream of the V-shaped section 200 by a partition 101 . The V-shaped section 200 is a hollow cavity with a triangular cross-section. The internal cavity of the V-shaped section 200 is divided into several layers of interconnected oil cooling chambers 20 from the inside to the outside. Several fuel impact holes on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com