Low-lactose and lactose-free milk product and process for production thereof

A dairy product, low lactose technology, applied in dairy products, milk formulations, applications, etc., to achieve the effect of improving recovery and loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1. Ultrafiltration of hydrolyzed skim milk under cool conditions (K=1.9)

[0055] Skim milk (40 L) was hydrolyzed (6° C., 18 hours) with Godo YNL2 lactase (Godo Shusei Company, Japan) at a dose of 0.15%. And the fully hydrolyzed skim milk was subjected to ultrafiltration with HFK-131 membrane (Koch Membrane Systems Inc., USA) at a temperature of 9° C. to 19° C. and a pressure of 4.5 bar to 5.0 bar. The permeate flow is 3.81 / m 2 h~6.51 / m 2 h. Ultrafiltration was continued until the concentration factor was 1.9, ie, the volume of UF retentate was 21 L and the volume of UF permeate was 19 L.

[0056] Samples were taken from the feed (hydrolyzed skim milk), UF retentate and UF permeate from which protein, dry matter, glucose, galactose and ash were determined (Table 1).

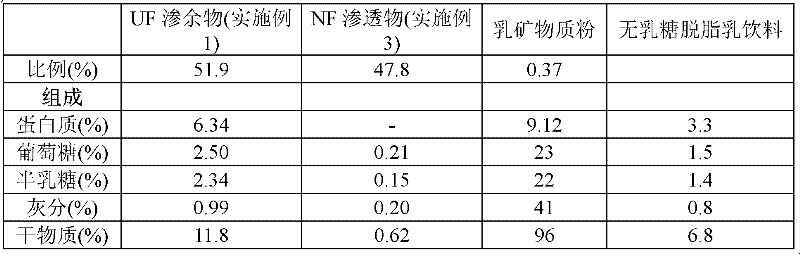

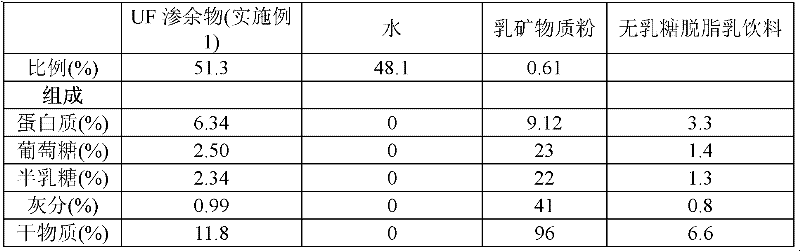

[0057] The UF retentate was used to make up milk drinks (Example 9; Tables 10 and 11).

[0058] Table 1 : Composition of ultrafiltration feed, retentate and permeate of hydrolyzed skim milk

...

Embodiment 2

[0060] Example 2. Ultrafiltration of hydrolyzed skim milk under warm conditions (K=4)

[0061] Skim milk (40 L) was hydrolyzed (6° C., 22 hours) with Godo YNL2 lactase (Godo Shusei Company, Japan) at a dose of 0.15%. The fully hydrolyzed skim milk was subjected to ultrafiltration with a HFK-131 membrane (Koch Membrane Systems Inc., USA) at a temperature of 45° C. to 50° C. and a pressure of 1 bar to 3.5 bar. The permeate flow is 7.81 / m 2 h~10.31 / m 2 h. Ultrafiltration was continued until the concentration factor was 4, ie the volume of UF retentate was 10 L and the volume of UF permeate was 30 L.

[0062] Samples were taken from the feed (hydrolyzed skim milk), UF retentate and UF permeate from which protein, dry matter, glucose, galactose and ash were determined (Table 2).

[0063] The UF retentate was used to make up milk drinks (Example 9; Table 12), to make flavored milk drinks (Example 10; Table 13) and to make up whey protein-containing milk drinks (Example 11; Table...

Embodiment 3

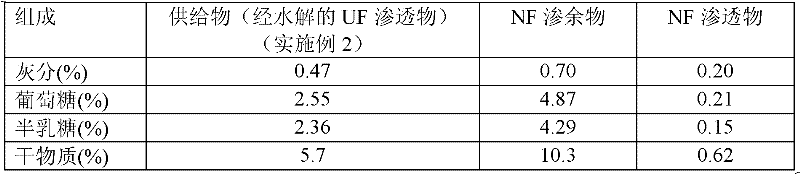

[0067] Example 3. Nanofiltration of Ultrafiltration Permeate of Hydrolyzed Skim Milk

[0068] Continuing with the experiment of Example 2, the ultrafiltration permeate was nanofiltered to a concentration factor of 2 with a Filmtec NF membrane (Dow, USA) at a filtration temperature of 10° C. to 16° C. The permeate flow is 101 / m 2 h, the pressure is 11 bar to 17 bar. The feed was 29.5 liters, the NF retentate was 14.5 liters, and the NF permeate was 15 liters.

[0069] Dry matter, glucose, galactose and ash were determined from feed, NF retentate and NF permeate. The results are shown in Table 3.

[0070] The NF permeate was used in the diafiltration step in Example 5.

[0071]NF permeate was also used to make up milk drinks (Example 9; Tables 10 and 12).

[0072] Table 3. Nanofiltration of UF permeate of hydrolyzed skim milk. Composition of feed, retentate and permeate.

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com