Apparatus for removing impregnating compound special for recovery of waste glass fiber

A technology for removing and removing glass fibers, applied in the field of soaking and removing special solvents for glass fiber recycling, can solve the problems of large amount of waste water, low production efficiency, and high labor cost, and can increase the number of recycling cycles, reduce the difficulty of treatment, and reduce cleaning. The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

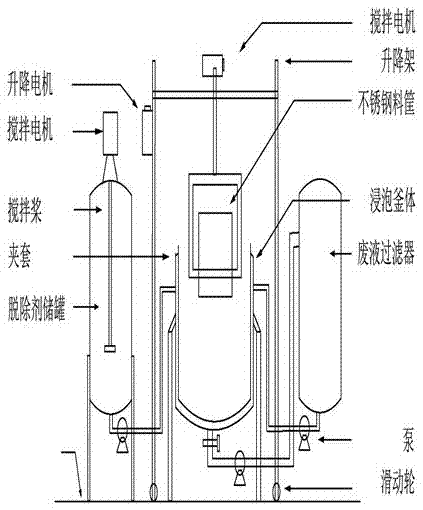

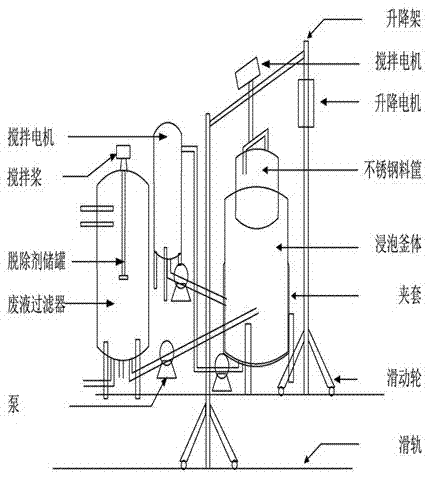

[0010] Such as figure 1 As shown, the special solvent immersion and removal device for glass fiber recovery includes a removal agent storage tank 12, a stainless steel basket 3, a soaking kettle body 4, and a waste liquid filter 5.

[0011] The specific operation process of the special solvent immersion and removal device for glass fiber recycling in the recycling process of glass fiber waste includes the following steps: put the waste glass fiber into the stainless steel basket 3, lift the basket through the lifting motor 8, and move it horizontally After reaching the top of the soaking kettle, use the lifting motor 8 to lower the material basket to the inside of the kettle body until it is immersed in the solvent, control the temperature and time according to the process requirements, lift the material basket to the upper part of the kettle body after soaking and removal, and suspend it above the solvent level. But the height does not exceed the upper opening of the kettle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com