One-bath desizing and refining method of pure starch sizing cotton fabric

A cotton fabric and starch technology, which is applied in the biochemical treatment of enzymes/microorganisms, plant fibers, textiles and papermaking, etc., can solve the problems of high energy consumption, water consumption and waste water discharge, unsatisfactory cotton seed hull removal effect, and serious environmental pollution. and other problems, to achieve the effect of reducing COD value and wastewater volume, clear texture and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the preparation method of Trametes fermented enzyme liquid

[0047] Weigh 200g of peeled potatoes, cut into small pieces, add 1.0L of water and boil for 30min, filter the potato pieces with 4 layers of gauze, make up the filtrate to 1.0L, add 20.0g of glucose, add 0.8g of lignosulfonate, fully dissolve . After subpackaging, sterilize under high pressure at 121°C for 20 minutes, cool down, perform aseptic operation, insert the bacterial suspension of the Trametessp.LEF01 strain that has been cultured on the PDA slant medium for 5 to 6 days, and place it in a constant temperature shaking incubator at 28°C. Under the shaking culture for 6 days, the rotation speed is 150rpm. After the fermentation was over, the fermentation broth was centrifuged at 4000rpm for 30min, and the supernatant was taken to measure the enzyme activity. Live 16800U / L.

Embodiment 2

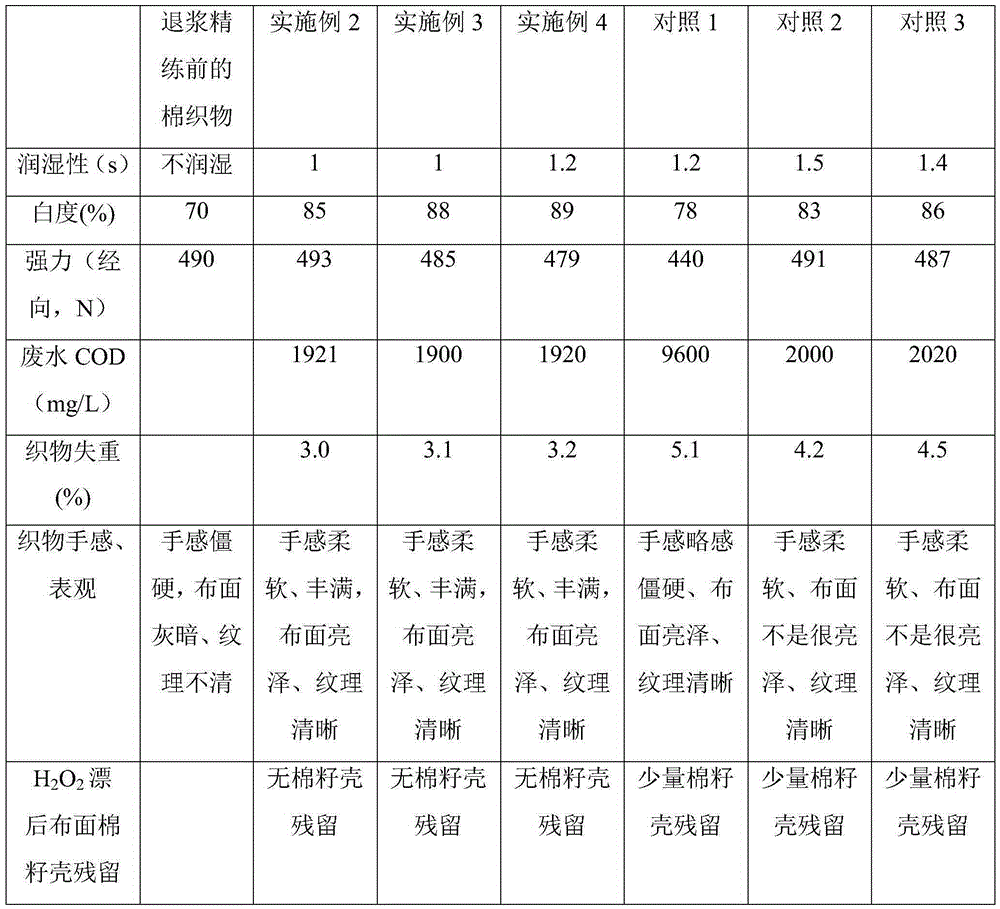

[0048] Example 2: One-bath desizing and scouring of pure starch sized cotton fabric

[0049] After singeing, carded cotton plain fabric (pure starch sizing) is subjected to one-bath desizing and scouring by the following steps:

[0050] (1) Compound the crude enzyme solution obtained by the method in Example 1 with α-amylase at a ratio of 2:1, the total enzyme solution dosage is 2 g / L, the penetrant is 1 g / L, the enzyme rolling temperature is 40°C, and the liquid rolling rate is 100%, the fabric is curled after enzyme rolling;

[0051] (2) The rolled fabric is stacked at 20°C for 24 hours, and the fabric roll needs to be rotated slowly during the stacking process;

[0052] (3) After the fabric is unrolled, wash in hot water at 90-95°C, wash in warm water at 60°C and wash in cold water.

Embodiment 3

[0053] Example 3: One-bath desizing and scouring of pure starch sized cotton fabric

[0054] Cotton fabrics are pure cotton gauze fabrics after singeing, and undergo one-bath desizing and scouring through the following steps:

[0055] (1) Compound the crude enzyme solution of CGMCCNo.10489 and α-amylase at a ratio of 9:1, the total enzyme solution dosage is 1g / L, the penetrant is 5g / L, the enzyme rolling temperature is 50°C, and the liquid rolling rate is 100%, The fabric is rolled after rolling;

[0056] (2) The rolled fabric is stacked at 35°C for 12 hours, and the fabric roll needs to be rotated slowly during the stacking process;

[0057] (3) After the fabric is unrolled, wash in hot water at 95°C, warm water at 60°C, and cold water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com