Anti-wet-slippery resin composite material

A technology of anti-wet skid resin and composite materials, which is applied to tire parts, transportation and packaging, special tires, etc., can solve the problems of limited popularization, increased difficulty of process processing, increased equipment load and energy consumption, etc. Dynamic performance, improved wet skid resistance, and increased water drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

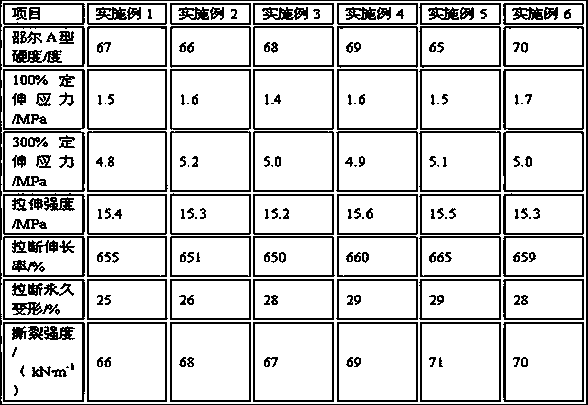

Examples

Embodiment 1

[0034] This embodiment provides an anti-wet skid resin composite material, which comprises the following components in parts by weight: 70 parts of modified terpene resin, 13 parts of aromatic polysulfone resin, 12 parts of alicyclic hydrocarbon resin, compatibilizer 5 doses.

[0035] The preparation process of the composite material is as follows:

[0036] Step (1): Put the modified terpene resin into the reaction kettle, heat until it melts, then start stirring, and continue to heat up;

[0037] Step (2): When the temperature of the material in the reactor rises to 135-140°C, start to keep warm, put in all compatibilizers, and keep stirring for 20-25 minutes; Step (3): Then start to cool down, when the temperature of the material in the reactor When the temperature drops to 125°C, put in all the aromatic polysulfone resin and alicyclic hydrocarbon resin, then keep warm at 120-125°C and continue stirring for 45-50min to obtain a light yellow translucent homogeneous solution;...

Embodiment 2

[0040] This embodiment provides an anti-wet skid resin composite material, which comprises the following components in parts by weight: 68 parts of modified terpene resin, 14 parts of aromatic polysulfone resin, 14 parts of alicyclic hydrocarbon resin, compatibilizer 4 doses.

[0041] The preparation process of the composite material is as follows:

[0042] Step (1): Put the modified terpene resin into the reaction kettle, heat until it melts, then start stirring, and continue to heat up;

[0043]Step (2): When the temperature of the material in the reactor rises to 135-140°C, start to keep warm, put in all compatibilizers, keep warm and stir for 20-25min;

[0044] Step (3): Then start to lower the temperature. When the temperature of the material in the reactor drops to 125°C, put in all the aromatic polysulfone resin and alicyclic hydrocarbon resin, and then keep warm at 120-125°C and continue stirring for 45-50 minutes to obtain Light yellow translucent homogeneous soluti...

Embodiment 3

[0047] This embodiment provides an anti-wet skid resin composite material, which comprises the following components in parts by weight: 62 parts of modified terpene resin, 15 parts of aromatic polysulfone resin, 16 parts of alicyclic hydrocarbon resin, compatibilizer 7 doses.

[0048] The preparation process of the composite material is as follows:

[0049] Step (1): Put the modified terpene resin into the reaction kettle, heat until it melts, then start stirring, and continue to heat up;

[0050] Step (2): When the temperature of the material in the reactor rises to 135-140°C, start to keep warm, put in all compatibilizers, keep warm and stir for 20-25min;

[0051] Step (3): Then start to lower the temperature. When the temperature of the material in the reactor drops to 125°C, put in all the aromatic polysulfone resin and alicyclic hydrocarbon resin, and then keep warm at 120-125°C and continue stirring for 45-50 minutes to obtain Light yellow translucent homogeneous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com