Preparation method of star-shaped solution polymerized butadiene styrene rubber with wide molecular weight distribution

A technology of solution-polymerized styrene-butadiene rubber and wide molecular weight distribution is applied in the field of preparation of star-shaped solution-polymerized styrene-butadiene rubber with wide molecular weight distribution. The effect of reducing shrinkage and rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

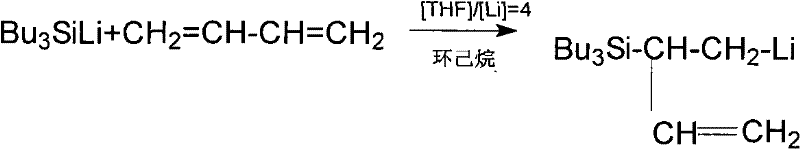

[0031] Bu 3 Synthesis of SiLi:

[0032] In a 5L glass reactor with a silicone oil temperature control device, the system was replaced three times with argon gas. Add 3150ml of hexane and 2.11g of THF to the polymerization kettle, turn on the stirring, add 56g of metal lithium, and use a silicone oil bath to raise the temperature. When the temperature rises to 35°C, add chloroform at a flow rate of 5-10ml / min by dropwise 320ml of n-butane, while adding SiCl at a flow rate of 3-5ml / min in a dropwise way 4 110ml, the temperature of the whole reaction process was controlled at 50°C, after 70 minutes of reaction, it was naturally cooled at room temperature, settled for 4 hours, and suction filtered to obtain Bu 3 SiLi products are stored in vacuum airtight storage at -10°C.

Embodiment 2

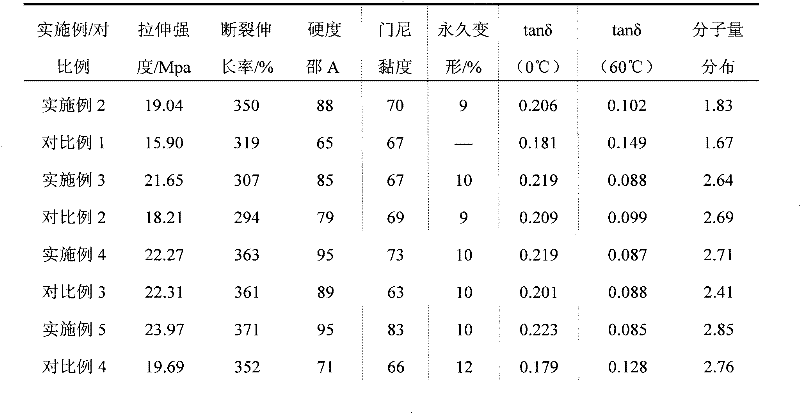

[0034] In a jacketed 15L stainless steel reactor, the system was replaced three times with argon gas. In the polymerization kettle, add cyclohexane 7950g, styrene 300g (accounting for 25% of the total amount of monomers), butadiene 900g (accounting for 75% of the total amount of monomers), THF4.32g, once adding 12.1mmol Bu 3 SiLi is used as an initiator, the temperature is raised to 50°C, and the polymerization is carried out for 75 minutes. After the monomer is completely converted, the temperature is raised to 70°C, and 3.3 mmol of SnCl is added at a time. 4 The coupling agent is used for coupling reaction, and the reaction time is 60 minutes. After the coupling reaction was completed, the coupled reaction mixture was treated with water, 100 g of water and 12 g of antioxidant 1010 [tetrakis-(4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaerythritol ester] were added and stirred. The glue is coagulated and dried by wet method.

Embodiment 3

[0038] In a jacketed 15L stainless steel reactor, the system was replaced three times with argon gas. In the polymerization kettle, add cyclohexane 7962g, styrene 330g (27.5% of the total monomers), butadiene 870g (62.5% of the total monomers), THF8.64g, add 12.1mmol of n-butyl Lithium and Bu 3 The initiator composed of SiLi (n-butyllithium and Bu 3 The mass ratio of SiLi is 30:70), the initiator is added in two times, the adding time interval is 3min, 6.1mol is added for the first time, 6.0mol is added for the second time, the temperature is raised to 60°C, and the polymerization is 50min, after the monomer is completely converted Raise the temperature to 80°C, add 6.6mmol SnCl twice 4 (Adding SnCl for the first time 4 80% of the total amount, after 15 minutes of reaction, add the remaining 20%) coupling agent to carry out the coupling reaction, and the reaction time is 80 minutes. After the coupling reaction was completed, the coupled reaction mixture was treated with wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com