Patents

Literature

121results about How to "Easy breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

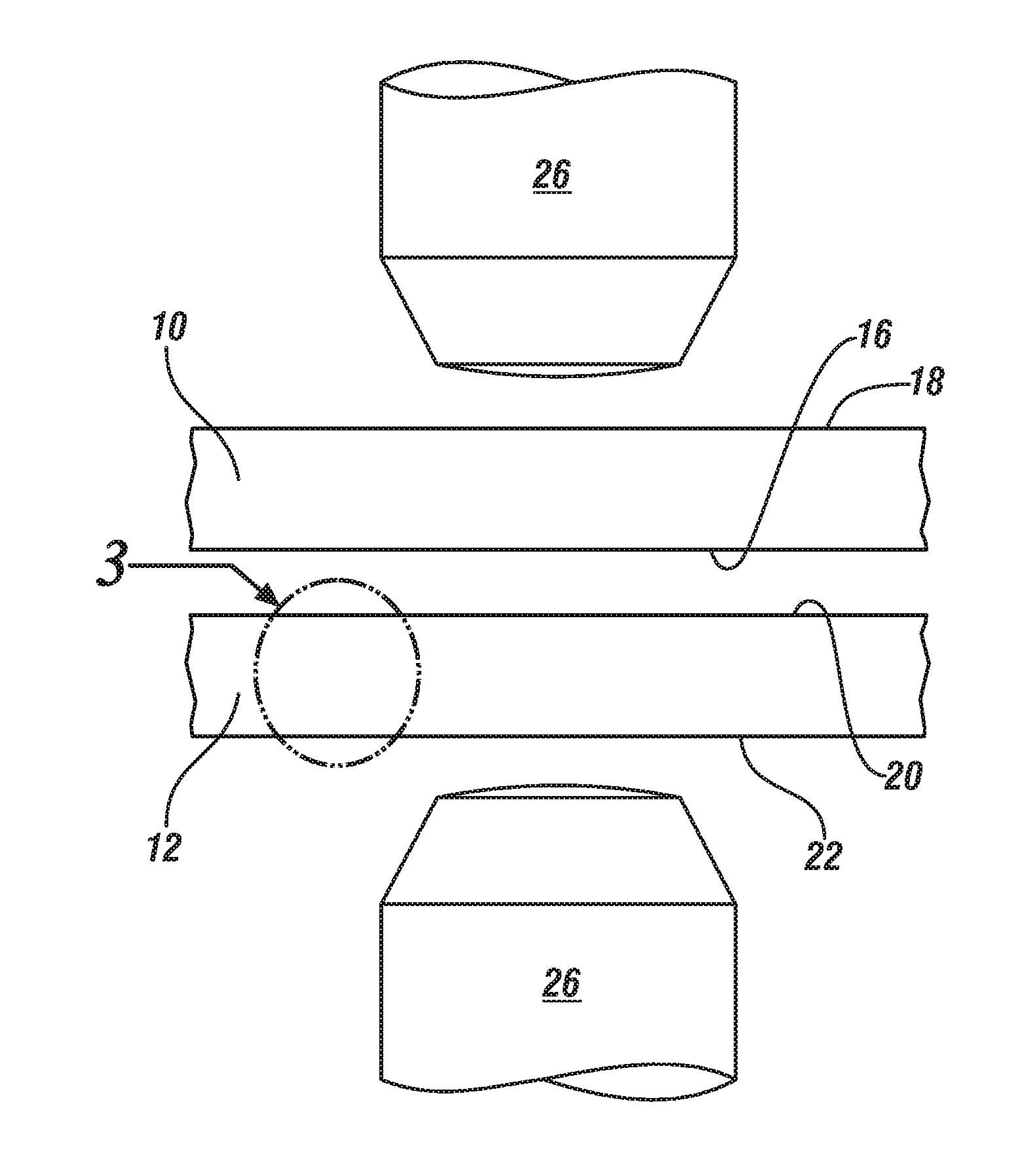

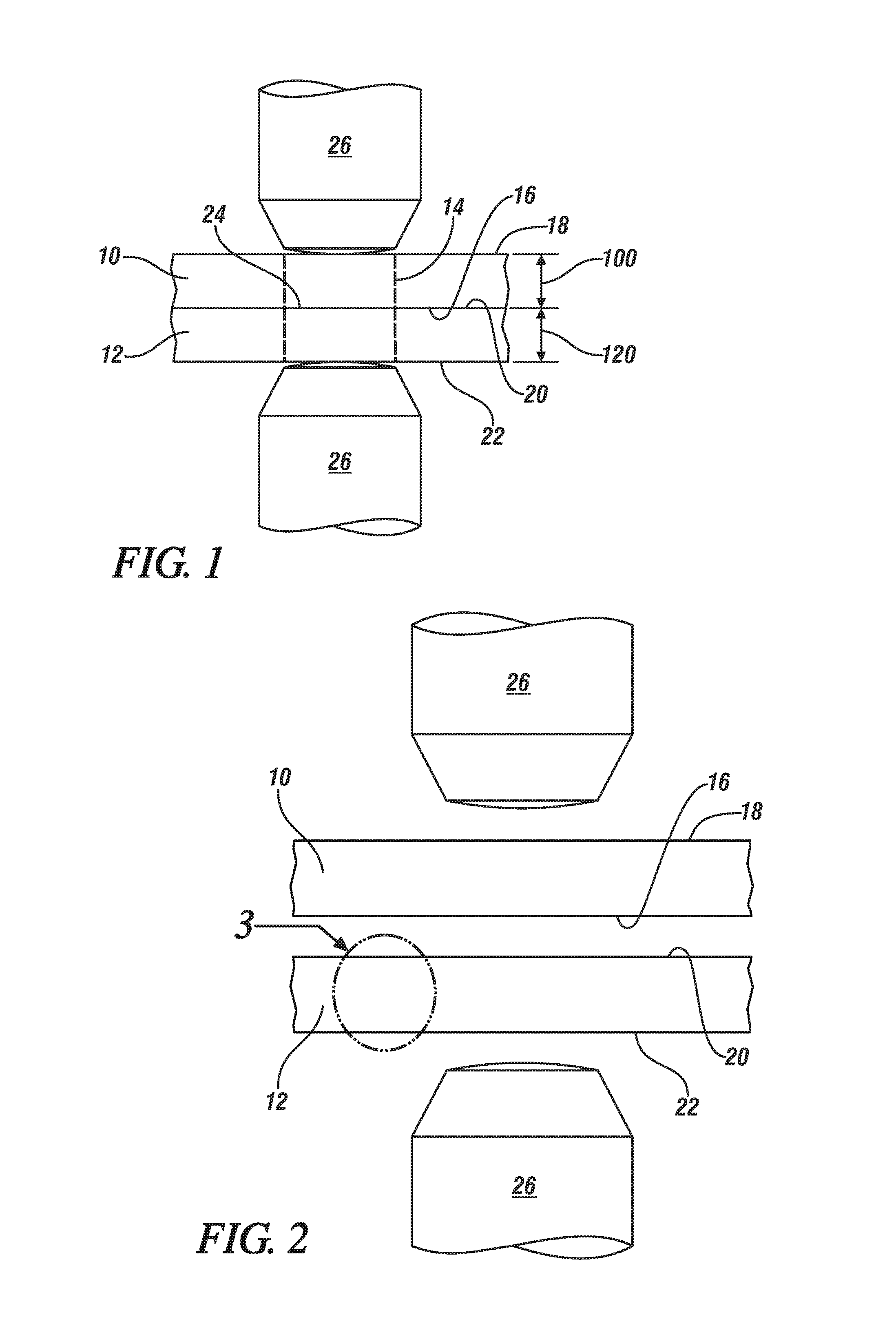

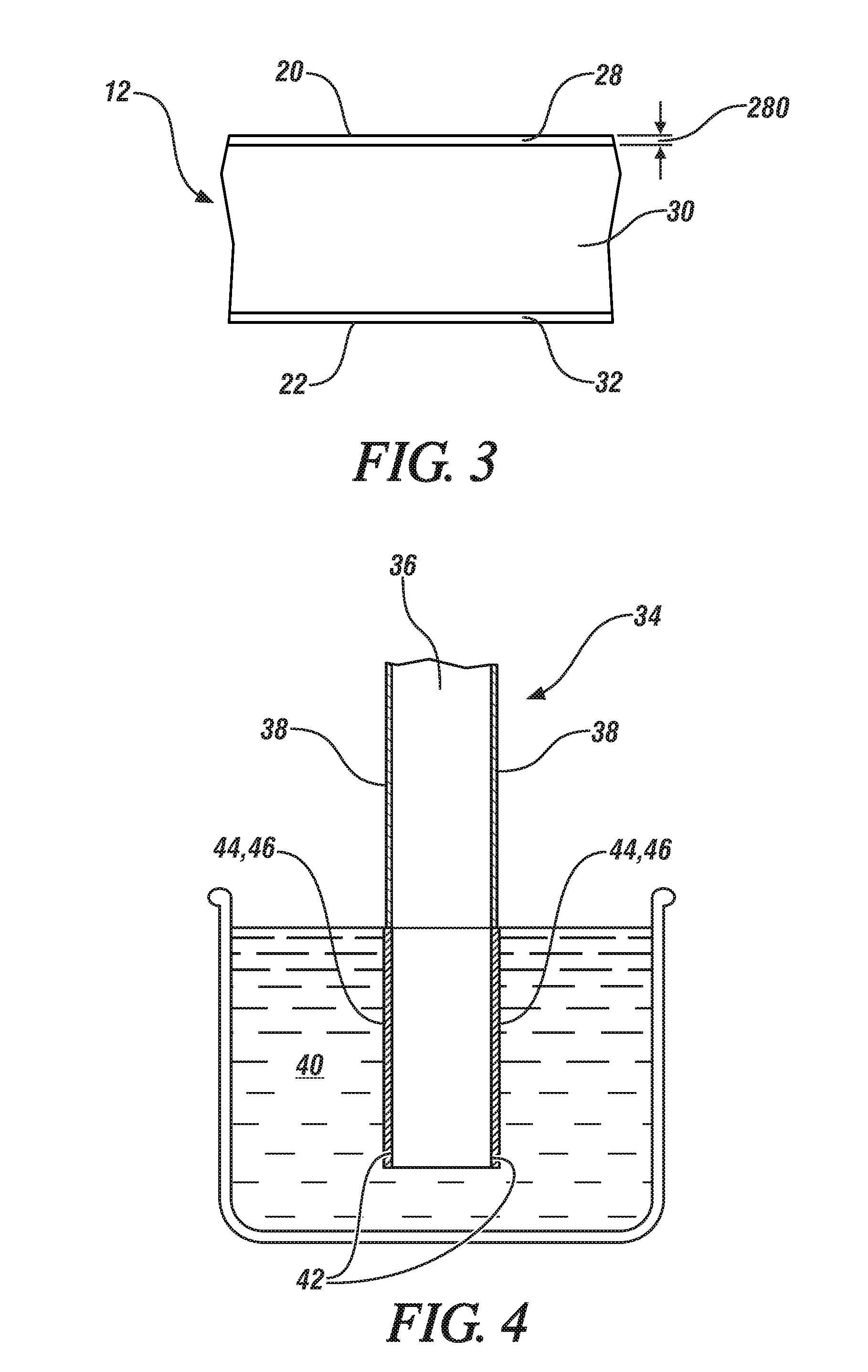

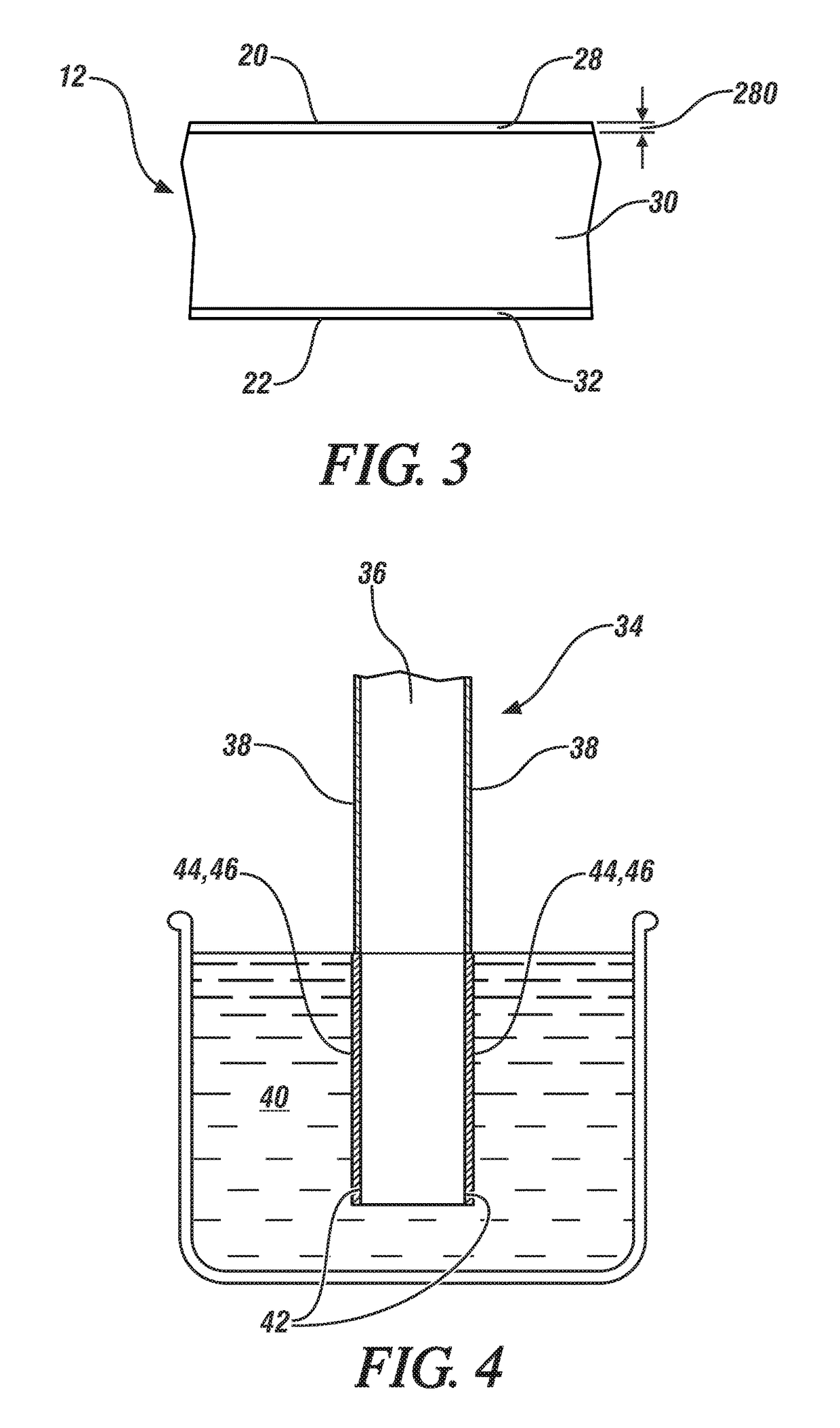

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

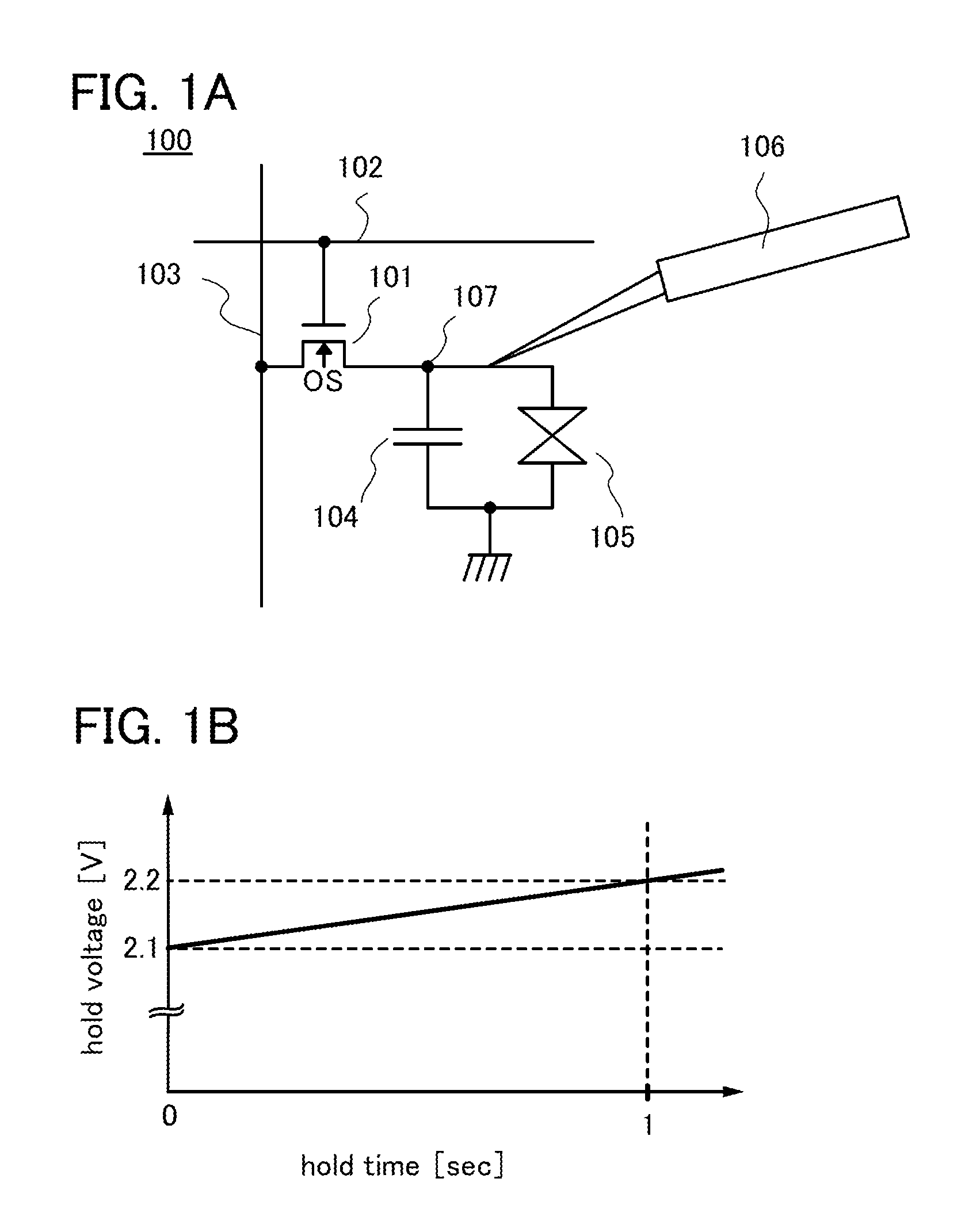

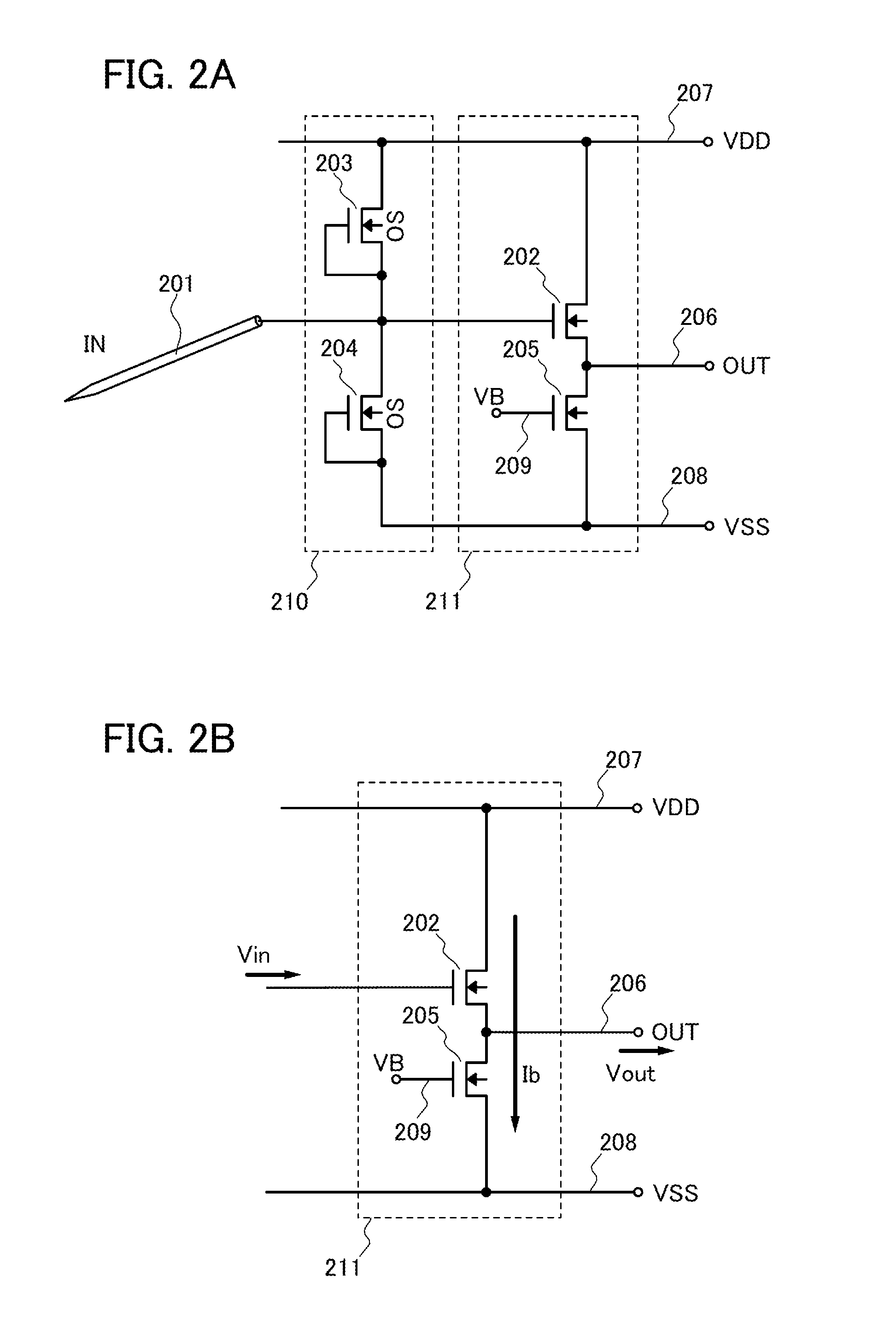

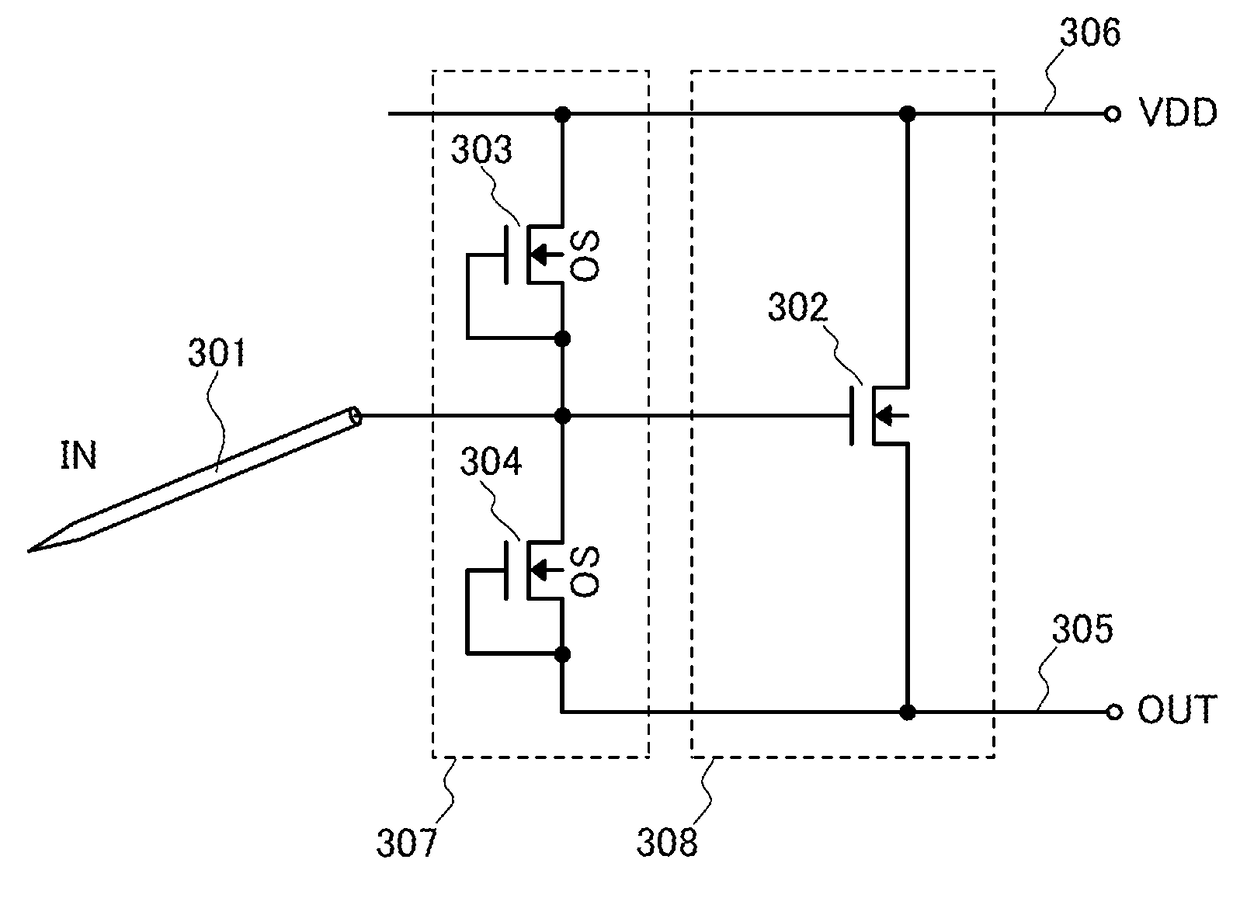

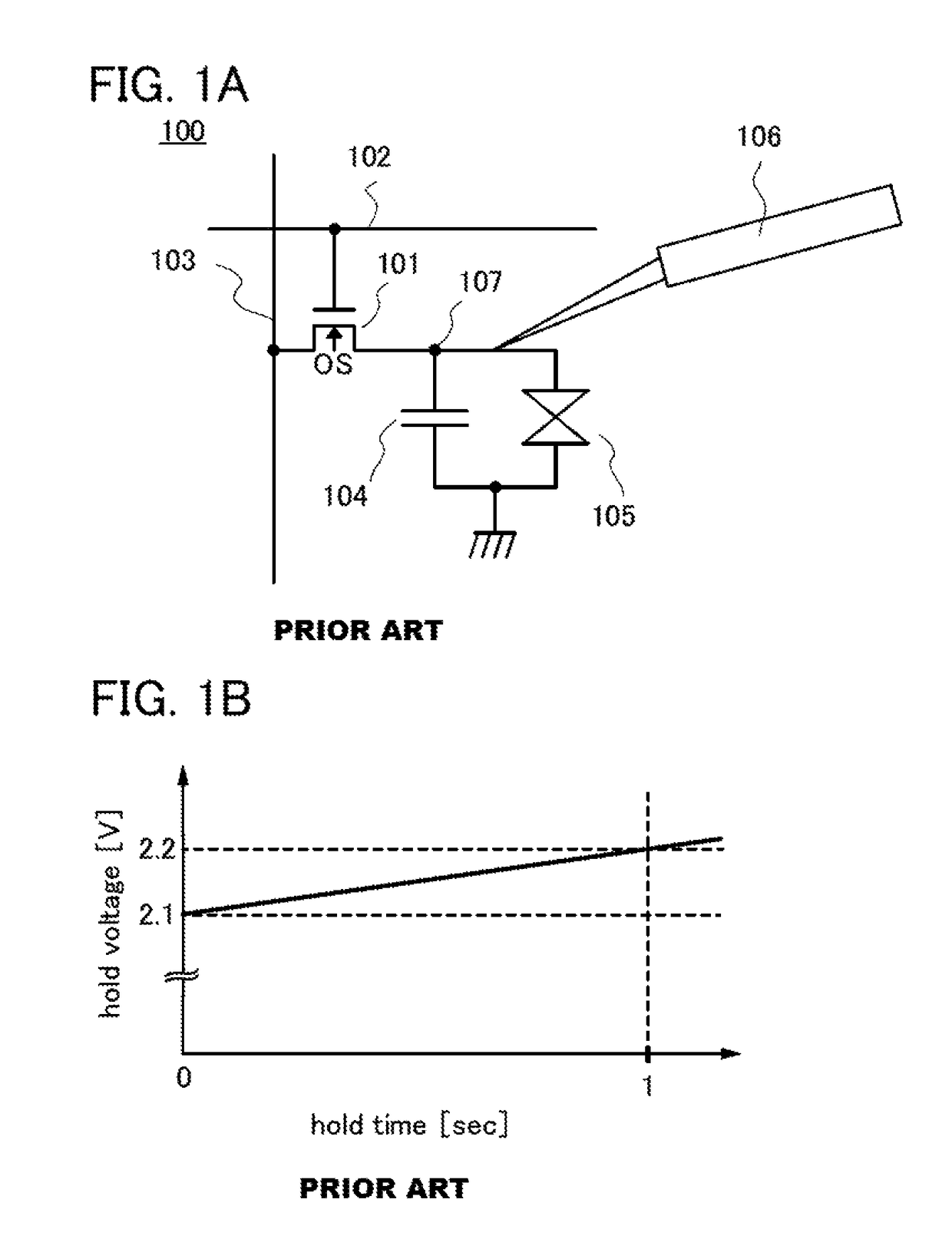

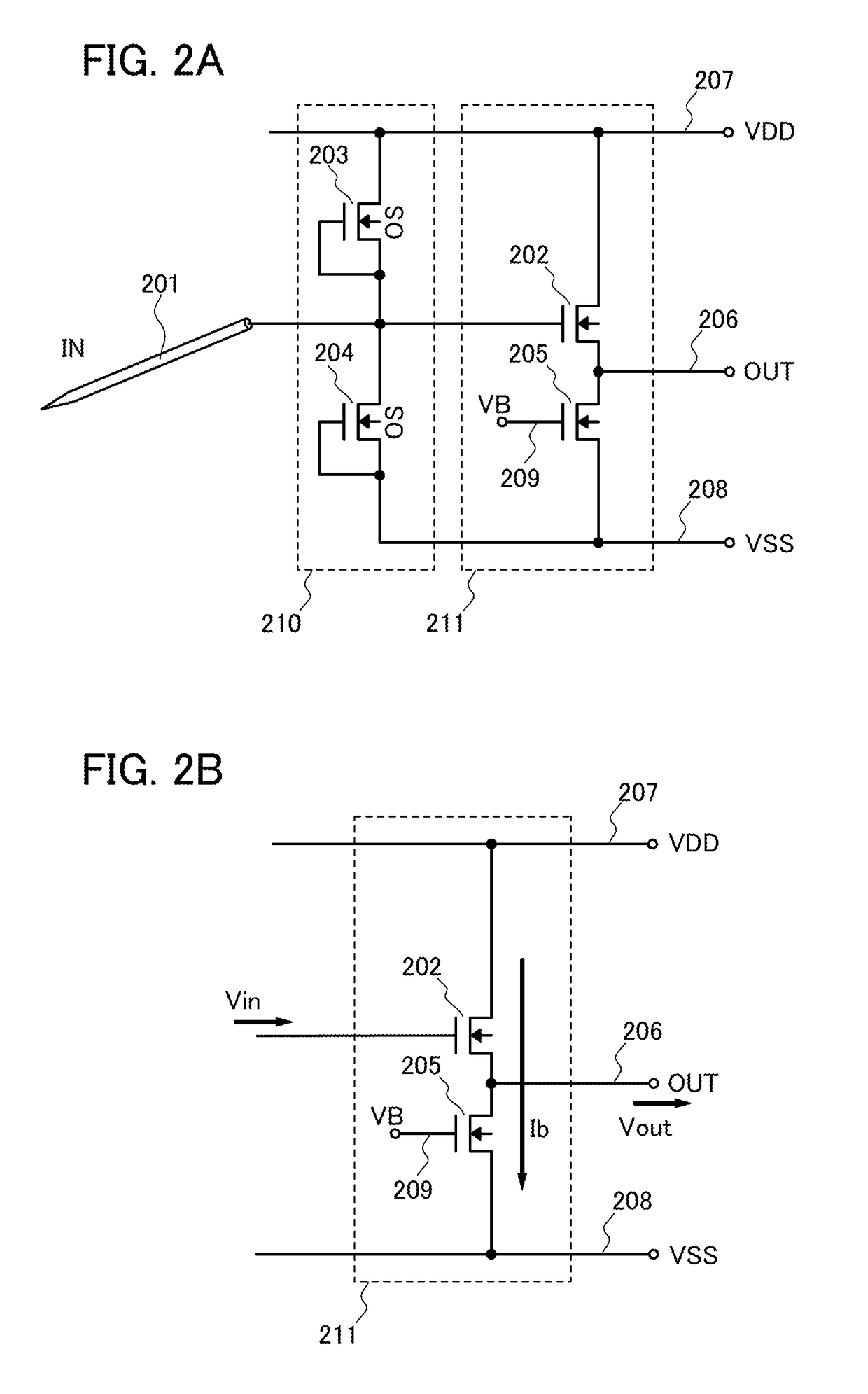

Measurement device

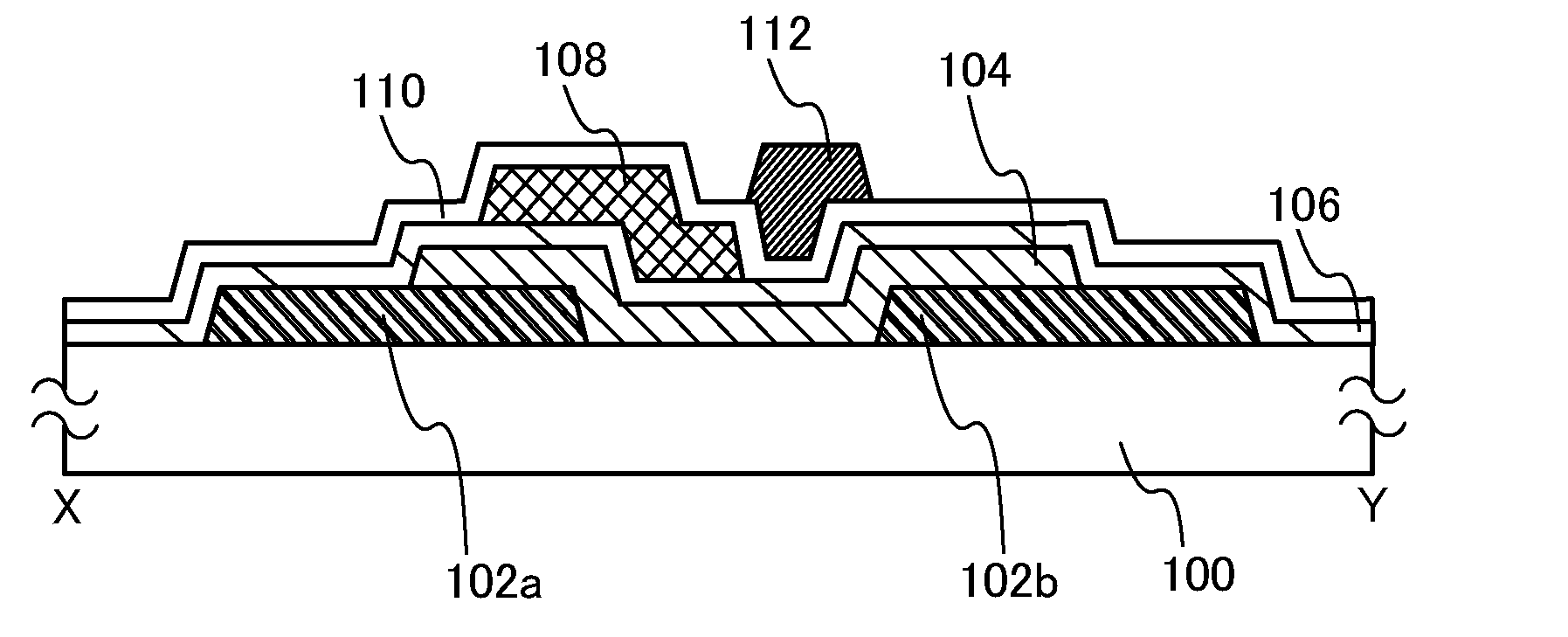

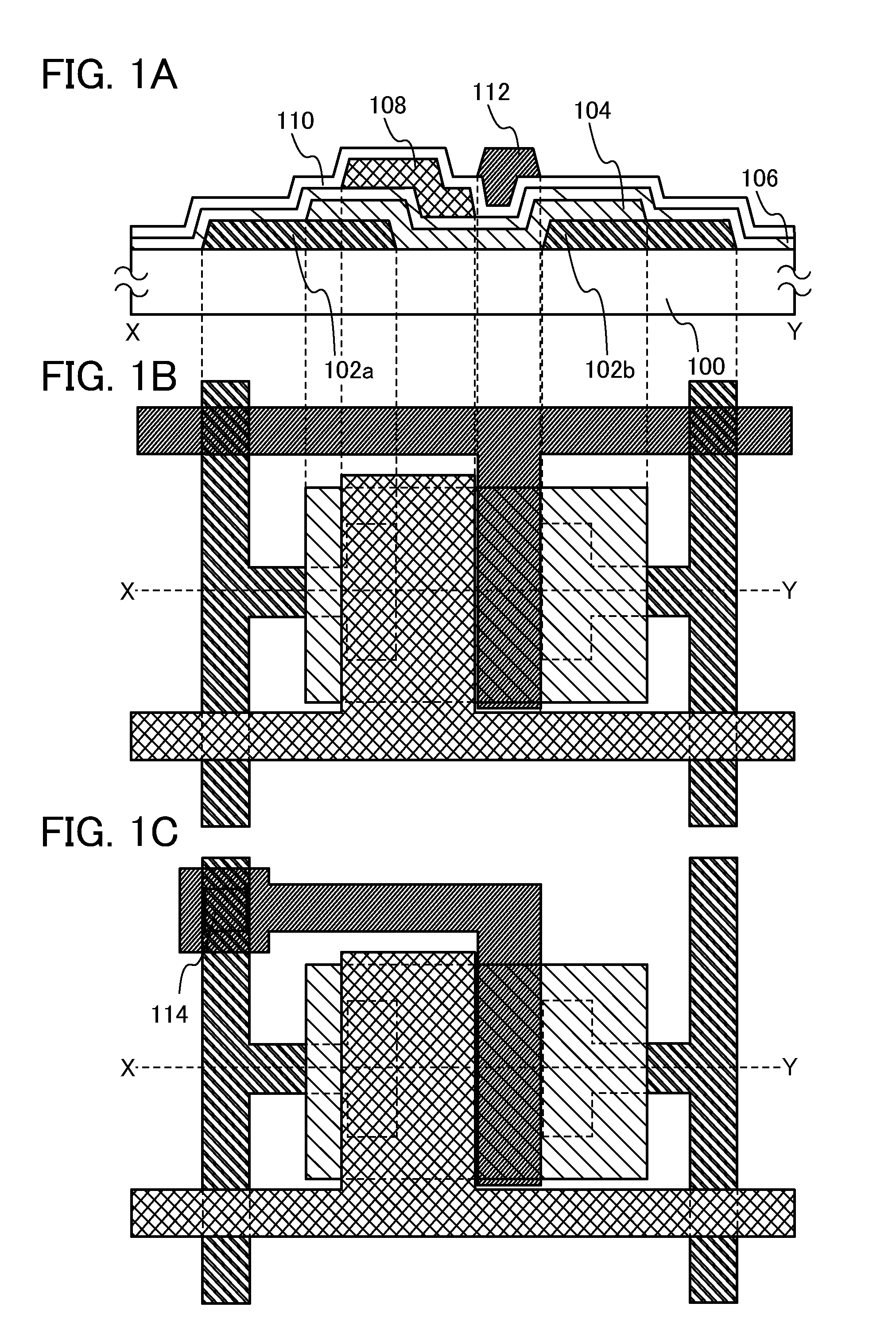

ActiveUS20130314074A1Accurate voltage measurementReduce leakage currentOverload protection arrangementsElectrical testingElectrical resistance and conductanceMeasurement device

To provide a measurement device which allows long-term accurate measurement of voltage without adversely affecting a device under test, by ensuring a predetermined level of resistance to ESD and reducing leakage current. A measurement device includes a probe needle for contacting a device under test, a first FET for detecting voltage of the device under test, and a protection circuit for protecting the first FET from static electricity. The protection circuit includes a second FET having an oxide semiconductor film as a channel formation region.

Owner:SEMICON ENERGY LAB CO LTD

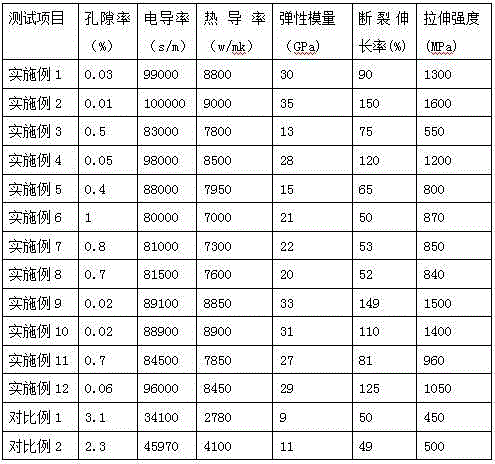

Carbon material film with high electric conductivity, heat conductivity and strength and preparing method thereof

The invention provides a carbon material film with high electric conductivity, heat conductivity and strength and a preparing method thereof. The carbon material film is prepared according to the steps of adding functional carbon material powder and a dispersant to a solvent to be mixed and stirred; adding a binder and a plasticizer, and conducting mixing to obtain uniform and stable slurry; forming a blank film; placing the blank film in the solvent for reaction; evaporating the solvent; increasing temperature to 1000-3000 DEG C for sintering lasting 1-10 h to obtain the carbon material film. Through functional modification and then tape-casting and sintering of the surface of the carbon material, active groups between different sheets of the carbon material react with one another to form chemical bonds, and a carbon net stable structure is formed finally so that different sheets of the carbon material can be connected in the true sense. In this way, the mechanical strength, electric conductivity and heat conductivity of the carbon material film are improved greatly.

Owner:HEFEI GENIUS NEW MATERIALS

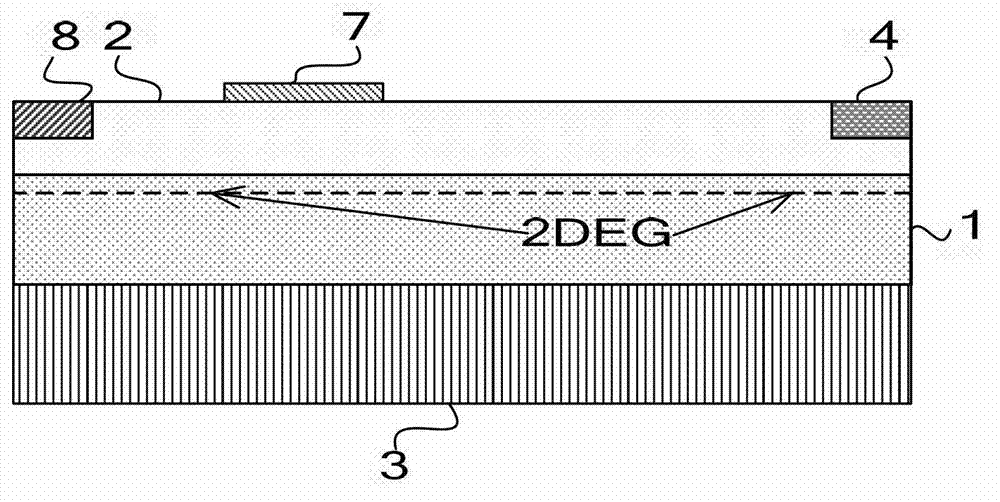

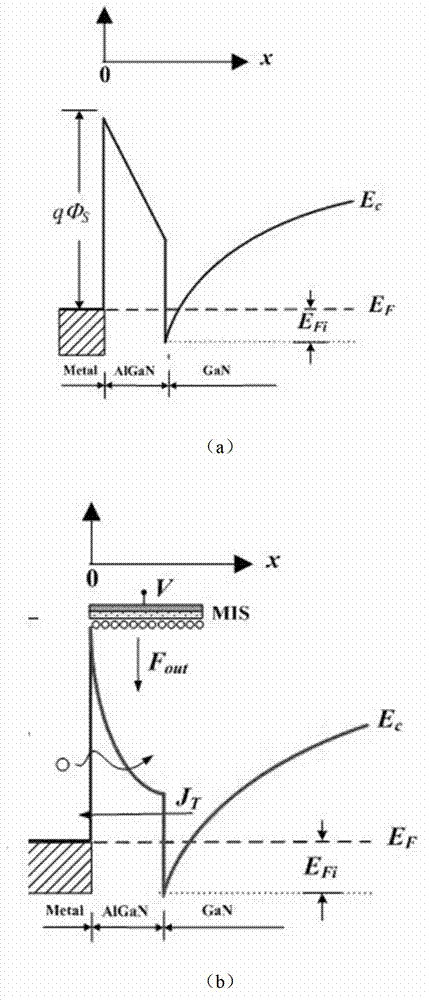

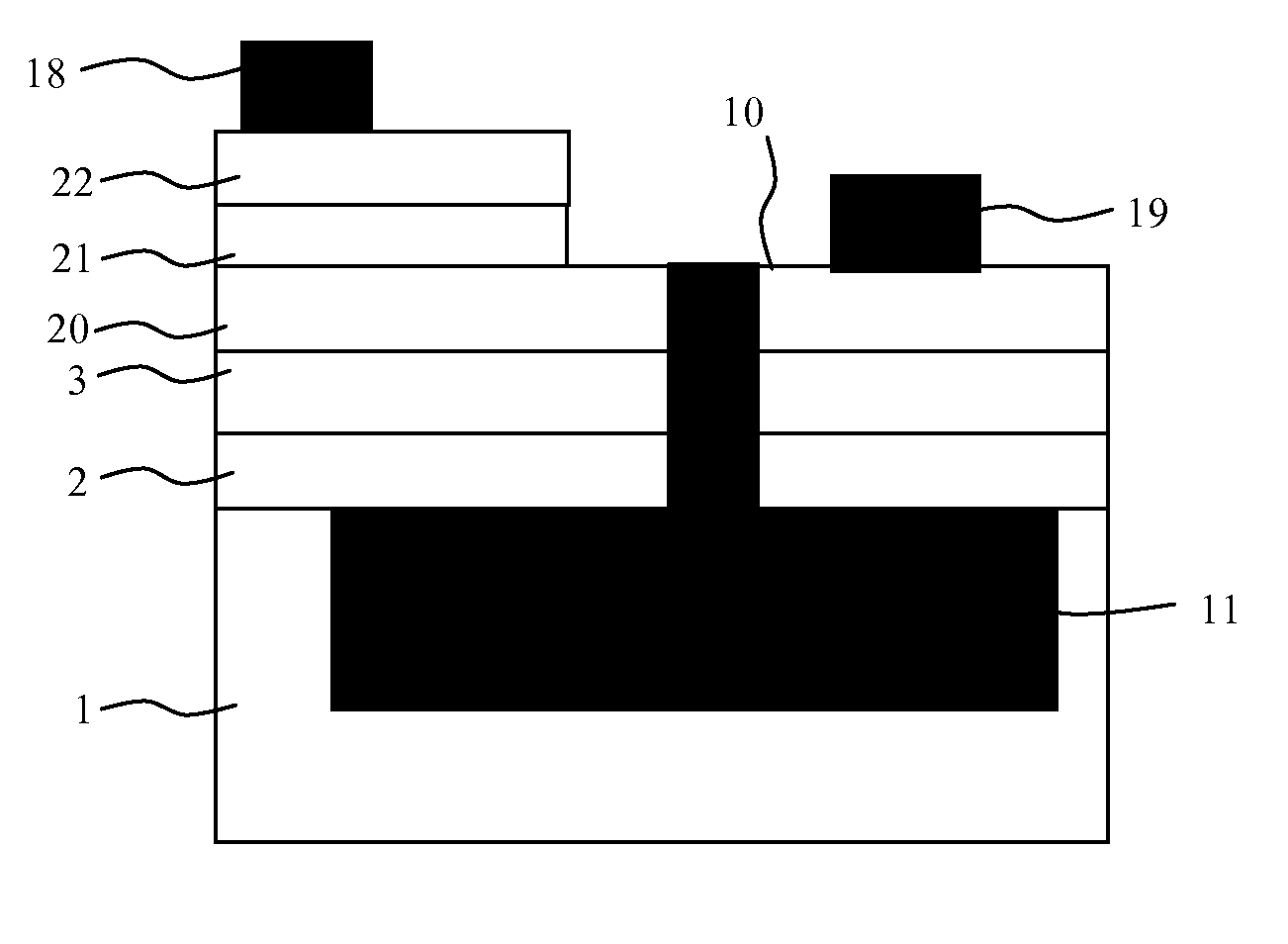

Field-induced tunneling enhanced HEMT (high electron mobility transistor) device

InactiveCN102881716AGood positive characteristicsImprove pressure resistanceSemiconductor devicesSchottky barrierElectron

The invention belongs to the technical field of semiconductor devices, and particularly relates to a field-induced tunneling enhanced HEMT (high electron mobility transistor) device. The field-induced tunneling enhanced HEMT device is different from conventional AlGaN / GaN HEMT devices in that metal sources are in Schottky barrier contact instead of ohm contact in conventional structures; and metal gates are not positioned between the sources and drains but form insulating gate electrodes at the edges, away from the drains, of the sources through etching grooves. Field-control conductive channels are realized by means of the insulating layer and groove technology, field control of the field-control conductive channels is realized by voltage applied to the groove gate electrodes, and electrons subjected to band bending can directly tunnel barriers to be accumulated below the channels in gate modulation when forward voltage is applied to the gate electrodes, so that normally closed channels are realized, and frequency characteristics of the device can be promoted without affecting reverse voltage withstand capability of the device. Meanwhile, the preparation process of the device is compatible to traditional processes, and thereby solid foundation is established for the GaN power integration technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

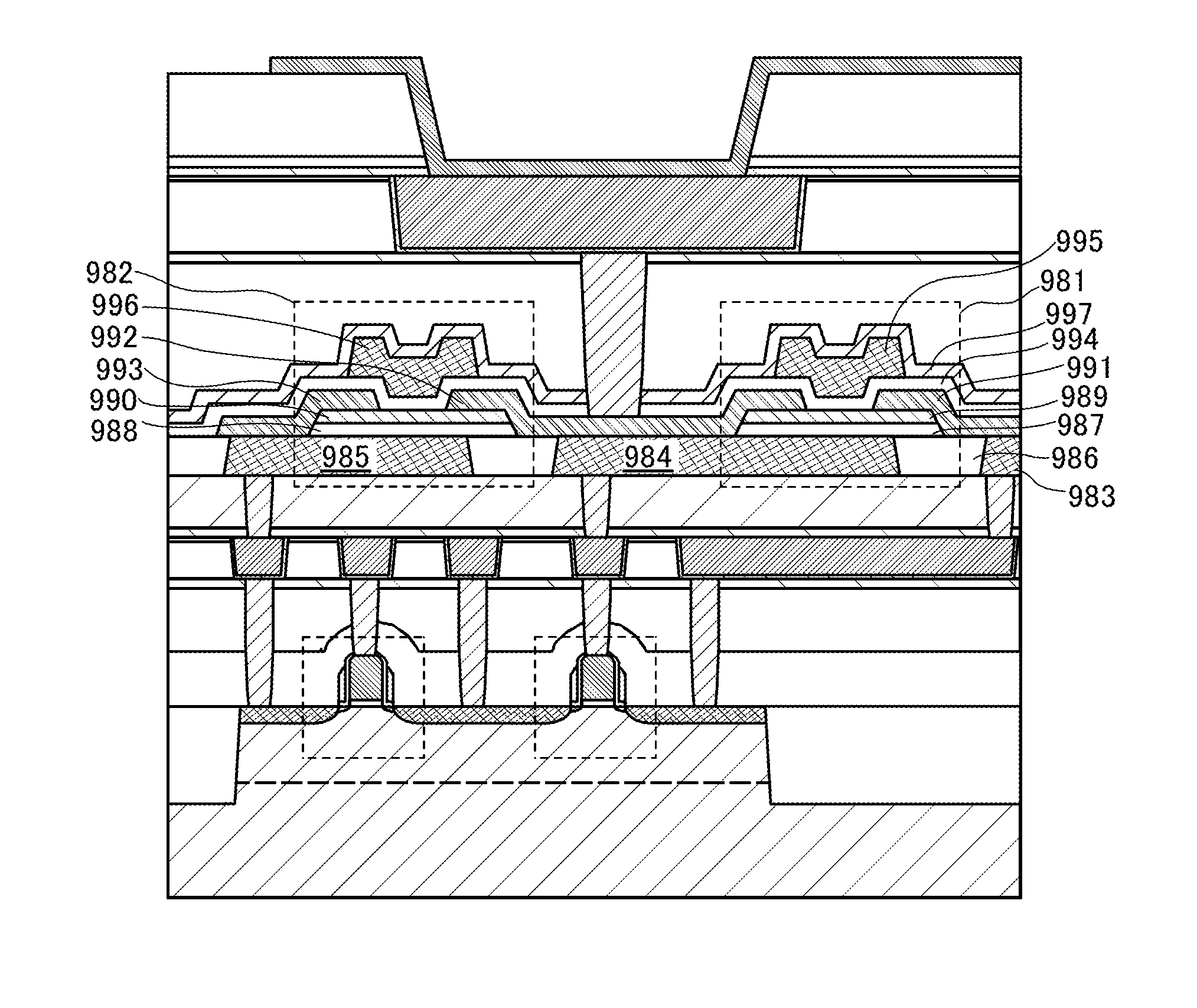

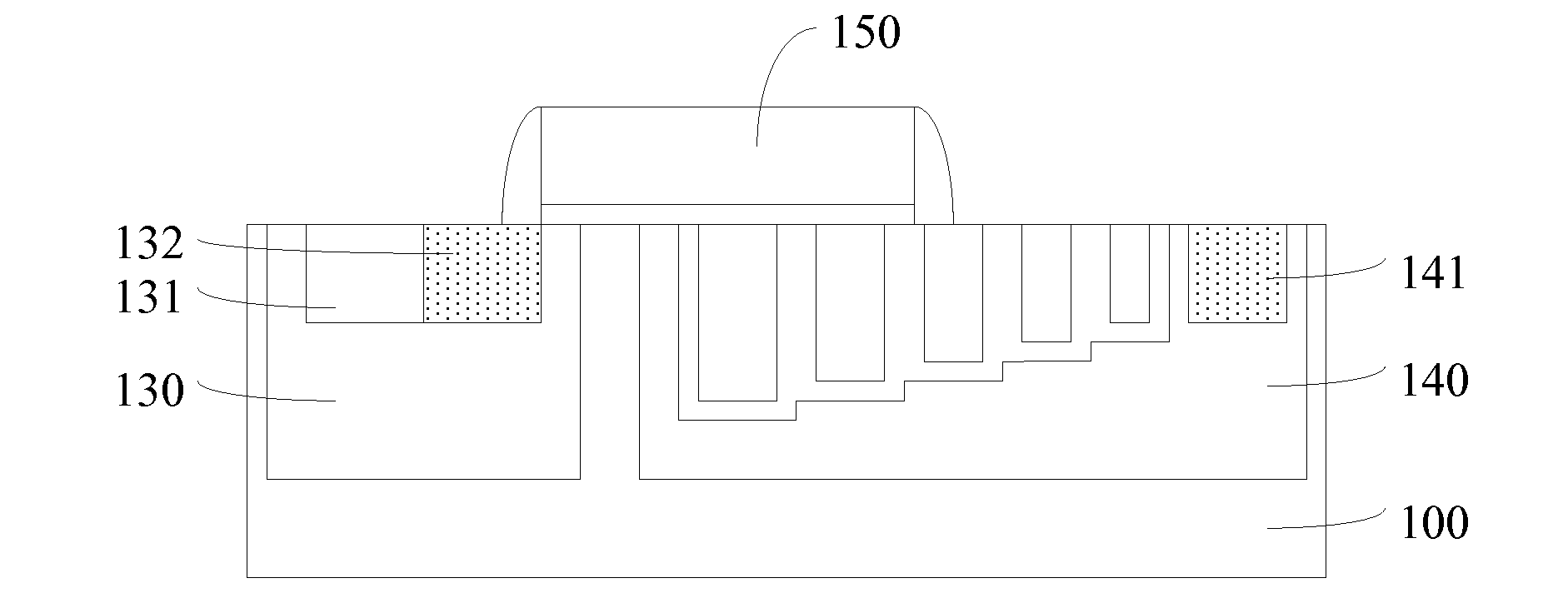

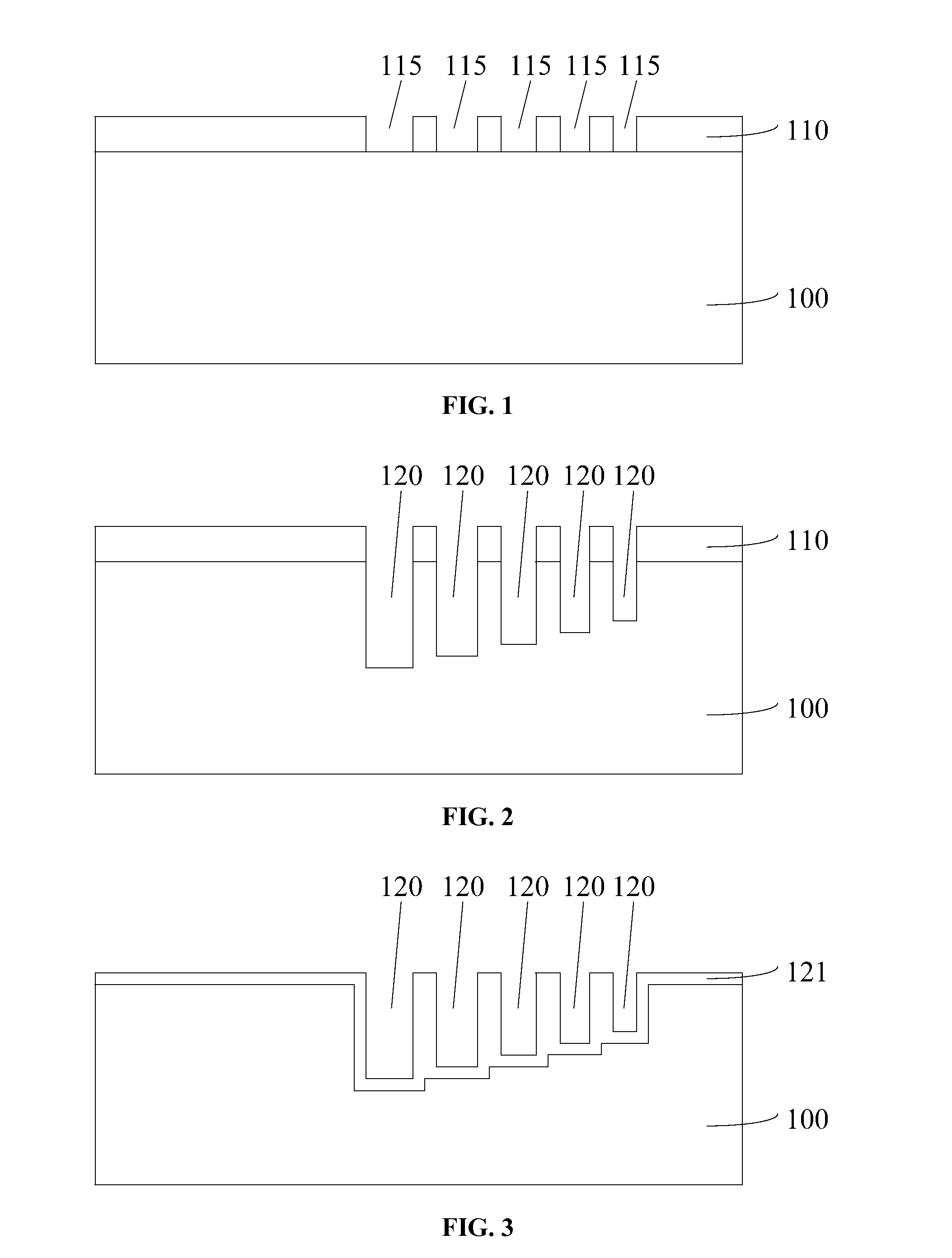

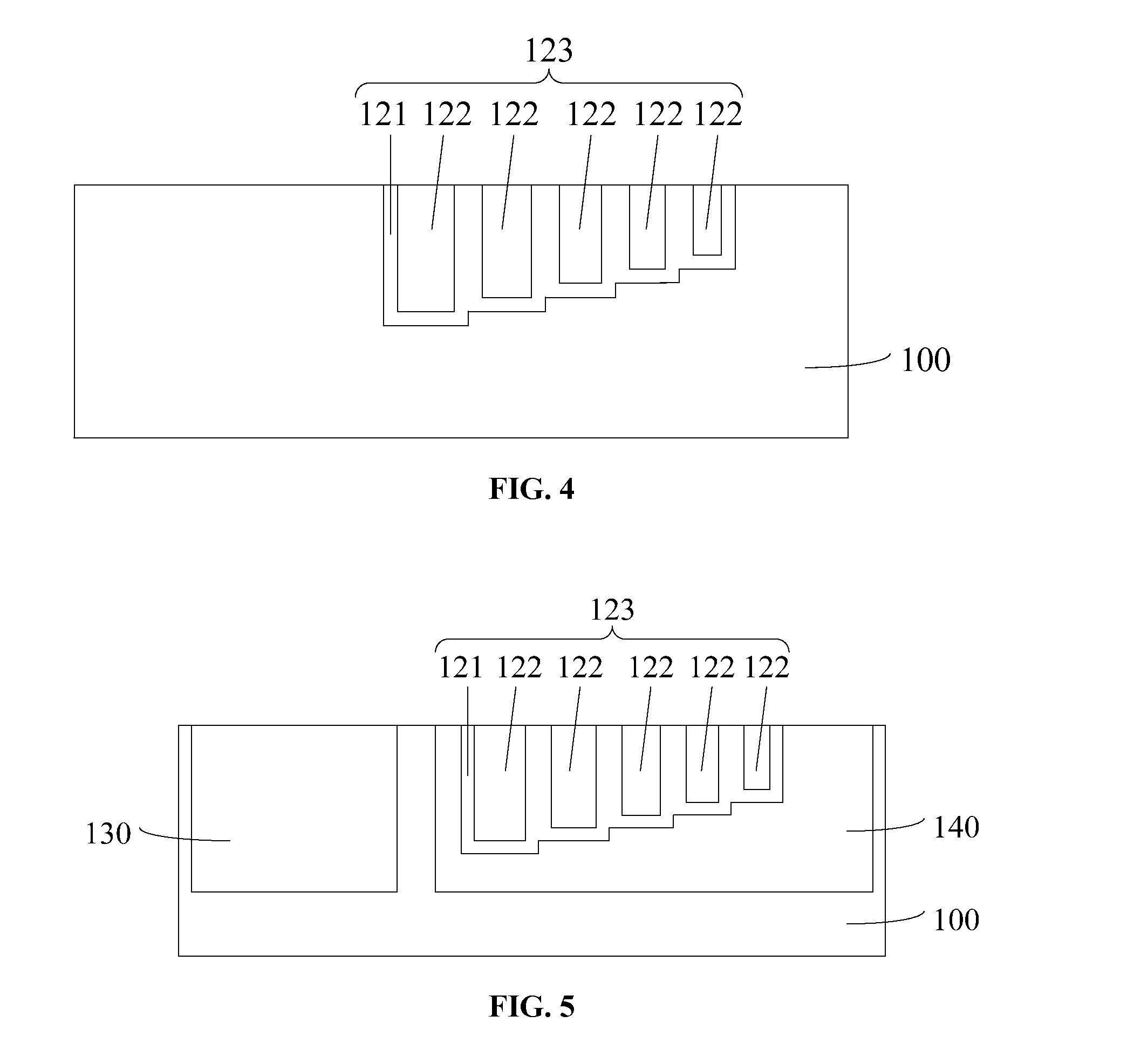

Semiconductor devices and fabrication methods thereof

ActiveUS20150076555A1Increase the on-currentLower breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesBody regionCondensed matter physics

A semiconductor device is provided. The semiconductor device includes a semiconductor substrate; and a body region and a drift region formed in the semiconductor substrate. The semiconductor device also includes a bulk region and a source region formed in the body region. Further, the semiconductor device includes a drain region and a first shallow trench isolation structure having a ladder-like bottom formed in the drift region. Further, the semiconductor device also includes a gate structure spanning over an edge of the body region and an edge of the drift region formed on the semiconductor substrate and covering a portion of the first shallow trench isolation structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

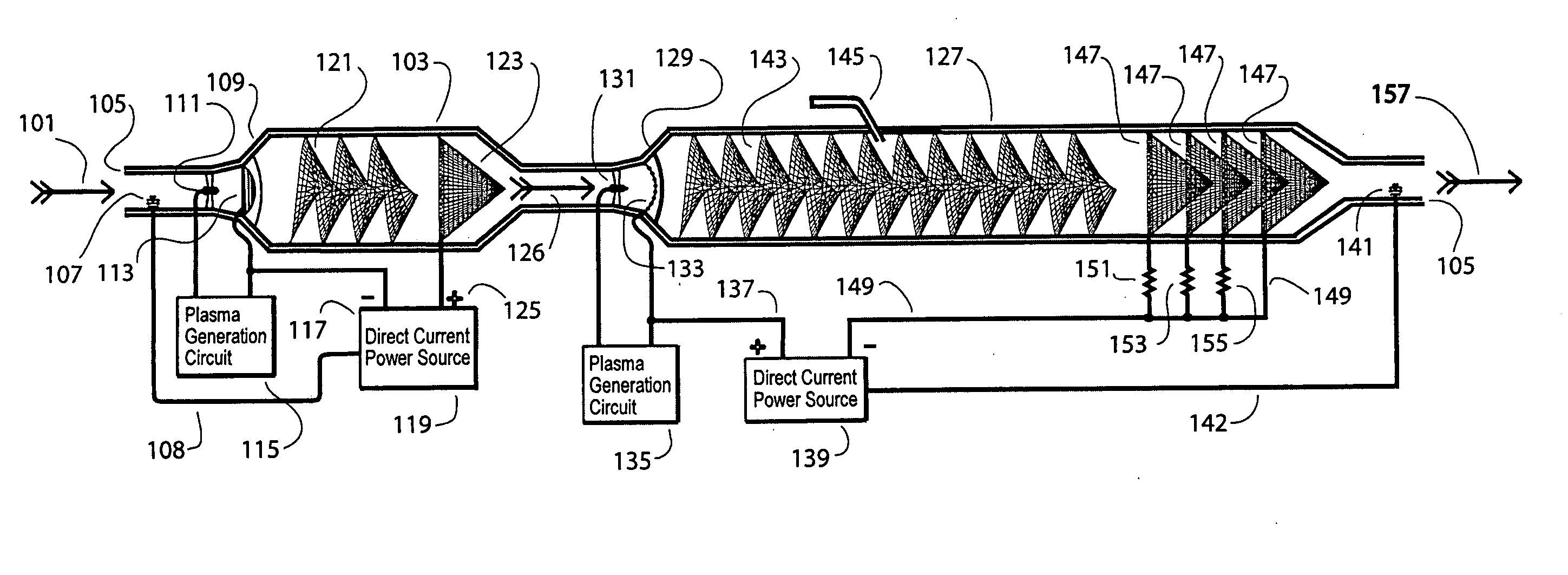

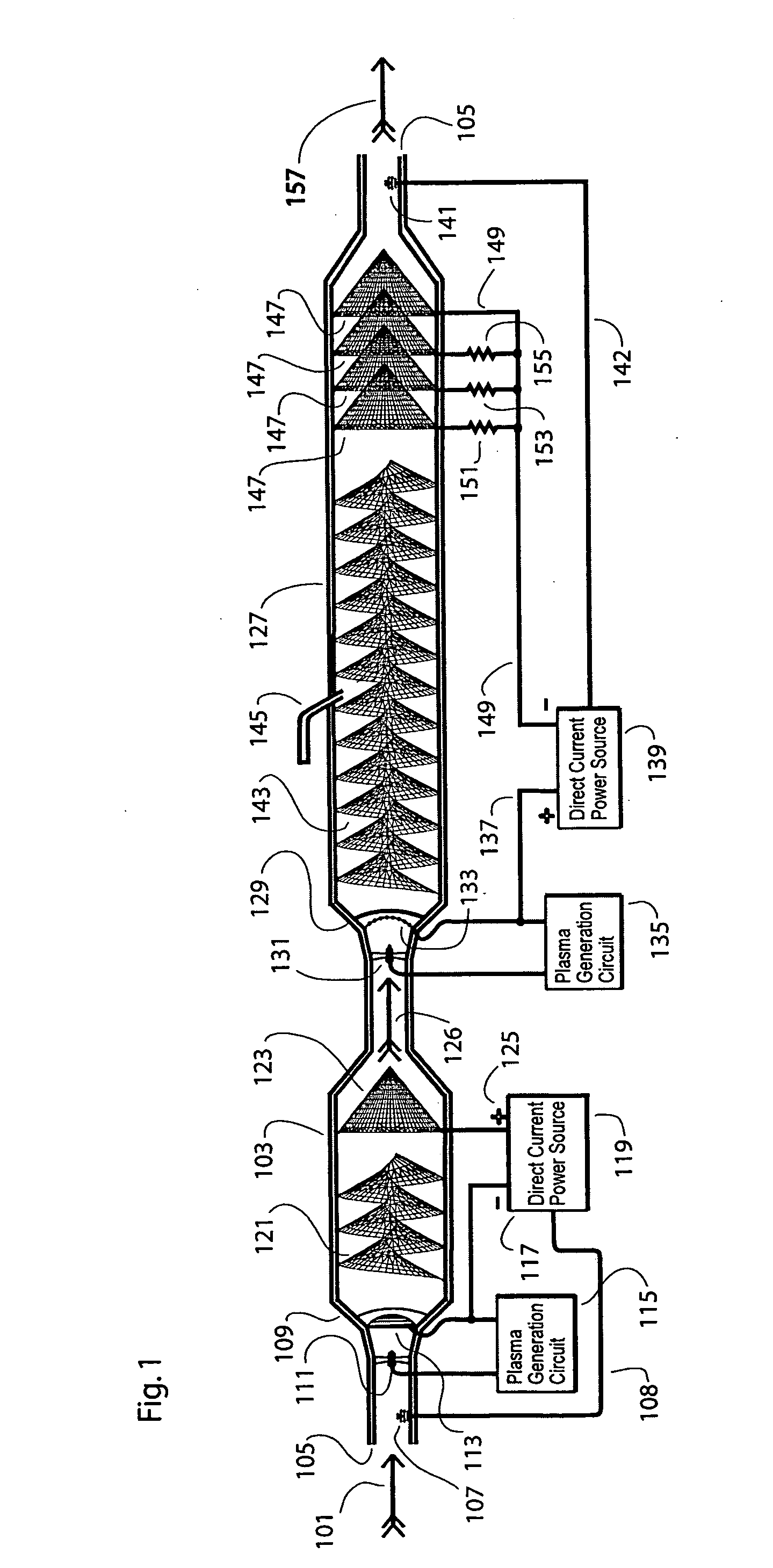

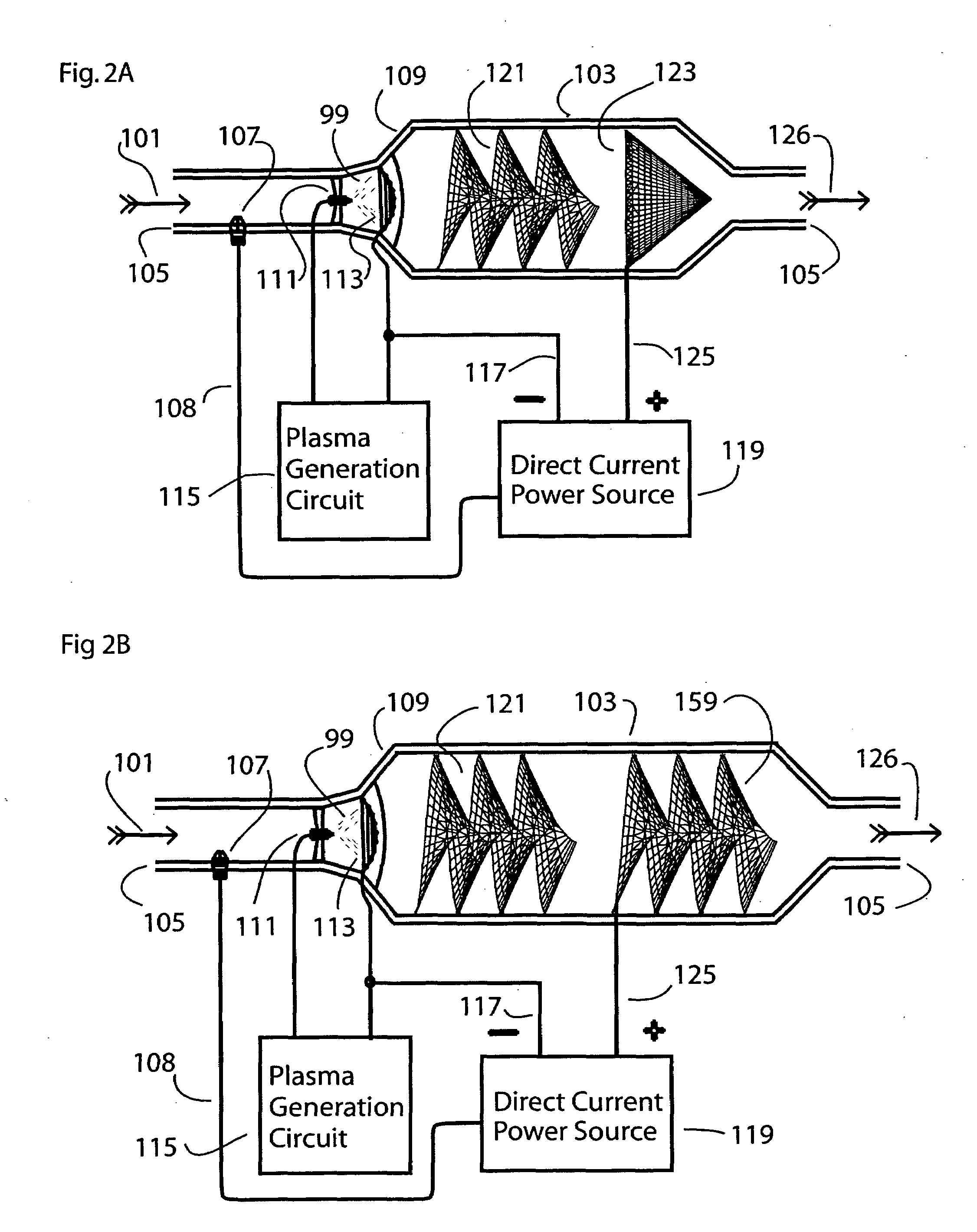

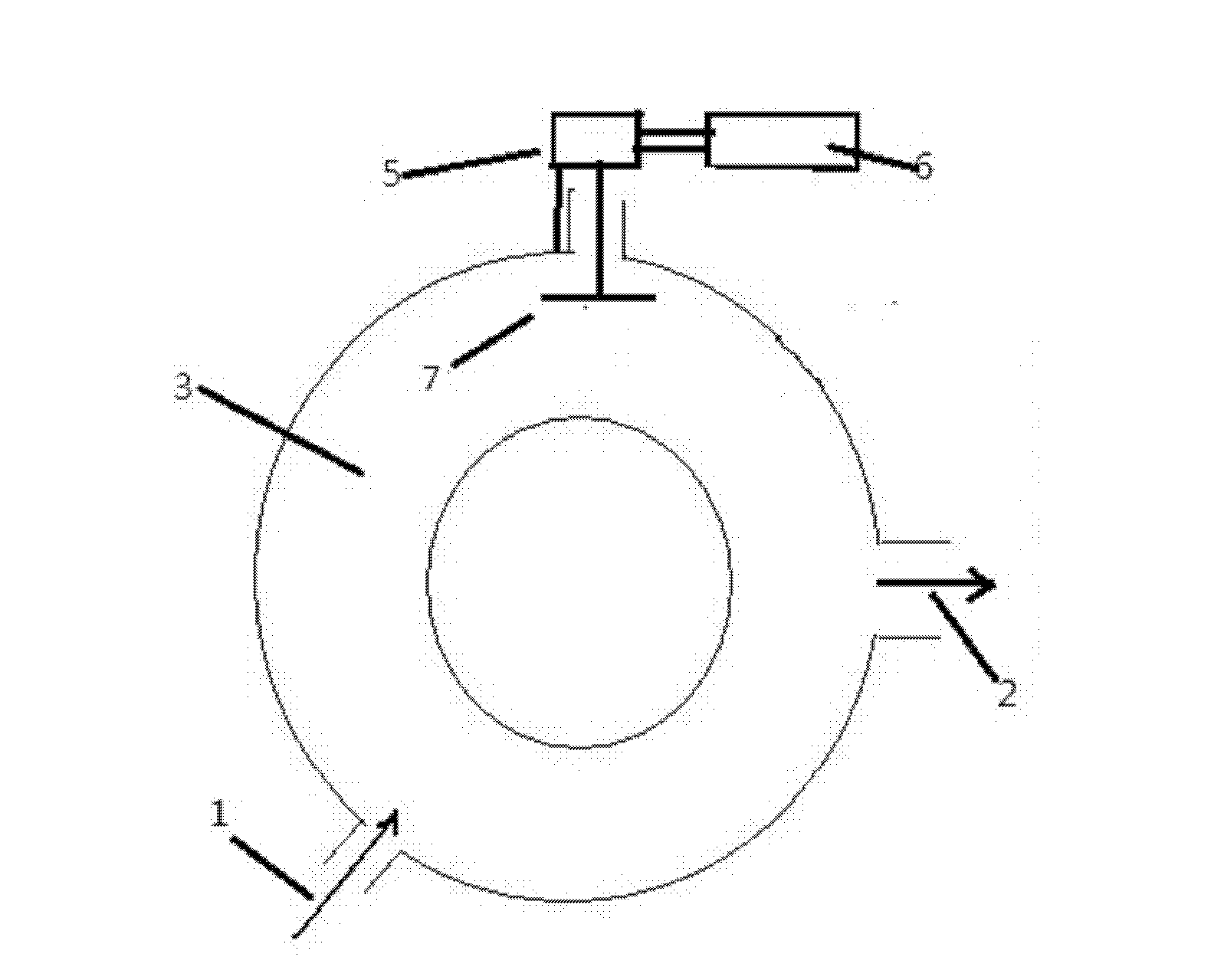

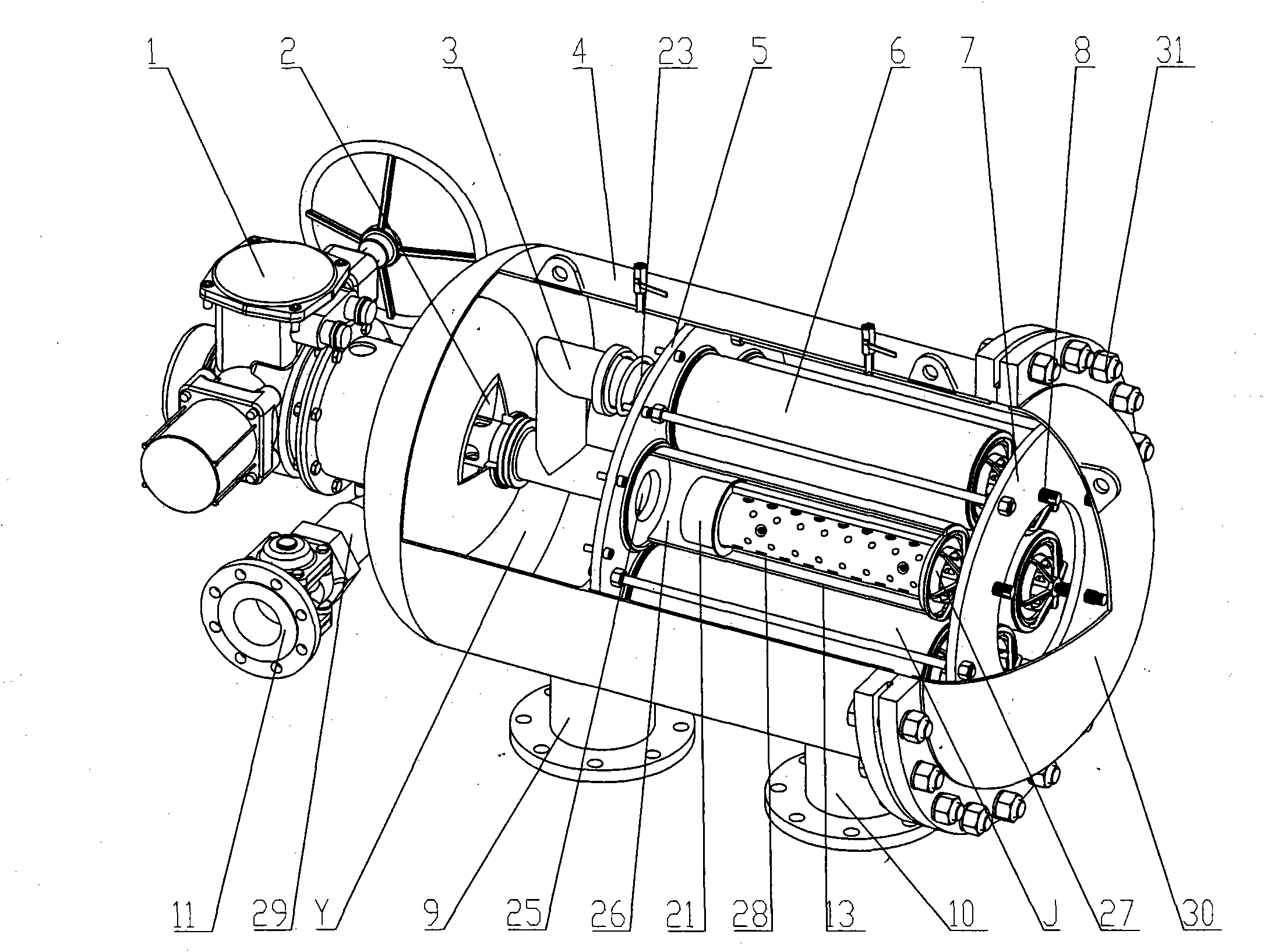

Plasma actuated electronic catalytic converter

InactiveUS20080241004A1Minimal expenseEasy breakdownExhaust apparatusSilencing apparatusAtmospheric airExhaust fumes

An apparatus and method for the breakdown of exhaust gas pollutant molecules into their constituent atoms and then re-assembling those atoms into low energy state non-toxic molecules that are found in the atmosphere naturally is disclosed. A plasma actuated electronic catalytic converter includes an exhaust gas inlet, a first oxidization reaction chamber, a second reduction reaction chamber, an exhaust gas outlet, and an electronics power source. A first reaction chamber includes a plasma discharge electrode and semi-spherical screen that are negatively biased by a direct current source followed by a mixing screen and an anode screen. A second reaction chamber includes a plasma discharge electrode and semi-spherical screen that are positively biased by a direct current source followed by a mixing screen, if needed, a fresh air inlet, and a screen or screens that are negatively biased so as to gradually return electrons to the exhaust gasses.

Owner:JAYNE MICHAEL E +1

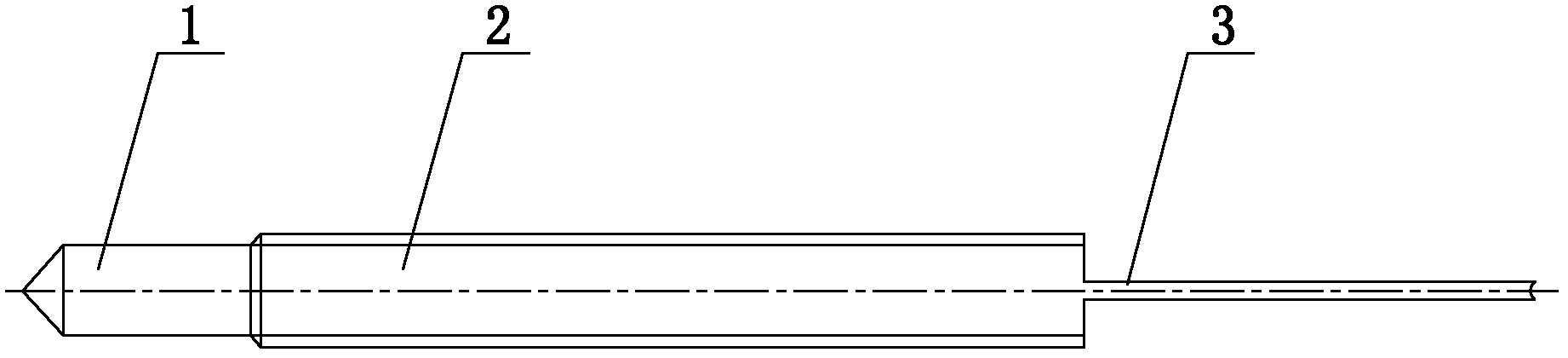

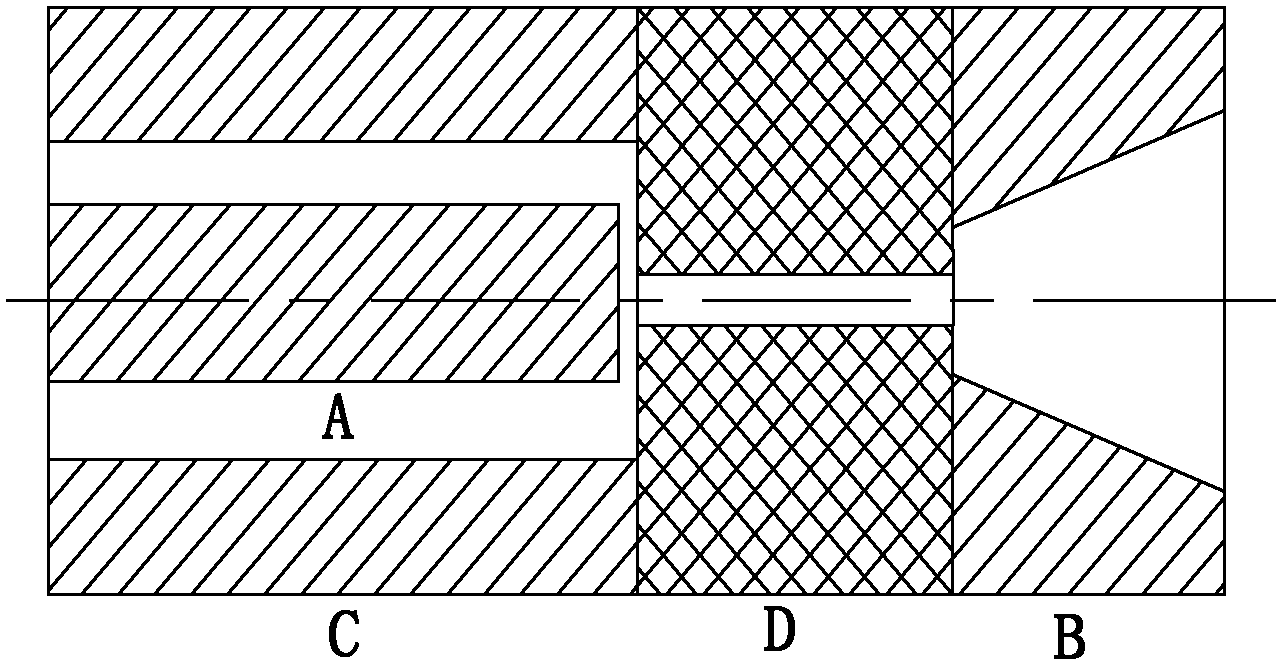

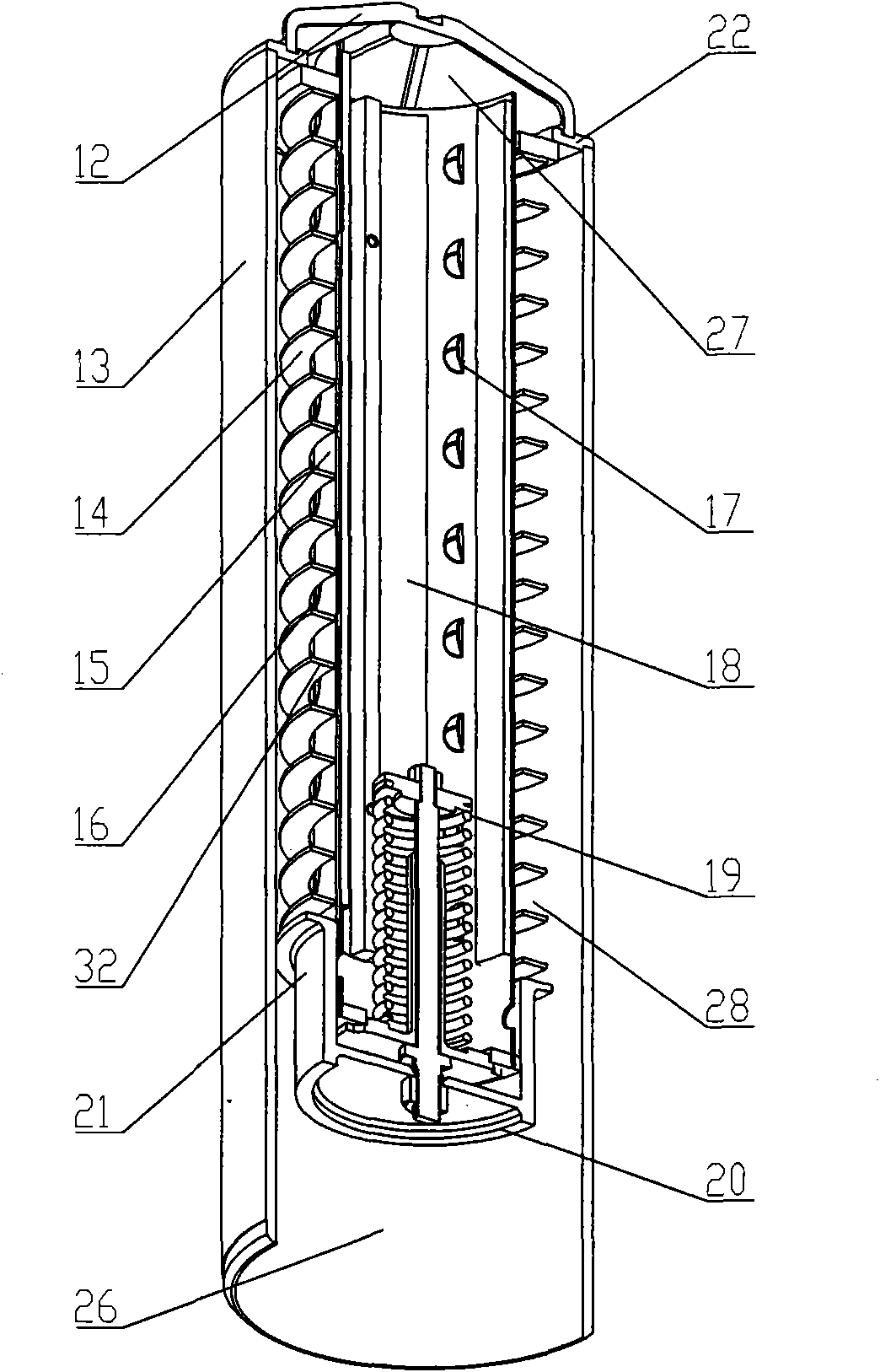

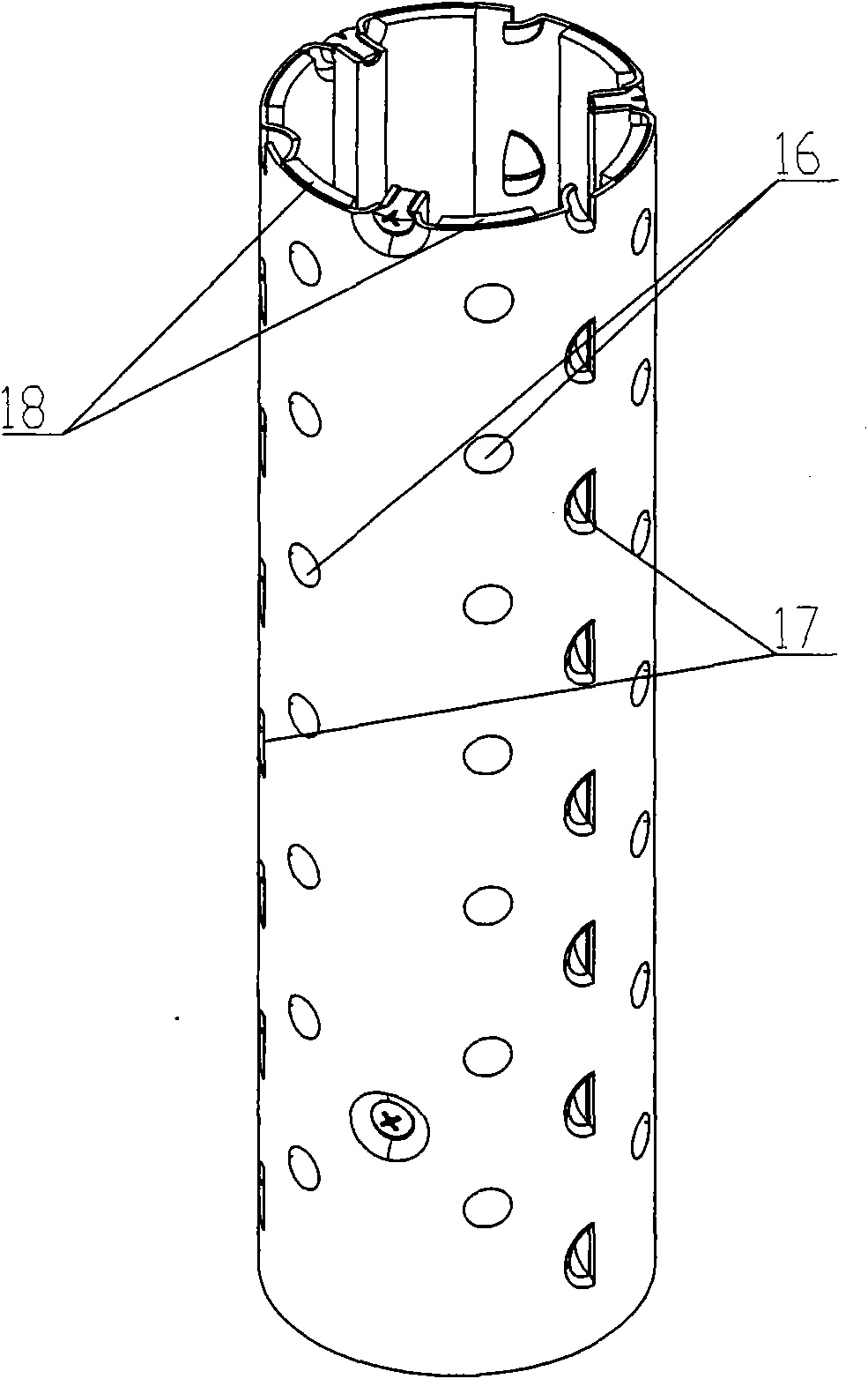

Discharge electrode used for capillary extreme ultraviolet photoetching light source

InactiveCN102496538ASolve breakdown difficultiesSolve the adjustmentDischarge tube main electrodesPhotomechanical exposure apparatusElectricityExtreme ultraviolet

The invention, which belongs to the extreme ultraviolet photoetching light source technology field, relates to a discharge electrode used for a capillary extreme ultraviolet photoetching light source. Therefore, a problem that it is needed to use a mode of changing the length of a capillary to realize a change of a distance between two main pulse electrodes in an extreme ultraviolet photoetching light source can be solved. The discharge electrode comprises a main pulse electrode segment with an adjustable length, a prepulse electrode segment and a discharge electrode segment. The prepulse electrode segment is in a cylindrical shape; one end of the prepulse electrode segment is fixedly connected with one end of the discharge electrode segment; and the end surface of the other end of the discharge electrode segment is a concave spherical surface. One end of the main pulse electrode segment is inserted into the prepulse electrode segment from the other end of the prepulse electrode segment as well as is electrically connected with the prepulse electrode segment; the other end of the main pulse electrode segment is exposed outside the prepulse electrode segment; and the end of the main pulse electrode segment has a tip. And the discharge electrode segment is in a columnar shape; and a range of a section radius of the discharge electrode segment is from 0.2mm to 3.5 mm. According to the invention, the provided discharge electrode is used as one for extreme ultraviolet photoetching light source.

Owner:HARBIN INST OF TECH

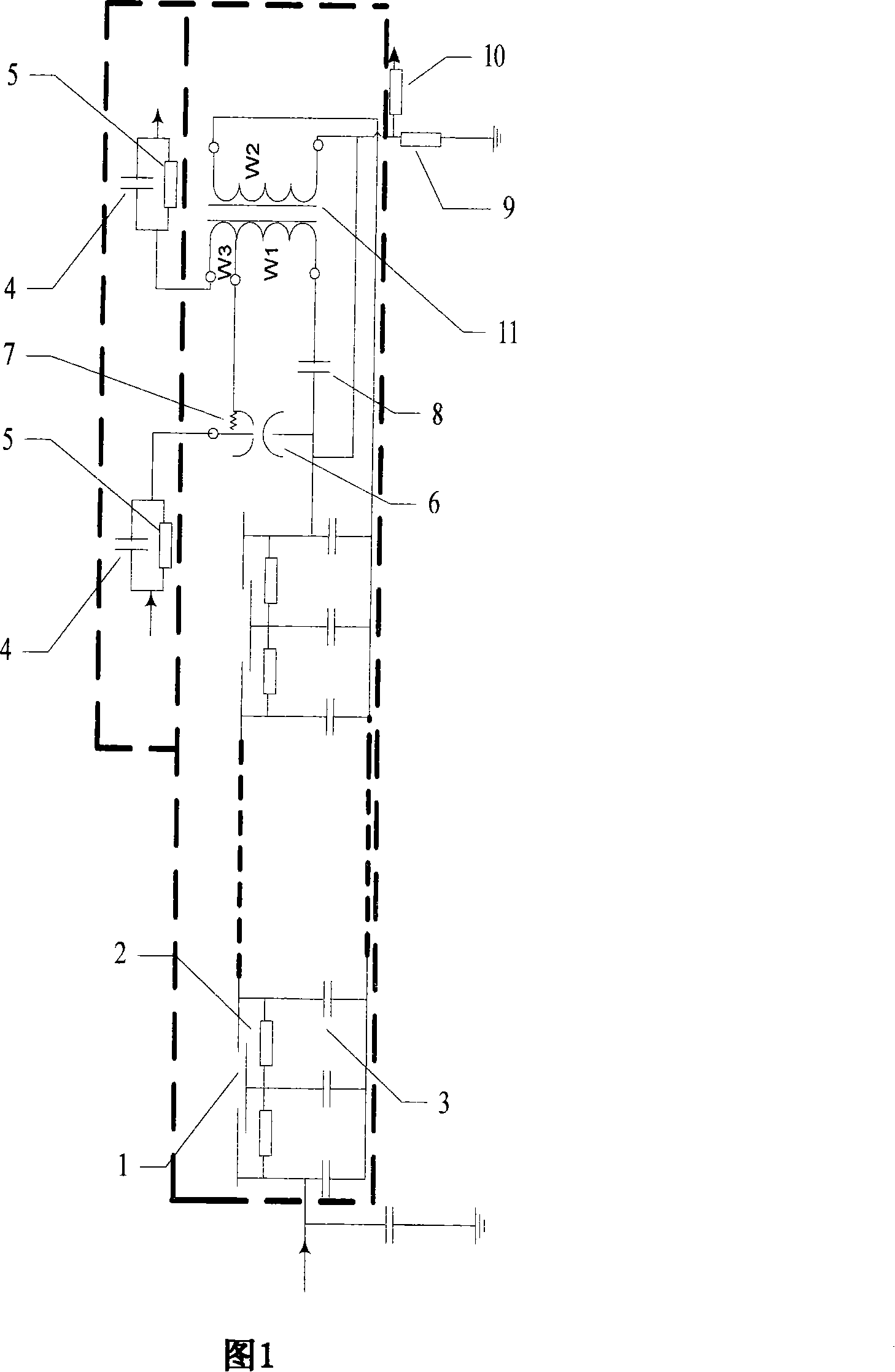

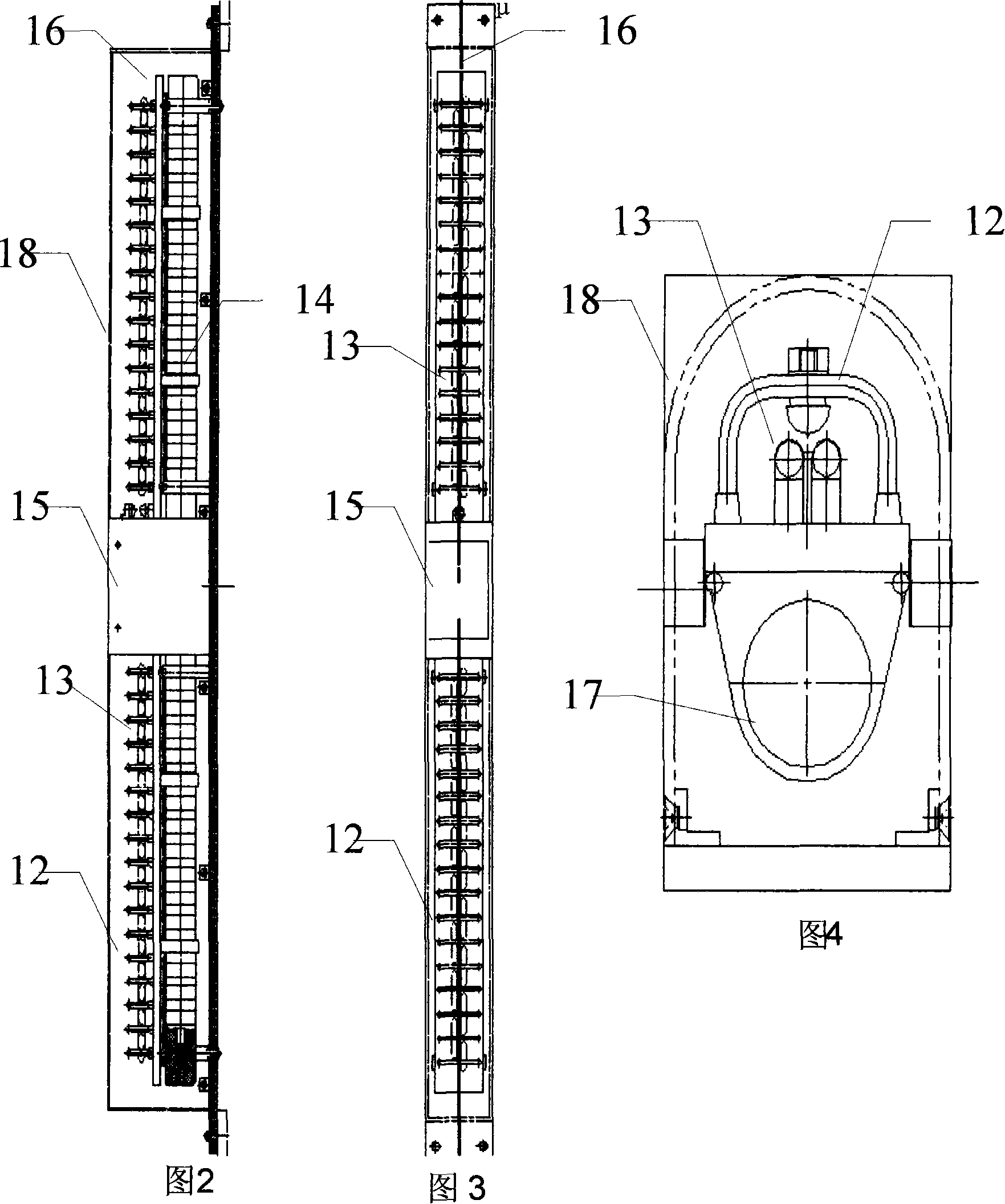

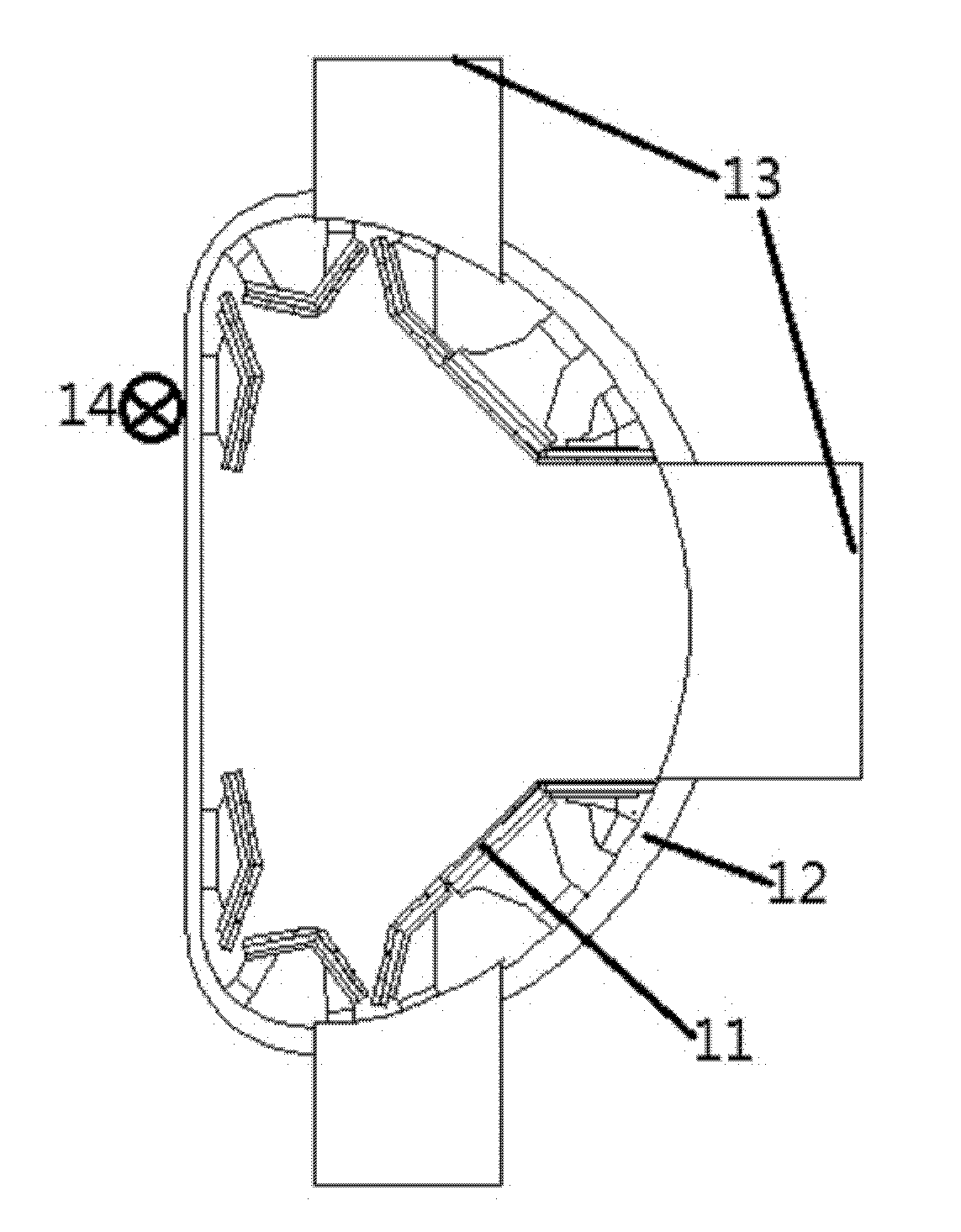

Multi-pole ignition device of impulse voltage generator

ActiveCN101220792AShort on-timeGood synchronizationInstallations with capacitive energy storageCapacitanceLow voltage

The invention provides a multi-pole ignition device of an impulse voltage generator. The invention is characterized in that the device mainly comprises a pulse voltage generator, a multi-pole main clearance and a transmission resistance capacitor; the pulse voltage generator consists of a low voltage primary winding W1 and two high voltage secondary windings W2 and W3; the multi-pole main clearance consists of a plurality of small clearances 1; each small clearance 1 is provided with two tungsten-copper alloy rods 13; the transmission resistance capacitor consists of a transmission capacitor 4 and a transmission resistance 5. Owning to short conduction time of the multi-pole main clearance, the ignition process and the ignition pulse transmission process of each pole are achieved at the same time; the impulse voltage generator has good synchronousness, is not required to adjust the sphere gap before the impulse voltage is generated each time and is not affected by the environmental condition, has wide range of triggered voltage and small dispersion, and leads to easy breakdown of the clearance of each pole.

Owner:STATE GRID ELECTRIC POWER RES INST

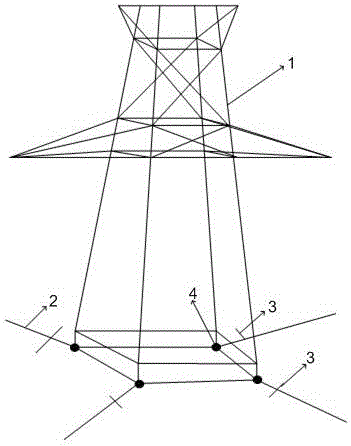

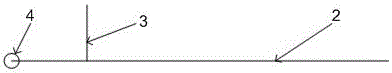

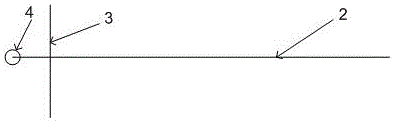

Device and method for reducing grounding resistance of grounding grid

InactiveCN106451030AEasy breakdownGood resistance reduction effectCoupling device engaging/disengagingGrounding gridElectrical resistance and conductance

The invention discloses a device for reducing grounding resistance of grounding grid. The device comprises at least one horizontal grounding conductor which is fixed at the bottom of the tower. The horizontal grounding conductor is provided with at least one spark thorn conductor which is fixed between the middle part of the horizontal grounding conductor and the impingement current injection point of the horizontal grounding conductor. By setting the spark thron conductor at the front middle of the impingement current injection point near the horizontal grounding conductor, a large part of the current flow of the injection point will flow to the spark thorn conductor, so that the equivalent radius of the spark effect of the spark conductor is enlarged, the soil is more prone to breakdown, and the spark effect is very significant, which, at the same time, has a great influence on the current distribution of the horizontal grounding conductor, so that the resistance value of the grounding resistance is reduced, and the resistance reduction effect is remarkable.

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +1

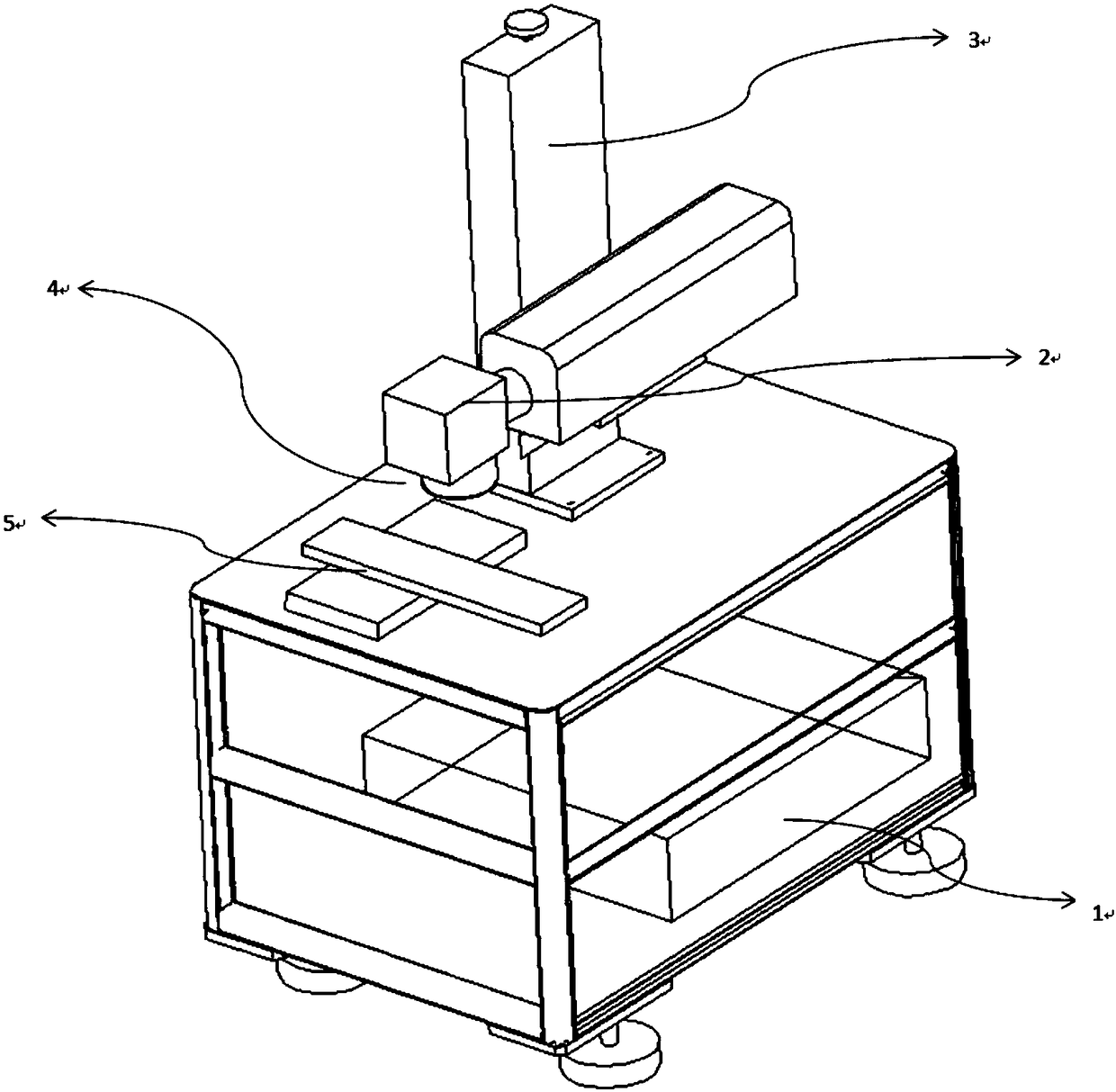

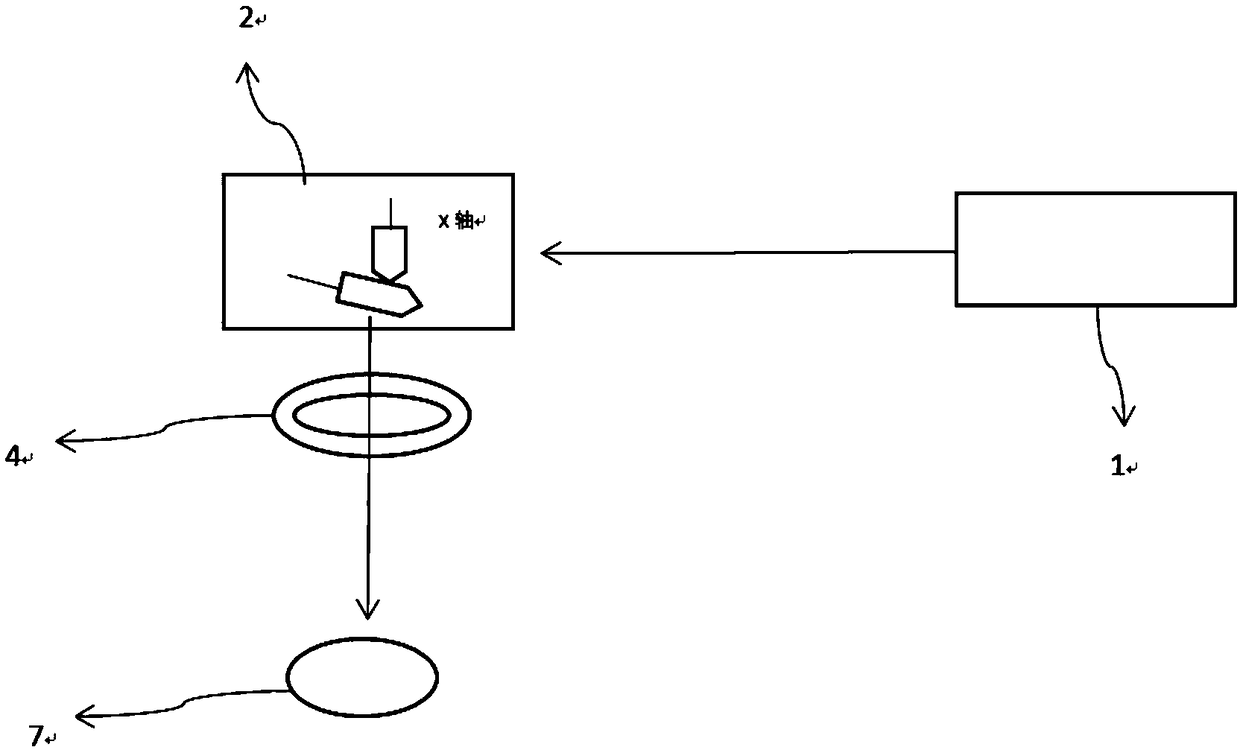

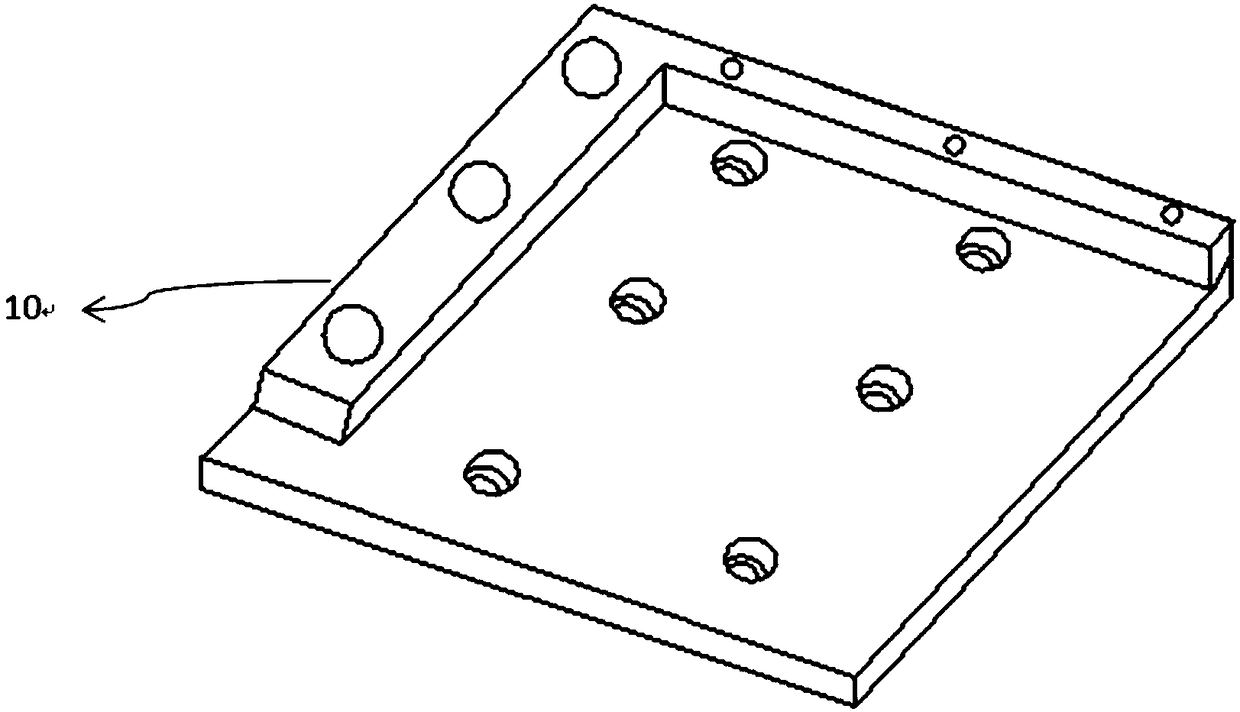

Laser path of laser welding point, and laser welding method

ActiveCN108356414AStrong pullControllable stacking timesLaser beam welding apparatusShielding gasLaser scanning

The invention discloses a laser path of a laser welding point, and a laser welding method. The laser welding method comprises the steps of fixing a product to be welded onto a two-dimensional platformthrough a fixture, utilizing a pulse laser for scanning welding a welding point in a welding area of the product to be welded, and dividing a laser scanned path graph of the welding point into threesegments, wherein the first segment is a straight-line segment or a curved segment, the second segment is formed by multiple reciprocating disjoint straight-line segments or curved segments, startingpoints of each two adjacent straight-line segments or curved segments are connected through a transition segment, the third segment is a straight-line segment or a curved segment, and the first segment, the second segment and the third segment are sequentially connected; and crossing the straight-line segments or the curved segments of the first segment and the second segment, crossing the straight-line segments or the curved segments of the third segment and the second segment, and during a laser scanning welding process, blowing a protection gas to the welding point. According to a speciallyedited point-shaped welding graph, a thin slice is welded through a single-pulse superposition track manner, multiple small molten pools are formed in the thin slice material, and the welding point with a large tensile force is obtained.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

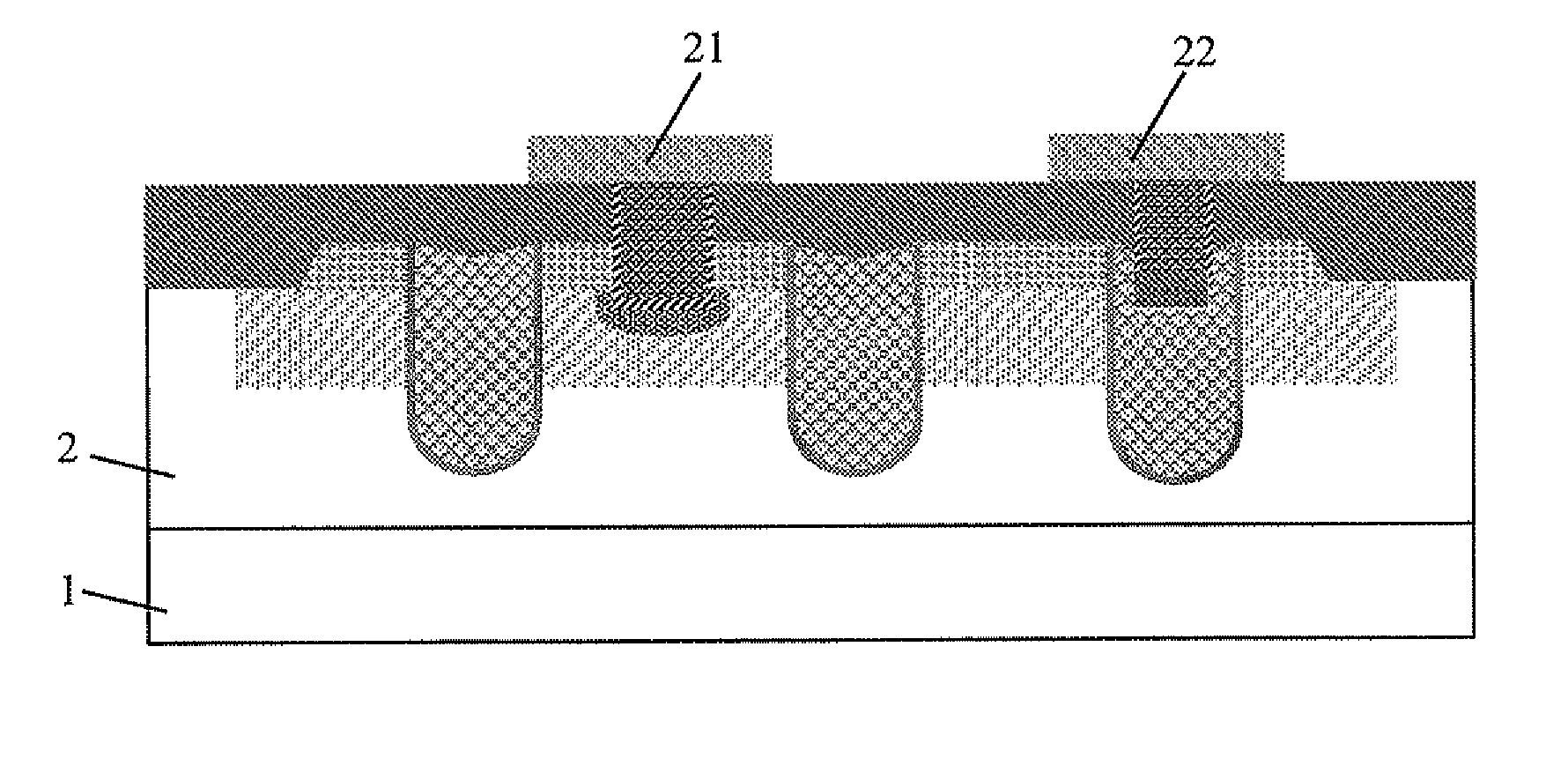

Method for improving CuxO electric resistance memory fatigue property

InactiveCN101145598AExcellent fatigue propertiesEasy breakdownElectrical apparatusDigital storageElectrical resistance and conductanceMaterials science

The invention belongs to the field of microelectronic technique and specifically relates to a method for improving the fatigue property of a CuxO memistor. The method removes a superficial CuO layer by means of plasma bombardment, or increases the electrical conductivity thereof, so that the method can reduce the current and voltage of the first-time write operation, protect the CuxO storage medium with resistance conversion property below the CuO layer from the damage of heavy current, and improve the fatigue property of the device.

Owner:FUDAN UNIV

Method for cleaning first wall of magnetic confinement fusion device by using high-frequency field

ActiveCN102500589AEasy breakdownImprove cleaning efficiencyHollow article cleaningProduct gasIonization

The invention discloses a method for cleaning a first wall of a magnetic confinement fusion device by using a high-frequency field. The method is implemented by the steps of: (1) previously filling gas of 0.1-10 Pa in a vacuum chamber of the magnetic confinement fusion device; (2) arranging a high-frequency antenna in the vacuum chamber of the magnetic confinement fusion device, then taking the vacuum chamber of the magnetic confinement fusion device as a negative electrode and the high-frequency antenna which extends into the vacuum chamber of the magnetic confinement fusion device as a positive electrode, and applying the high-frequency field with voltage of 3-5 KV, frequency of 20-50 KHz and power of 2-10 KW between the negative electrode and the positive electrode; and (3) breaking down gas under the action of ionization of the high-frequency field and generating stable high-frequency plasma discharge, performing effective bombardment on the first wall of the vacuum chamber of the magnetic confinement fusion device, and cleaning the first wall after discharge cleaning of 1-10 hours. Through the method, the cleaning efficiency can be doubled.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

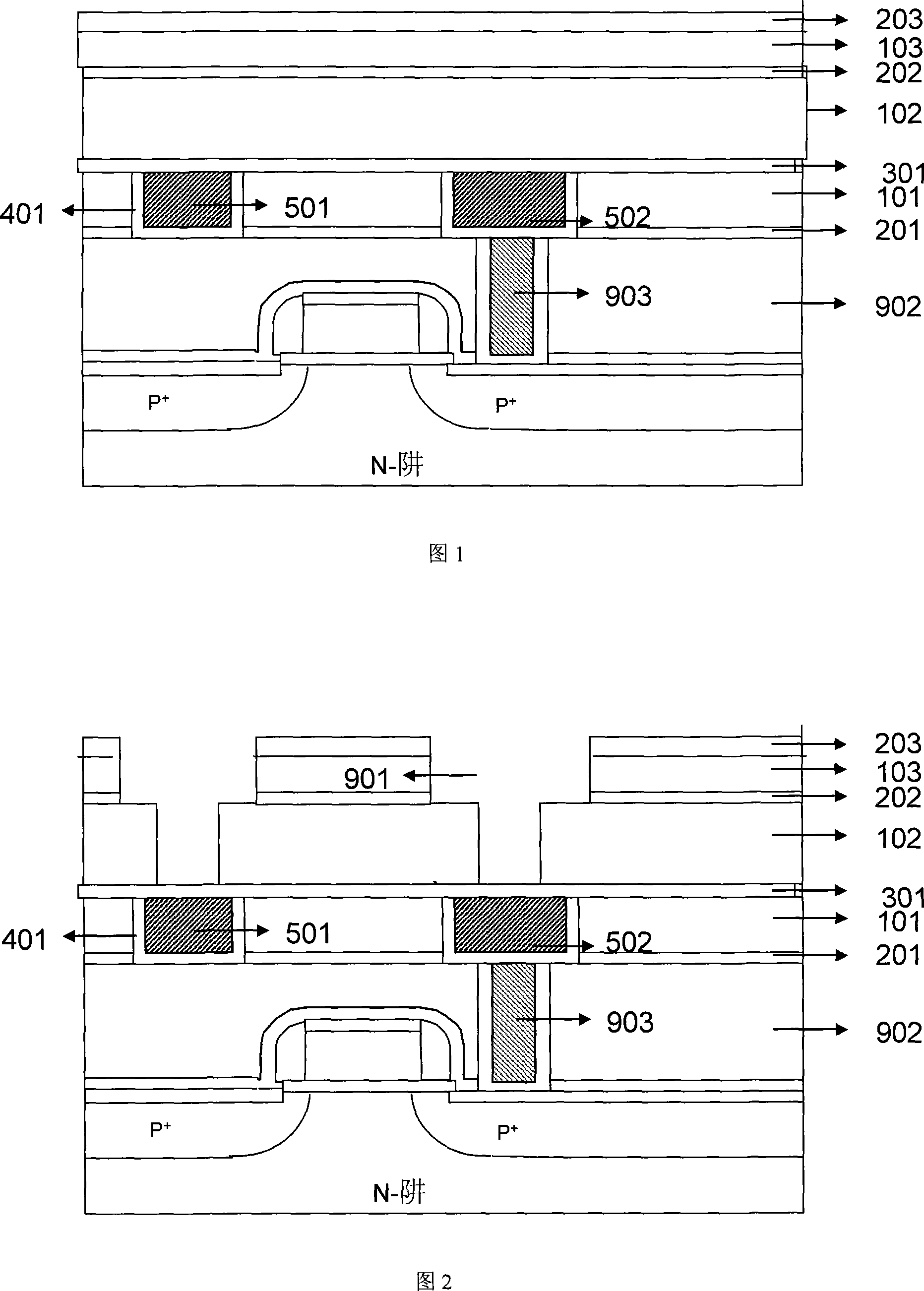

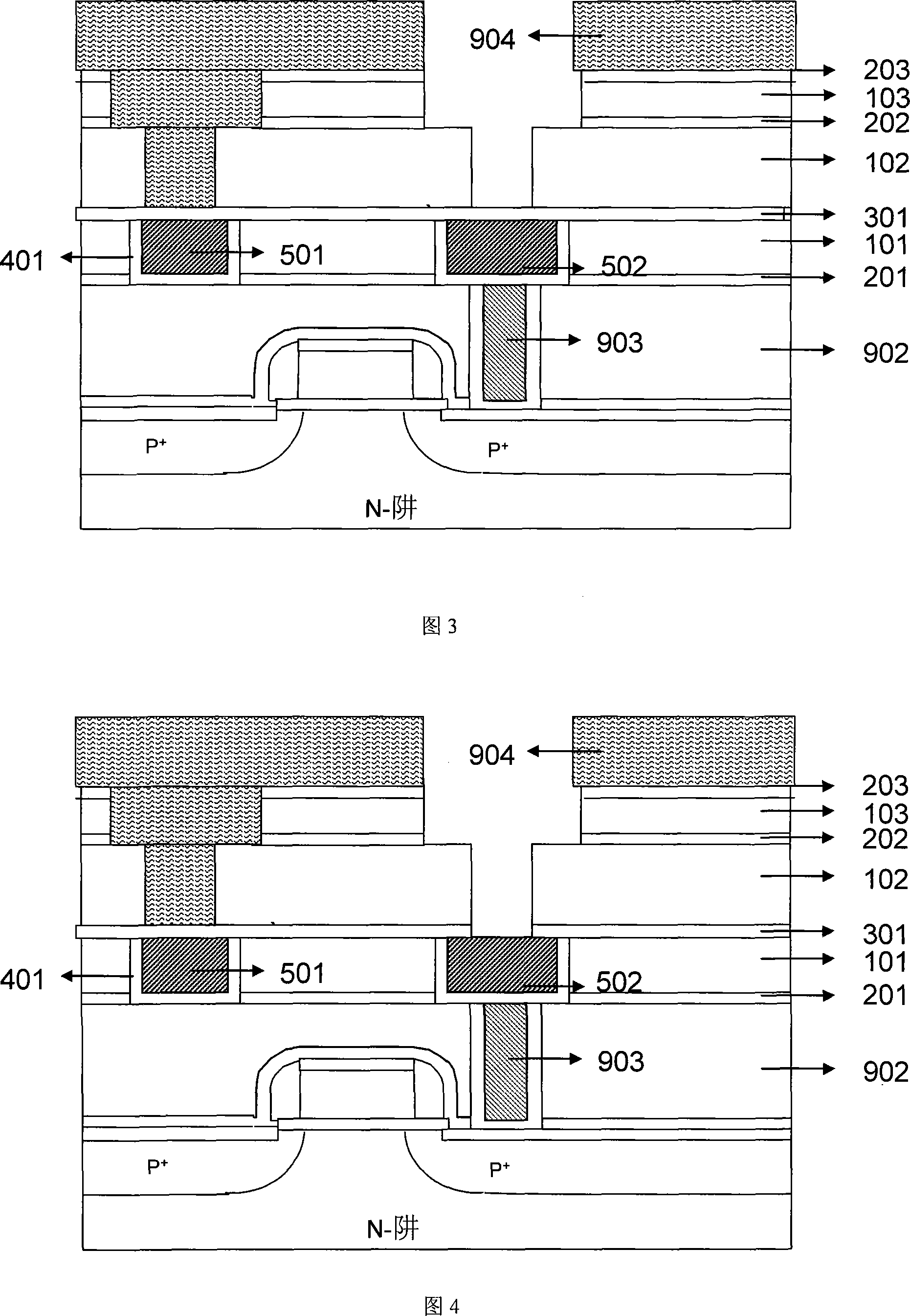

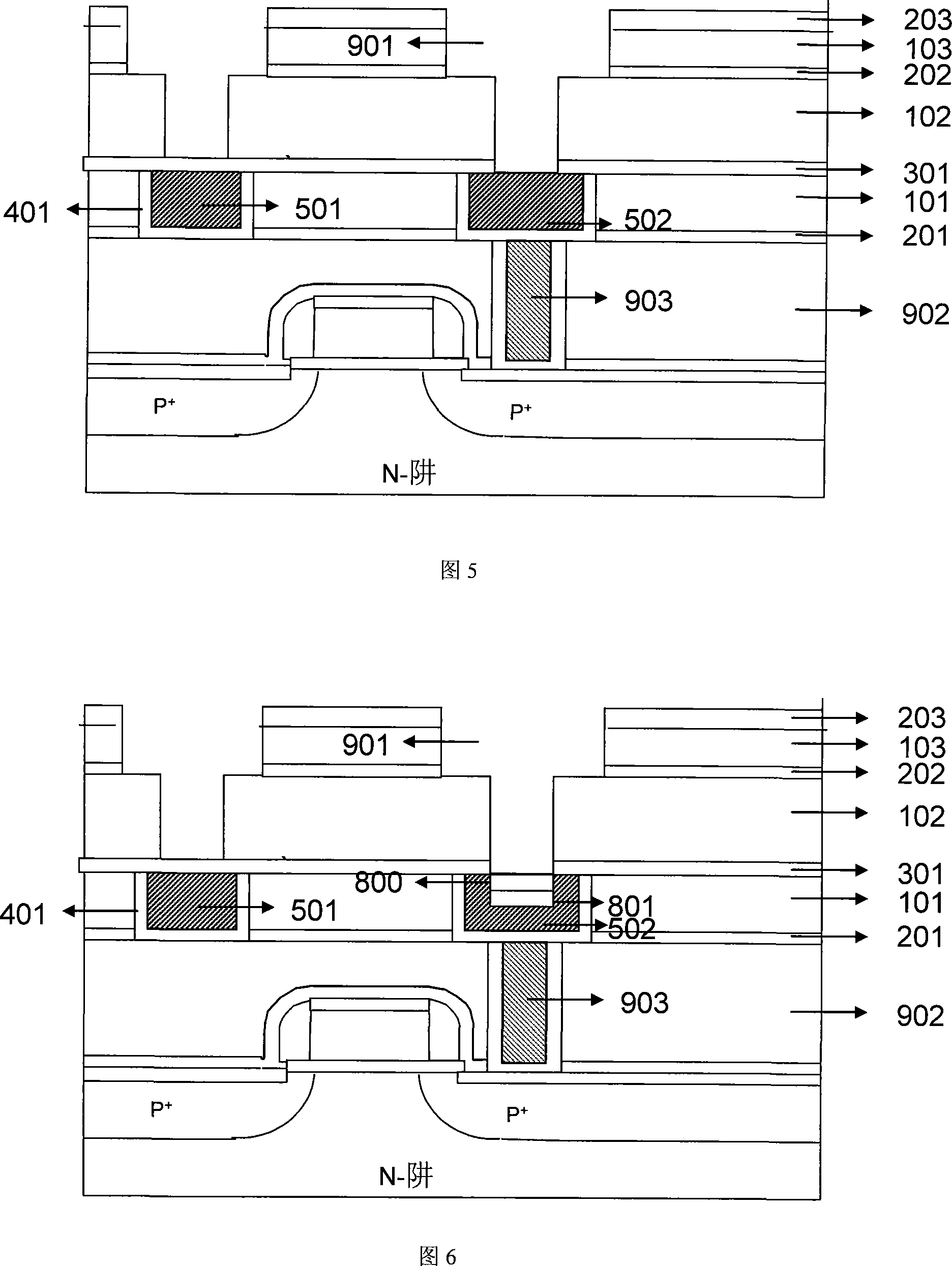

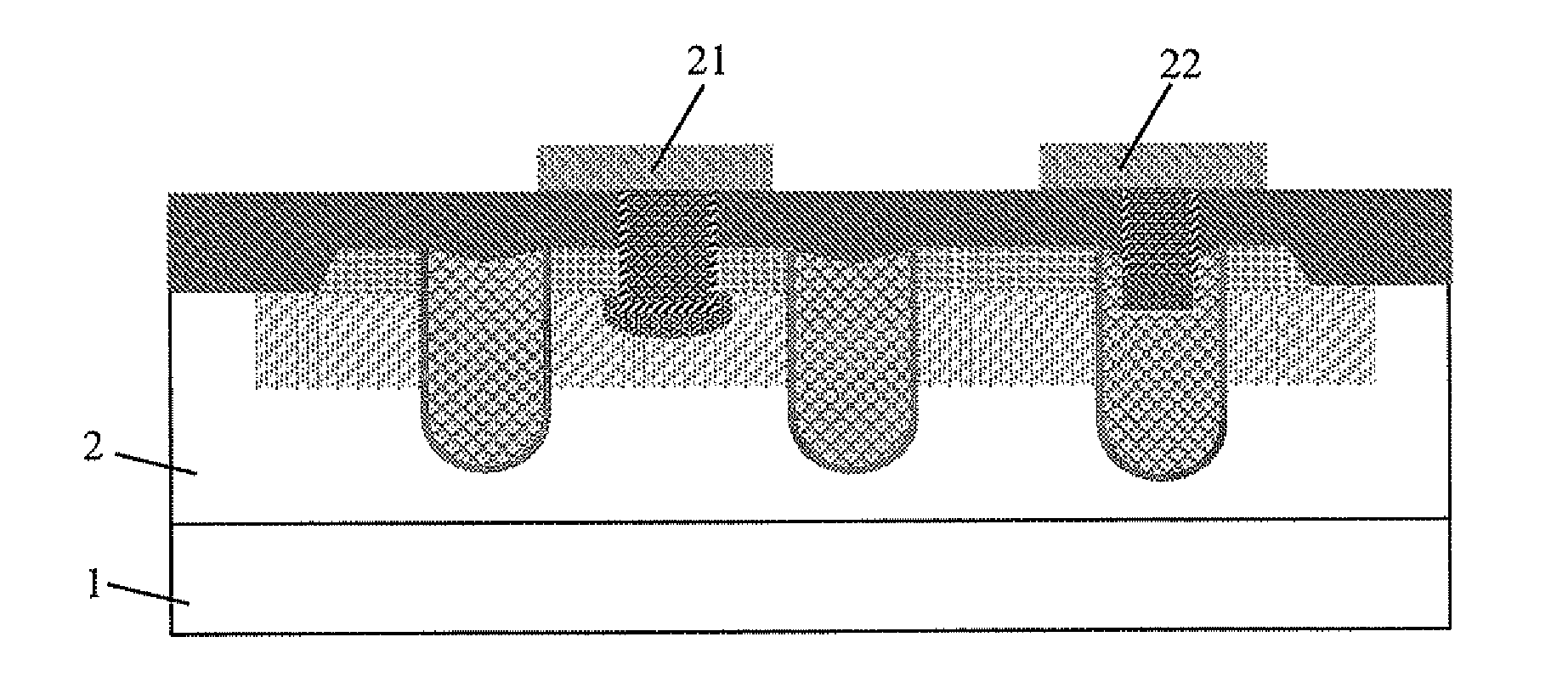

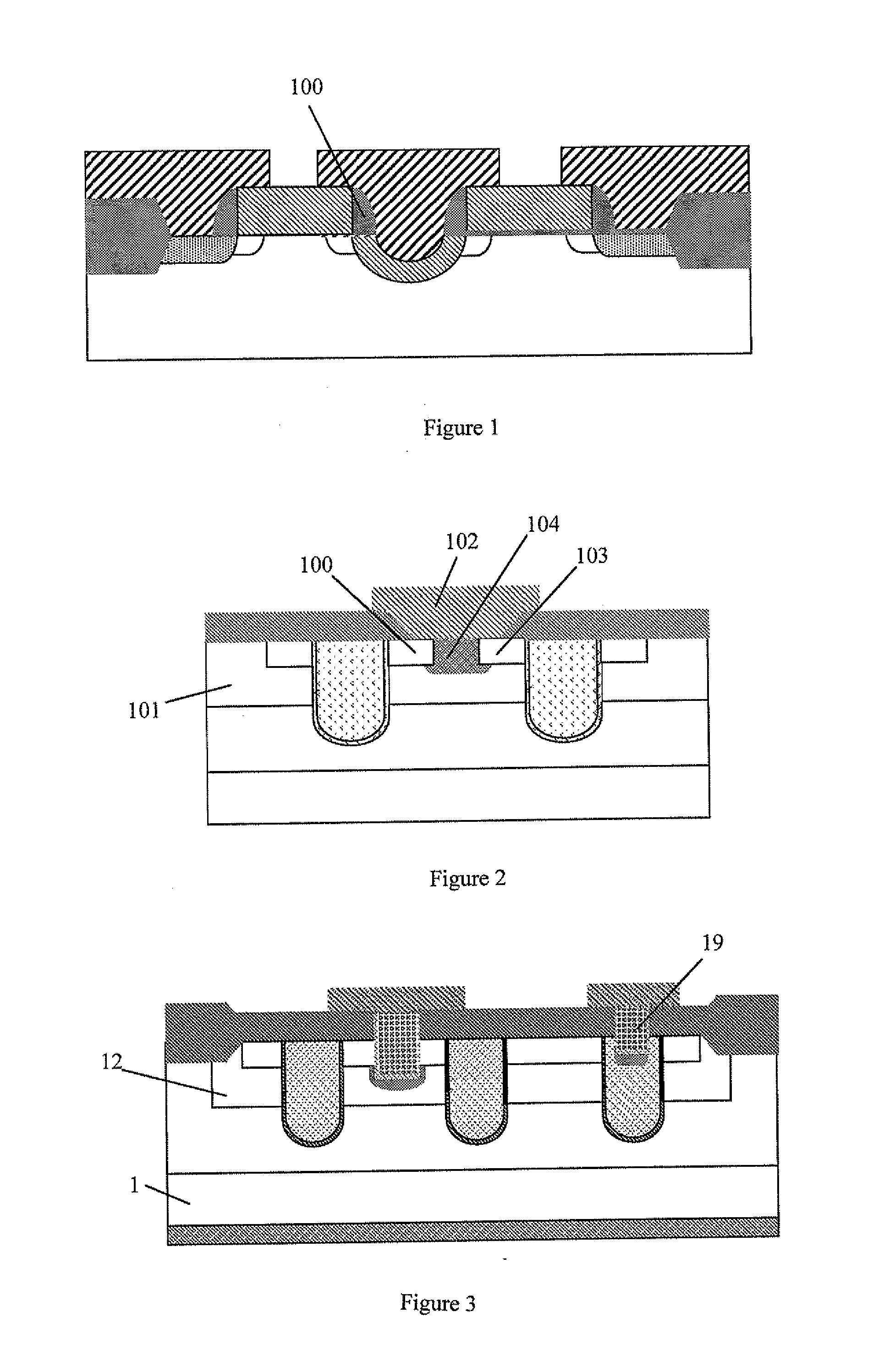

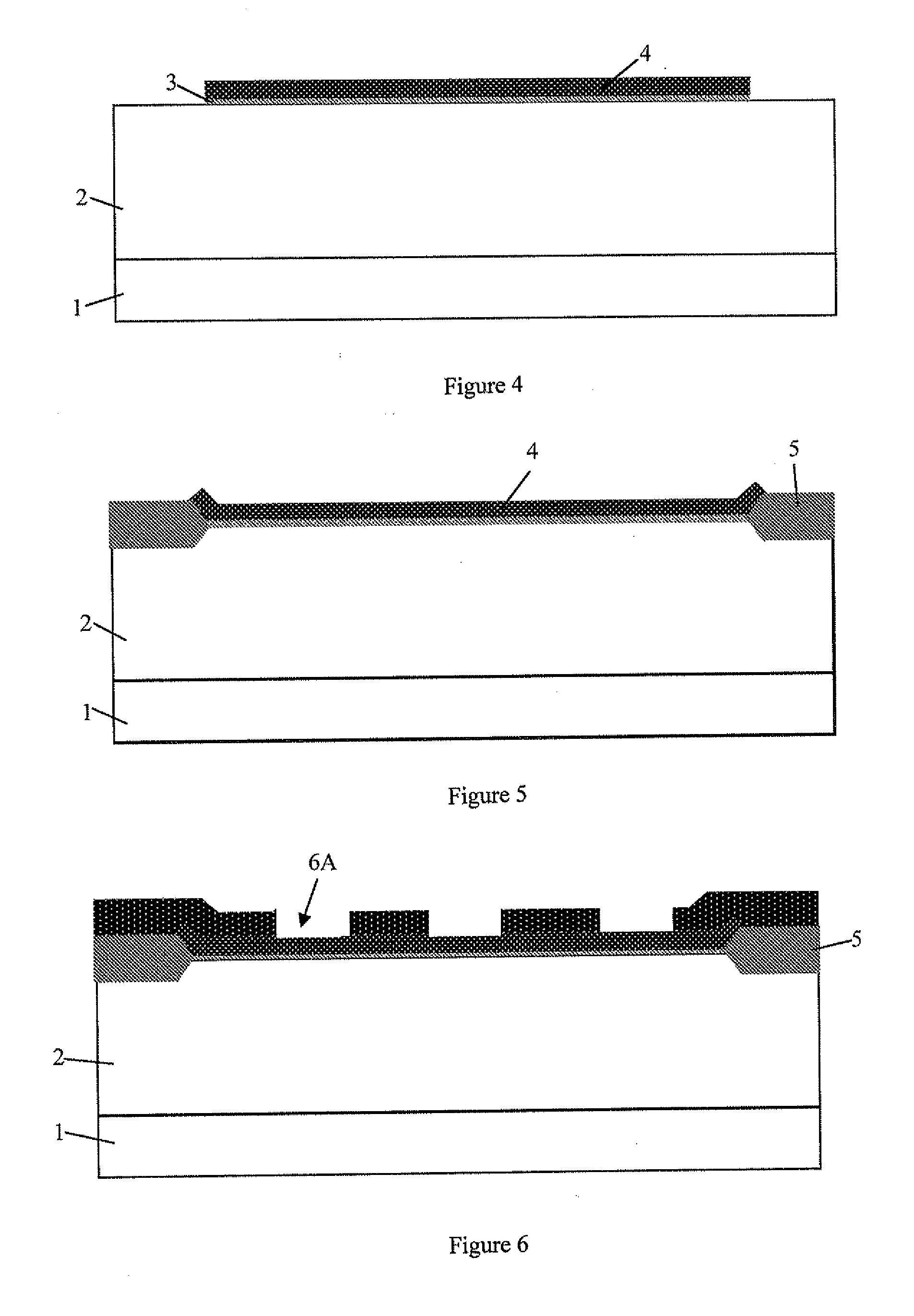

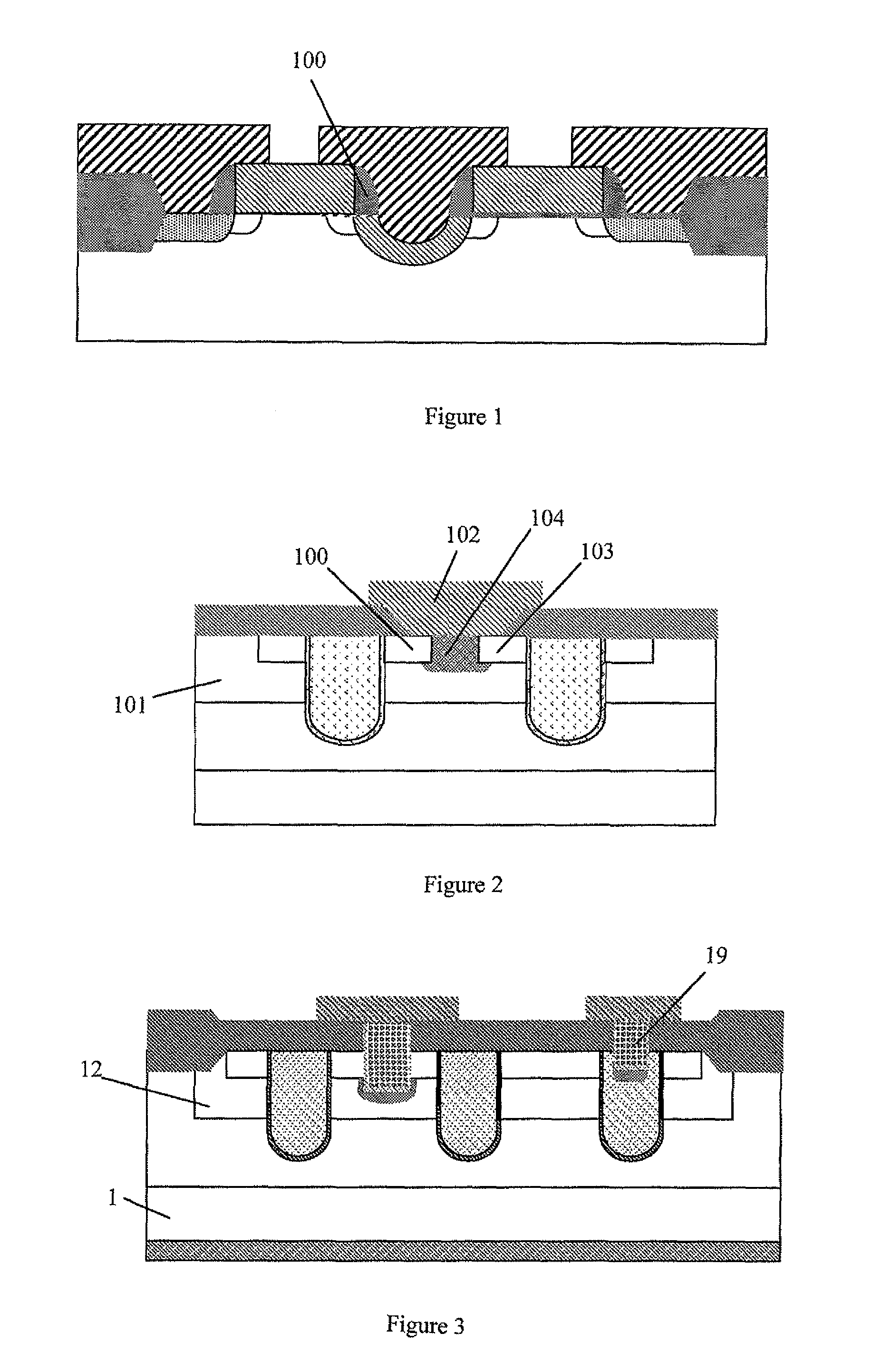

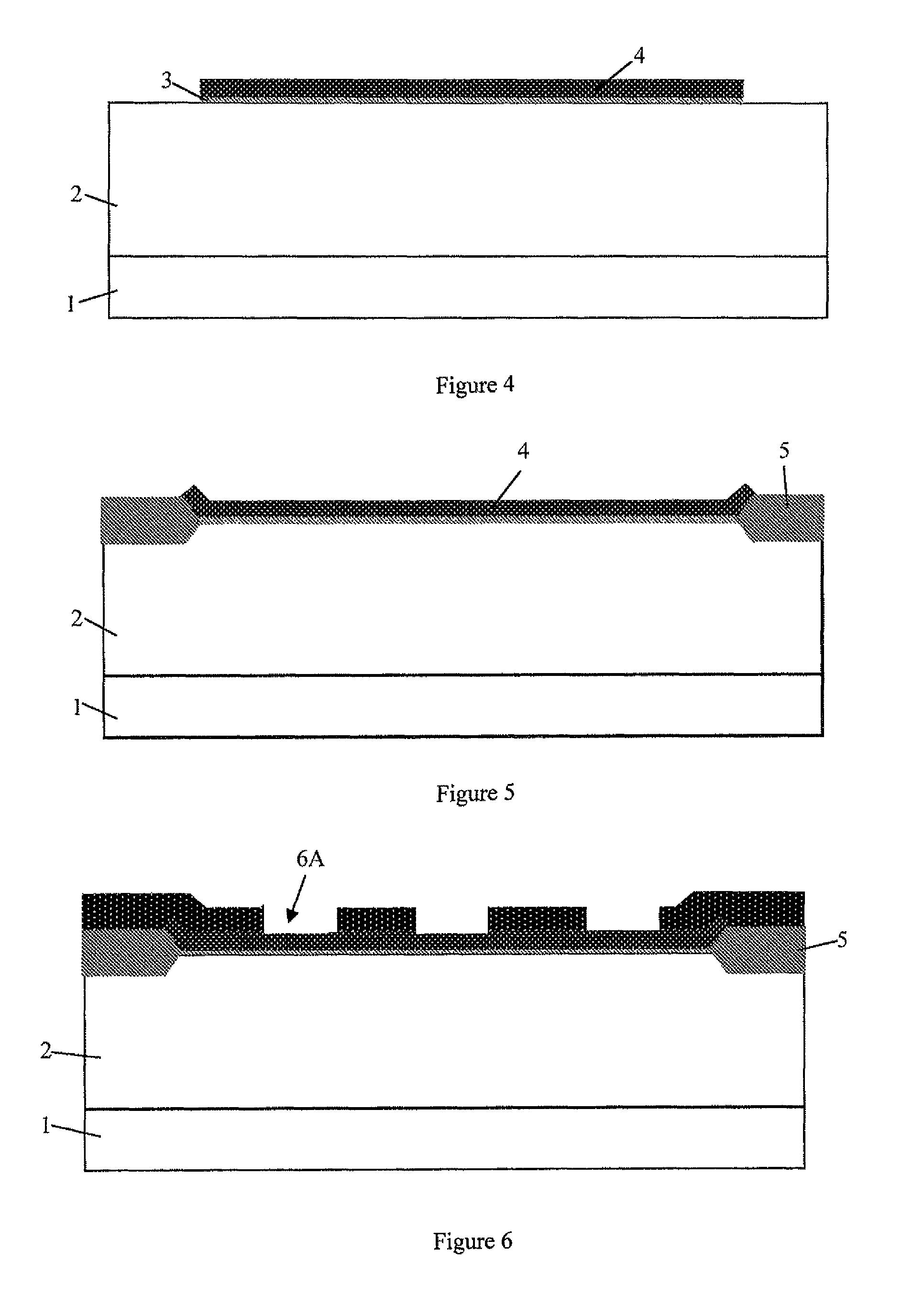

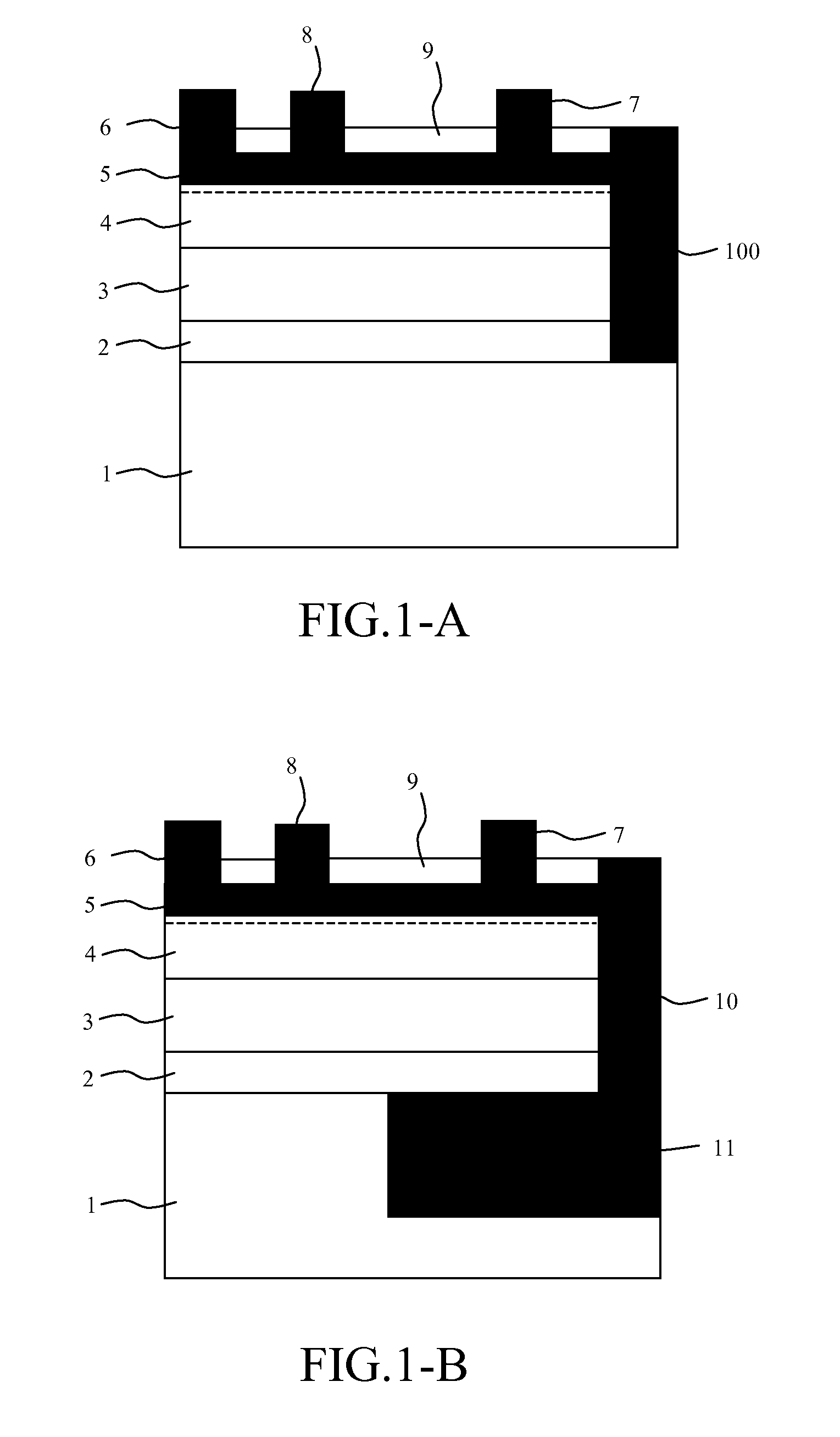

Trench mosfet with trench contact holes and method for fabricating the same

ActiveUS20120091523A1Mutual solubilityJunction breakdown can be preventedSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetGate oxide

A trench MOSFET with trench contact holes and a method for fabricating the same are disclosed. The MOSFET includes an N type substrate, an N type epitaxial layer on the substrate; a P well region on top of the epitaxial layer; a source region formed on the P well region; an oxide layer on the source region; a plurality of trenches which traverse the source region and the P well region and contact the epitaxial layer; a gate oxide layer and polysilicon formed in the trenches; a source contact hole and a gate contact hole, wherein the source contact hole and the gate contact hole have a titanium metal layer, a titanium nitride layer, and tungsten metal sequentially, respectively; a P+ implanted region; a source electrode formed above the source contact hole and a gate electrode formed above the gate contact hole.

Owner:WILL SEMICON (SHANGHAI) CO LTD

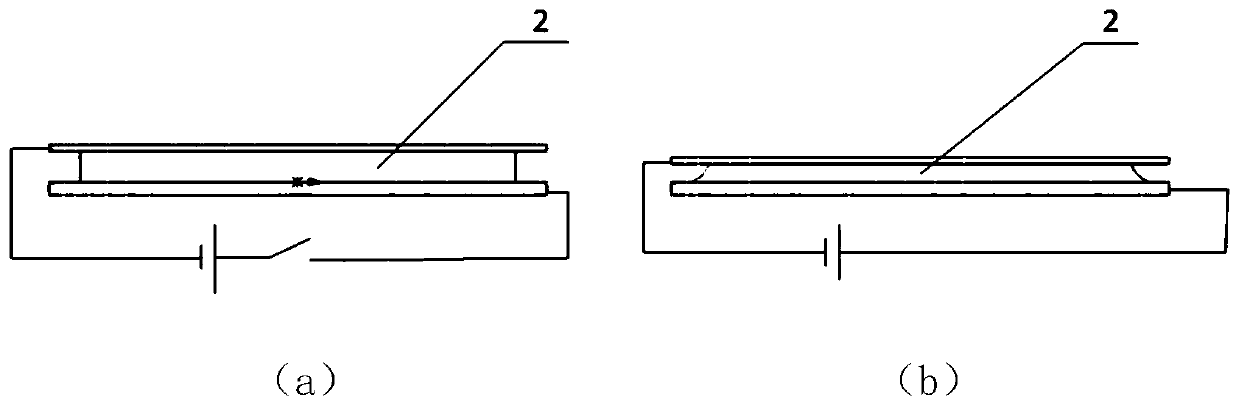

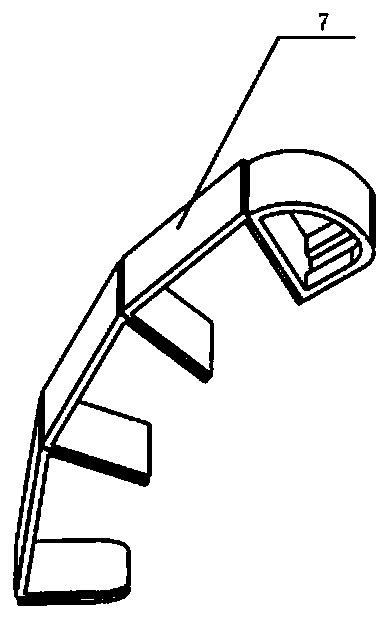

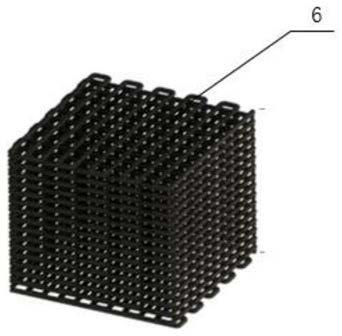

PVC gel driven flexible mechanical tongs and preparing method thereof

ActiveCN111113380AFunctionalSimple drive formProgramme-controlled manipulatorAdditive manufacturing apparatusEngineeringStructural engineering

The invention discloses PVC gel driven flexible mechanical tongs and a preparing method thereof. A multi-layer PVC driver is arranged in a flexible outer frame. A flexible sensor is arranged on the top of the flexible outer frame. The multi-layer PVC driver is formed by stacking a plurality of single-layer PVC drivers, and object grabbing is achieved through the layer number of the single-layer PVC drivers and voltage applying. The PVC gel driven flexible mechanical tongs have the grabbing function and the sensing function at the same time, and on the basis of PVC gel driving, the drive form is simple.

Owner:XI AN JIAOTONG UNIV

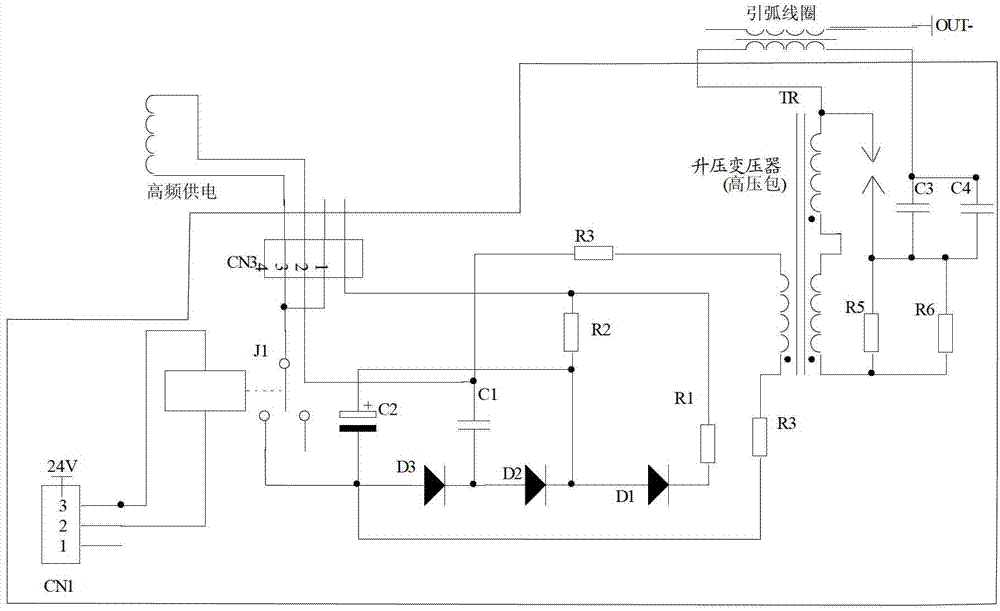

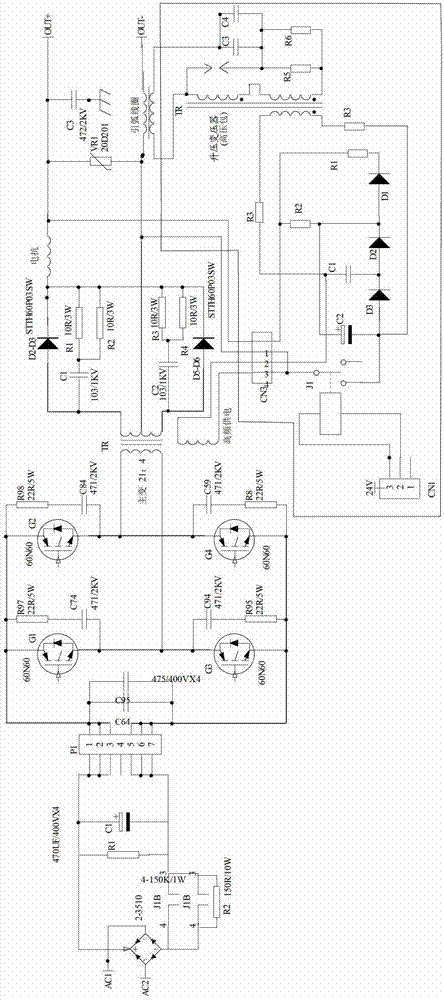

High frequency arc ignition circuit with direct current voltage output

InactiveCN103111719AEasy breakdownIncrease success rateArc welding apparatusEngineeringHigh pressure

The invention relates to a high frequency arc ignition circuit with direct current voltage output. The high frequency arc ignition circuit with direct current voltage output comprises a high frequency signal source, a relay, a high frequency voltage booster circuit and a voltage doubling circuit. The high frequency signal source is respectively connected with the input end of the voltage doubling circuit and the input end of the high frequency voltage booster circuit through the relay. The output end of the voltage doubling circuit outputs direct current voltage to secondary positive and negative electrodes of a welding machine main circuit. The high frequency voltage booster circuit produces high frequency high voltage signals and the high frequency high voltage signals are coupled to the secondary negative electrode of the welding machine main circuit and outputted. With the aid of the voltage doubling circuit, the direct current voltage is added to the high frequency arc ignition circuit with direct current voltage output on the condition of high frequency arc starter, air can be punctured more easily at the time of high frequency arc starter, arcing is easier, and success rate of arcing and arcing performance of the welding machine can be improved.

Owner:广东世博科焊接工程技术有限公司

Trench MOSFET with trench contact holes and method for fabricating the same

ActiveUS8697518B2Easy breakdownMutual solubilitySemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetTitanium

A trench MOSFET with trench contact holes and a method for fabricating the same are disclosed. The MOSFET includes an N type substrate, an N type epitaxial layer on the substrate; a P well region on top of the epitaxial layer; a source region formed on the P well region; an oxide layer on the source region; a plurality of trenches which traverse the source region and the P well region and contact the epitaxial layer; a gate oxide layer and polysilicon formed in the trenches; a source contact hole and a gate contact hole, wherein the source contact hole and the gate contact hole have a titanium metal layer, a titanium nitride layer, and tungsten metal sequentially, respectively; a P+ implanted region; a source electrode formed above the source contact hole and a gate electrode formed above the gate contact hole.

Owner:WILL SEMICON (SHANGHAI) CO LTD

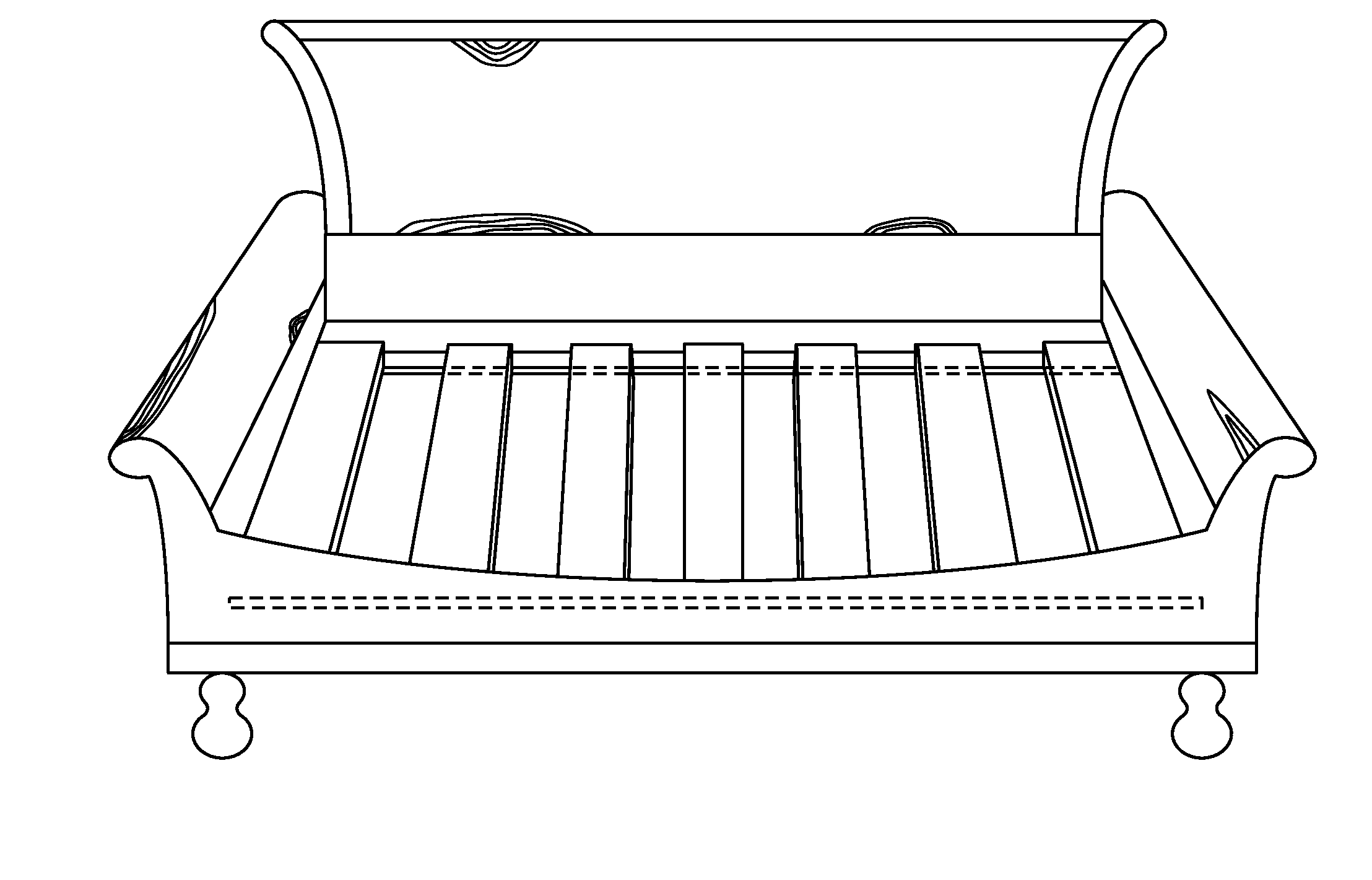

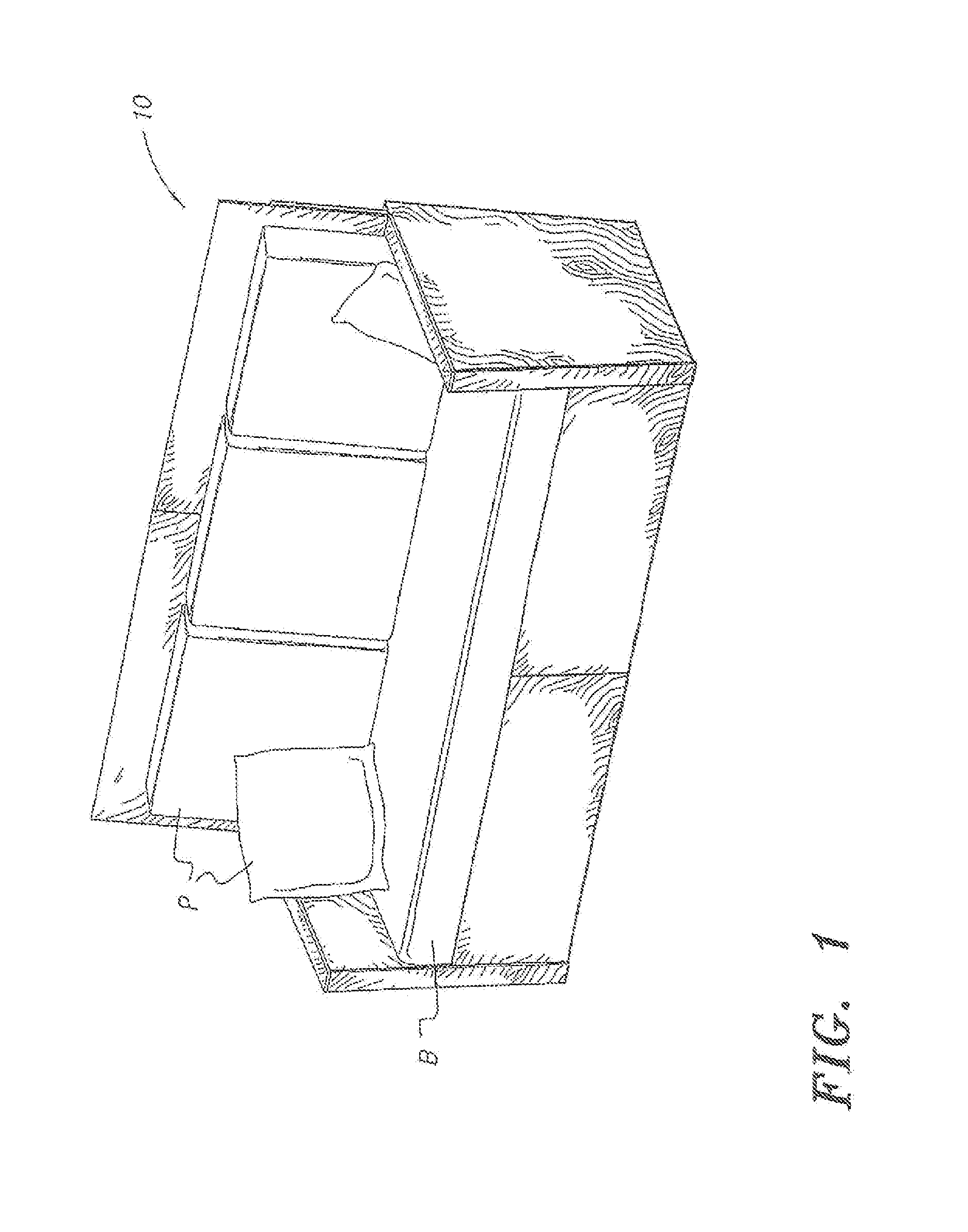

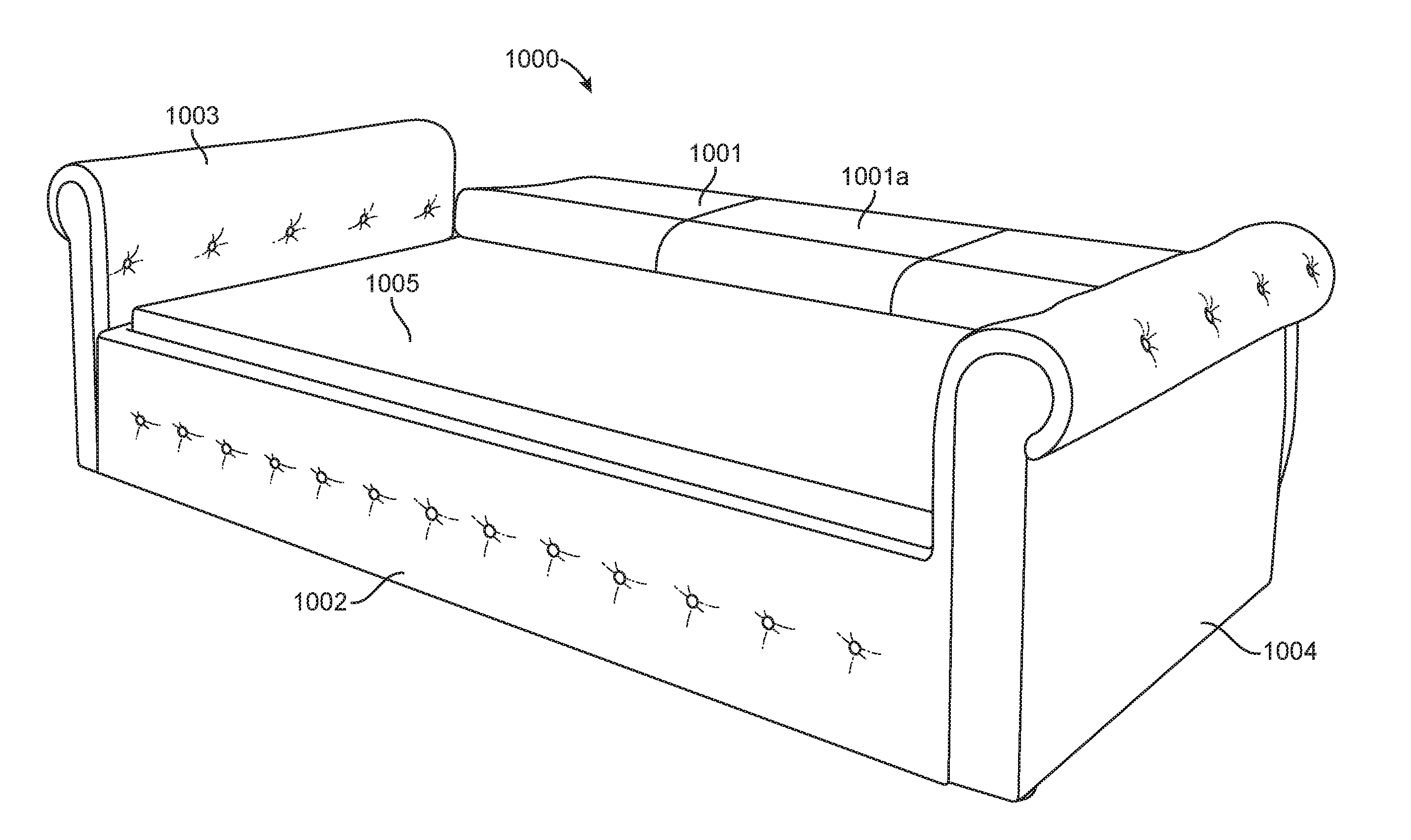

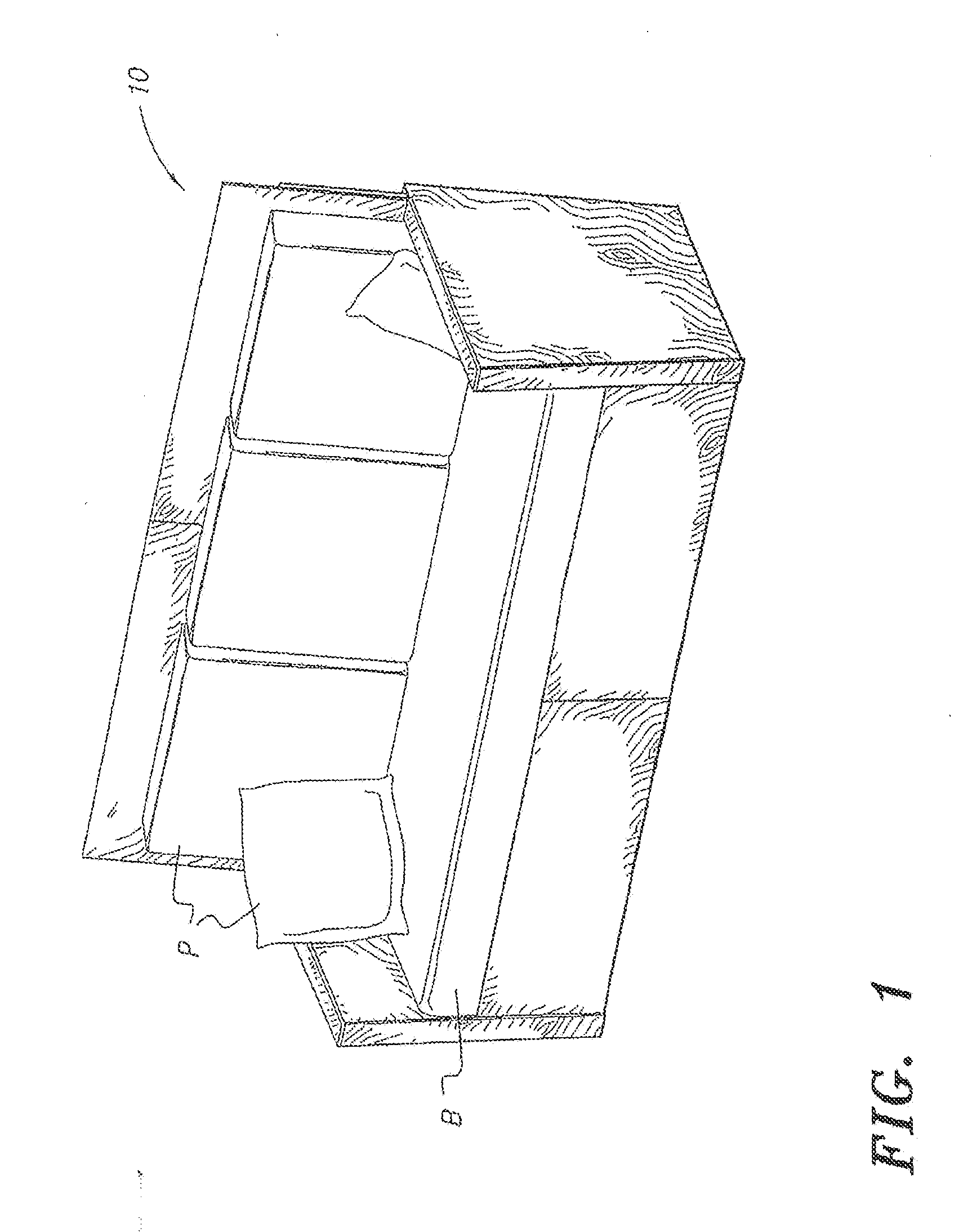

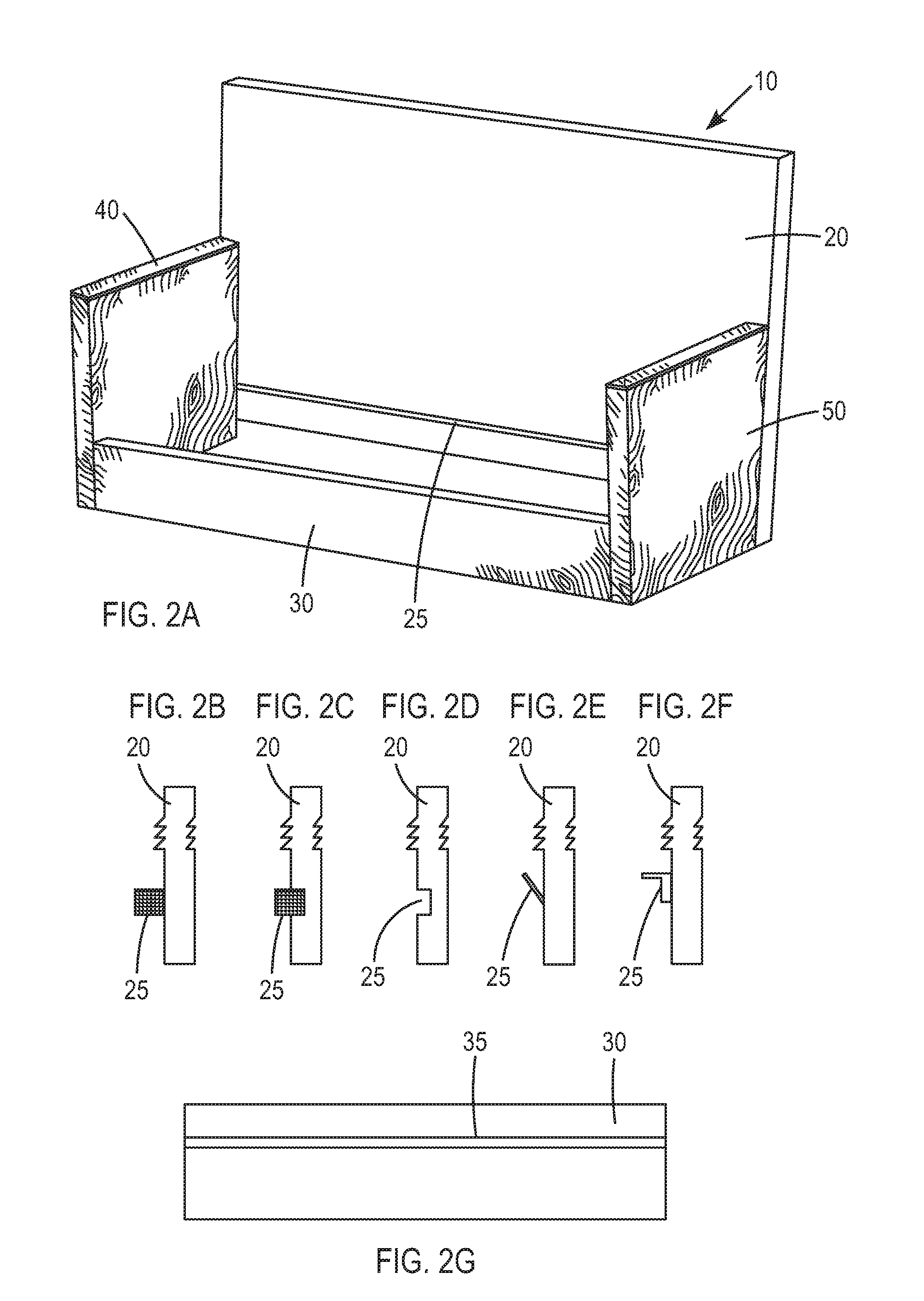

Bed to a sofa conversion frame

A bed to a sofa conversion frame, without a seating area, a space reserved for the traditional bed, which is a conventional manufactured mattress, or ii) a conventional manufactured mattress and a box spring, or iii) a conventional manufactured mattress and a two rail frame, optionally with a box spring. The bed to a sofa conversion frame includes a backrest, a footer (optional) and a pair of armrests configured to be connected as a solid state and or assembled together to form a sofa frame around a traditional bed, wherein the backrest comprises a horizontally-extending backrest ridge configured to hold and secure, directly or indirectly, a conventional manufactured mattress and when used as an option the footer comprises a horizontally-extending backrest ridge configured to hold and secure, directly or indirectly, a mattress. The pair of armrests forms a base for mounting the backrest and the footer via corresponding mounting hardware and mounting slots.

Owner:BED TO A SOFA CONVERSION COMPANY

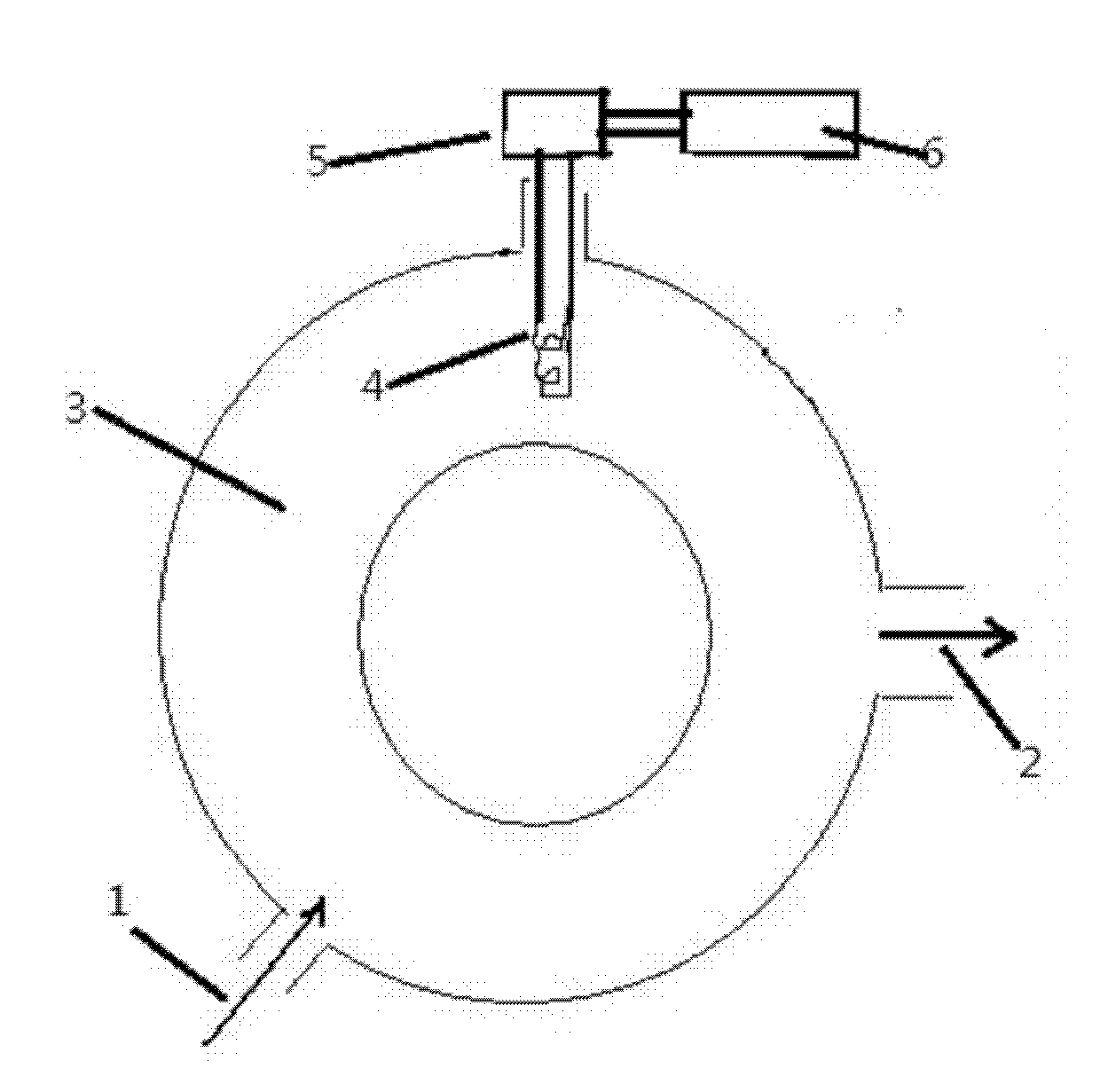

Backwashing filter

ActiveCN101940852AReduce points of failureEasy to controlStationary filtering element filtersFriction lossEngineering

The invention relates to a device for filtering a fluid medium transported in a pipeline, in particular to a backwashing filter which can filter impurities in the fluid medium in various use environments. The filter is provided with a driving device, a blowdown device, a filter shell and a filtering unit, the driving device is arranged at one side of the filter shell, the filter shell is internally provided with the blowdown device and the filtering unit, and one end of the blowdown device is connected with the driving device. The filter has the advantages of simple and compact structure, little occupied land and better filtering and backwashing effects, can work normally in various pressure conditions and solves the problems of tedious control process, multiple fault points and large resistance loss when the device runs existing in the prior art.

Owner:罗兰德流体控制(营口)有限公司

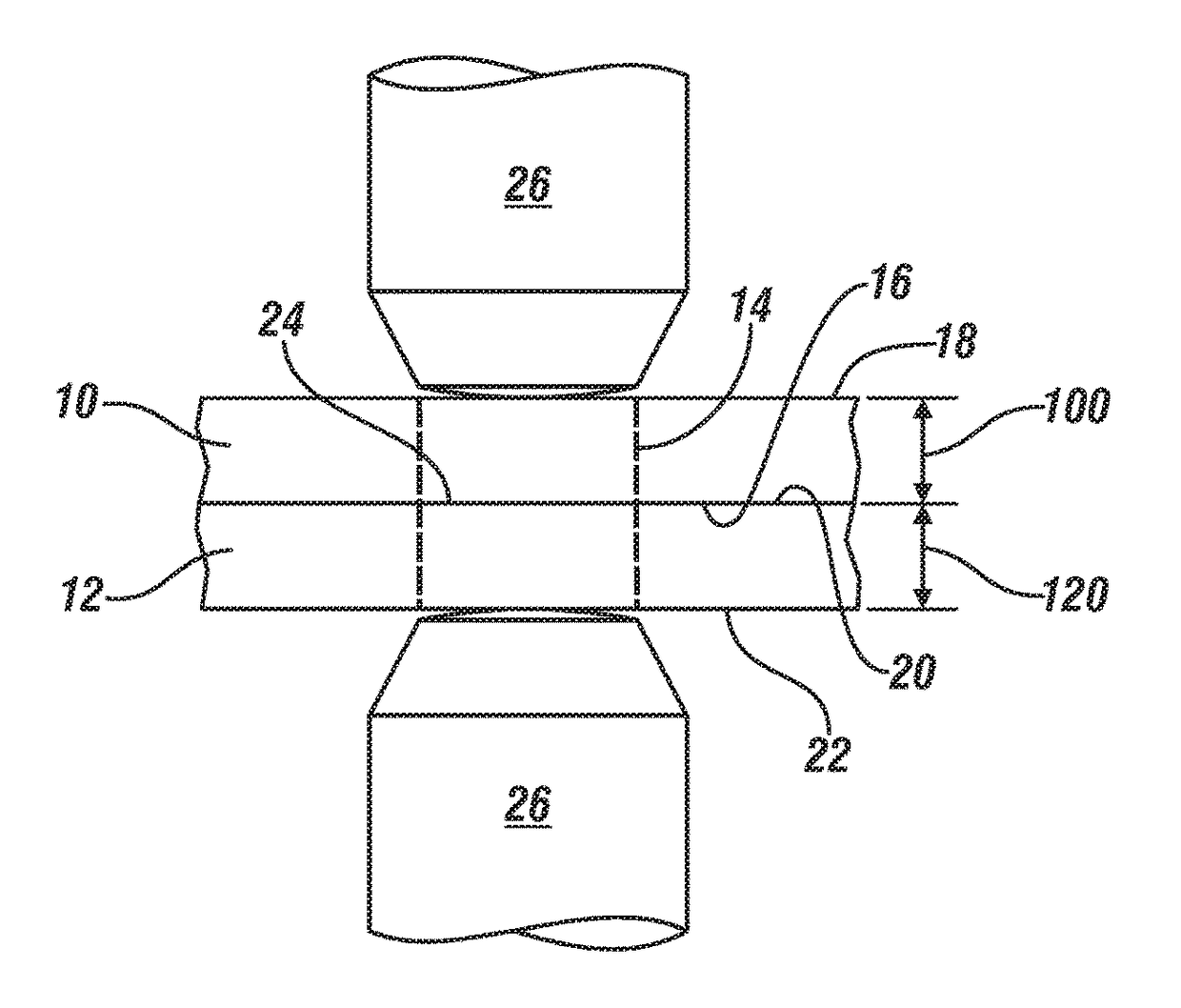

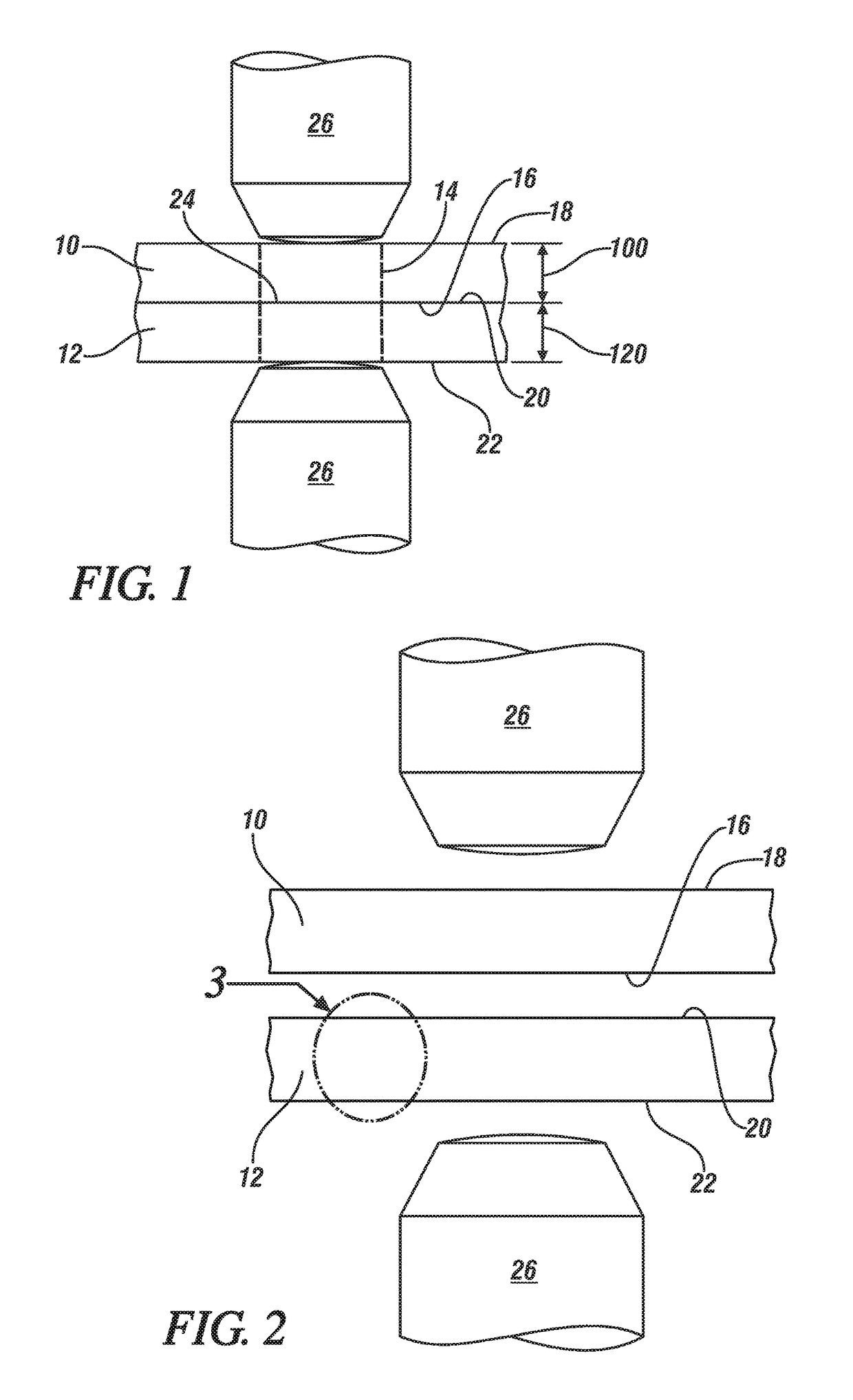

Resistance spot welding of steel to pre-coated aluminum

ActiveUS9987705B2Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

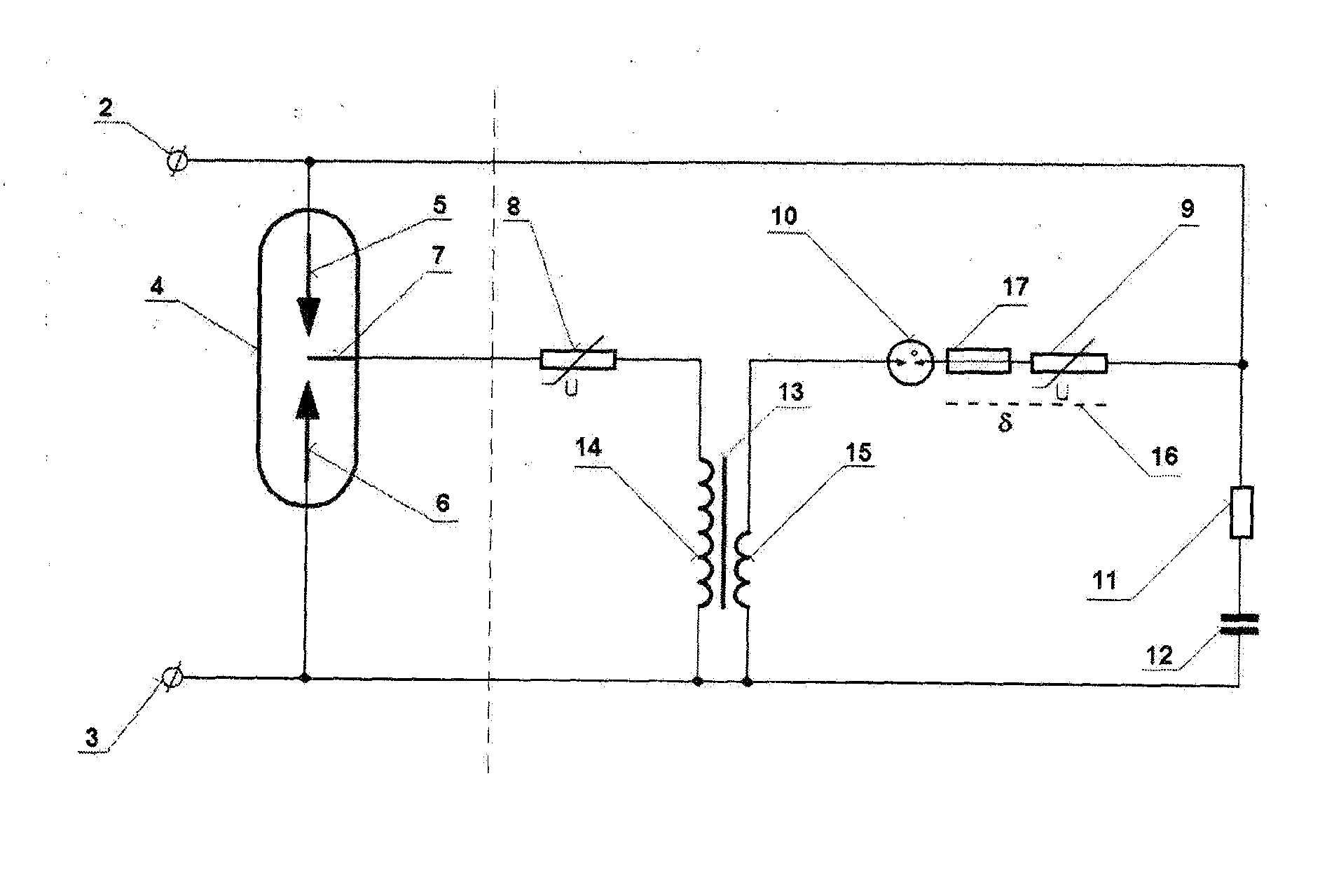

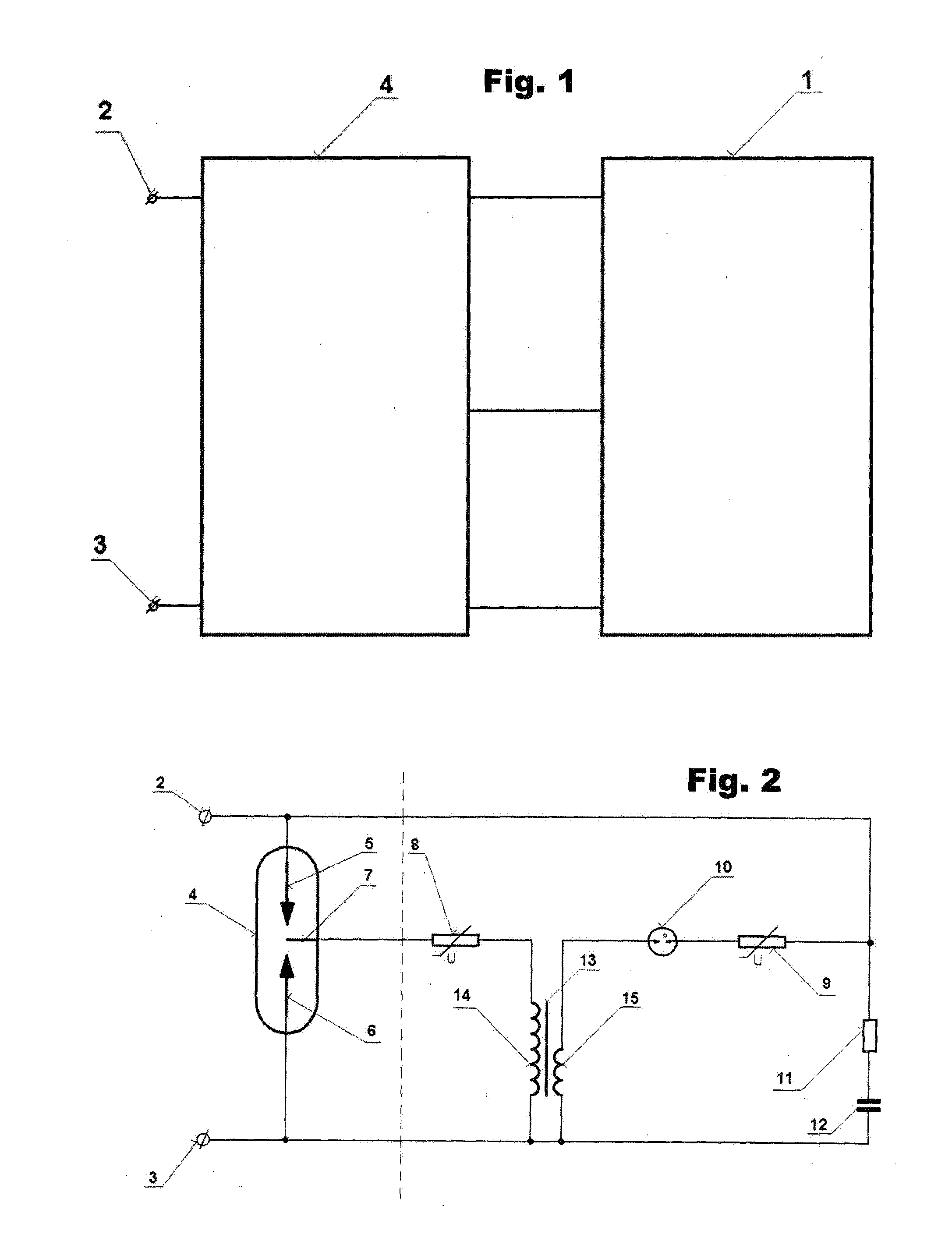

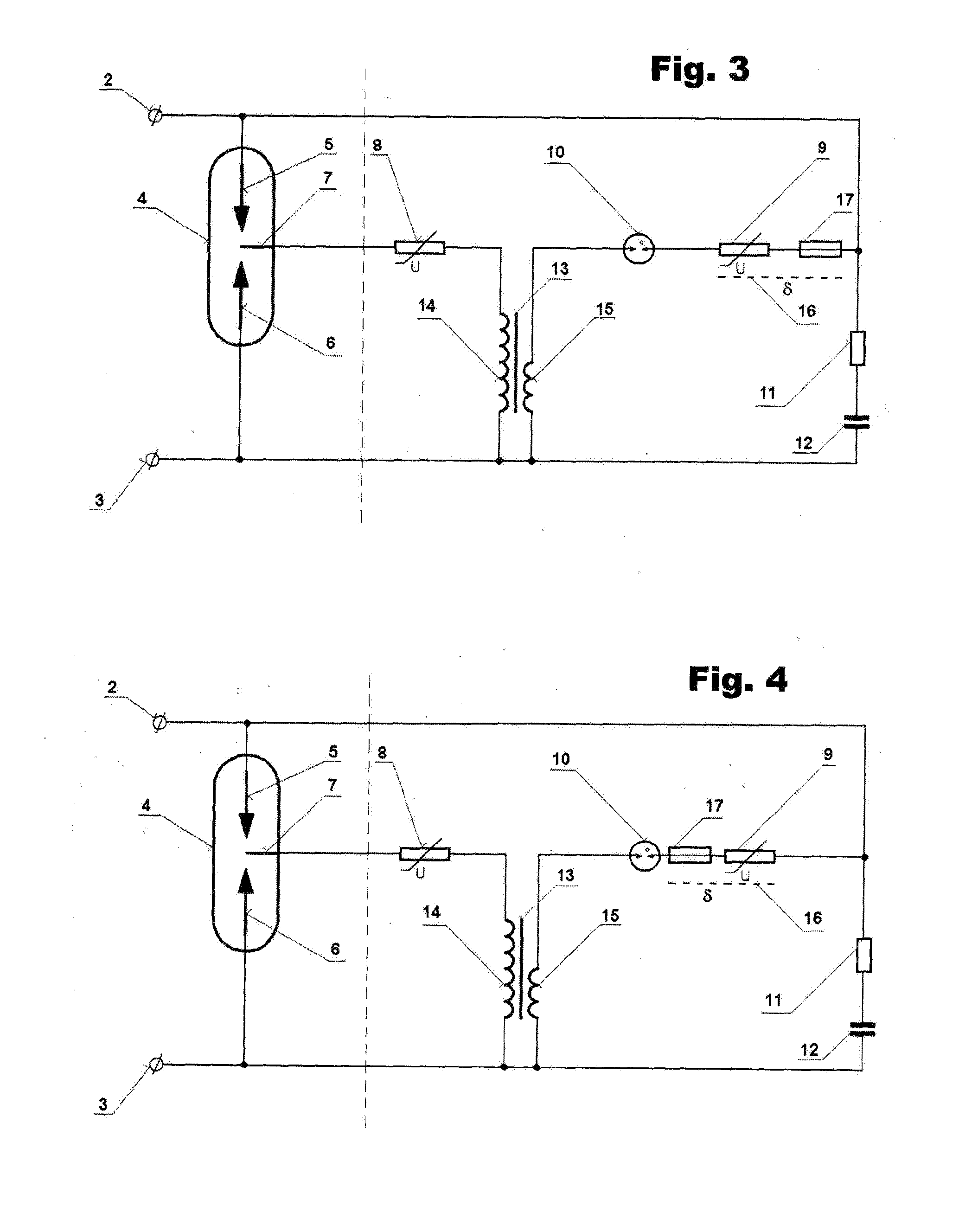

Triggering circuit of the overvoltage protection

ActiveUS20150236483A1Easy breakdownTriggering abilitySpark gap detailsSpark gaps with auxillary triggeringOvervoltageTransformer

The design of the triggering circuit 1 of the overvoltage protection, connected via three poles 4 to the spark gap of the overvoltage protection, provided with the first input terminal 2 and the second main terminal 3, whose principle consists that an auxiliary electrode 7 of the spark gap 4 is connected in series to the first varistor 8 and one end of the secondary winding 14 of the transformer 13, the other end of which is connected to the second main electrode 6 of the spark gap 4 and the second input terminal 3, whereas one end of the primary winding 15 of the transformer 13 is connected in series to the gas discharge tube 10, the second varistor 9, resistor 11 and capacitor 12, connected to the other end of the primary winding 15 of the transformer 13, connected to the second input terminal 3, whereas the junction connecting the second varistor 9 to the resistor 11 is interconnected with the junction, connecting the first input terminal 2 to the first main electrode 5 of the spark gap 4. The advantage of such a design of the triggering circuit 1 of overvoltage protection resides in the thermosensitive disconnector 17 coupled with the thermal coupling 16 to the second varistor 9, is either connected in series to the second varistor 9, or connected to the link of the junction connecting the second varistor 9 to the resistor 11 and the junction connecting the first input terminal 2 to the first main electrode 5 of the spark gap 4, or that the thermosensitive disconnector 17 is connected between the primary winding 15 of the transformer 13 and the gas discharge tube 10.

Owner:SALTEK

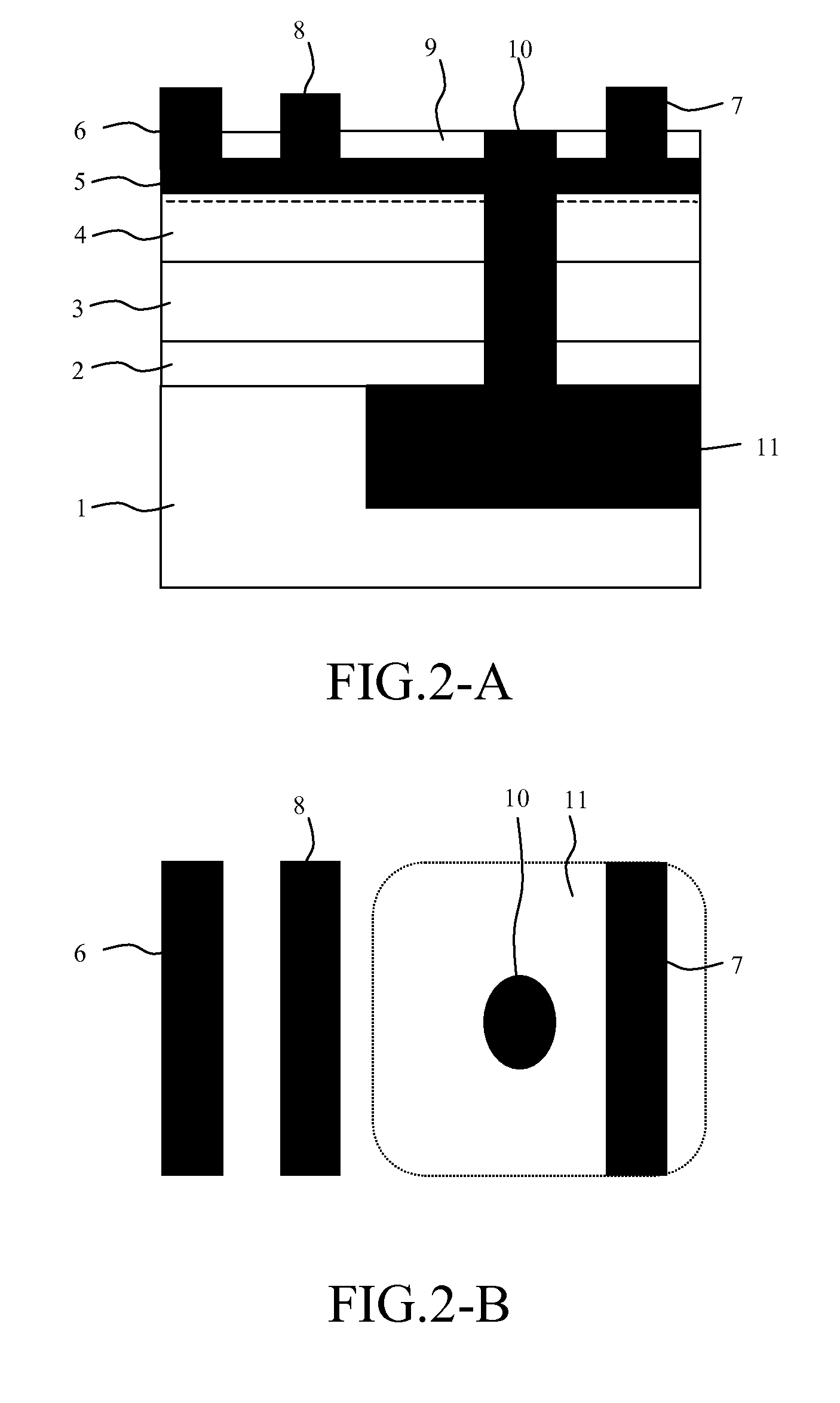

Semiconductor device and method for driving the same

ActiveUS20120056646A1Reduce electric field concentrationReduce concentrationTransistorSolid-state devicesPower semiconductor deviceEngineering

An object is to alleviate the concentration of an electric field in a semiconductor device. A gate electrode and a drain electrode are provided not to overlap with each other, and an electric-field control electrode is provided between the gate electrode and the drain electrode over a top surface. Insulating layers are provided between the gate electrode and a semiconductor layer and between the electric-field control electrode and the semiconductor layer, and the insulating layer provided between the electric-field control electrode and the semiconductor layer has a larger thickness than the insulating layer provided between the gate electrode and the semiconductor layer. Further, when the semiconductor device is driven, the potential of the electric-field control electrode may be higher than or equal to a source potential and lower than a gate potential, and for example, connection between the electric-field control electrode and the source potential enables such a structure.

Owner:SEMICON ENERGY LAB CO LTD

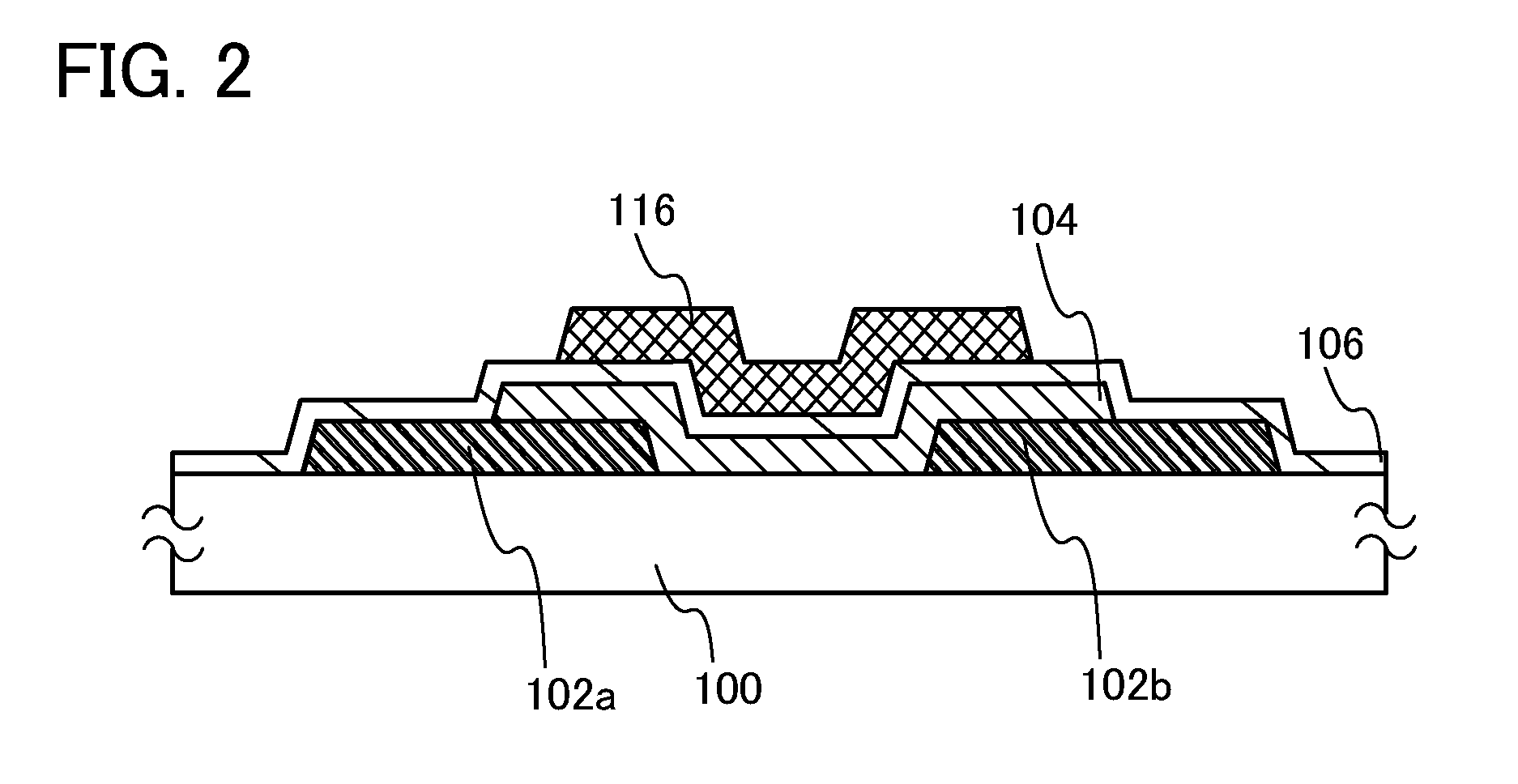

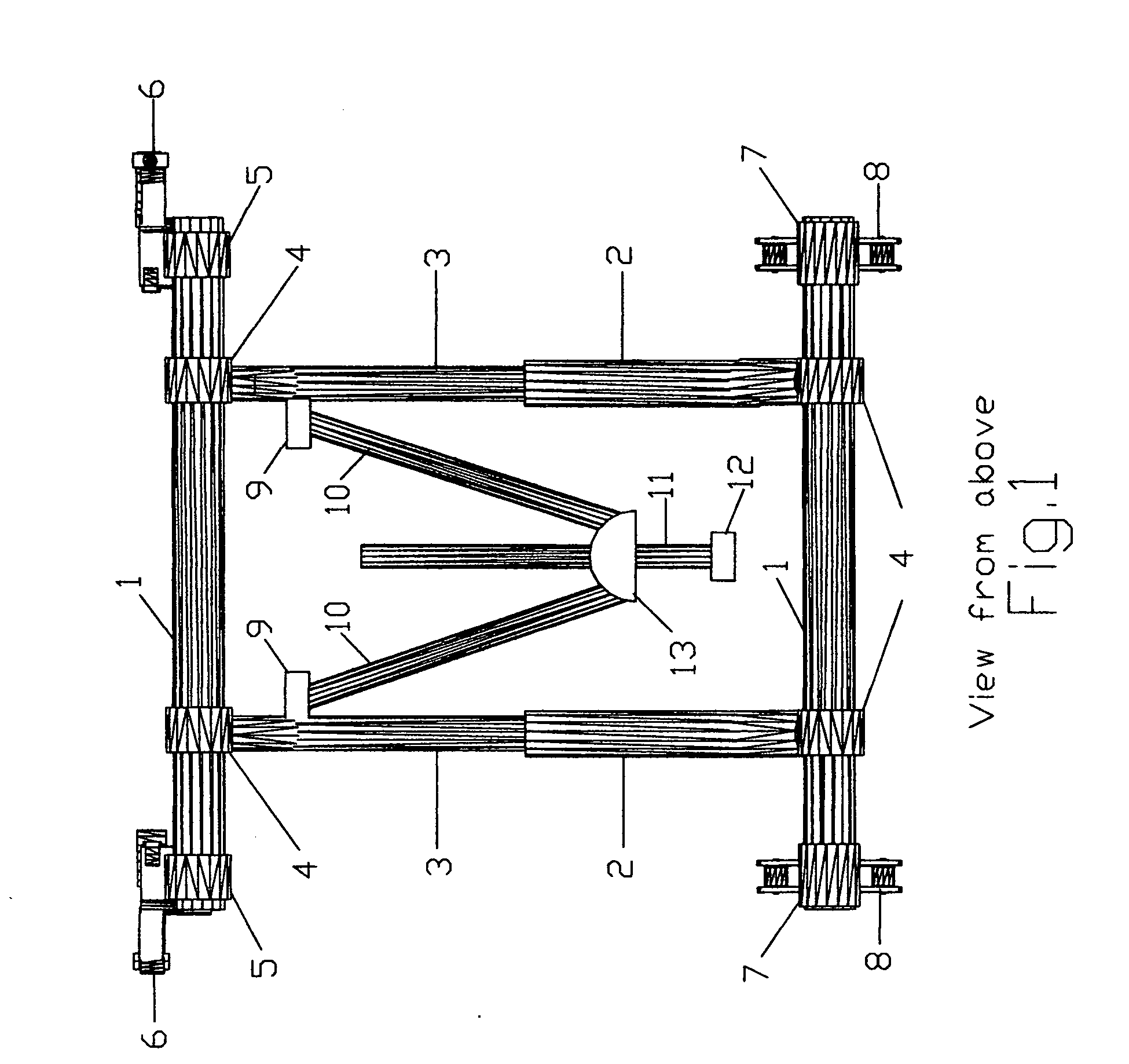

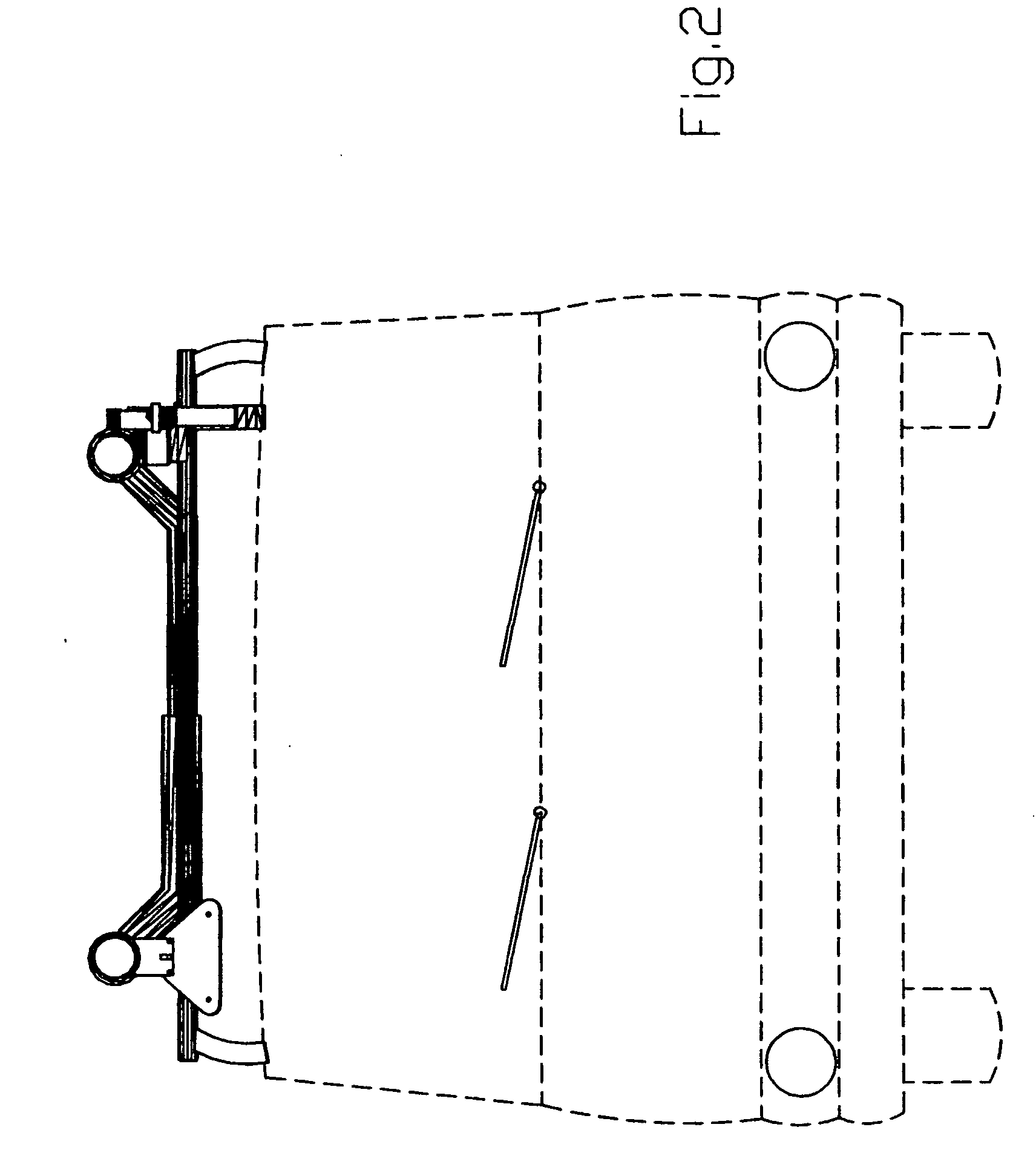

Portable retractable adjustable cargo rack assembly

InactiveUS20060099059A1Easy breakdownEasy to storeSupplementary fittingsOther load carrying vehiclesSupporting systemVehicle orientation

A portable retractable adjustable cargo rack assembly intended to affix to an existing cargo support system of a vehicle, meaning roof-mounted (but not limited to such), and to deploy to a near juxtaposed position to facilitate loading and unloading of cargo, thereby alleviating the need for vertical assistance or mechanical devices to deploy or secure. The assembly includes roller bearing housings that attach securely to the existing vehicle rack cross-members, and are secured to the portable rack assembly allowing movement over the surface of the pre-existing cross-members from a secured position atop the vehicle to an extended loading / unloading position at a near-juxtaposed position with respect to the plane of the roof of the vehicle—while remaining attached to pre-existing base frame. This invention also includes a clamping device that secures the assembly to the existing vehicle rack atop the vehicle. Two or more telescoping cross-shafts are included in this invention that may be used to secure and / or support cargo while atop base structure. A retractable support brace attached to the cross-shafts can be deployed to rest against the vehicle or telescoped to the ground to give support while loading / unloading. Two shafts or frames, positioned opposite each other, lengthwise with respect to the direction of the vehicle, connecting the roller housing and clamps to the assembly, respectfully.

Owner:ERVIN ERIC EDWIN

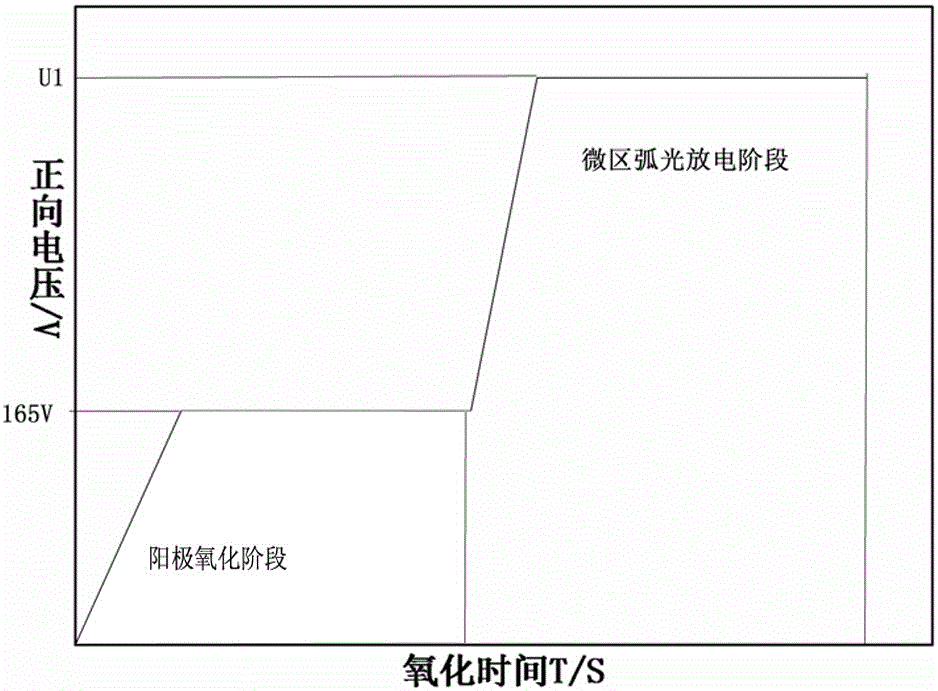

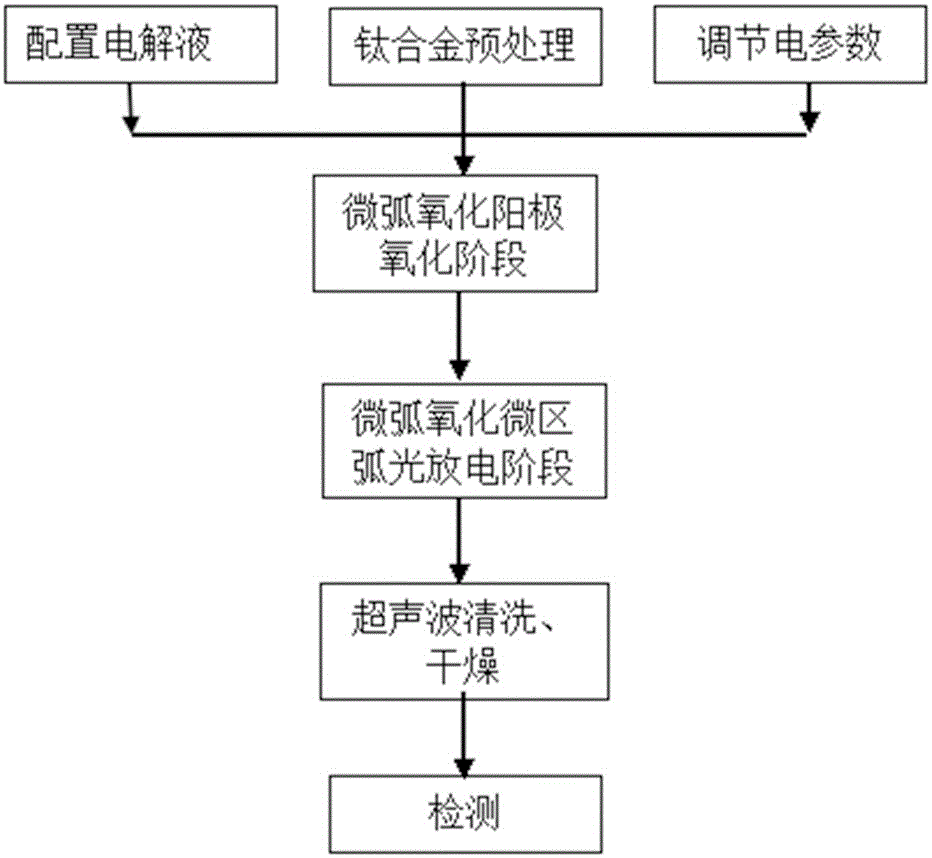

Method for preparing biological ceramic membrane layer on titanium alloy surface through graded combined oxidation in stages

ActiveCN104988558AIncrease the thickness of the dense layerIncreasing the thicknessSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing a biological ceramic membrane layer on the titanium alloy surface through combined oxidation in stages. The method comprises the steps of pretreatment, combined micro-arc oxidation in stages and posttreatment, wherein the step of combined micro-arc oxidation in stages is implemented by adjusting electrical parameters; electrical parameter adjustment includes prolonging the time of the anodic oxidation stage in the micro-arc oxidation process, increasing the thickness of a compact layer of an oxidation film layer, improving the corrosion resistance of titanium alloy, solving the problem that since the compact layer of the oxidation film layer is thin, metal ions drifts are freed to a base body to cause an adverse reaction between the implanted body and the base body when the micro-arc oxidation film is implanted into a living body as a medical material, increasing the working voltage so that an insulative anode oxide film can be broken through more easily and appropriately shortening the discharge time of microcell arc light in the micro-arc oxidation process so as to prevent the situation that holes formed in the surface at the early stage are covered with melt sprayed at the later stage due to too long discharge time of the arc light.

Owner:KUNMING METALLURGY INST

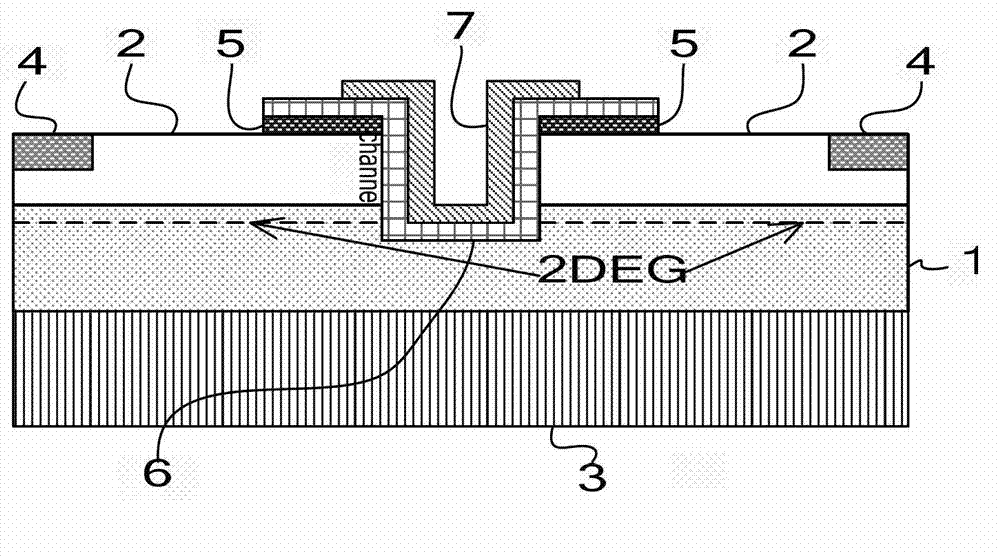

High-voltage Nitride Device and Manufacturing Method Thereof

ActiveUS20150340485A1Improve breakdown voltageIncrease the electric field strengthSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideSilicon

A high-voltage nitride device which can avoid vertical breakdown and has a high breakdown voltage includes: a silicon substrate; a nitride epitaxial layer, prepared on the silicon substrate; a source electrode and a drain electrode, both of which are contacted with the nitride epitaxial layer; a gate electrode, prepared between the source electrode and the drain electrode; and, at least one spatial isolation area, formed in a region between the silicon substrate and the nitride epitaxial layer vertically and between the source electrode and the drain electrode horizontally.

Owner:ENKRIS SEMICON

Bed to a sofa conversion frame with movable back

ActiveUS20160206109A1Easy breakdownEasy to storeSofasCouchesClassical mechanicsStructural engineering

A bed to a sofa conversion frame, without a seating area, a space reserved for the traditional bed, which is a conventional manufactured mattress, or ii) a conventional manufactured mattress and a box spring, or iii) a conventional manufactured mattress and a two rail frame, optionally with a box spring. The bed to a sofa conversion frame includes a backrest, a footer (optional) and a pair of armrests configured to be connected as a solid state and or assembled together to form a sofa frame around a traditional bed, wherein the backrest is movable from a sofa position to a bed position, in order to convert the frame from a sofa configuration to a bed configuration.

Owner:BED TO A SOFA CONVERSION COMPANY

Measurement device

ActiveUS9817032B2High input impedanceReduce input capacitanceOverload protection arrangementsStatic indicating devicesMeasurement deviceLeakage current reduction

To provide a measurement device which allows long-term accurate measurement of voltage without adversely affecting a device under test, by ensuring a predetermined level of resistance to ESD and reducing leakage current. A measurement device includes a probe needle for contacting a device under test, a first FET for detecting voltage of the device under test, and a protection circuit for protecting the first FET from static electricity. The protection circuit includes a second FET having an oxide semiconductor film as a channel formation region.

Owner:SEMICON ENERGY LAB CO LTD

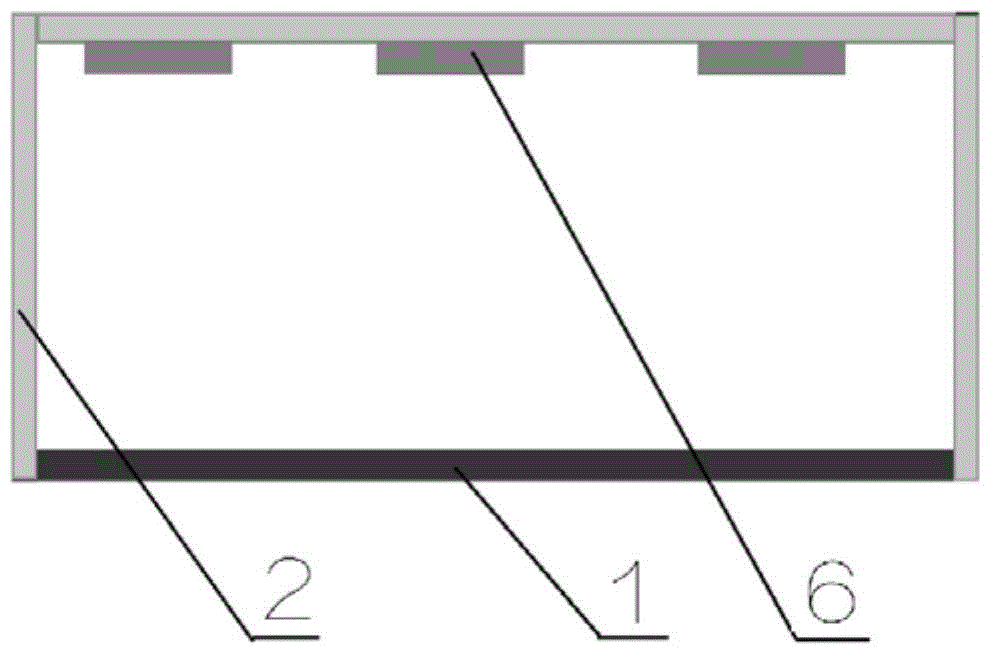

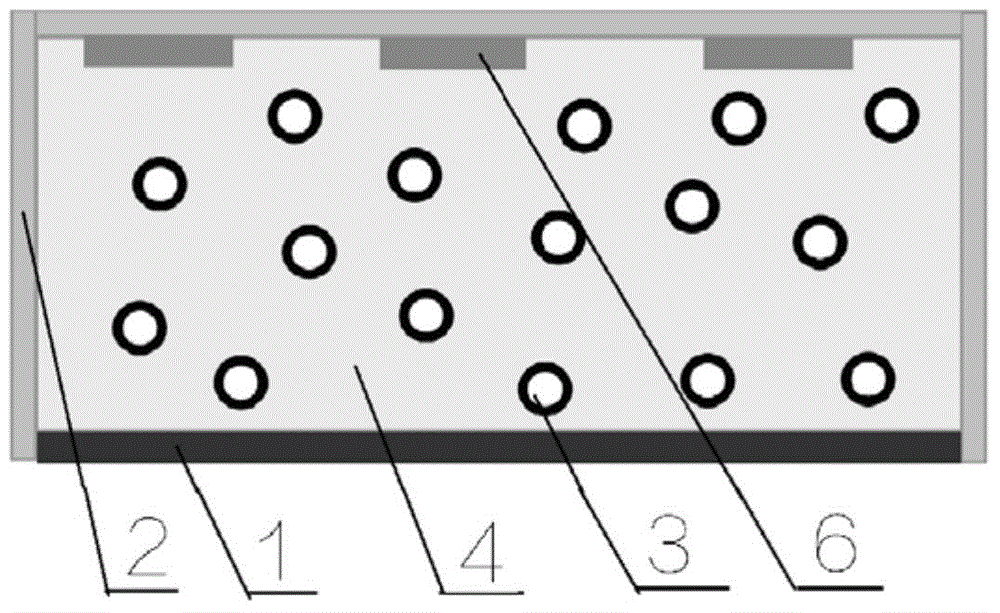

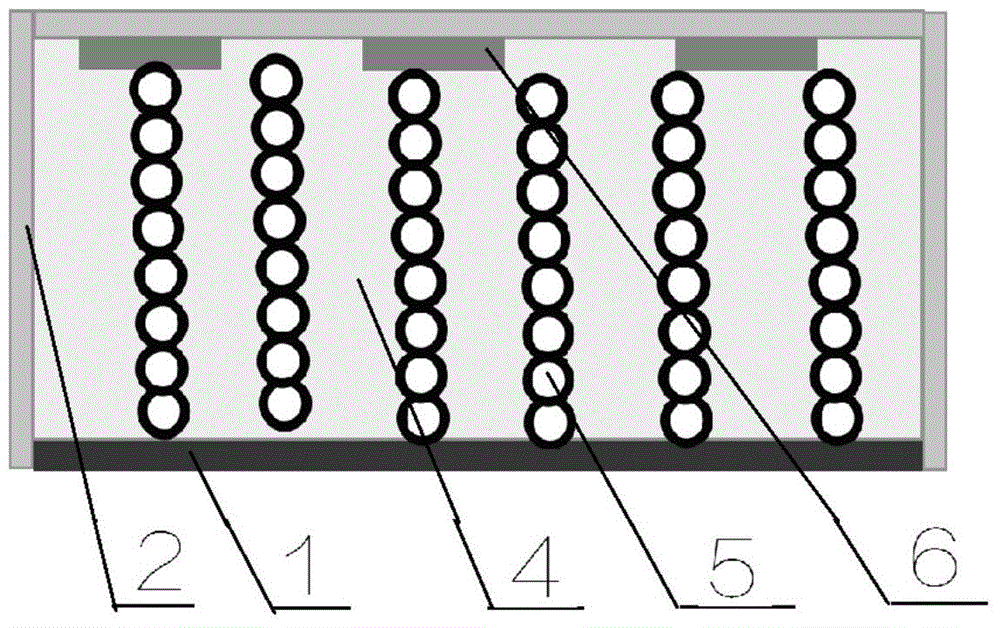

Liquid solar cell and preparation method thereof

The invention discloses a liquid solar cell with variable structure and adjustable photovoltaic effect and a preparation method of the liquid solar cell. The liquid solar cell comprises a container, wherein the container comprises a substrate and a surrounding wall; the surrounding wall is composed of a side wall and a top wall; the surrounding wall is fixed on the substrate to form the container; an upper electrode is arranged on the lower surface of the top wall; a lower electrode is arranged on the upper surface of the substrate; the container is filled with magnetoelectric liquid; the magnetoelectric liquid is prepared by mixing core-shell structure nanoparticles, a hydrophilic surfactant and oily base liquid; the cores of the core-shell structure nanoparticles are magnetic particles; and the claddings are ferroelectric particles. The preparation method of the liquid solar cell comprises the following steps: (1) preparing the upper electrode and the lower electrode; (2) preparing the container; and (3) adding the magnetoelectric liquid to the container to obtain the liquid solar cell.

Owner:嘉兴鼎尚信息科技有限公司

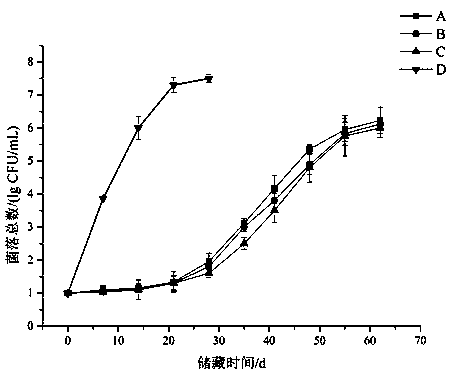

Method for prolonging quality guarantee period of egg liquid

InactiveCN109497127AImprove thermal conductivityImprove conductivityEggs preservation by irradiation/electric treatmentEggs preservation by freezing/coolingLiquid productPasteurization

The invention provides a method for prolonging the quality guarantee period of egg liquid and belongs to the technical field of processing of egg products. The method comprises the following steps: taking eggs as a main raw material; carrying out pre-treatment (washing, disinfection, drying, breaking the eggs, separating and filtering), adding a compound, carrying out high-pressure homogenization,carrying out pulse electric field assisted pasteurization and carrying out sterile filling to obtain an egg liquid product with stable quality. The added compound can be used for remarkably improvingthe sterilization efficiency of the pulse electric field assisted pasteurization, and functions and properties of the egg liquid can be kept to the greatest extent; the egg liquid product with stablequality and the quality guarantee period of 56 to 63 days is provided.

Owner:NANCHANG UNIV

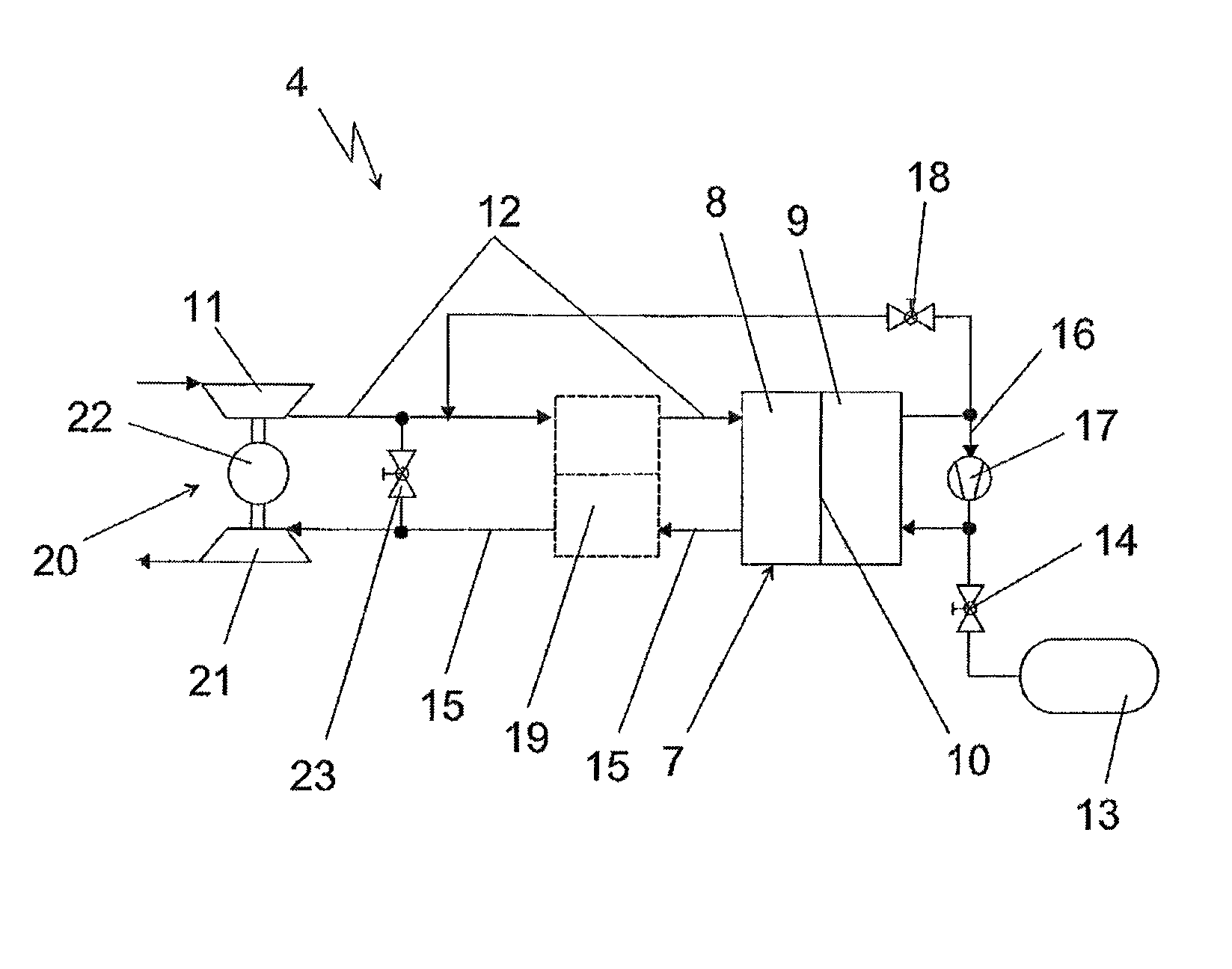

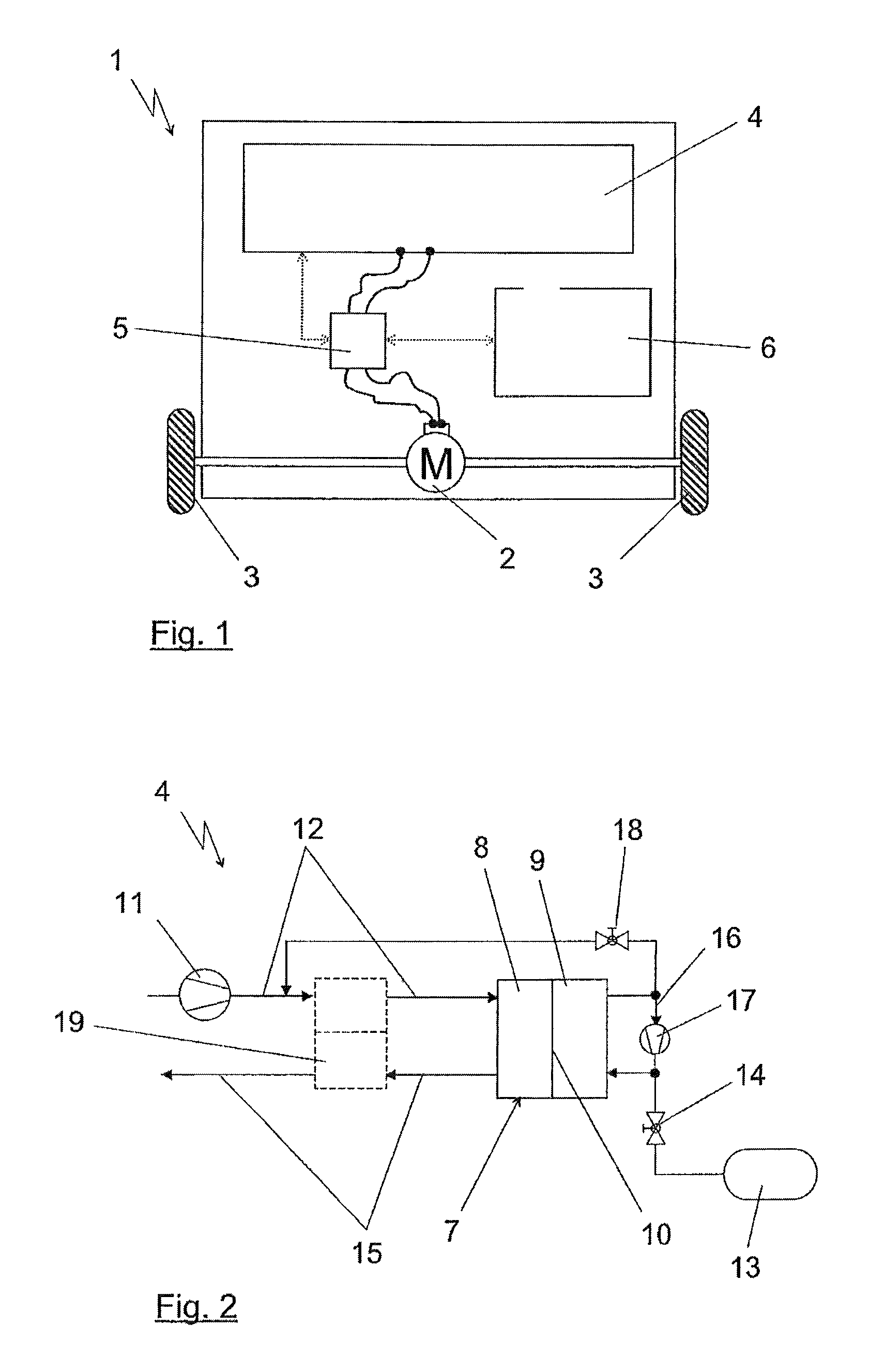

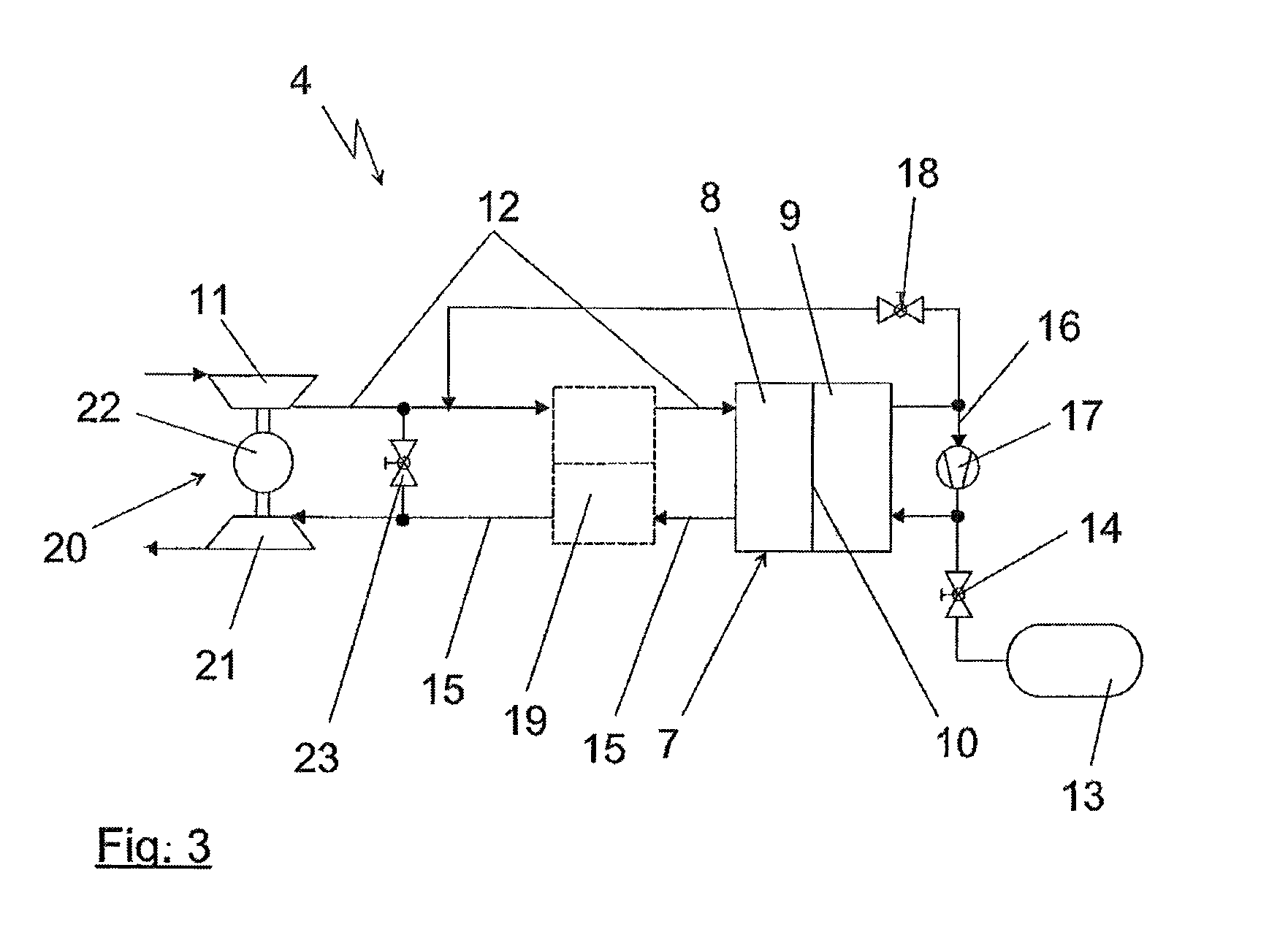

Method for operation of a fuel cell system in a vehicle

ActiveUS9034529B2Save energyReduce noiseFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsCombustion

A method of operating a fuel cell system in a vehicle that is switchable to a temporary stop mode and restarted from the stop mode. When, in certain driving situations, it is required to switch to the stop mode, it is then checked whether the operating conditions of the fuel cell system allow a switch to the stop mode. If the switch is allowed it takes place. When a restart of the fuel cell system is required on the basis of the vehicle the settings of the stop mode are cancelled again. The switch to the stop mode involves, with further existing electric contacting of the fuel cell, the air mass flow conveyed by the air conveying device being switched off or reduced to a predefined value and the pressure of the combustion gas supplied being reduced to a predefined value.

Owner:CELLCENTRIC GMBH & CO KG

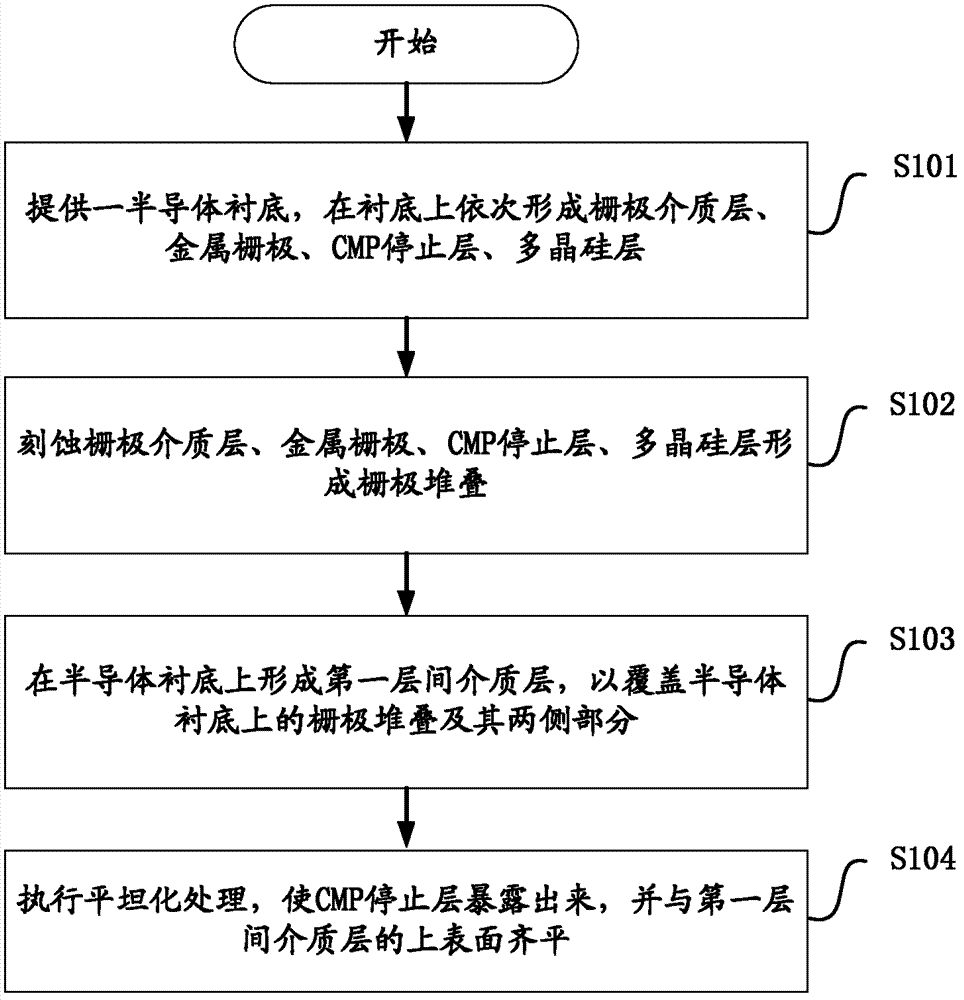

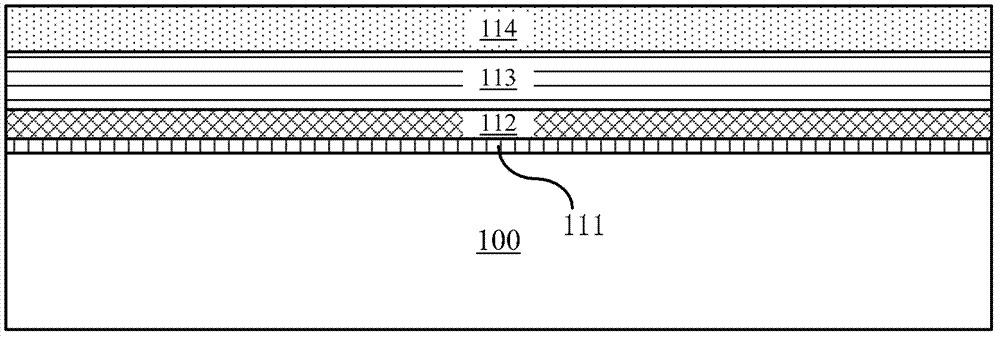

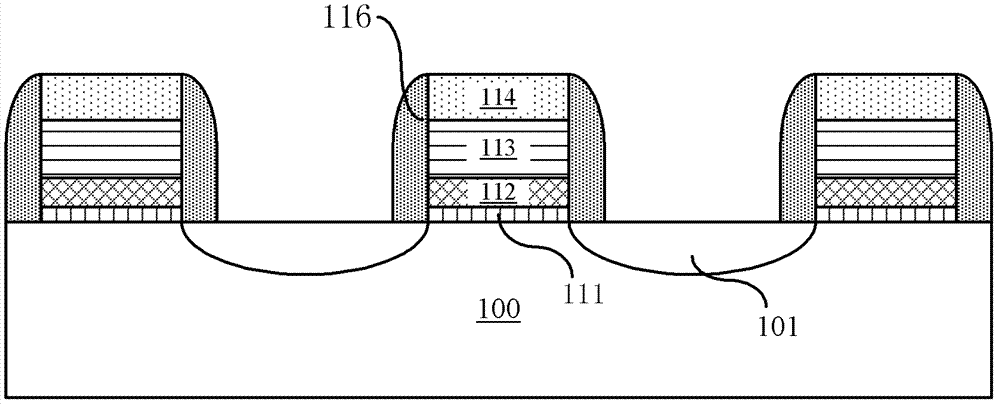

Semiconductor structure and manufacturing method thereof

InactiveCN102820328AAdvantage structureMerit methodSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceElectrical conductor

The invention provides a semiconductor structure and a manufacturing method thereof. The method comprises the steps of providing a semiconductor substrate, and forming a grid dielectric layer, a metal grid, a chemical-mechanical polishing (CMP) stop layer and a polycrystalline silicon layer sequentially on the semiconductor substrate; etching the grid dielectric layer, the metal grid, the CMP stop layer and the polycrystalline silicon layer to form a grid stack; forming a first interlayer dielectric layer on the semiconductor substrate to cover the grid stack and portions on two sides of the grid stack on the semiconductor substrate; and conducting planarization treatment to expose the CMP stop layer and enabling the CMP stop layer to be flush with the upper surface of the first interlayer dielectric layer. According to the semiconductor structure and the manufacturing method, the CMP stop layer is added, so that the height of the metal grid is effectively reduced, the capacitance of the metal grid and the capacitance of a contact area are effectively reduced, and a subsequent contact hole etching process is optimized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com