Multi-pole ignition device of impulse voltage generator

A technology of impulse voltage and ignition device, which is applied in the direction of capacitive energy storage device, etc., can solve the problems of poor synchronization performance and large dispersion, and achieve the effect of good synchronization, small dispersion and short conduction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

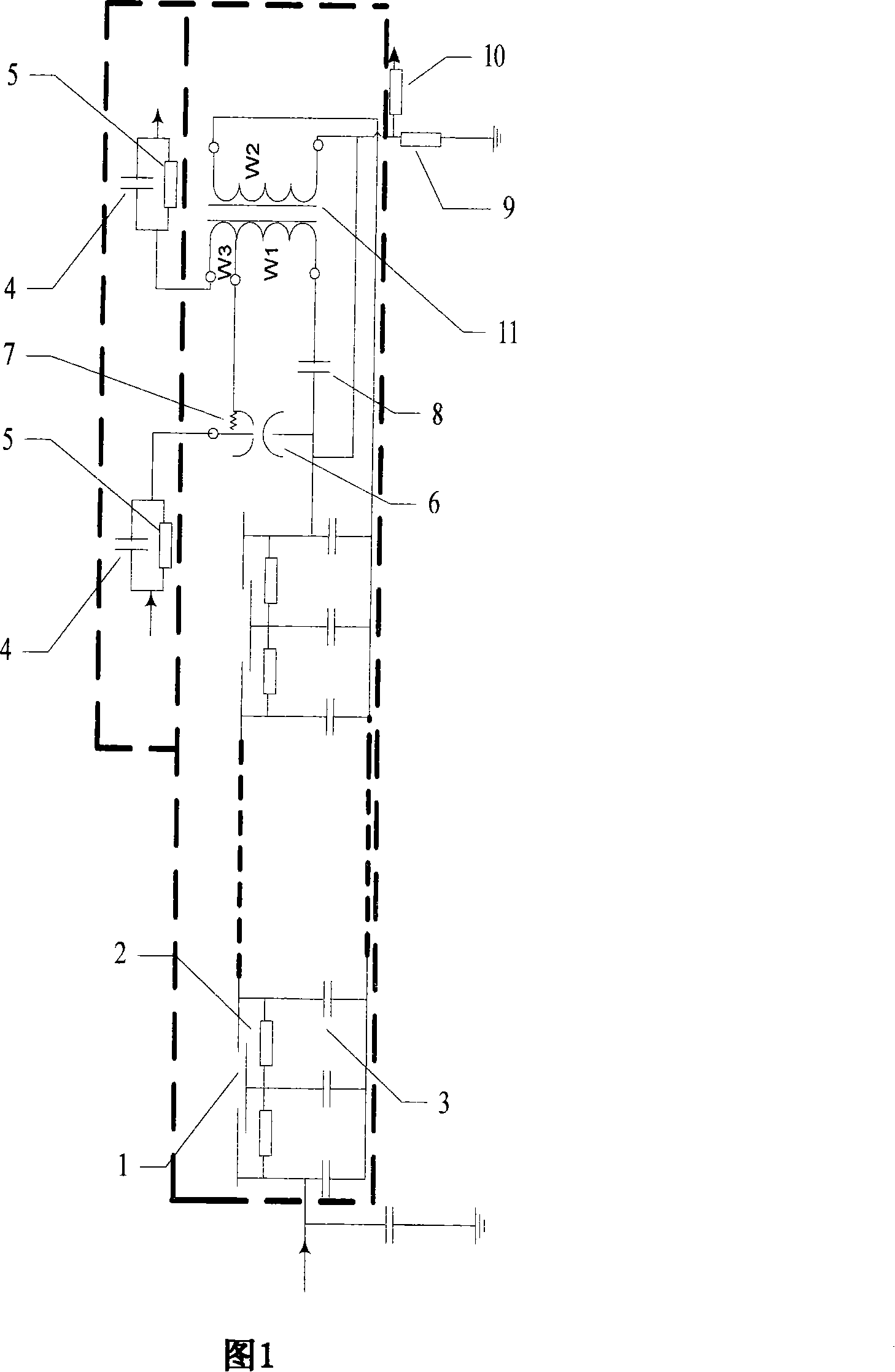

[0020] Description of the marks in Figure 1: 1-small gap; 2-voltage equalizing resistance; 3-voltage equalizing capacitance; 4-transfer capacitance; 5-transfer resistance; 6-three-electrode ignition ball gap; 7-resistance; 8-capacitance; 9, 10-resistor; 11-pulse transformer; winding W 1 , W 2 , W 3 .

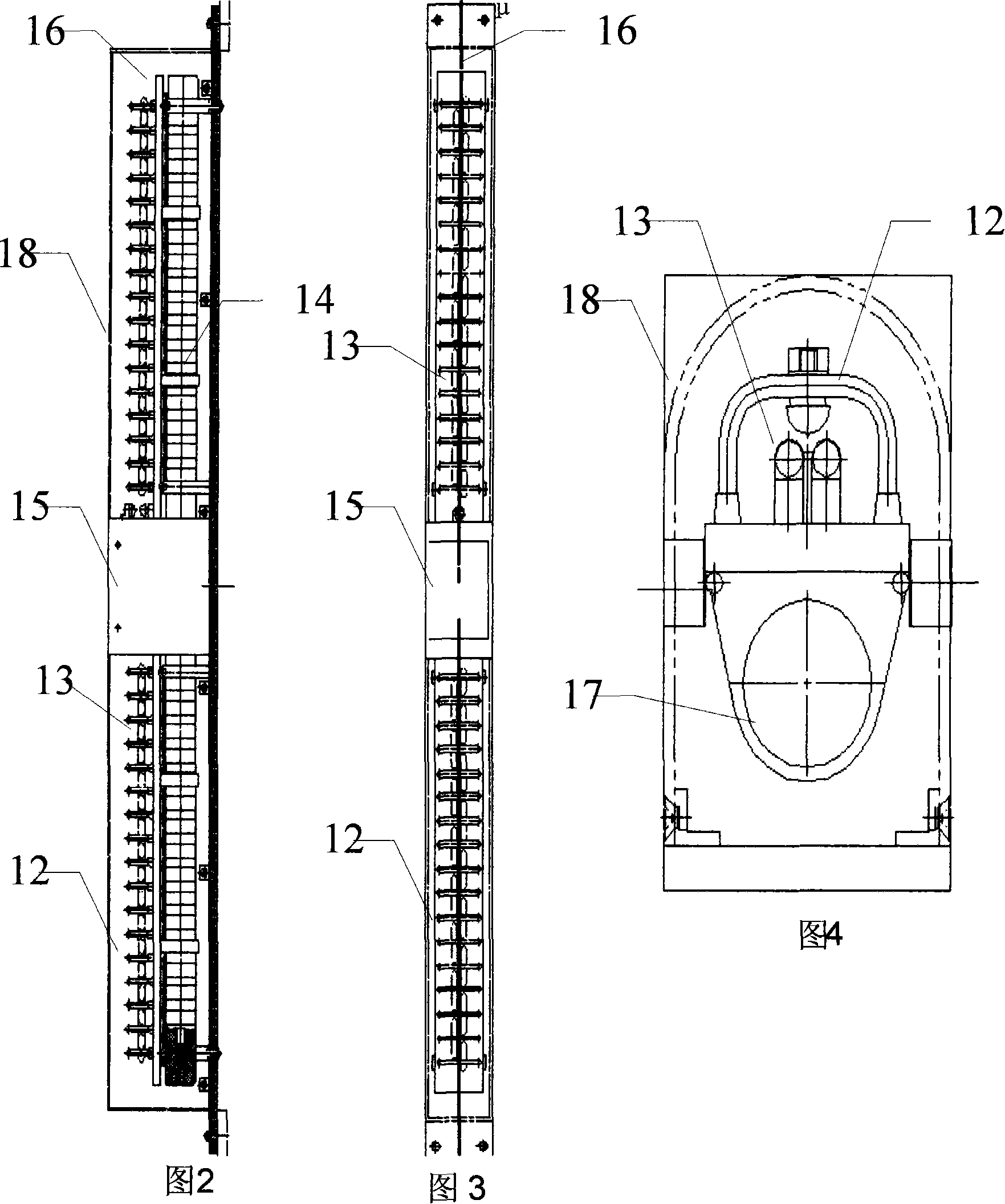

[0021] Instructions marked in Figures 2, 3, and 4: 12-pressure equalizing copper tube; 13-copper tungsten alloy rod; 14-ring copper sheet; 15-epoxy resin box; 16-epoxy resin board; 17-epoxy Capacitor rod; 18-transparent plastic cover.

[0022] In Fig. 1 is a schematic diagram of each multi-pole ignition device, which is mainly composed of three parts: (1) pulse voltage generator; (2) multi-pole main gap; (3) transfer resistance and capacitance.

[0023] (1) The components included in the pulse voltage generator are: a low-voltage primary wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com