Backwashing filter

A filter and anti-cleaning technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of many fault points, large loss of medium flow resistance, cumbersome control process, etc., and achieve fewer fault points , Low failure rate of equipment operation, simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

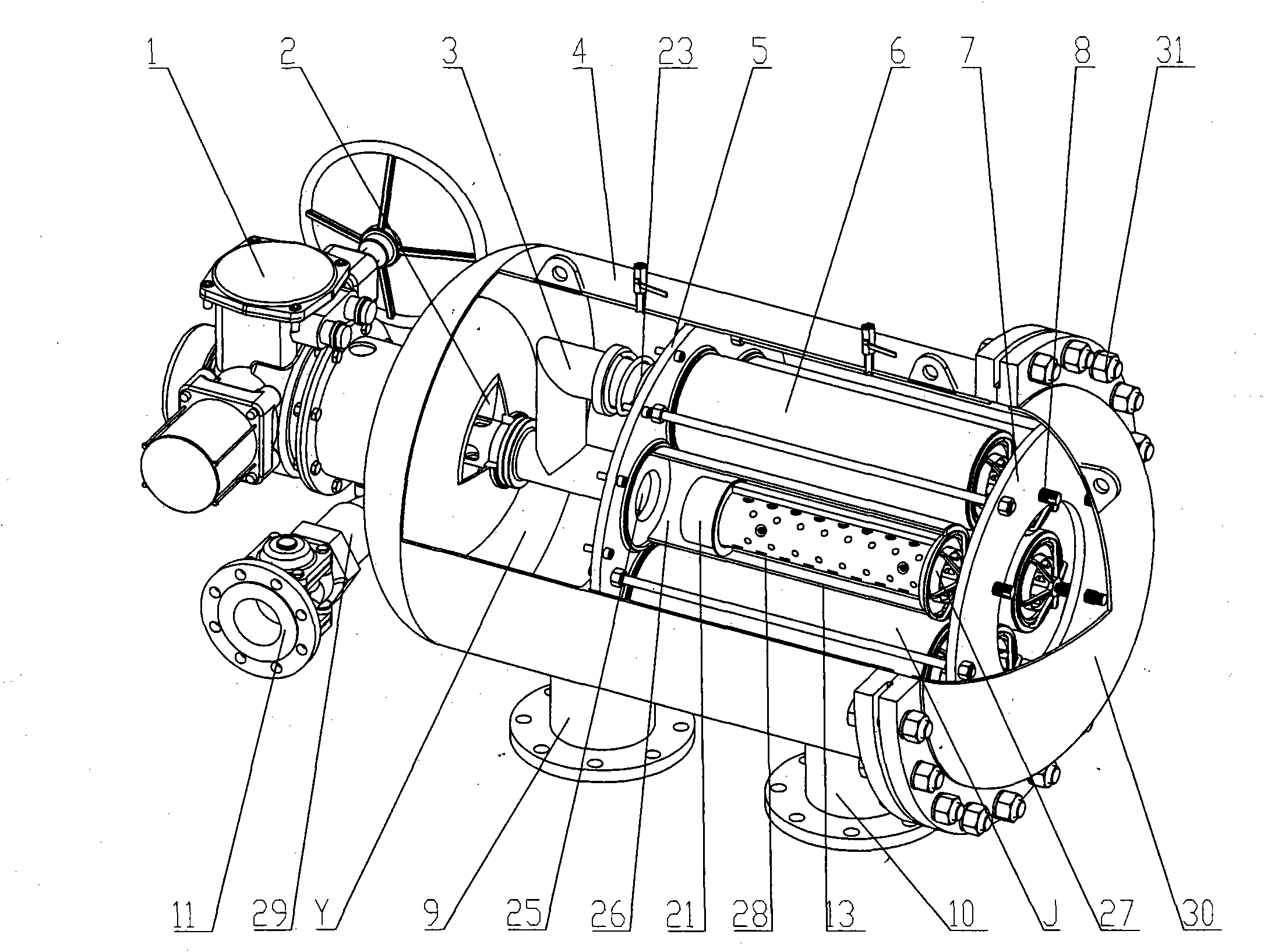

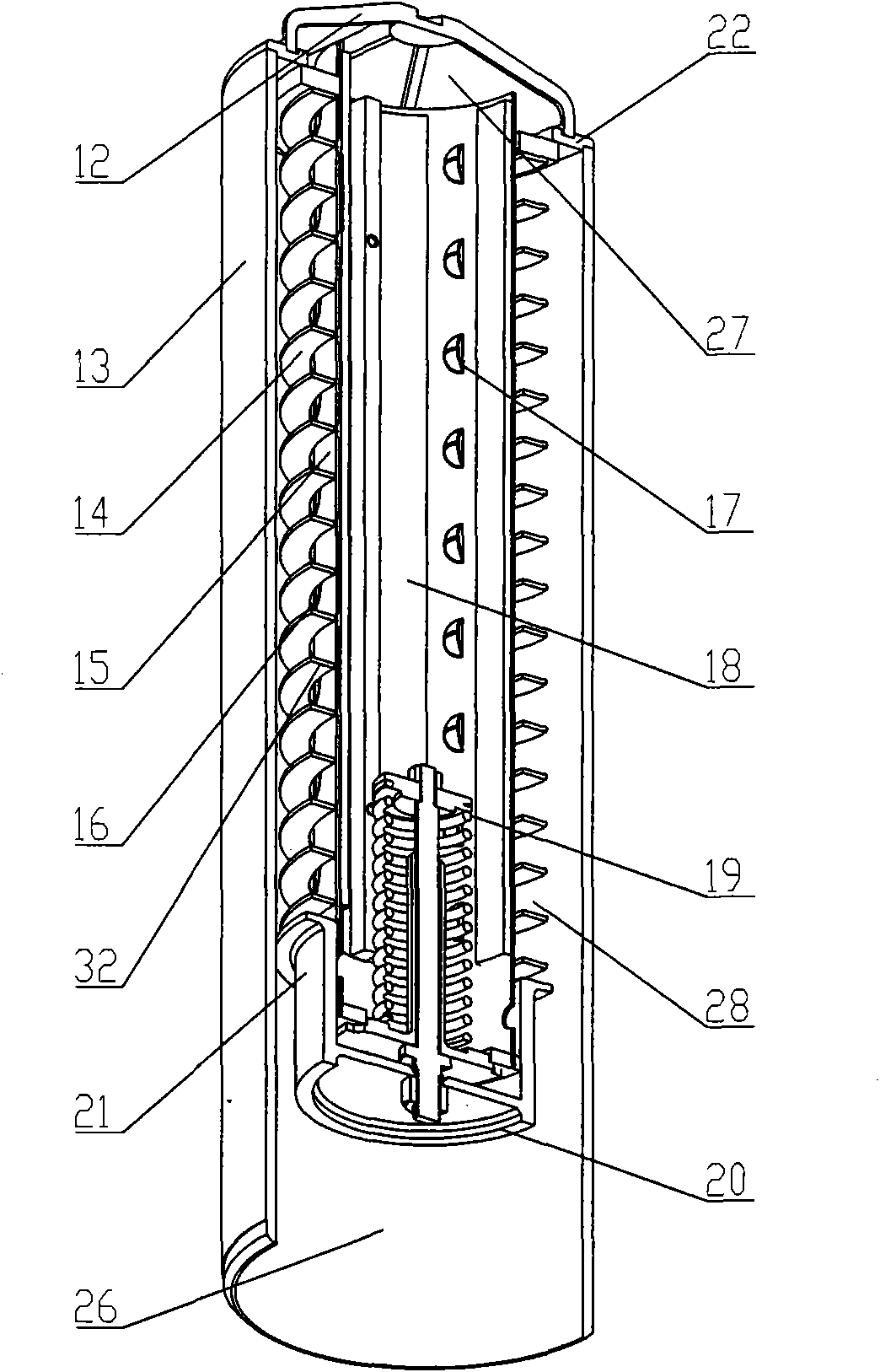

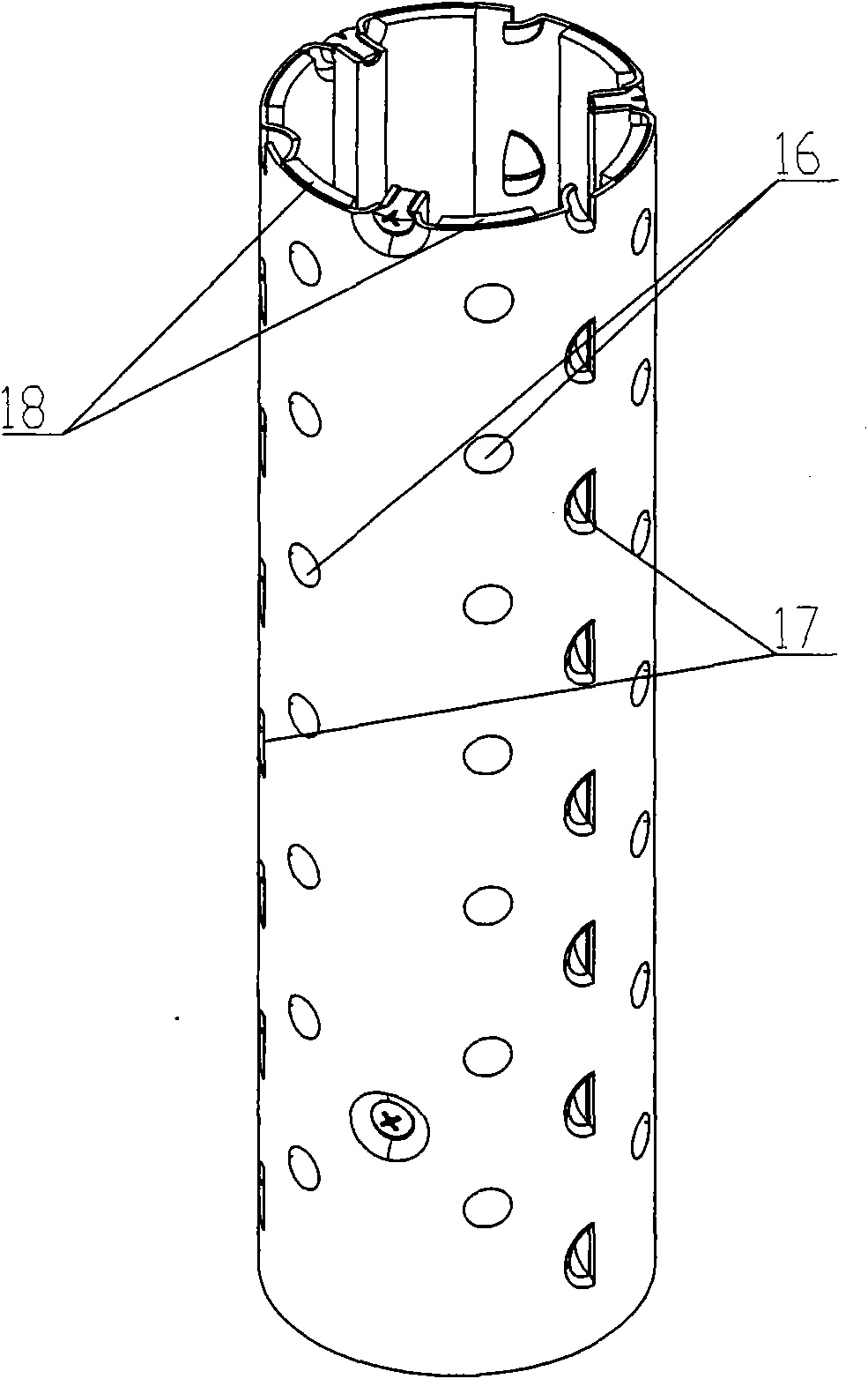

[0027] like figure 1 , Figure 5 Shown, the structure of the backwashable filter of the present invention is as follows:

[0028] The filter is composed of a drive device 1, a sewage device 3, a filter housing 4, a filter unit 6, etc., and the drive device 1 is installed on one side of the filter housing 4, and the filter housing 4 is provided with Sewage discharge device 3 and filter unit 6, one end of sewage discharge device 3 is connected with driving device 1, the other end of sewage discharge device 3 is provided with sewage suction nozzle 23, and sewage discharge device 3 is also provided with sewage discharge port 24, in filter housing 4 One end is equipped with a sewage discharge chamber 2, the sewage suction pipe mouth 23 communicates with the sewage discharge chamber 2 through the sewage discharge port 24, and a sewage discharge pipe 29 is arranged on the filter housing 4, the sewage discharge chamber 2 communicates with the sewage discharge pipe 29, and the sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com