Discharge electrode used for capillary extreme ultraviolet photoetching light source

A technology of extreme ultraviolet lithography and discharge electrodes, which is applied to the main electrodes of discharge tubes, microlithography exposure equipment, and photolithography exposure devices, etc., which can solve problems such as distance changes, achieve simple changes, solve breakdown difficulties, and easily The effect of breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

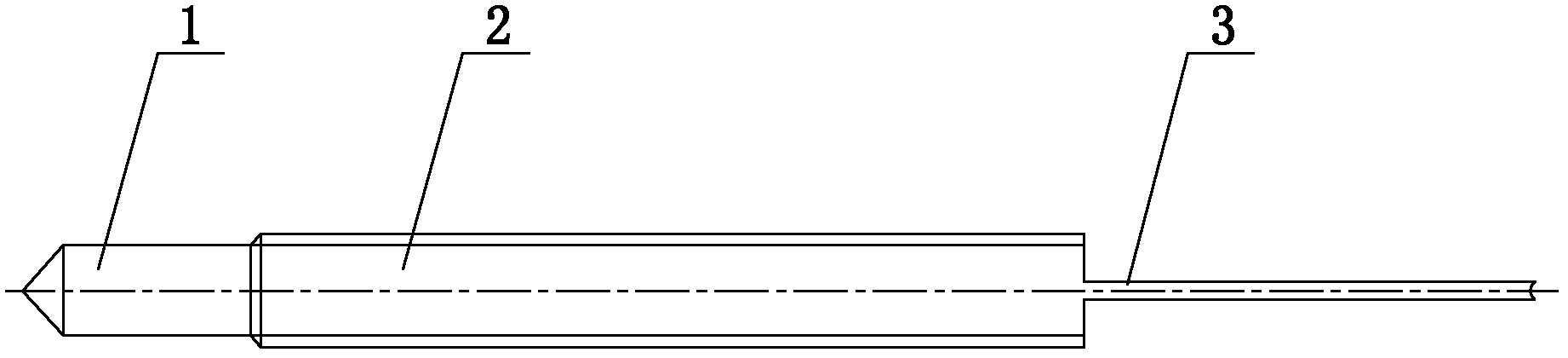

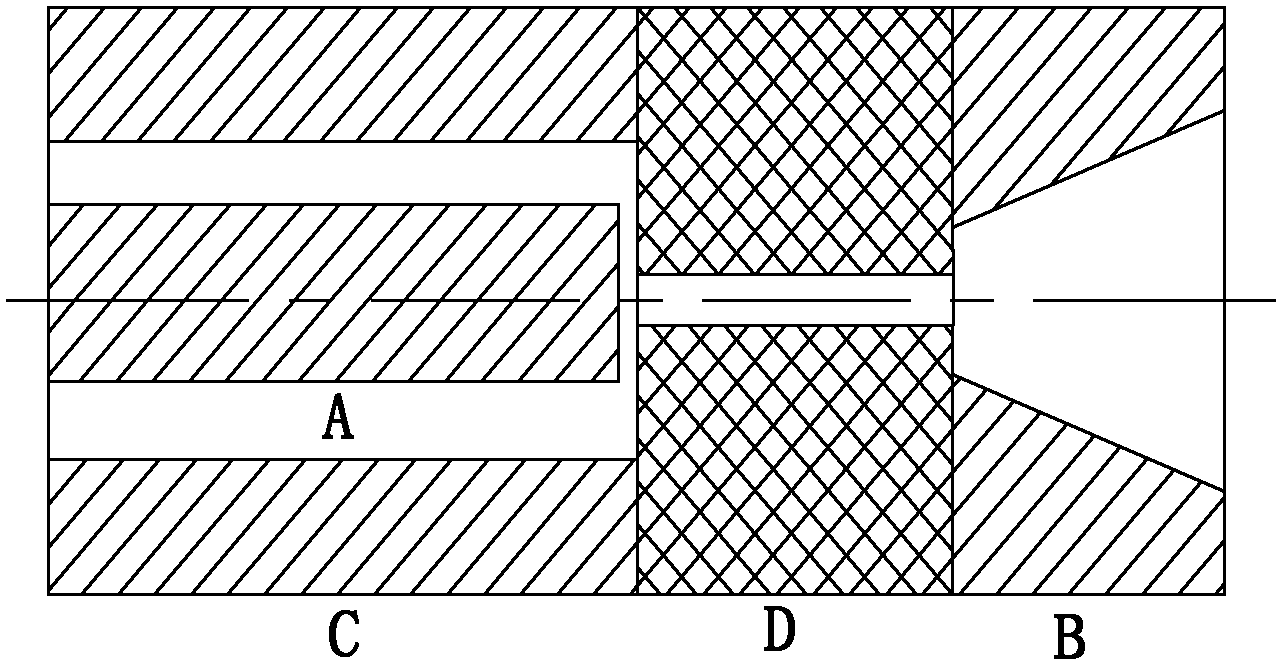

[0019] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment mode, this embodiment mode is used for the discharge electrode of the capillary extreme ultraviolet lithography light source, it comprises the main pulse electrode segment 1 of adjustable length, the pre-pulse electrode segment 2 and the discharge electrode segment 3,

[0020] The pre-pulse electrode segment 2 is cylindrical,

[0021] One end of the pre-pulse electrode segment 2 is fixedly connected to one end of the discharge electrode segment 3, and the end face of the other end of the discharge electrode segment 3 is a concave spherical surface;

[0022] One end of the main pulse electrode segment 1 is inserted into it from the other end of the pre-pulse electrode segment 2, and is electrically connected with the pre-pulse electrode segment 2, and the other end of the main pulse electrode segment 1 is exposed outside the pre-pulse electrode segment 2, and its en...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is a further description of Embodiment 1. The length adjustment range of the main pulse electrode segment 1 is greater than 0 mm and less than or equal to 14 mm.

[0028] The length adjustment range of the main pulse electrode section 1 is selected according to the length of the capillary, in order to realize the adjustable electrode distance in the capillary from 0 to 14 mm, so as to realize capillary discharge with different electrode distances.

specific Embodiment approach 3

[0029] Specific Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The section radius of the discharge electrode segment 3 is 1.5 mm.

[0030] The diameter of the pre-pulse electrode segment 2 only needs to be larger than the diameter of the main pulse electrode segment 1, so as to achieve a good socket installation between the two. The size of the section radius of the discharge electrode segment 3 is selected according to the inner diameter of the capillary, and the inner ring radius of the capillary is generally 0.5 mm to 10 mm, so the radius of the discharge electrode segment 3 is smaller than the inner radius of the capillary.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com