Butadiene styrene rubber composition with wear-resisting characteristic and preparation method thereof

A technology of styrene-butadiene rubber and its composition, which is applied in the field of styrene-butadiene rubber composition and its preparation, can solve the problems of high price and high energy consumption of cross-linking monomers, and achieve improved wet skid resistance, reduced extrusion expansion, The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0078] The formula composition of the rubber compound is listed in Table 1, and the preparation process of the rubber compound is the same as that of the comparative example. Each component in Table 1 is in parts by weight.

[0079] Table 1 comparative example and embodiment formula

[0080] material name

[0081] Note: * SBR1712 is a mixture of 100 parts by weight SBR and 37.5 parts oil

[0082] The main properties of comparative examples and examples are listed in Tables 2-4.

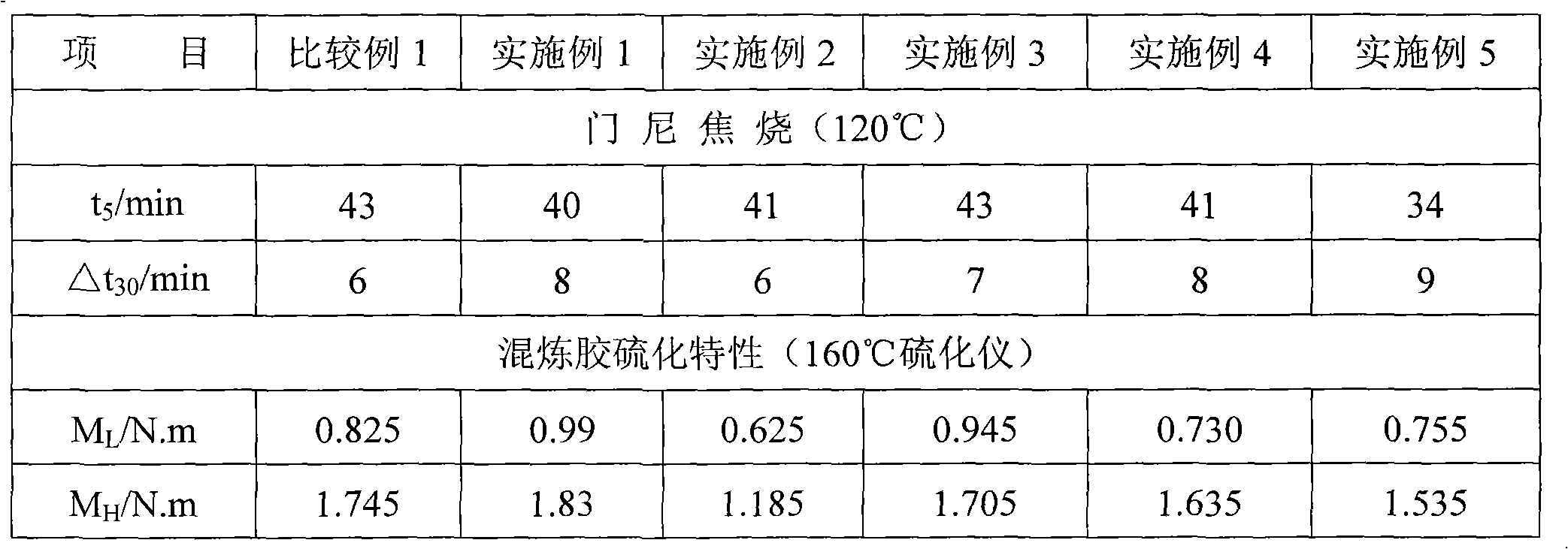

[0083] Table 2 Vulcanization characteristics and Mooney scorch

[0084]

[0085]

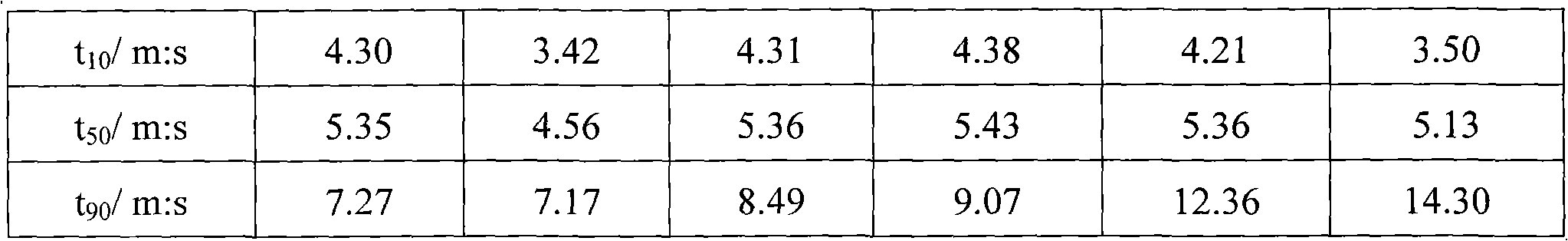

[0086] Physical and mechanical properties after table 3 vulcanization

[0087]

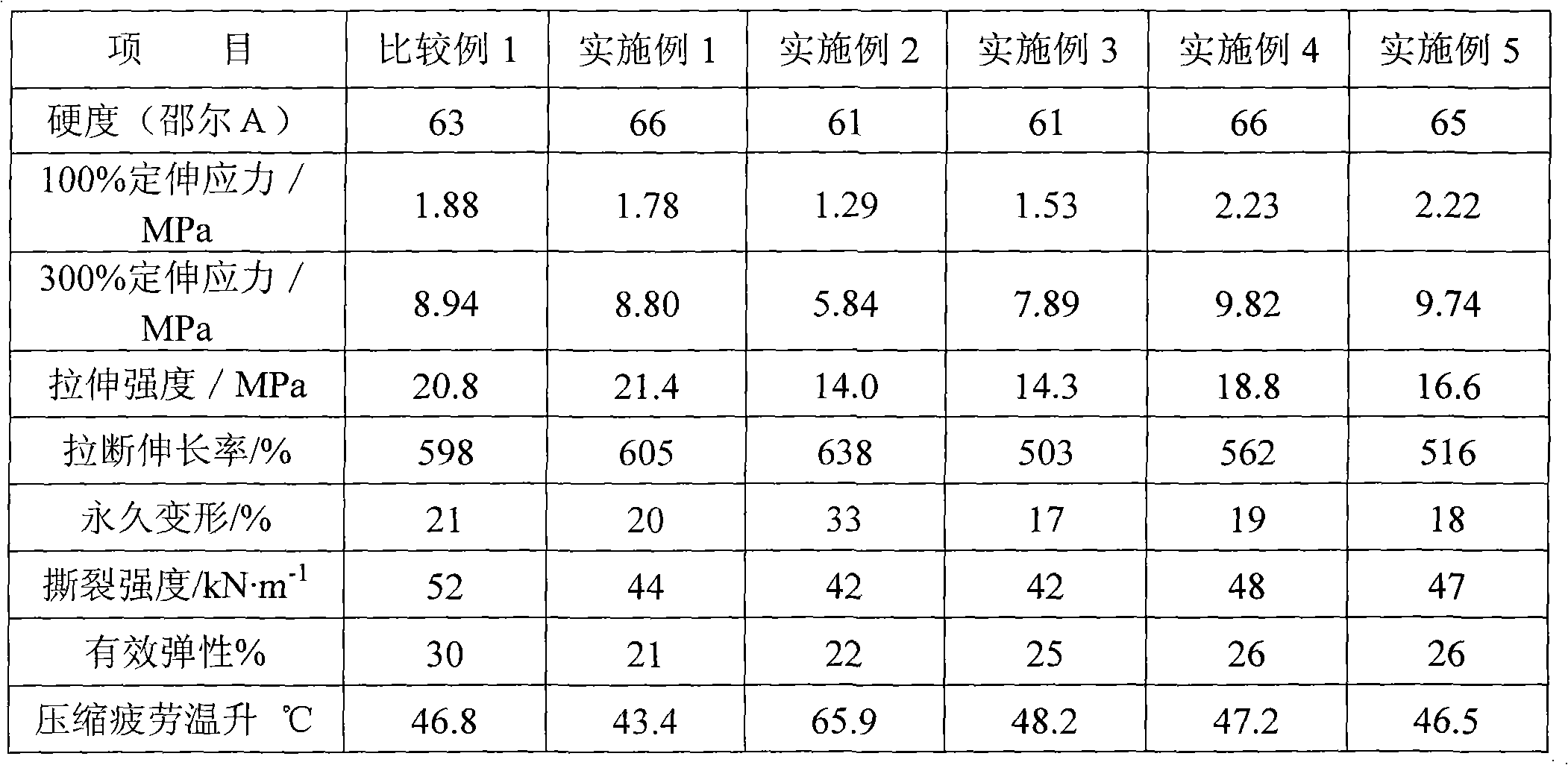

[0088] Table 4 Wear resistance, wet skid resistance and rolling resistance after vulcanization

[0089] project

[0090] From the results of Table 3 and Table 4, it can be seen that the modified styrene-butadiene powder rubber is used in the styrene-butadiene rubber formulation system, the wet skid resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com