High-performance rubber cracking preventing agent

A technology of anti-cracking agent and anti-agent, which is applied in the field of anti-cracking agent, can solve the problems of high price, low service life, lack of rubber protection mechanism and in-depth research on the root of precipitation, etc., and achieves low cost, long effective effect, and improved heat elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

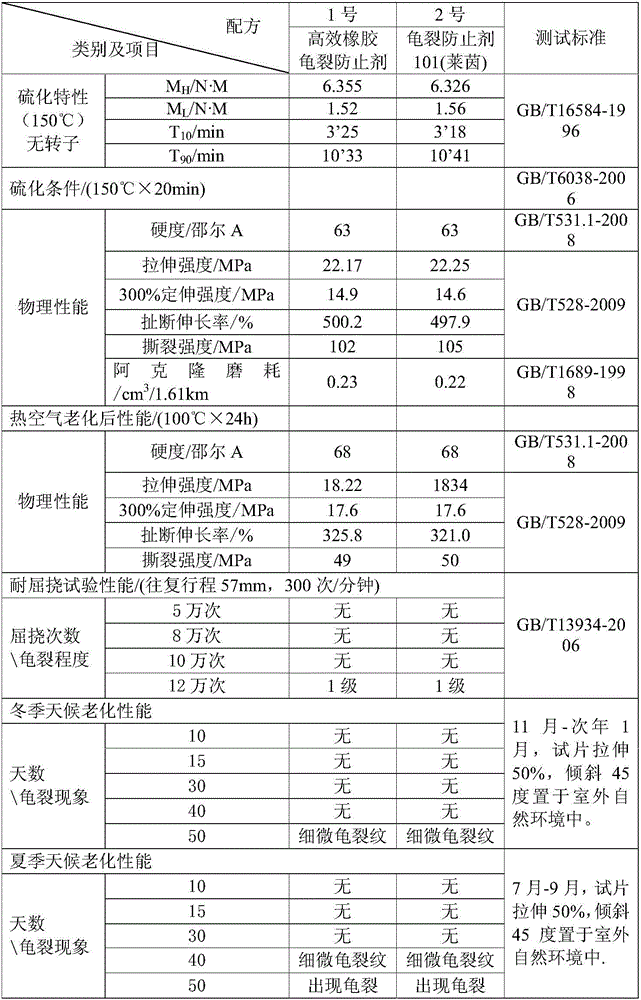

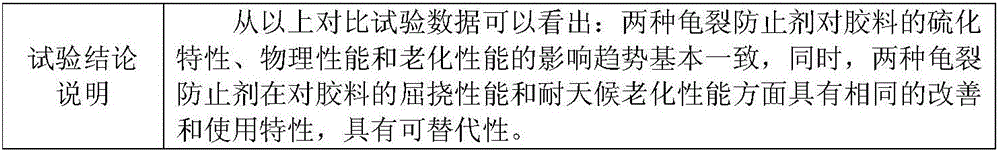

Image

Examples

Embodiment 1

[0043] This embodiment provides a high-efficiency rubber cracking inhibitor, which includes the following components in parts by weight: No. 58 fully refined paraffin wax: 20 parts, No. 58 semi-refined paraffin wax: 15 parts, and No. 70 microcrystalline wax: 22 parts, No. 85 microcrystalline wax: 18 parts, oxidized polyethylene wax: 4 parts, polyethylene wax: 2 parts.

[0044] The preparation process of this preventive agent is specifically carried out according to the following steps:

[0045] Step (1): put No. 85 microcrystalline wax into the reactor, heat and stir;

[0046] Step (2): when the temperature of the material in the reaction kettle rises to 90°C in step (1), put in No. 70 microcrystalline wax, keep stirring for 5min;

[0047] Step (3): heating up, when the temperature of the material in the reaction kettle reaches 110 ° C, put in all the oxidized polyethylene wax and polyethylene wax, then keep the temperature at 110 ° C and stir for 20 min to obtain a modified ...

Embodiment 2

[0053] This embodiment provides a high-efficiency rubber cracking inhibitor, which includes the following components in parts by weight: No. 58 fully refined paraffin wax: 30 parts, No. 58 semi-refined paraffin wax: 25 parts, and No. 70 microcrystalline wax: 34 parts, microcrystalline wax No. 85: 30 parts, oxidized polyethylene wax: 8 parts, polyethylene wax: 5 parts.

[0054] The preparation process of this preventive agent is specifically carried out according to the following steps:

[0055] Step (1): put No. 85 microcrystalline wax into the reactor, heat and stir;

[0056] Step (2): when the temperature of the material in the reaction kettle rises to 100°C in step (1), put in No. 70 microcrystalline wax, keep stirring for 5-8min;

[0057] Step (3): heating up, when the temperature of the material in the reaction kettle reaches 110 ° C, put all the oxidized polyethylene wax and polyethylene wax into it, then keep the temperature at 120 ° C and stir for 30 min to obtain a m...

Embodiment 3

[0063] This embodiment provides a high-efficiency rubber crack preventing agent, which includes the following components in parts by weight: No. 58 fully refined paraffin wax: 25 parts, No. 58 semi-refined paraffin wax: 19 parts, and No. 70 microcrystalline wax: 27 parts, No. 85 microcrystalline wax: 22 parts, oxidized polyethylene wax: 6 parts, polyethylene wax: 4 parts.

[0064] The preparation process of this preventive agent is specifically carried out according to the following steps:

[0065] Step (1): put No. 85 microcrystalline wax into the reactor, heat and stir;

[0066] Step (2): when the temperature of the material in the reaction kettle rises to 95°C in step (1), put in No. 70 microcrystalline wax, keep stirring for 7min;

[0067] Step (3): heating up, when the temperature of the material in the reaction kettle reaches 110 ° C, put all the oxidized polyethylene wax and polyethylene wax into it, then keep the temperature at 115 ° C and stir for 25 min to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com