Active red SBE, synthetic method and its composite active red dye

A technology of reactive red dye and synthesis method, applied in azo dyes, organic dyes, monoazo dyes and other directions, can solve the problems of complex production process, large amount of sewage and high unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

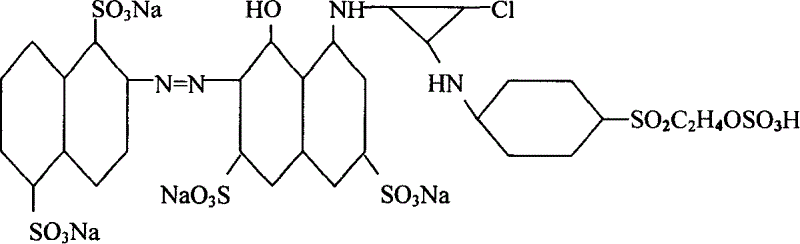

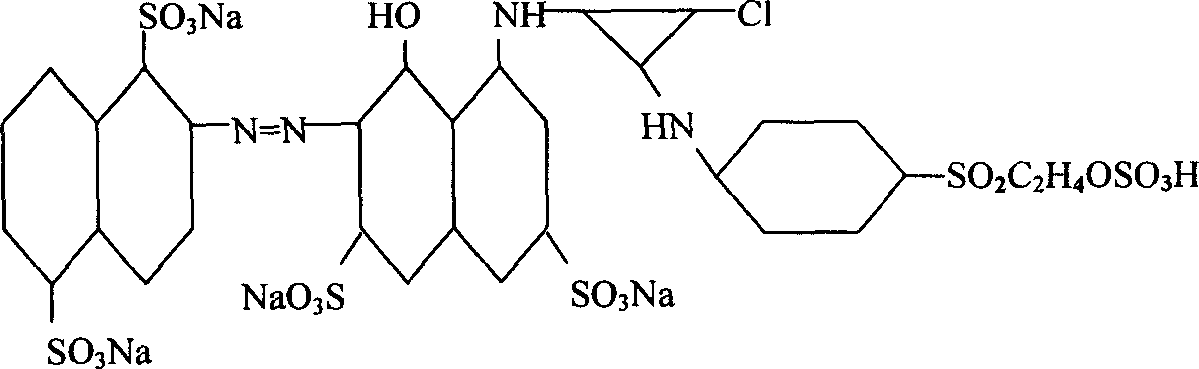

Image

Examples

Embodiment 1

[0010] Example 1, 100 parts of cyanuric chloride and 2 parts of dispersant are beaten to powder in the presence of crushed ice, and 100 parts of dry product are added to condense (β-sulfate ethyl sulfone) aniline once to control the pH value of 3 ~4, temperature 8~12℃, when the free amine is less than 1.5%, add 100 parts of dry H acid for secondary condensation, control the temperature at 25~35℃, control the pH value between 3~5, and cool down to Coupling with 100 parts of dry product 1,5-disulfonic acid-2-naphthylamine diazonium salt at 20-26°C, spraying dry directly after coupling.

Embodiment 2

[0011] Example 2, 100 parts of cyanuric chloride and 5 parts of dispersant are beaten to powder in the presence of crushed ice, and 104 parts of dry product are added to condense (β-sulfate ethyl sulfone) aniline once to control the pH value to 2.5 ~3.5, temperature 6~10℃, when the free amine is less than 1.5%, add 100 parts of dry product H acid for secondary condensation, control the temperature at 25~35℃, control the pH value of 4~5, cool down to 25~ after the reaction Coupling with 100 parts of dry product 1,5-disulfonic acid-2-naphthylamine diazonium salt at 30°C, spraying dry directly after coupling.

Embodiment 3

[0012] Embodiment 3, composite reactive red dyestuff, is made up of 90 parts of reactive red SBE monomers, 2 parts of dustproof agent, 8 parts of sodium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com