Transparent electrode and manufacturing method thereof

A technology of transparent electrodes and transparent substrates, which is applied in the manufacture of circuits, electrical components, and final products. It can solve problems such as high light transmittance, achieve excellent electrical conductivity, strong bending and flexibility, and expand the scope of optoelectronic applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

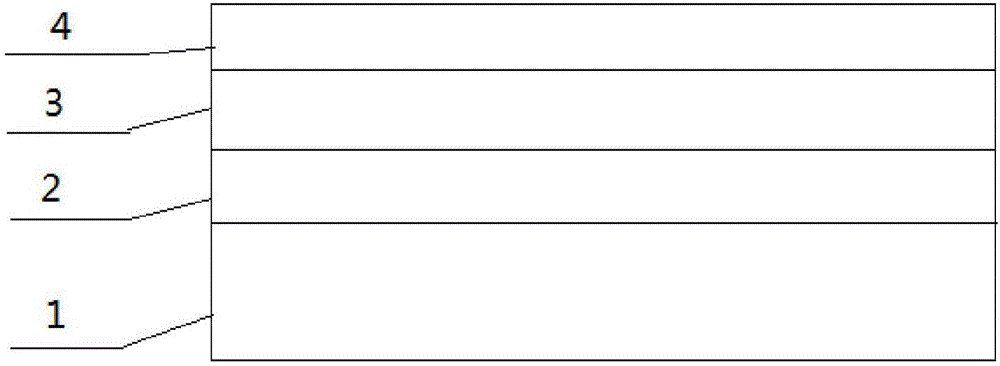

[0051] refer to figure 1 As shown, this embodiment provides a transparent electrode based on a broadband optically transparent continuous metal film layer and its preparation method, which can have the inherent perfect electrical conductivity characteristics of the metal film layer and also have excellent optical transparency characteristics.

[0052] The transparent electrode includes a transparent substrate 1 , a first high dielectric film layer 2 , a metal film layer 3 , and a second high dielectric film layer 4 from bottom to top.

[0053] The metal film layer is a continuous metal film layer; the continuous metal film layer means that the film layer itself has no voids / holes or cracks. Generally, if the metal film layer is too thin, it will be just a cluster of particles rather than a complete film layer that communicates with each other.

[0054] The dielectric constant of the high dielectric film layer is greater than or equal to 6.25.

[0055] High-dielectric materia...

Embodiment 2

[0062] This embodiment provides a transparent electrode, including figure 1 The transparent substrate 1 , the first high dielectric film layer 2 , the metal film layer 3 , and the second high dielectric film layer 4 are arranged sequentially from bottom to top.

[0063] Wherein, the metal material of the metal film layer 3 is gold, the material of the high dielectric film layer is titanium dioxide, the thickness of the metal film layer 3, the thickness of the first high dielectric film layer 2 and the second high dielectric film layer 4 are respectively 15nm, 40nm, 40nm. The material of the transparent substrate 1 is polydimethylsiloxane (PDMS), a flexible substrate material, with a thickness of 5 microns.

[0064] The preparation method of the transparent electrode of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

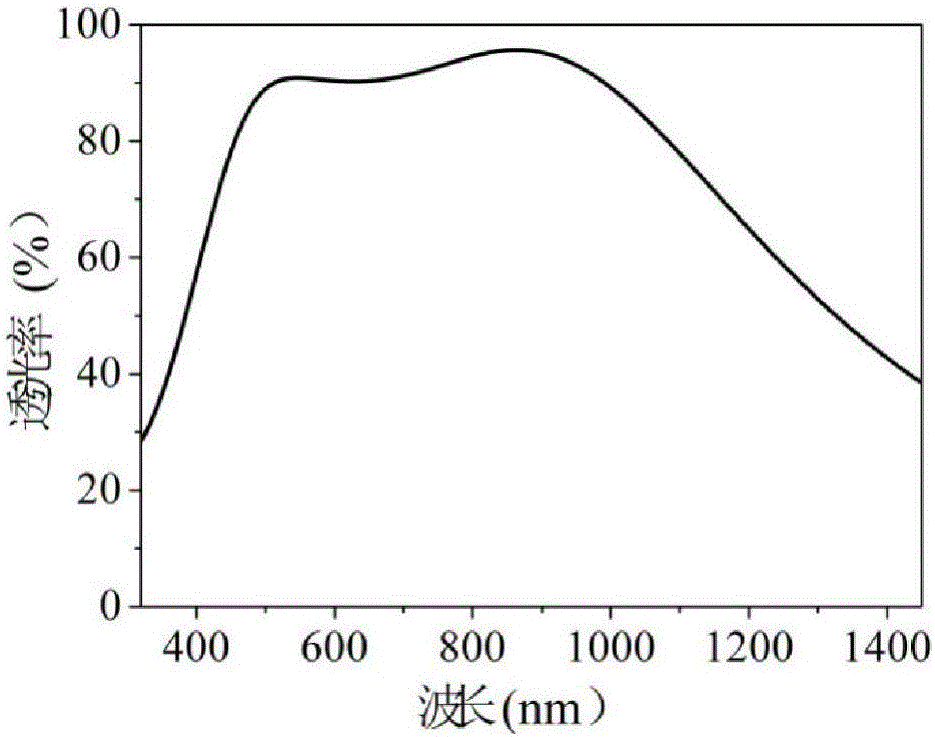

[0065] refer to figure 2 As shown, this embodiment is based on the light transmittance diagram of the transparent electro...

Embodiment 3

[0068] This embodiment provides a transparent electrode, including figure 1 The transparent substrate 1 , the first high dielectric film layer 2 , the metal film layer 3 , and the second high dielectric film layer 4 are arranged sequentially from bottom to top.

[0069] Wherein, the metal material of the metal film layer 3 is silver, the material of the high dielectric film layer is titanium dioxide, the thickness of the metal film layer 3, the thickness of the first high dielectric film layer 2 and the second high dielectric film layer 4 are respectively 15nm, 40nm, 40nm. The material of the transparent substrate 1 is polydimethylsiloxane (PDMS), a flexible substrate material, with a thickness of 5 microns.

[0070] The preparation method of the transparent electrode of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

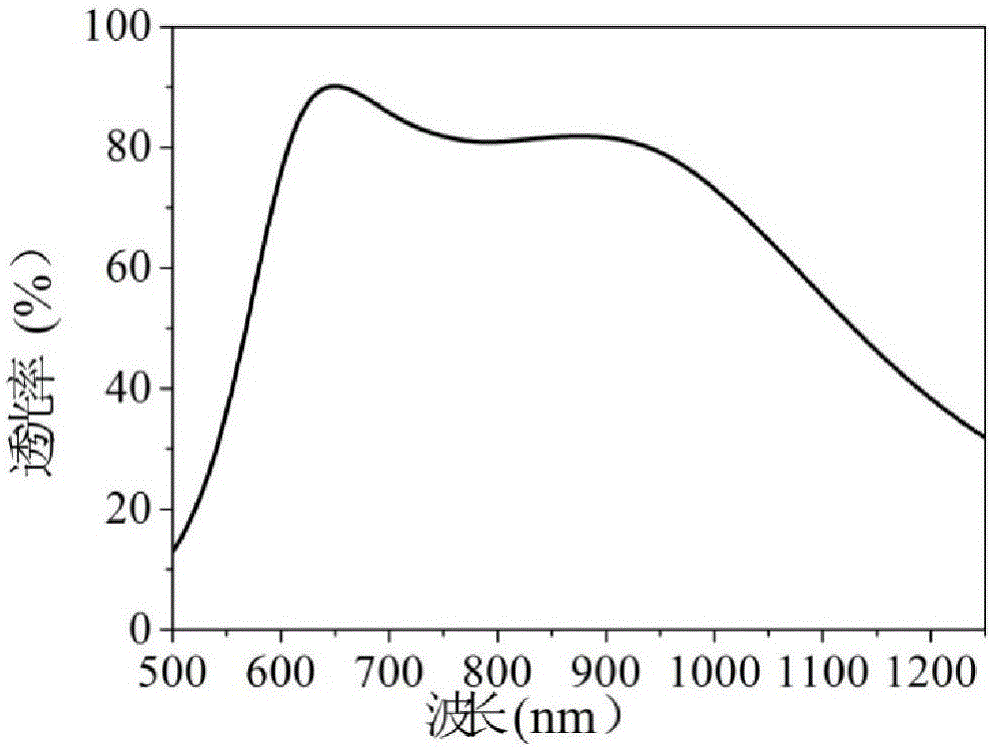

[0071] refer to image 3 As shown, this embodiment is based on the light transmittance diagram of the transparent electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com