Solar spectrum conversion resin and preparation and application methods thereof

A solar spectrum and resin technology, applied in chemical instruments and methods, photovoltaic power generation, luminescent materials, etc., can solve problems such as non-agricultural film, environmental pollution, etc., and achieve the effects of improving mechanical strength, increasing application scope, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

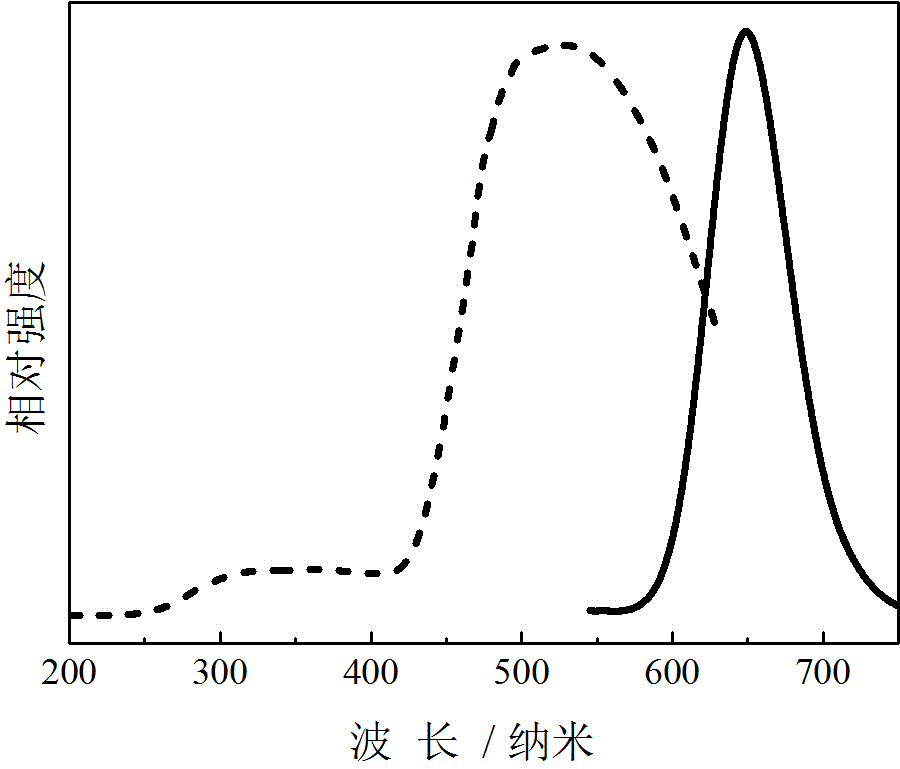

[0039] Example 1: Preparation of green-to-red-to-light PVB resin film and light-to-light laminated glass

[0040] (1) Take 10.0 g of the green-to-red light-converting agent CaS:Eu with an average particle size of 2.0 μm 2+ , add 1.0 g of KH-570 and 1.0 g of methyl silicone oil, add 5.0 mL of absolute ethanol, and grind until the ethanol is evaporated and ground evenly, then package and set aside.

[0041] (2) Take 1000 g of polyvinyl butyral, 300 g of plasticizer 3G8, and 5.0 g of surface-modified green-to-red light-changing agent, mix them evenly, and cast and extrude PVB film with a bidirectional screw extruder , that is, green-to-red-to-light PVB resin for light-turning laminated glass. The body temperature is 100-140 ℃, the head temperature is about 130 ℃, and the extruder speed is 25-30 r / min. The PVB film thickness is 0.76 mm.

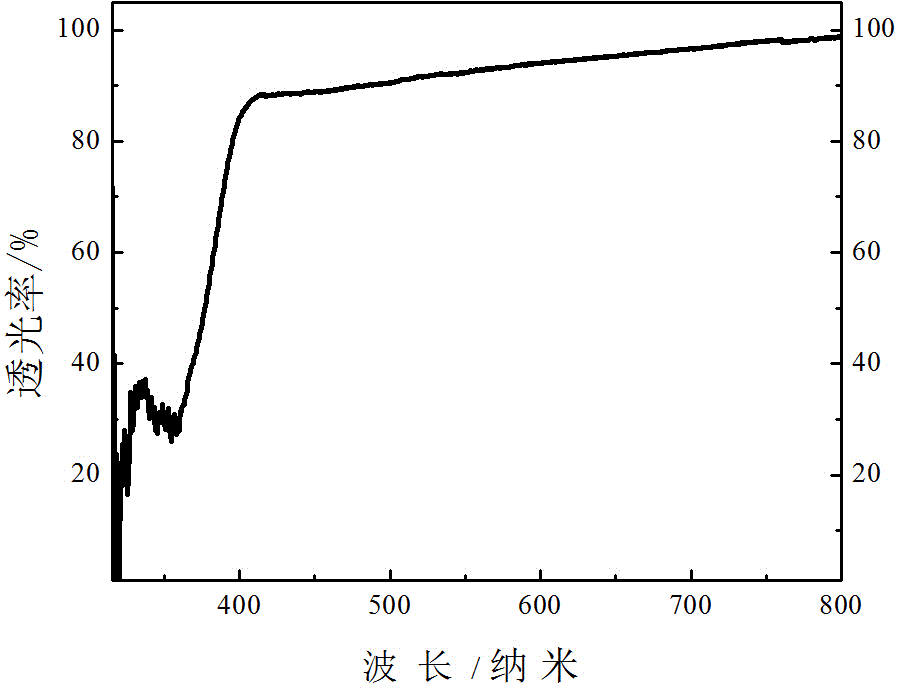

[0042] (3) Take two pieces of ultra-clear glass with a diameter of 50 mm and a thickness of 2.0 mm, wash and dry, and cut a piece of the gree...

example 1

[0044] Example 1 shows that by adopting the light-converting glass resin of the present invention, the light-converting agent with solar light energy conversion function can be successfully dispersed in PVB resin, and applied to the preparation of laminated glass to obtain a light-energy conversion agent with corresponding light-converting agent. The light-changing laminated glass provides new technical support for the realization of high-tech agriculture and forestry.

Embodiment 2

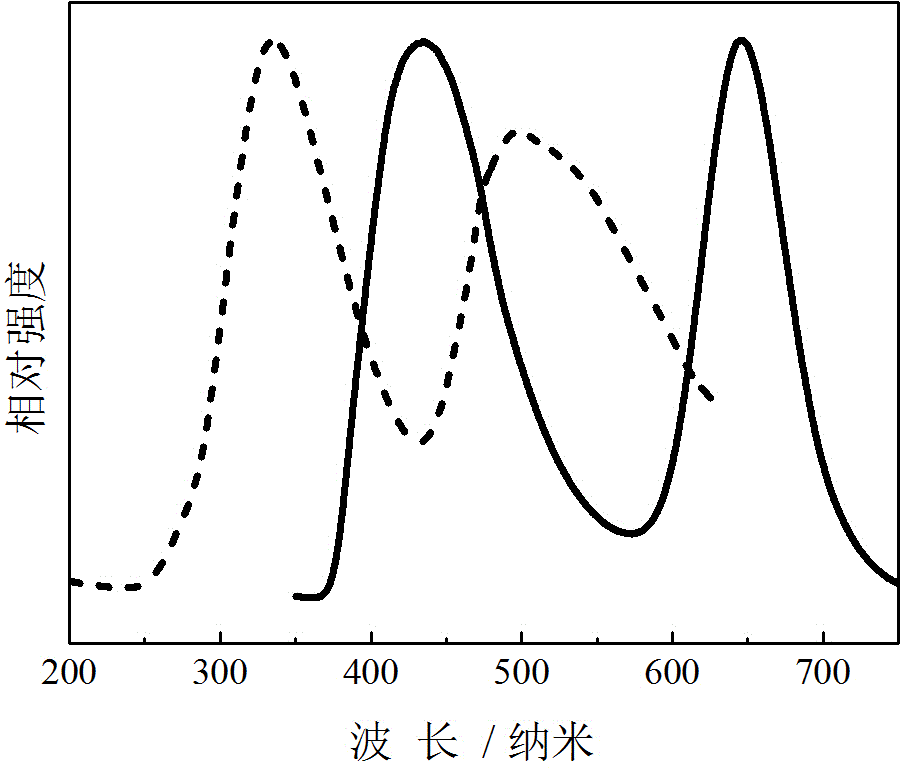

[0045] Example 2: Preparation of light-cured red and blue double-transition glass resin and light-conversion laminated glass

[0046] (1) Take 5.0 g of red and blue double light conversion agent CaS:Eu with an average particle size of 2.0 μm 2+ ,Cu + , add 1.0 g of stearic acid and 0.5 g of methyl silicone oil, add 5.0 mL of absolute ethanol, and grind until the ethanol is evaporated and ground evenly, then package and set aside.

[0047] (2) Take 10 g of liquid industrial light-curing glass resin, put it in a clean and absolutely dry Erlenmeyer flask, add 0.2 g of surface-modified red and blue double light-changing agent, and seal it; at room temperature, under the condition of no light , ultrasonically disperse for 20 min, and keep the temperature of the water medium in the sonicator not exceeding room temperature, and obtain a uniformly dispersed light-cured red-blue double-transition glass resin.

[0048] (3) Take two pieces of ultra-clear glass of 50 mm × 50 mm × 2.0 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com