Production technology of high temperature resistant temperature controller

A production process and technology for thermostats, applied in electrical components, electrical switches, circuits, etc., can solve the problems of the physical properties of shrapnel and bimetals falling, the safety performance of thermostats cannot be guaranteed, and improve the safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

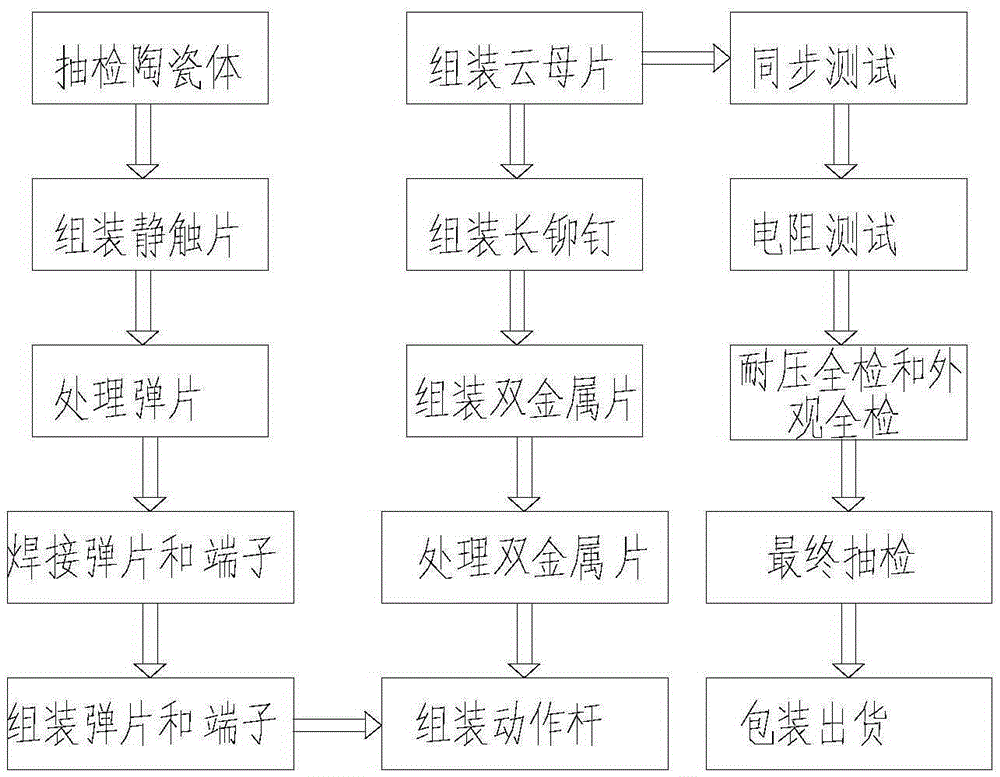

[0034] A kind of production technology of high temperature resistant thermostat of the present invention is characterized in that, comprises the following steps:

[0035] a) Sampling inspection of ceramic shells: sampling inspection of purchased ceramic shells;

[0036] b) Assembling the static contact piece: First, weld the static contact piece to the silver contact, and then assemble it on the qualified ceramic shell with short rivets;

[0037] c) Treatment of shrapnel: Put the shrapnel that has been cut into the aging machine for heat treatment for more than half an hour, and then weld the shrapnel after heat treatment to silver contacts;

[0038] d) welding shrapnel and terminals: welding the shrapnel and terminals processed in step c) together;

[0039] e) Assembling the shrapnel and terminals: Assembling the shrapnel and terminals welded in step d) onto the ceramic shell after step b);

[0040] f) Assembling the action rod: first, the incoming material inspection is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com