Low-reflection and high-transmittance glass and coating process thereof

A light-transmitting glass, low-reflection technology, applied in the coating and other directions, can solve the problems of high cost, glass reflection, low light transmittance, etc., to achieve the effect of strong light transmittance, guaranteed transmission, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

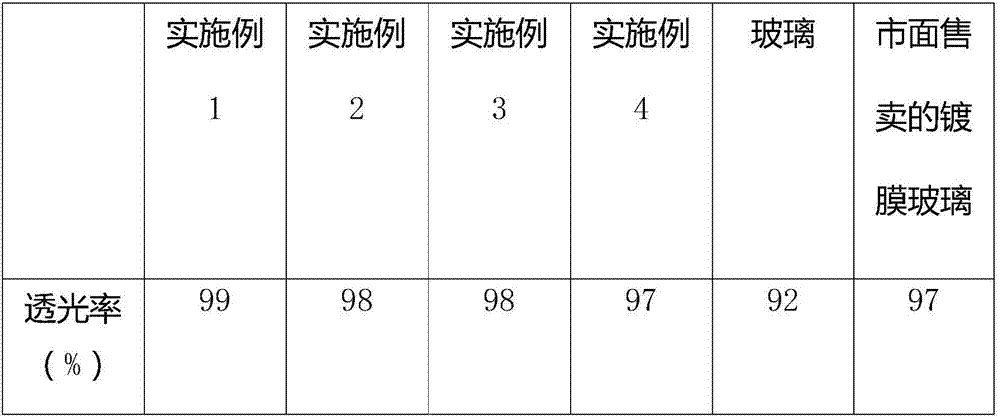

Embodiment 1

[0022] A low-reflection, high-transmittance glass and its coating process:

[0023] (1) When starting the coating preparation, thoroughly clean the working platform to ensure that there are no visible debris;

[0024] (2) Turn on the cooling circulating water pump to ensure that the working temperature of the instrument is in a constant state;

[0025] (3) Put various cleaning solutions in the cleaning tank, then put transparent silicon-based glass of the same size into the cleaning tank for cleaning, and use ultrasonic waves for ultrasonic cleaning, and the cleaning times are 3 times;

[0026] (4) Then transport the cleaned glass to a vacuum cleaning room for further cleaning. The water used in the cleaning process is deionized water, and special cleaning agents are used for cleaning, and ultrasonic cleaning is performed using ultrasound. The number of cleanings is 3 Second-rate;

[0027] (5) Transport the cleaned glass to a vacuum drying oven for drying at 80°C for 2 hours...

Embodiment 2

[0031] A low-reflection, high-transmittance glass and its coating process:

[0032] (1) When starting the coating preparation, thoroughly clean the working platform to ensure that there are no visible debris;

[0033] (2) Turn on the cooling circulating water pump to ensure that the working temperature of the instrument is in a constant state;

[0034] (3) Put various cleaning solutions in the cleaning tank, then put transparent silicon-based glass of the same size into the cleaning tank for cleaning, and use ultrasonic waves for ultrasonic cleaning, and the cleaning times are 5 times;

[0035] (4) Then transport the cleaned glass to a vacuum cleaning room for further cleaning. The water used in the cleaning process is deionized water, and special cleaning agents are used for cleaning, and ultrasonic cleaning is carried out, and the cleaning times are 5 Second-rate;

[0036] (5) Transport the cleaned glass to a vacuum drying oven for drying at 100°C for 1 hour;

[0037] (6)...

Embodiment 3

[0040] A low-reflection, high-transmittance glass and its coating process:

[0041] (1) When starting the coating preparation, thoroughly clean the working platform to ensure that there are no visible debris;

[0042] (2) Turn on the cooling circulating water pump to ensure that the working temperature of the instrument is in a constant state;

[0043] (3) Put various cleaning solutions in the cleaning tank, then put transparent silicon-based glass of the same size into the cleaning tank for cleaning, and use ultrasonic waves for ultrasonic cleaning, and the cleaning times are 5 times;

[0044] (4) Then transport the cleaned glass to a vacuum cleaning room for further cleaning. The water used in the cleaning process is deionized water, and special cleaning agents are used for cleaning, and ultrasonic cleaning is carried out, and the cleaning times are 5 Second-rate;

[0045] (5) Transport the cleaned glass to a vacuum drying oven for drying at 100°C for 2 hours;

[0046] (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com