Sintered high thermal shock resistance bauxite brick, and production method thereof

A production process and technology of bauxite, which is applied in the field of firing high thermal shock bauxite bricks and its production process, can solve the problems affecting the thermal shock resistance of high alumina bricks, achieve the improvement of slag erosion resistance, production The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

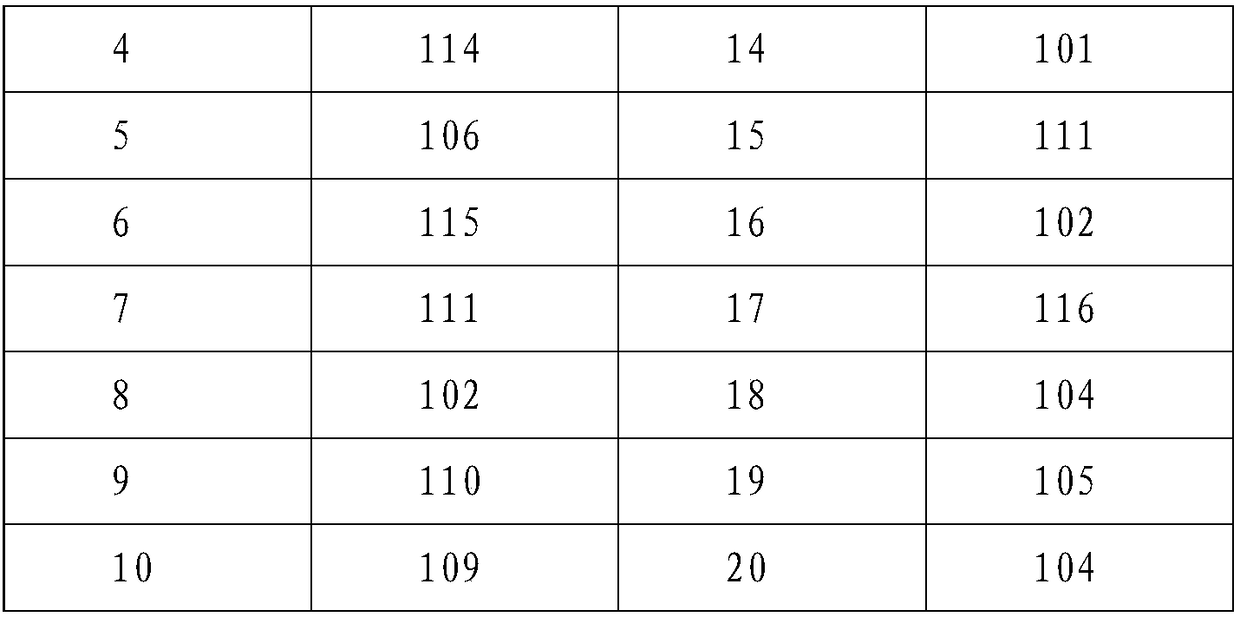

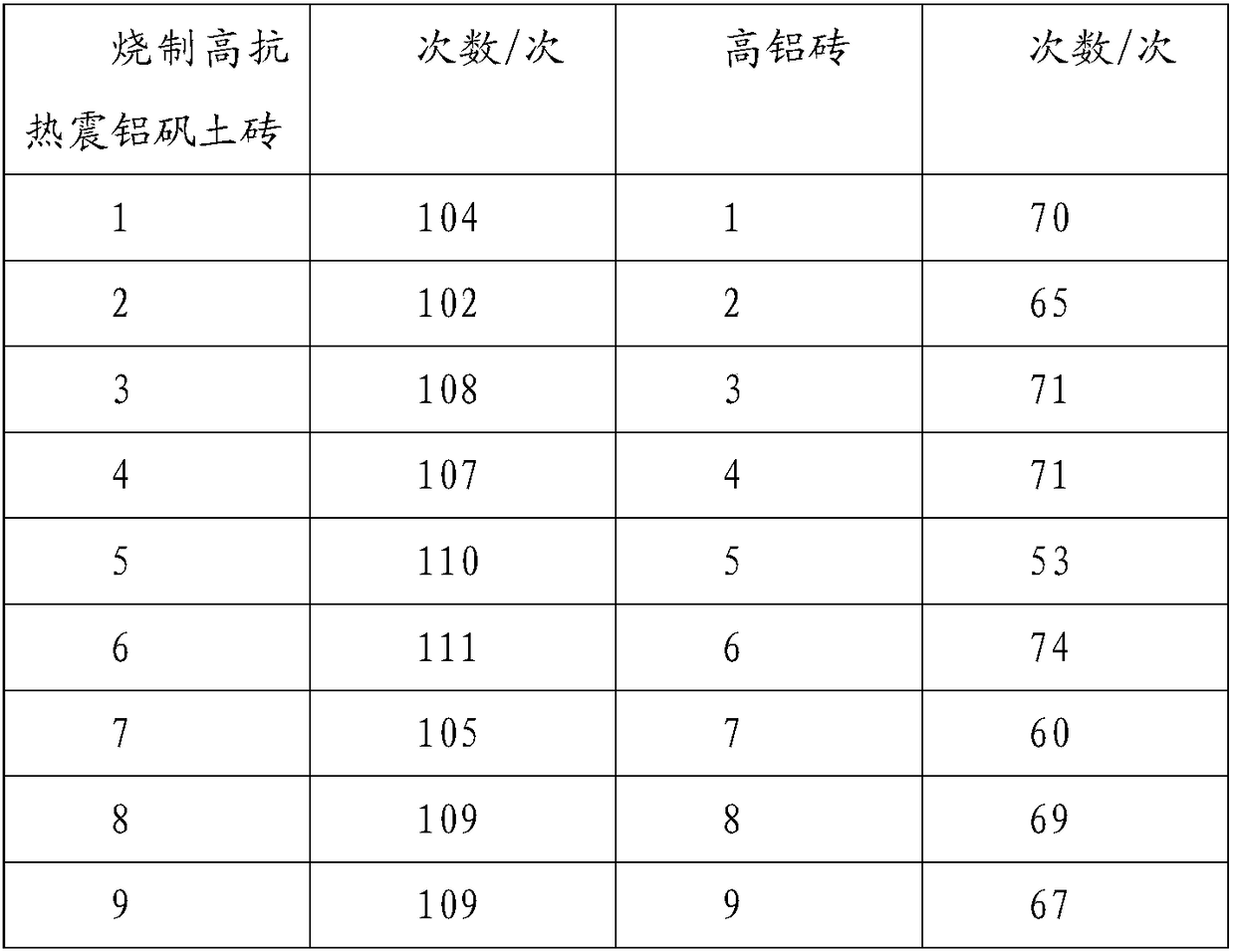

Examples

Embodiment 1

[0033] A fired high thermal shock resistant bauxite brick, characterized in that: the fired high thermal shock resistant bauxite brick includes the following components in parts by weight: 52 parts of high alumina bauxite mixture, silicon 15 parts of cordite powder, 8 parts of cordierite powder, 3 parts of alumina powder, 10 parts of Guangxi white clay, 1 part of zircon powder, and 1 part of silicon carbide fine powder.

[0034] Its preparation method comprises the following steps:

[0035] (1) Mixing and stirring: add high-alumina bauxite mixture, water, sillimanite powder, cordierite powder, alumina powder, zirconite powder and silicon carbide fine powder in sequence according to the proportion, mix and stir for 10 minutes, and then add Guangxi White clay, mixed and stirred for 10 minutes, obtained the initial product;

[0036] (2) Squeeze and fire: put the initial product into a 400-ton press, press and form it, and then fire it in a kiln to obtain a semi-finished product;...

Embodiment 2

[0039] A fired high thermal shock resistant bauxite brick, characterized in that: the fired high thermal shock resistant bauxite brick includes the following components in parts by weight: 55 parts of high alumina bauxite mixture, silicon 17 parts of wire stone powder, 10 parts of cordierite powder, 5 parts of alumina powder, 13 parts of Guangxi white clay, 2 parts of zircon stone powder, and 3 parts of silicon carbide fine powder.

[0040] Its preparation method comprises the following steps:

[0041] (1) Mixing and stirring: add high-alumina bauxite mixture, water, sillimanite powder, cordierite powder, alumina powder, zirconite powder and silicon carbide fine powder in sequence according to the proportion, mix and stir for 10 minutes, and then add Guangxi White clay, mixed and stirred for 10 minutes, obtained the initial product;

[0042] (2) Squeeze and fire: put the initial product into a 400-ton press, press and form it, and then fire it in a kiln to obtain a semi-finis...

Embodiment 3

[0045] A fired high thermal shock resistant bauxite brick, characterized in that: the fired high thermal shock resistant bauxite brick includes the following components in parts by weight: 58 parts of high alumina bauxite mixture, silicon 20 parts of wire stone powder, 12 parts of cordierite powder, 8 parts of alumina powder, 15 parts of Guangxi white clay, 5 parts of zircon stone powder, and 5 parts of silicon carbide fine powder.

[0046] Its preparation method comprises the following steps:

[0047](1) Mixing and stirring: add high-alumina bauxite mixture, water, sillimanite powder, cordierite powder, alumina powder, zirconite powder and silicon carbide fine powder in sequence according to the proportion, mix and stir for 10 minutes, and then add Guangxi White clay, mixed and stirred for 10 minutes, obtained the initial product;

[0048] (2) Squeeze and fire: put the initial product into a 400-ton press, press and form it, and then fire it in a kiln to obtain a semi-finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com