Vitrified bond end face grinding wheel for fine grinding of compressor sliding vane and preparation method thereof

A ceramic bond and compressor technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of poor synergistic effect of the bond, so as to avoid the weakening of abrasive performance, facilitate process control, and achieve sphericity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The utility model relates to a vitrified bond end face grinding wheel specially used for precise grinding of compressor sliding vanes, which is composed of a base body, abrasive sheets glued on the grinding wheel base body, and resin glue filling the gaps between the abrasive sheets.

[0029]The preparation method of the above-mentioned vitrified bond end face grinding wheel for fine grinding of the compressor slide vane comprises the following steps:

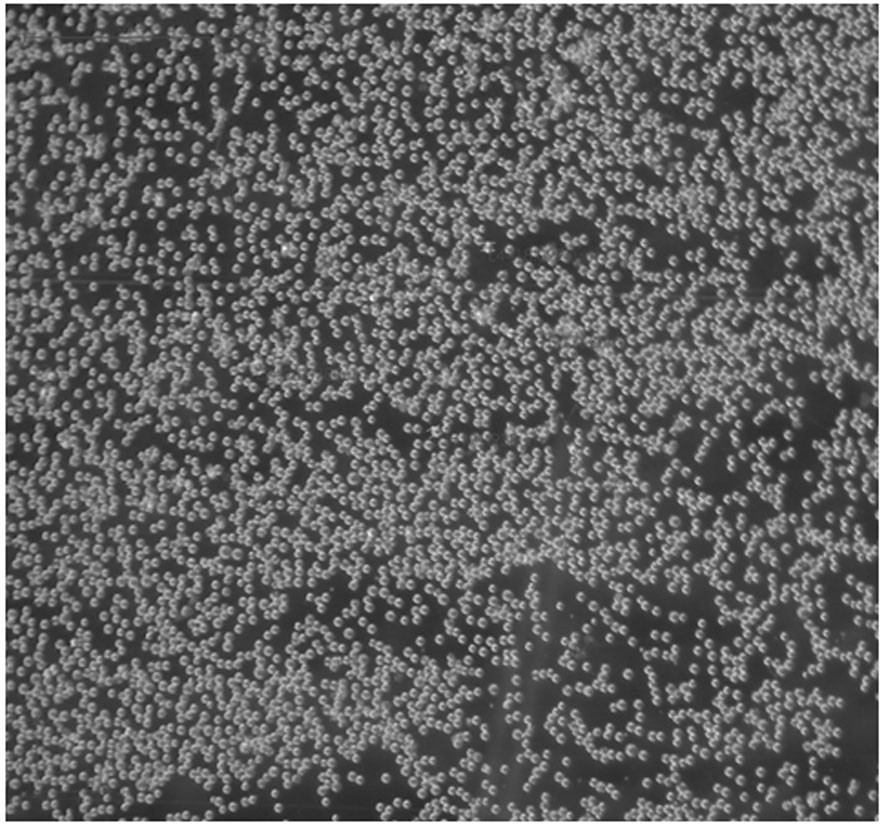

[0030] (1) Ingredients: Mix the diamond abrasive, white corundum, vitrified bond, pore-forming agent, and temporary binder (polyvinyl alcohol solution) in the prescribed amount and pass through a 100-mesh sieve to obtain a mixed raw material powder;

[0031] (2) Cold press forming: the mixed raw material obtained in step (1) is subjected to fixed mold cold press forming to obtain a green body; the pressure of cold press forming is 20MPa, and the time is 3s;

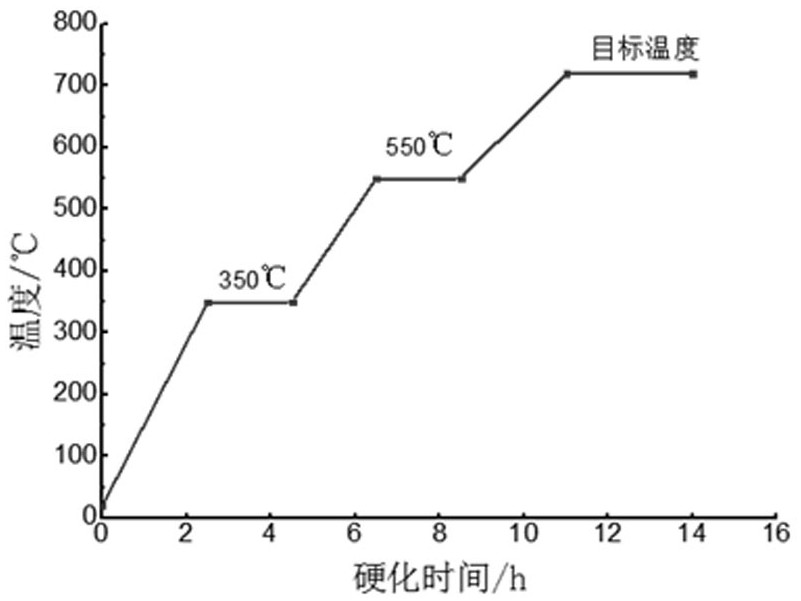

[0032] (3) Sintering molding: Place the grinding wheel blank f...

Embodiment 2

[0051] The SiO of Example 1 2 -Y 2 o 3 -Al 2 o 3 The binder is changed as follows:

[0052] SiO 2 45%, Al 2 o 3 15%, ZrO 2 8%, Bi 2 o 3 10%, P 2 o 5 0.5%, Y 2 o 3 for the margin.

[0053] All the other remains the same, the obtained emery wheel carries out the same processing of embodiment 1, and the single processing time is 40s, which is slightly inferior to that of embodiment 1; the good product rate is 100%, and the service life is stable and can reach more than 1,000,000 pieces.

Embodiment 3

[0055] On the basis of embodiment one, the raw material composition of raw material powder: diamond 45%, SiO 2 -Y 2 o 3 -Al 2 o 3 20% binder, 30% white corundum, 2% pore-forming agent, 3% temporary adhesive.

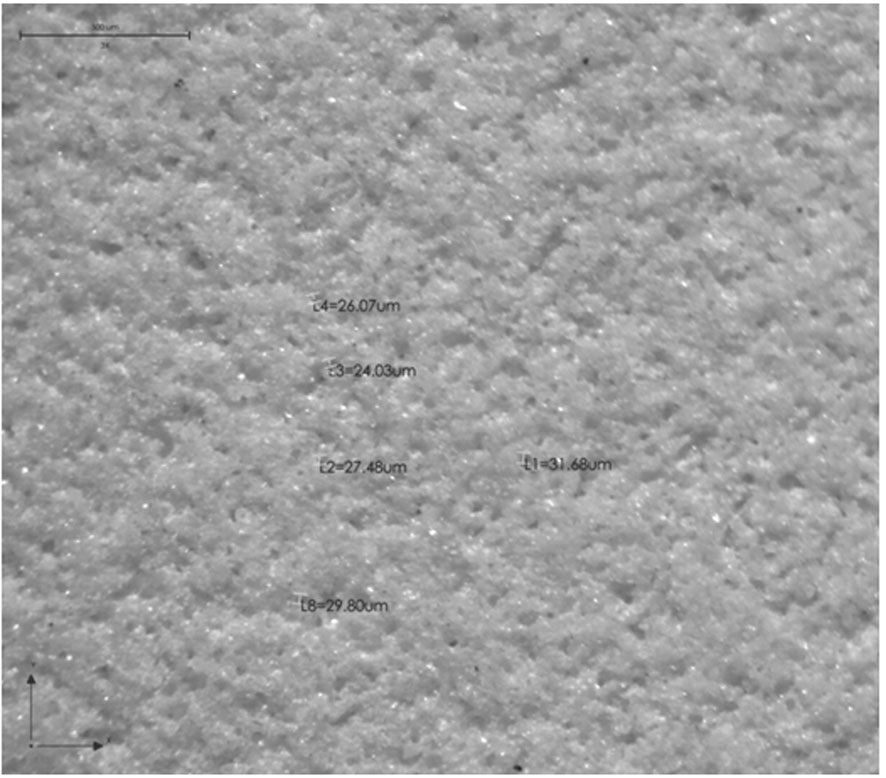

[0056]The rest remain the same, and the obtained grinding wheel is processed in the same way as in Example 1. The difference in flatness and parallelism of the 72 slides on the entire disk can reach within 0.002mm, and the difference in flatness and parallelism of a single slide can reach within 0.001mm. , The trimming interval can be 33 discs, which is slightly inferior to that of Embodiment 1; the yield rate is 100%, and the life stability can be more than 1 million pieces.

[0057] The vitrified bonded double-end grinding disc prepared in this implementation example can be used to process stainless steel and high-speed steel slides, which can meet the processing requirements of fine grinding, and the processing efficiency, the precision of the processed workpiece ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com