Al based on azeotropic distillation 2 o 3 /zro 2 Composite ceramics and its preparation method and application

A technology of azeotropic distillation and composite ceramics, which is applied in the direction of ceramic molding machines, manufacturing tools, branch equipment, etc., can solve the problems of unfavorable industrial production, narrow sintering temperature range, uneven powder particle size, etc., and achieve the purpose of inhibiting grain growth, The effect of wide sintering range and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

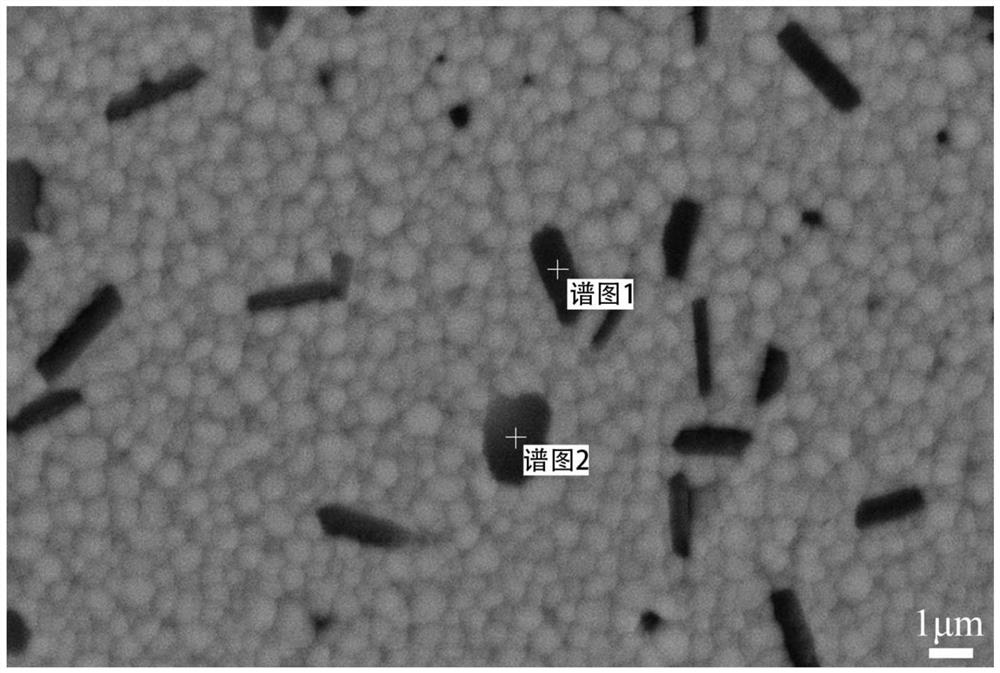

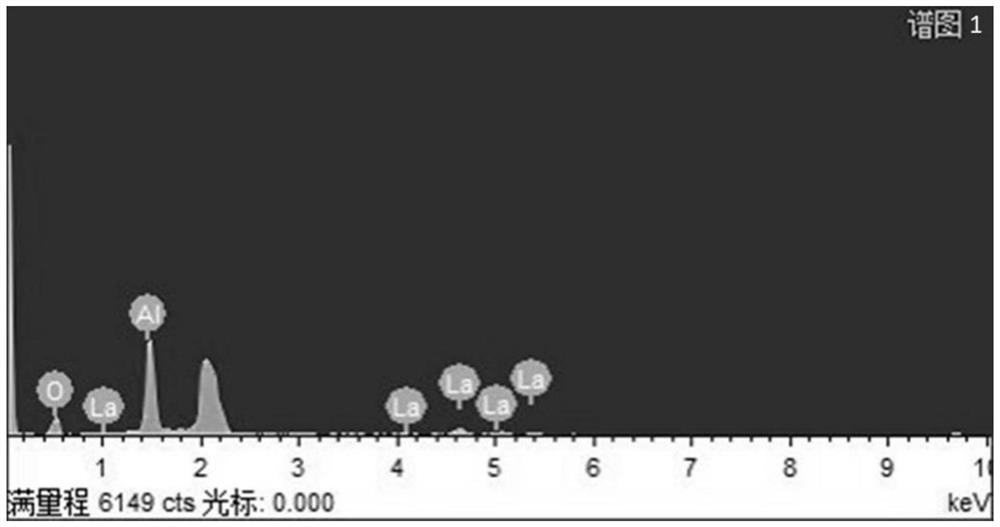

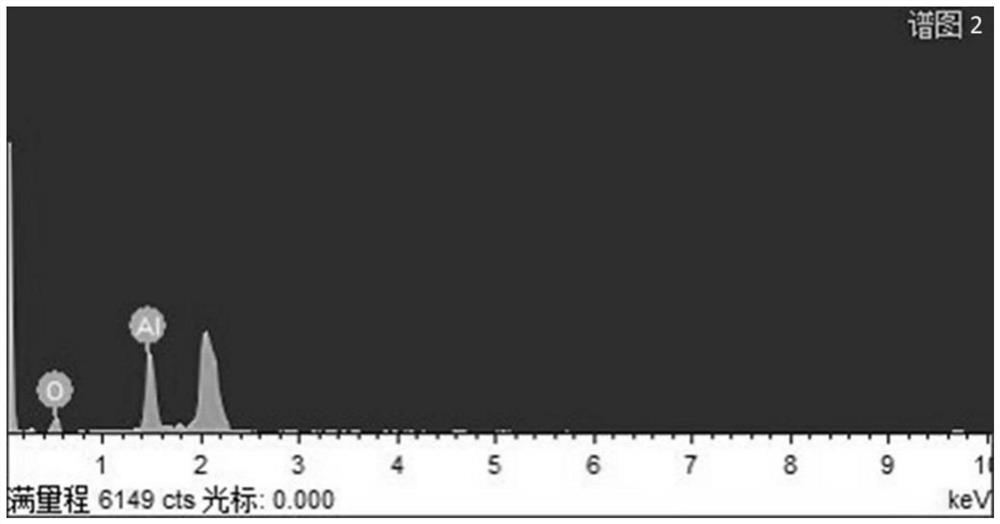

[0046] A kind of Al based on azeotropic distillation 2 o 3 / ZrO 2 A preparation method for composite ceramics, comprising the steps of:

[0047] 1) ZrOCl 2 , YCl 3 , AlCl 3 、LaCl 3 Mix with ethanol to obtain a mixed solution with a cation concentration of 0.3mol / L, and Zr in the solution 4+ with Al 3+ The molar ratio is 5:3, Y 3+ with Zr 4+ The molar ratio is 3:100, La 3+ with Zr 4+ and Al 3+ The molar ratio of the total amount is 0.4:100,.

[0048] 2) After adding 1% of the total mass of surfactant PEG400 and 1% of PEG2000 into the mixed solution, mechanical stirring was performed at a speed of 800 r / min for 5 minutes. Ammonia solution was added dropwise again, and the dropwise addition was stopped when the pH was 9.5.

[0049]3) The obtained translucent sol was aged for 18 hours, then centrifuged, and washed with deionized water and ethanol in sequence to obtain the sol.

[0050] 4) After adding n-butanol to the gel, carry out mechanical stirring. The ratio of...

Embodiment 2

[0058] A kind of Al based on azeotropic distillation 2 o 3 / ZrO 2 A preparation method for composite ceramics, comprising the steps of:

[0059] 1) ZrOCl 2 , YCl 3 , AlCl 3 、LaCl 3 Mix with ethanol to obtain a mixed solution with a total cation concentration of 0.5mol / L, Zr in the solution 4+ with Al 3+ The molar ratio is 8:1, Y 3+ with Zr 4+ The molar ratio is 2.3:100, La 3+ with Zr 4+ and Al 3+ The molar ratio of the total amount is 0.3:100.

[0060] 2) Add salt (ZrOCl 2 , YCl 3 , AlCl 3 、LaCl 3 ) Surfactant PEG2000 with a total mass of 2.5%, followed by mechanical stirring at a speed of 500 r / min for 8 min. Ammonia water was then added dropwise, and the dropwise addition was stopped when the pH was 9.

[0061] 3) The obtained translucent sol was left to age for 24 hours, then centrifuged, and washed with deionized water and ethanol in sequence to obtain a gel.

[0062]4) Add n-butanol to the gel, the ratio of the amount of n-butanol added to the gel volum...

Embodiment 3

[0067] A kind of Al based on azeotropic distillation 2 o 3 / ZrO 2 A preparation method for composite ceramics, comprising the steps of:

[0068] 1) ZrOCl 2 , YCl 3 , AlCl 3 、LaCl 3 Mix with ethanol to obtain a mixed solution with a cation concentration of 0.6mol / L, and Zr in the solution 4+ with Al 3+ The molar ratio is 2:1, Y 3+ with Zr 4+ The molar ratio is 2:100, La 3+ with Zr 4+ and Al 3+ The molar ratio of the total amount is 0.2:100,.

[0069] 2) After adding 1% total mass of surfactants PEG400 and 3% PEG2000 into the mixed solution, perform mechanical stirring at a speed of 600 r / min for 8 minutes. Ammonia water was then added dropwise, and the dropwise addition was stopped when the pH was 10.

[0070] 3) The obtained translucent sol was left to age for 22 hours, then centrifuged, and washed with deionized water and ethanol in sequence to obtain a gel.

[0071] 4) After adding n-butanol to the gel, carry out mechanical stirring, the amount of n-butanol ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com