Preparation method of non-pickling raw kaolin ore

A technology of kaolin and non-pickling, which is applied in the field of preparation of non-pickling kaolin ore, which can solve the problems of high production cost, poor bleaching effect, environmental pollution, etc., and achieve high iron removal rate, slow decline speed and good safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

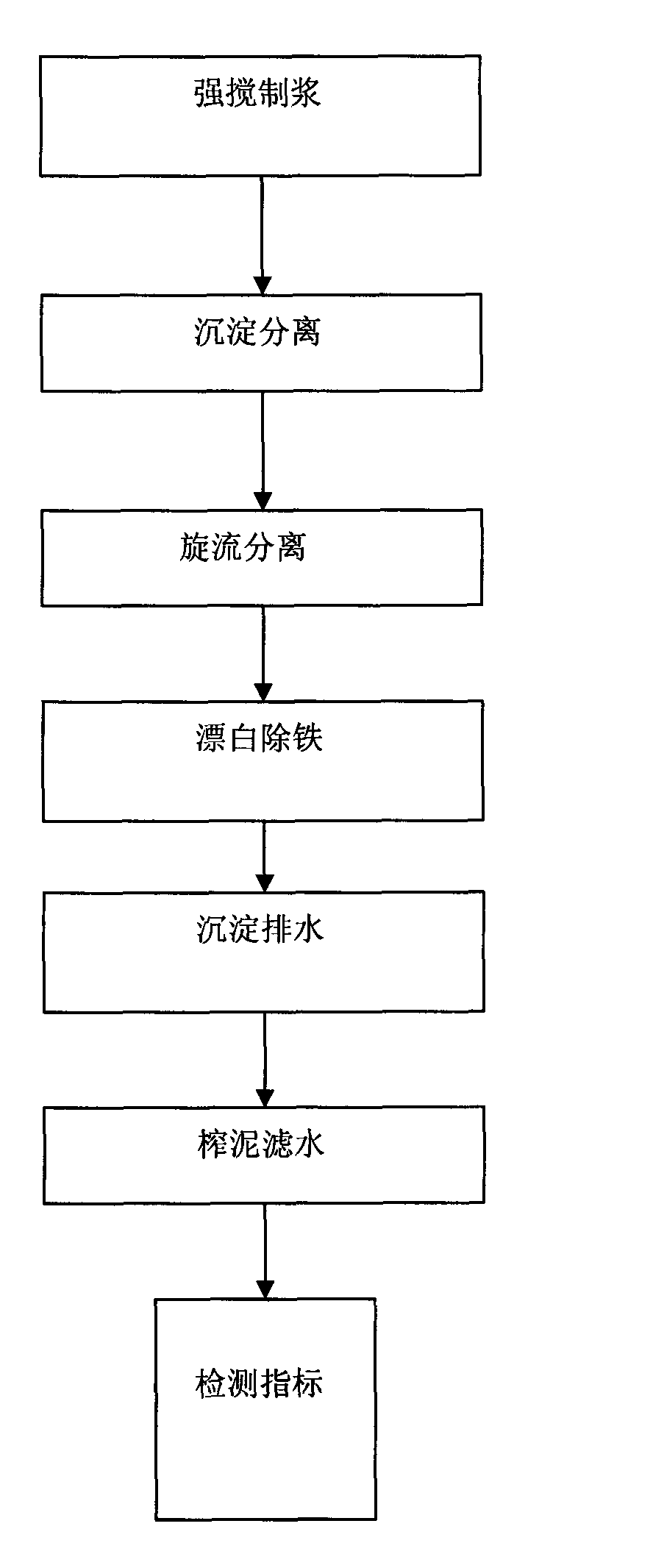

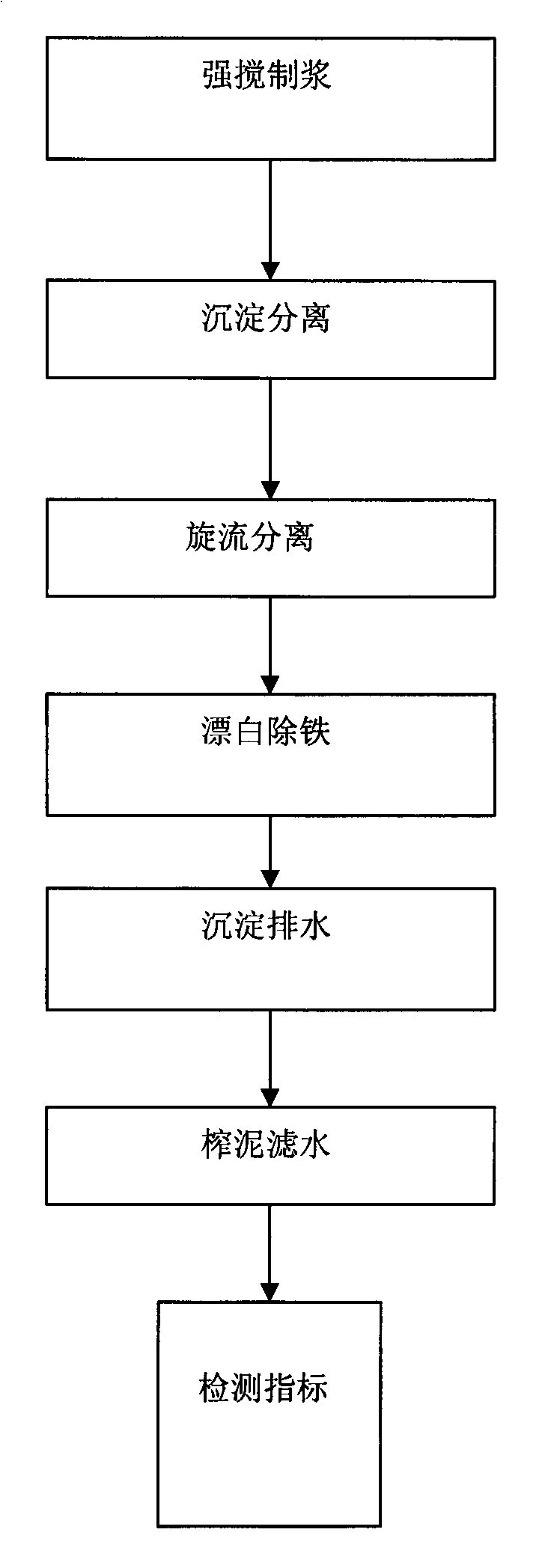

[0011] see figure 1 , because many harmful substances in kaolin limit its application, it is necessary to purify the raw ore of kaolin. When implementing the non-pickling kaolin raw ore preparation method involved in the present invention, first pour the kaolin after the grinding mesh into the stirring tank, and follow the steps under the premise of using special batching equipment and containers:

[0012] ①Strong agitation pulping-sedimentation separation-swirl separation-bleaching iron removal-sedimentation drainage-squeezing mud filtration-testing indicators.

[0013] ②Add chelating agent to reduce the oxidation ability of Fe2+ and improve the iron removal efficiency of the product.

[0014] ③Add cationic adsorbent (cation adsorbent: Fe 2+ (molar ratio)=0.5~1.5:1), reduce the adsorption of Fe on the surface of kaolin 2+ The ability to improve the iron removal efficiency of the product.

[0015] ④ Add strong water sinking agent to increase pulp concentration and increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com