Method for controlling slag overflow in converter tapping process

A technology of tapping process and converter, applied in the direction of manufacturing converters, etc., can solve the problems of increasing and decreasing the probability of outliers, outliers in molten steel composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

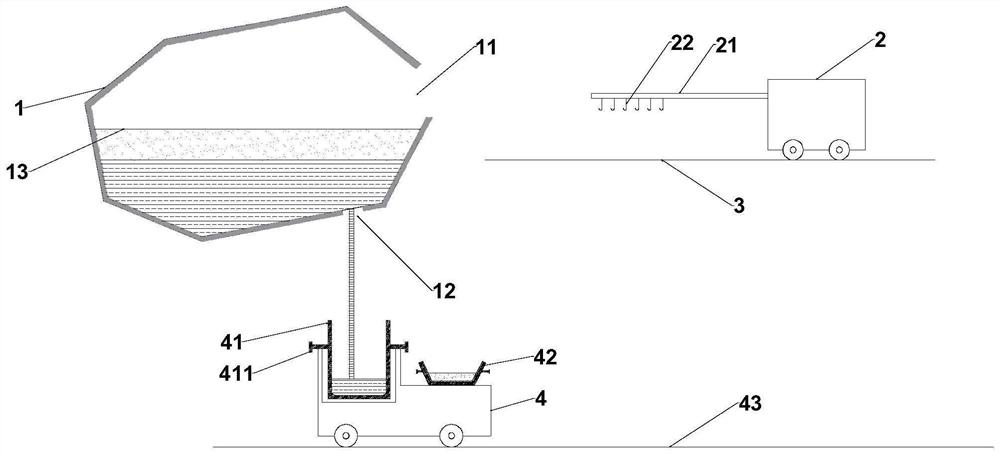

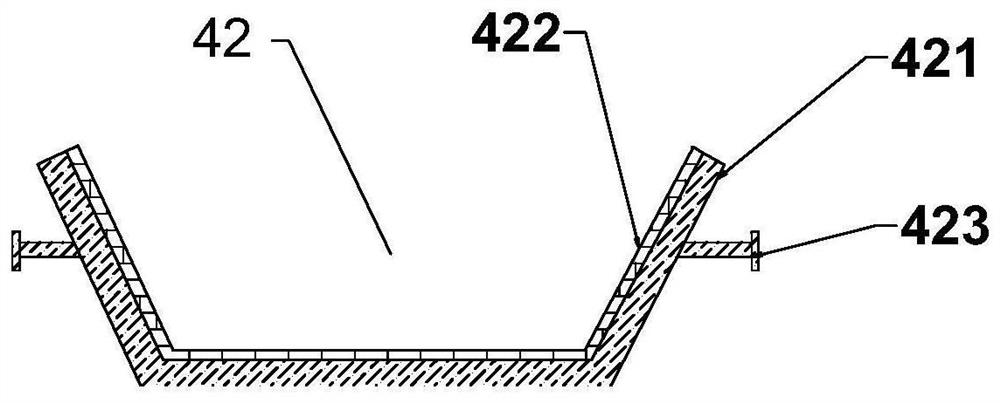

[0028] The invention provides a method for controlling slag overflow in the tapping process of a converter, which mainly includes the following steps:

[0029] S1. After the blowing of converter 1 is completed, 1-1.5 kg / t of dolomite is added into the furnace mouth 11 of the converter through the high-level feed bin at one time. The dolomite components are CaO≥30wt%, MgO≥19wt%; add this component The main purpose of the dolomite is to cool down the slag, increase the MgO content of the slag, reduce the foaming of the slag, and at the same time, the cost is low, which is beneficial to the subsequent routine maintenance of the furnace body;

[0030] S2. Adjust the height of the converter oxygen lance and purge the slag surface with high-pressure nitrogen: In order to cooperate with the nitrogen power purge after dolomite is added, after combining comprehensive factors such as furnace type, molten pool height, slag surface height, and purge damage to the furnace body, etc. Lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com