Kitchen wet wipe and preparation method of kitchen wet wipe impregnation liquid

A technology for wet wipes and kitchen is applied in the field of preparation of kitchen wet wipes and kitchen wet wipes soaking liquid, which can solve the problem of difficult cleaning of oil stains, and achieve the effects of strong oil removal power, strong cleaning ability and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of kitchen wet towel and the preparation method of kitchen wet towel soaking liquid

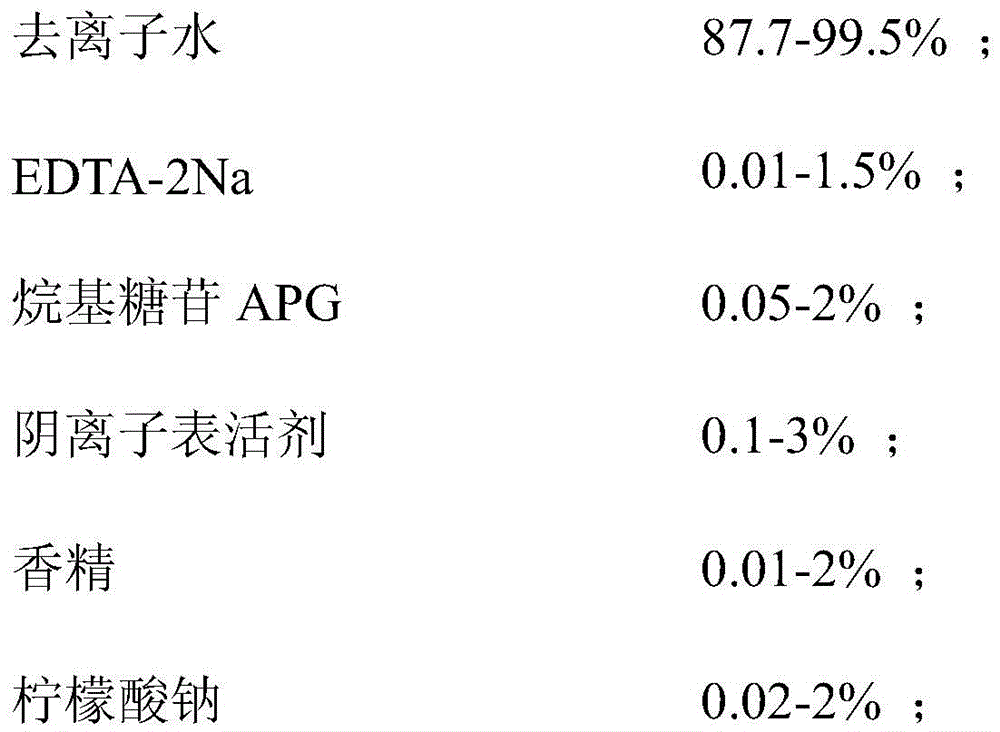

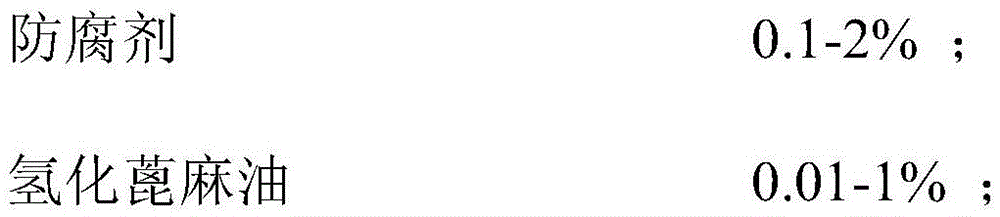

[0026] A kitchen wet towel, which is composed of a wet towel carrier and a kitchen wet towel soaking solution, the wet towel carrier is a pearl pattern non-woven fabric; in terms of weight percentage, the kitchen wet towel soaking solution is composed of the following components :

[0027]

[0028] The pH of the soaking solution of the kitchen wet towel is 5.8-6.3.

[0029] The preparation method of this example kitchen wet towel dipping liquid comprises the following steps:

[0030] (1) Add deionized water to the liquid distribution tank;

[0031] (2) Weigh the remaining raw materials with an electronic scale, and add EDTA-2Na, alkyl glycoside APG, anionic surfactant, and preservative to the liquid mixing tank, and stir for 20 minutes;

[0032] (3) Mix the essence and hydrogenated castor oil, heat and stir at a constant temperature of 30±5°C for 10 minutes, a...

Embodiment 2

[0034] Embodiment 2 A kind of kitchen wet towel and the preparation method of kitchen wet towel soaking liquid

[0035] A kitchen wet towel, which is composed of a wet towel carrier and a kitchen wet towel soaking solution, the wet towel carrier is a pearl pattern non-woven fabric; in terms of weight percentage, the kitchen wet towel soaking solution is composed of the following components :

[0036]

[0037] The pH of the soaking solution of the kitchen wet towel is 5.8-6.3.

[0038] The preparation method of this example kitchen wet towel comprises the following steps:

[0039] (1) Add deionized water to the liquid distribution tank;

[0040] (2) Weigh the remaining raw materials with an electronic scale, and add EDTA-2Na, alkyl glycoside APG, anionic surfactant, and preservative to the liquid mixing tank, and stir for 20 minutes;

[0041] (3) Mix the essence and hydrogenated castor oil, heat and stir at a constant temperature of 30±5°C for 10 minutes, and then add it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com