Cleaning agent used for solar grade silicon wafers and preparing method thereof

A technology for solar-grade silicon wafers and cleaning agents, which is applied in the directions of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of few rinsing steps, high cleaning efficiency, low cleaning foam, etc., and achieve cleaning effect. Good, simple formula, low foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

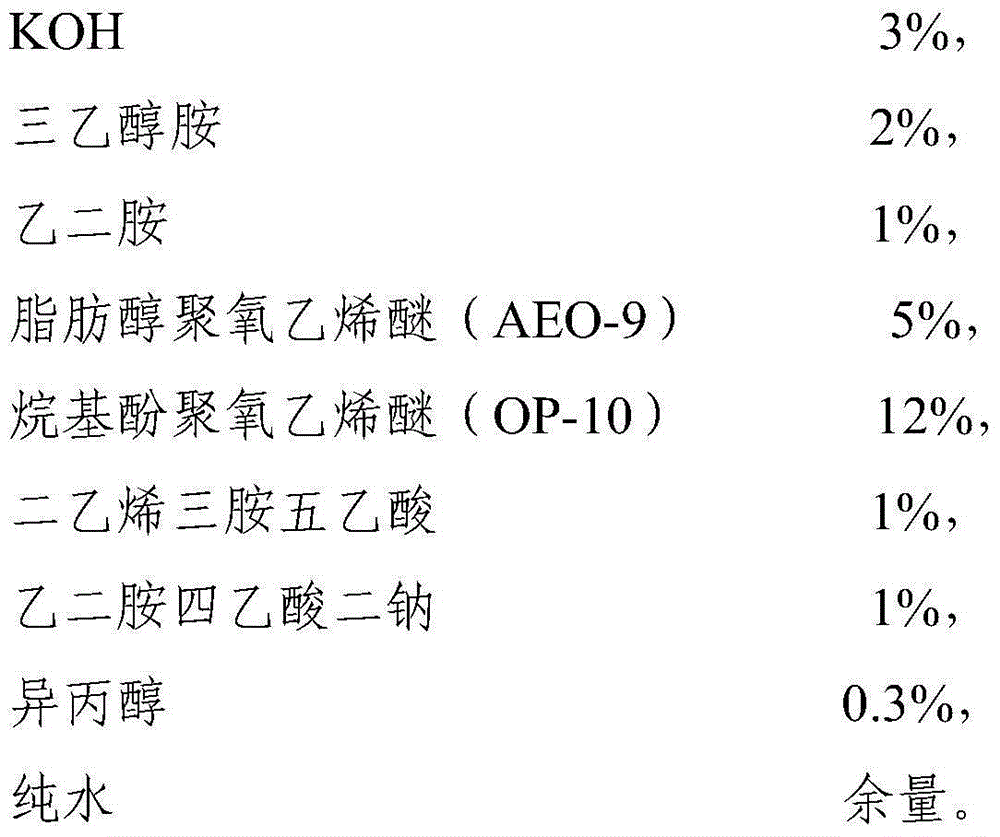

[0022] Cleaning agent comprises the raw material of following weight portion:

[0023]

[0024] The preparation method of the above-mentioned cleaning agent is as follows: firstly mix the pure water and the surfactant fatty alcohol polyoxyethylene ether and alkylphenol polyoxyethylene ether, and slowly add KOH in small amounts several times while stirring at a speed of 400 rpm, and continue Stir for 20 minutes, and finally add complexing agent diethylenetriaminepentaacetic acid; corrosion inhibitor triethanolamine, ethylenediamine and auxiliary agent isopropanol, stir to dissolve completely, and obtain the cleaning agent.

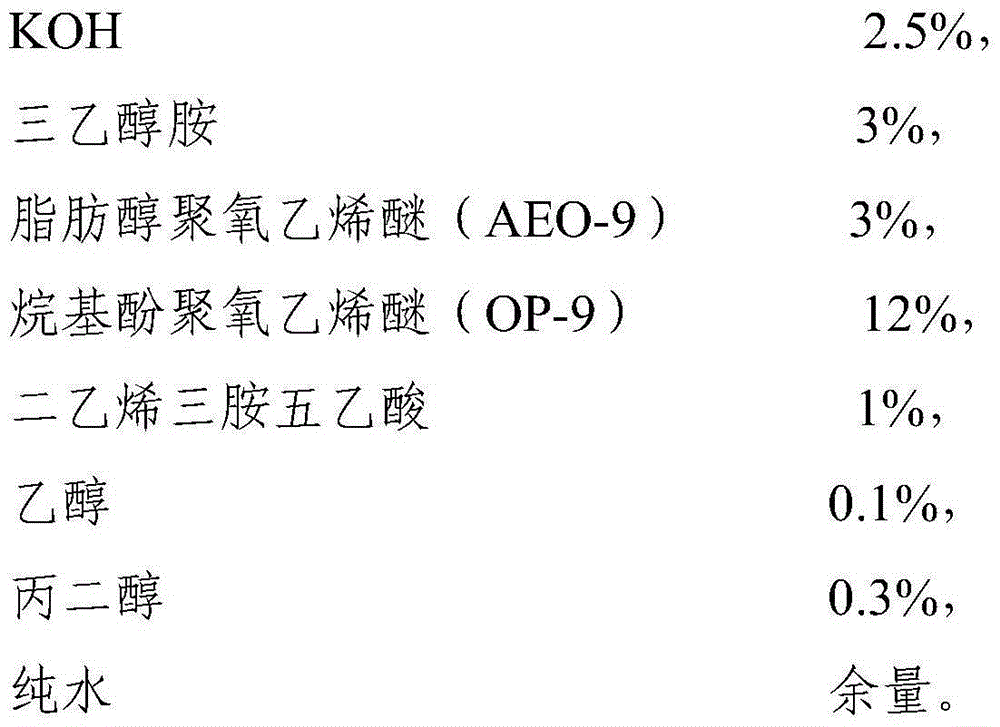

Embodiment 2

[0026]

[0027] The preparation method of the above-mentioned cleaning agent is as follows: firstly mix the pure water and the surfactant fatty alcohol polyoxyethylene ether and alkylphenol polyoxyethylene ether, and slowly add KOH in small amounts several times while stirring at a speed of 500 rpm, and continue Stir for 10 minutes, and finally add complexing agents diethylenetriaminepentaacetic acid and disodium ethylenediaminetetraacetate; corrosion inhibitor triethanolamine and auxiliary agents ethanol and propylene glycol, and stir to dissolve completely to obtain a cleaning agent.

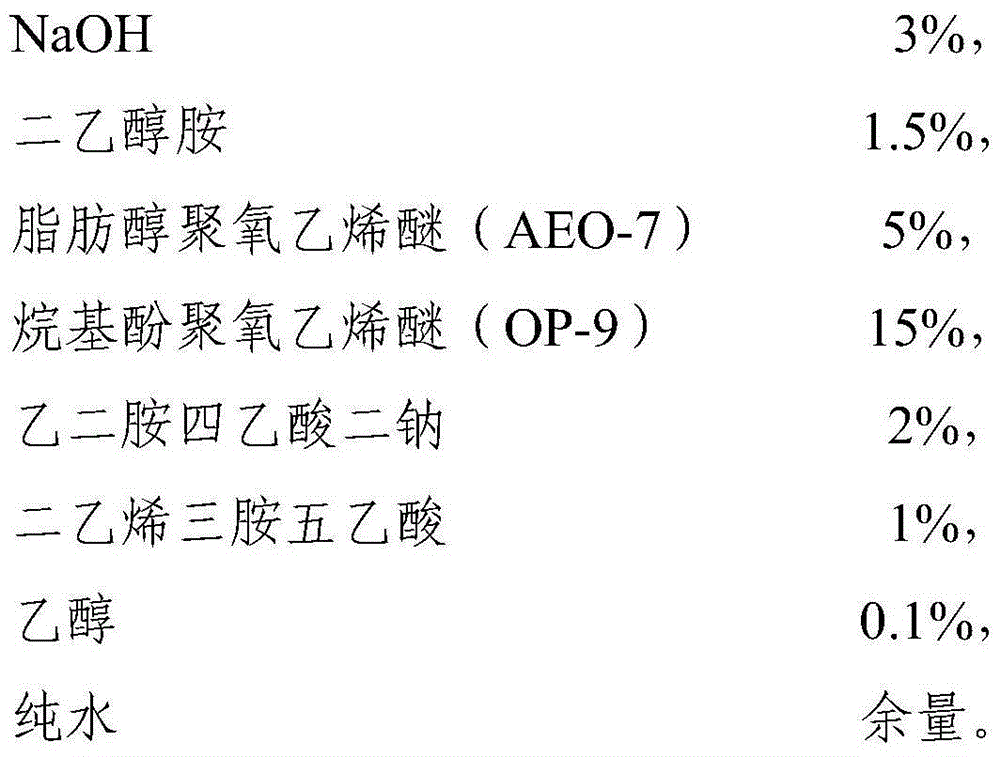

Embodiment 3

[0029] Concrete formula is as follows in the present embodiment:

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com