Photosensitive resin composition, photosensitive element employing the same, method of forming resist pattern, and process for producing printed wiring board

A photosensitive resin and photoresist technology, which is used in the manufacture of printed circuits, printed circuits, and the removal of conductive materials by chemical/electrolytic methods. Achieve good product qualification rate, reduce replacement frequency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~4

[0143] Binder polymers 1 to 3 as (A) component, photopolymerizable compounds 1 to 5 as (B) component, photopolymerization initiator as (C) component, additives, and solvents were listed in Table 1. Mixed as shown, the solution of the photosensitive resin composition of Examples 1-3 and Comparative Examples 1-4 was obtained. And the preparation of a solution mixes (B) component after mixing components other than (B) component first. The compounding quantity in Table 1 is shown by mass parts. In addition, (A) component shows the compounding quantity of a solid content.

[0144] Table 1

[0145] Material

[0146]

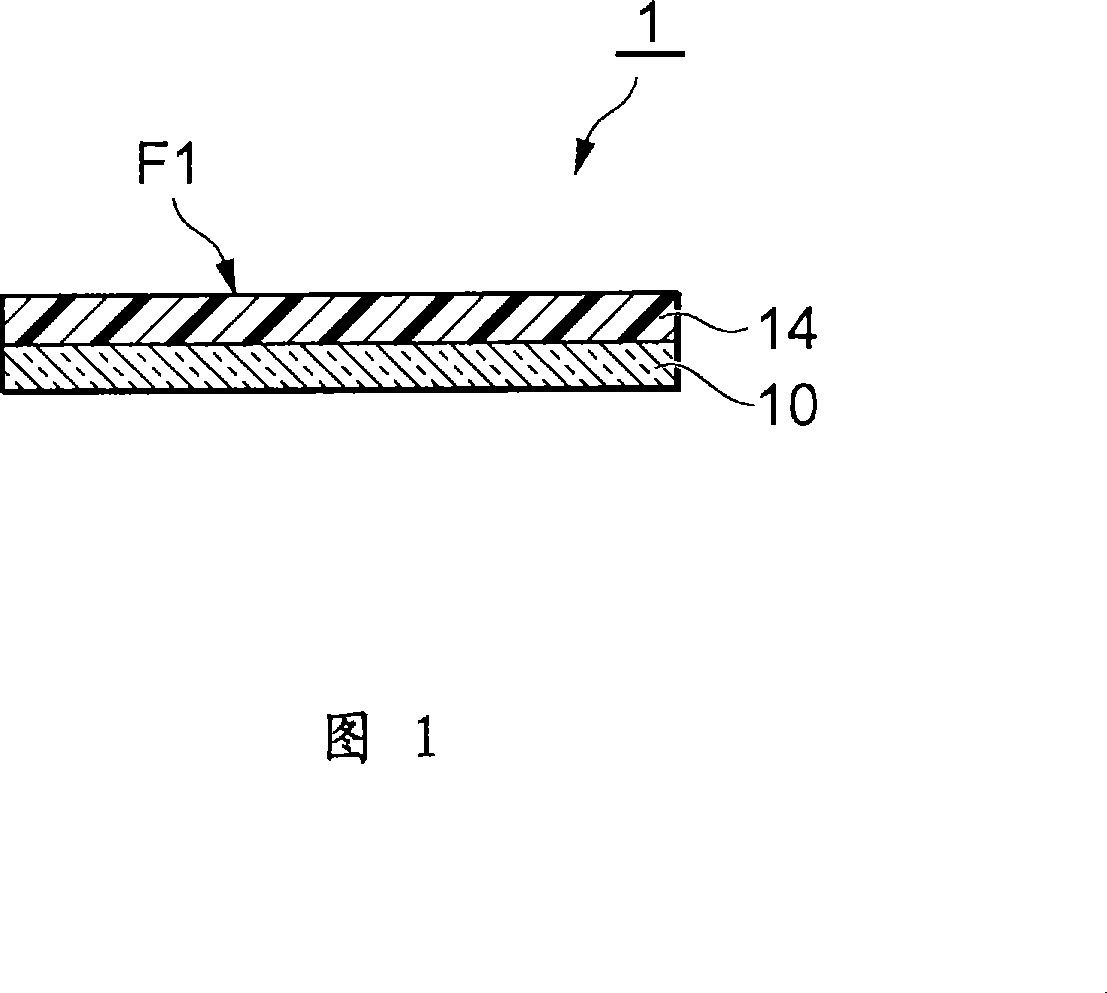

[0147] Using the solution of the photosensitive resin composition of Examples 1-3 and Comparative Examples 1-4, the photosensitive element was produced according to the following process procedure. First, on a polyethylene terephthalate film with a width of 380mm and a thickness of 16μm (manufactured by Teijin Corporation, trade name "G2-16" (hereinafte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com