Preparation method of iron ore powder pelletized magnesian binding agent

A preparation method and technology of iron ore powder, applied in the field of metallurgy, can solve the problems of increasing the viscosity of slag, reducing the grade of pellets, and high price, and achieve low-temperature pulverization and high-temperature metallurgical performance improvement, which is conducive to the stability and smooth operation of blast furnaces. Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: A company's No. 1 shaft furnace carried out an industrial test of replacing bentonite with magnesia binder.

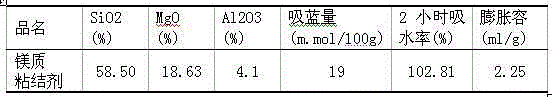

[0019] The chemical composition and properties of the raw materials used are shown in Table 1.

[0020] Table 1 embodiment one used raw material chemical composition and performance table

[0021]

[0022] Preparation process steps:

[0023] (1) Mixing and adding: the ratio of raw materials is 95% sepiolite and 5% magnesite, and the mass percentage of the chemical composition after preparation is SiO 2 58.5%, MgO18.63%, Al 2 o 3 4.1%, the blue absorption is 19m.mol / 100g, the water absorption is 102.81% in 2 hours, and the expansion capacity is 2.25ml / g; after mixing, fully mix with a spiral mixer or a cylinder mixer.

[0024] (2) Coarse crushing: use a hammer crusher or a jaw crusher to crush the mixture of sepiolite and magnesite until the particle size is less than 3mm.

[0025] (3) Grinding: Use a Raymond mill or a medium-speed mill to cont...

Embodiment 2

[0029] Example 2: A company's No. 2 shaft furnace conducts an industrial test of replacing bentonite with magnesia binder.

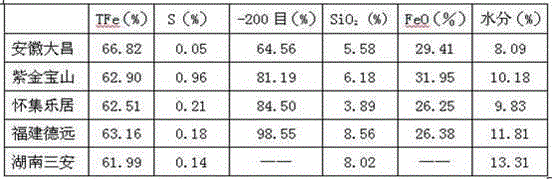

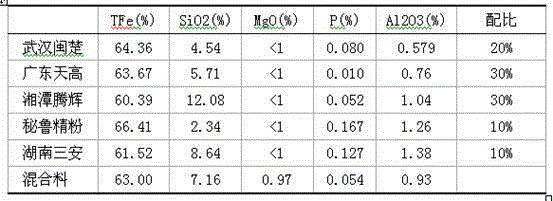

[0030] The chemical composition and properties of the raw materials used are shown in Table 3.

[0031] Table 3 embodiment two used raw material chemical composition and performance table

[0032]

[0033] Preparation process steps:

[0034] (2) Mixing and adding: the ratio of raw materials is 94% sepiolite and 6% magnesite, and the mass percentage of the chemical composition after preparation is SiO 2 57.9%, MgO18.89%, Al 2 o 3 3.8%, the blue absorption is 18.5m.mol / 100g, the 2-hour water absorption is 101.21%, and the expansion capacity is 2.43ml / g; after mixing, use a spiral mixer or a cylinder mixer to fully mix.

[0035] (2) Coarse crushing: use a hammer crusher or a jaw crusher to crush the mixture of sepiolite and magnesite until the particle size is less than 3mm.

[0036] (3) Grinding: Use a Raymond mill or a medium-speed mill to continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com