Low-expansion high-fracture-resistance tundish retaining wall castable

A high-resistance, castable technology, applied in the direction of improving process efficiency, can solve problems such as lack of purification of molten steel, high cost, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

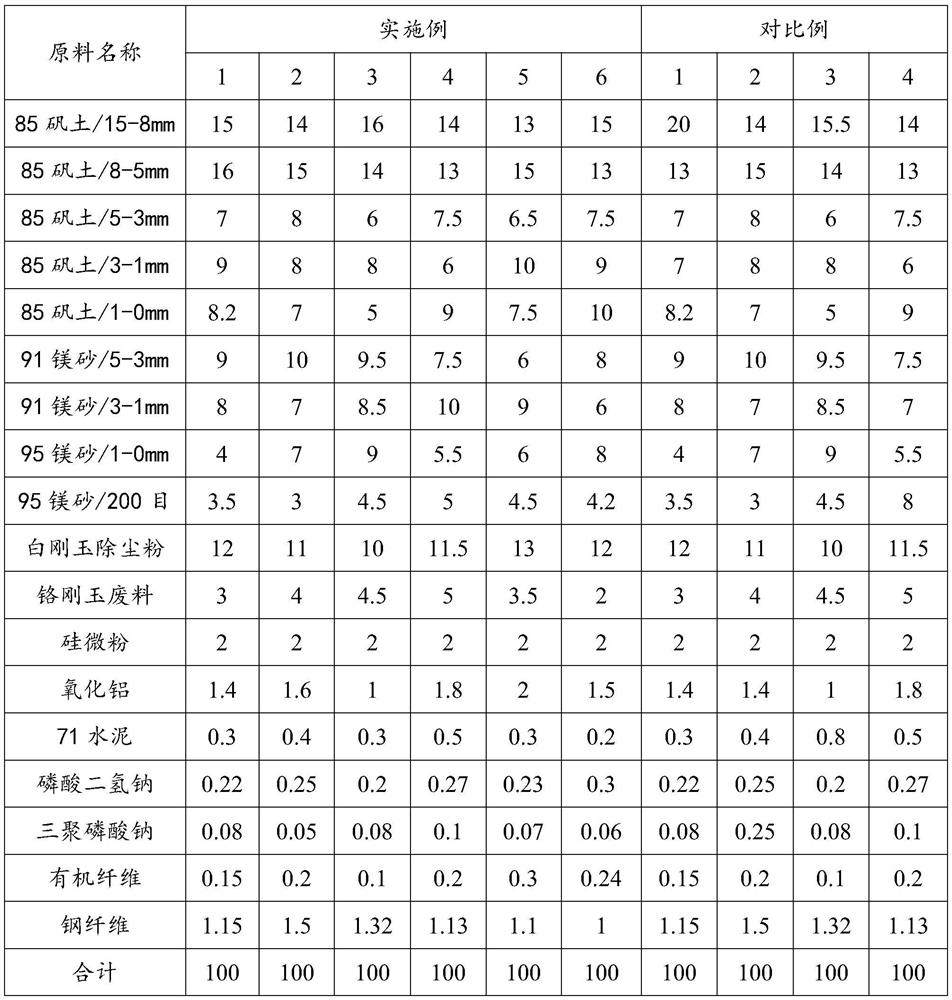

[0020] As a preferred embodiment of the present invention, the 85 alumina with a particle size of 15-8mm is 15%, the 85 alumina with a particle size of 8-5mm is 16%, and the 85 alumina with a particle size of 5-3mm is 7% , 85 alumina with a particle size of 3-1mm is 9%, 85 alumina with a particle size of 1-0mm is 8.2%, 91 magnesia with a particle size of 5-3mm is 9%, and 91 magnesia with a particle size of 3-1mm is 8%, 95 magnesia with a particle size of 1-0mm is 4%, 95 magnesia with a particle size of 200 mesh is 3.5%, white corundum dust is 12%, chrome corundum waste is 3%, silicon micropowder is 2%, alumina 1.4%, 71 cement 0.3%, sodium dihydrogen phosphate 0.22%, sodium tripolyphosphate 0.08%, organic fiber 0.15% and steel fiber 1.15%.

[0021] As a preferred embodiment of the present invention, the particle size of the white corundum dust removal powder is 200 mesh, Al2O3≥95%; the particle size of the chromium corundum waste is 200 mesh, Cr2O3≥60%; the SiO2 in the silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com