High-wear-resistance high-chromium cast iron universal roll collar and preparation method thereof

A high-chromium cast iron, high wear-resistant technology, used in casting molding equipment, molds, rolls, etc., can solve the problems of short rolling cycle, poor wear resistance, no wear resistance, etc. Effect of surface hardness and texture homogeneity, preventing risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

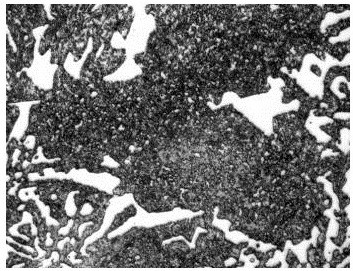

Image

Examples

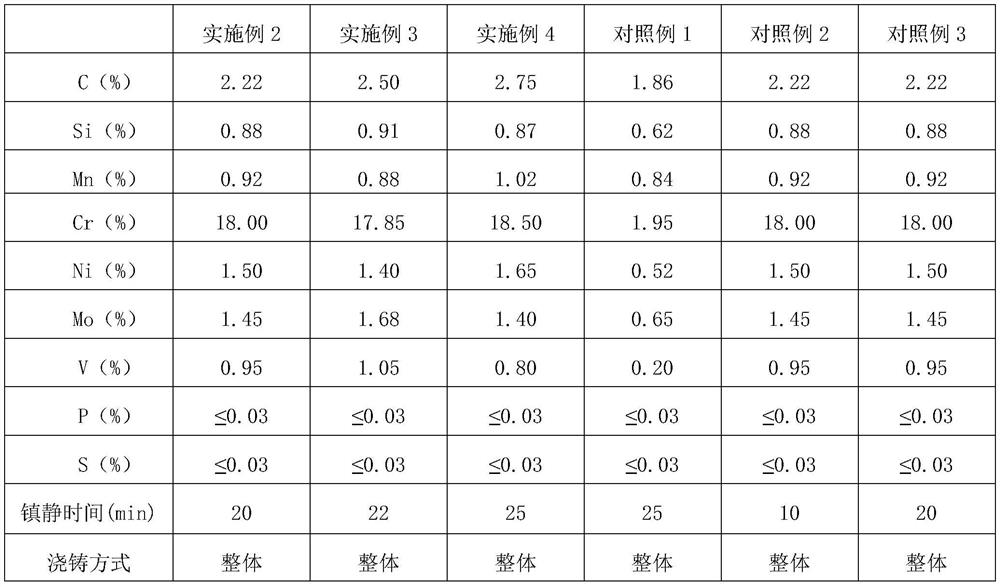

Embodiment 1

[0033] (1) Put the prepared alloy raw materials into an intermediate frequency furnace for smelting. The weight percentage of the raw material alloy composition and each alloy composition is C: 2.40%, Si: 0.80%, Mn: 0.85%, Cr: 15.0%, Ni : 1.45%, Mo: 1.40%, V: 0.85%, P≤0.03%; S≤0.03%, the rest is Fe and unavoidable impurities.

[0034] (2) After the smelting in step (1) is completed, the molten steel is quenched for 25 minutes.

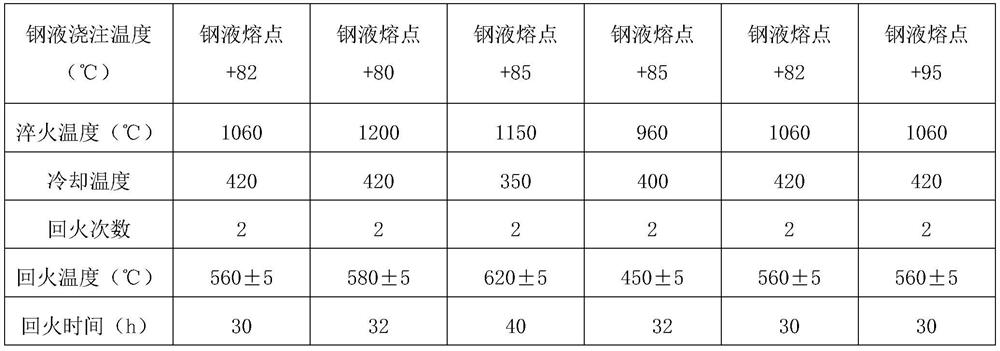

[0035] (3) When the temperature of the molten steel reaches the melting point of the molten steel + 80°C, pouring is started using the overall method;

[0036] (4) Carry out quenching treatment after the cast casting that step (3) pours is machined, and quenching temperature is 1060 ℃, then cools;

[0037] (5) When cooling to 420°C, stop cooling and carry out two-stage tempering treatment, the tempering temperature is 570±5°C, and the tempering time is 35h respectively to obtain a high wear-resistant high-chromium cast iron universal roll ring and a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com