Single-stander furnace rolling mill rolling plate shot-blasting pitted surface control method

A technology of a steckel rolling mill and a control method, which is applied in the field of metallurgy and can solve problems such as manual grinding and repair welding difficulties, large economic losses, and long rolled pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

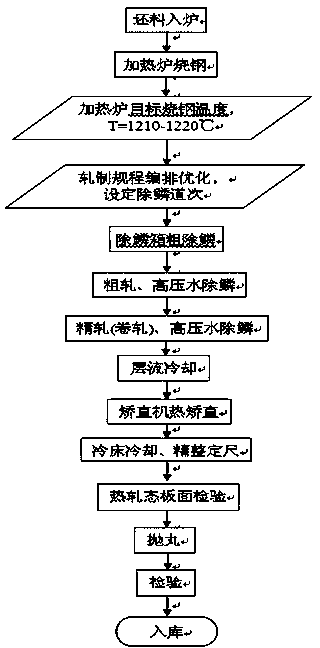

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, 150×3089×8205mm and 150*3089*8242mm large billet coils and rolled plates are selected, and the rolled finished product thickness is 8mm steel grade DNV-A. The entire rolling process is controlled as follows:

[0032] (1) Heating furnace to burn steel

[0033] Increase the firing temperature of the heating furnace to increase the rolling temperature of the rolled piece, and reasonably control the time of the billet in the furnace. See Table 1 for specific heating furnace steel burning process control.

[0034]

[0035] Table 1 Control data of heating furnace steel burning process

[0036] Billet No. Rolled Steel Billet specification furnace time Tapping temperature 01 DNV-A 150×3089×8205mm 147min 1215℃ 02 DNV-A 150×3089×8242mm 171min 1202℃

[0037] (2) Rolling schedule arrangement

[0038] While ensuring the shape of the plate, the rolling schedule is compiled according to the principle of least pass rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com