Super duplex stainless steel S32750 medium plate rolling process

A technology of duplex stainless steel and medium plate, applied in the field of steel rolling process, can solve problems such as cracks and steel plate scrap, and achieve the effects of reducing production costs, improving enterprise economic benefits, and increasing heating process temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Comparative Example 1

[0028] The method of rolling super duplex stainless steel S32750 medium plate according to the original process:

[0029] 1. Billet specifications and finished product specifications

[0030] Blank specification: 160*1238*1600mm; finished product specification: 11.5*1550*6000mm

[0031] 2. Heating process

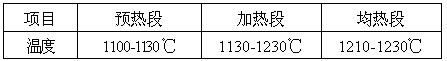

[0032] Total heating time 176 minutes

[0033]

[0034] 3. Rolling process

[0035] (1) The rolling temperature of the second roll is 1030°C, and the width is 200mm;

[0036] (2) The four-roll start rolling temperature is 980°C and the finish rolling temperature is 725°C;

[0037] (3) The feeding thickness of the two rollers is 41mm;

[0038] (4) Reduction pass and pass reduction rate: 11 passes for two-rollers, and the pass reduction rate is less than 20%, 13 passes for four-rollers, and the pass reduction rate is less than 20%;

[0039] 4. Rolling result

[0040] Due to the low heating temperature, many rolling passe...

Embodiment 2

[0041] Embodiment 2: comparative example 2

[0042] The method of rolling super duplex stainless steel S32750 medium plate according to the original process:

[0043] 1. Billet specifications and finished product specifications

[0044] Blank specification: 150*1238*1700mm; finished product specification: 11.5*1550*6000mm

[0045] 2. Heating process

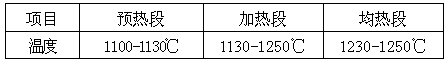

[0046] Total heating time is 168 minutes

[0047]

[0048] 3. Rolling process

[0049] (1) The rolling temperature of the second roll is 1050°C, and the width is 200mm;

[0050] (2) The four-roll start rolling temperature is 990°C, and the finish rolling temperature is 780°C;

[0051] (3) The feeding thickness of the two rollers is 26mm;

[0052] (4) Reduction pass and pass reduction rate: 13 passes with two rolls, reduction rate of each pass is less than 20%, 11 passes with four rolls, reduction rate of each pass is less than 20%;

[0053] 4. Rolling results

[0054] The feeding material of the second roll is relati...

Embodiment 3

[0056] Carry out the method for super duplex stainless steel S32750 plate rolling according to technology of the present invention:

[0057] (1) Select the medium plate rolling billet and finished product specifications:

[0058] Blank specification: Thickness*Width*Length corresponds to blank specification: 130*1238*1950mm,

[0059] Finished product specifications: thickness*width*length corresponds to 11.5*1550*6000mm;

[0060] (2) heating

[0061] Push the billet into the pusher type heating furnace for heating. The billet in the furnace should run at a constant speed to achieve uniform heating. During the process, the phenomenon of waiting for heating or waiting for time is not allowed. The billet is heated from 1100°C to 1250°C, and the temperature is controlled during the soaking stage At 1230-1250°C, the residence time of the continuous casting slab is 8-12min / 10mm;

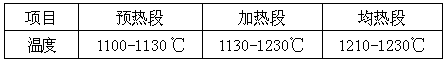

[0062] Total heating time is 150 minutes

[0063]

[0064] (3) High pressure water descaling

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com