Method and device for determining oxidation burning loss rate of plate blank

A technology for slabs and steel plates, which is applied in the field of determining the oxidation and burning loss rate of slabs, and can solve problems such as large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Here, since the short-flow roller hearth heating furnace is located in the middle of the continuous casting production line, the layout is compact, the continuous casting pendulum shear is only 4m away from the entrance of the road, and there is no space for cold slabs, so it is impossible to use the weighing method to measure the oxidation burning rate. and the temperature of the steel in the furnace is high, because the continuous casting outlet temperature is generally 980 ℃ ~ 1050 ℃, and the oxide scale is continuously generated during the steel loading process, so it is impossible to use the indirect measurement method of the oxide scale to determine the oxidation burning loss rate. Determination.

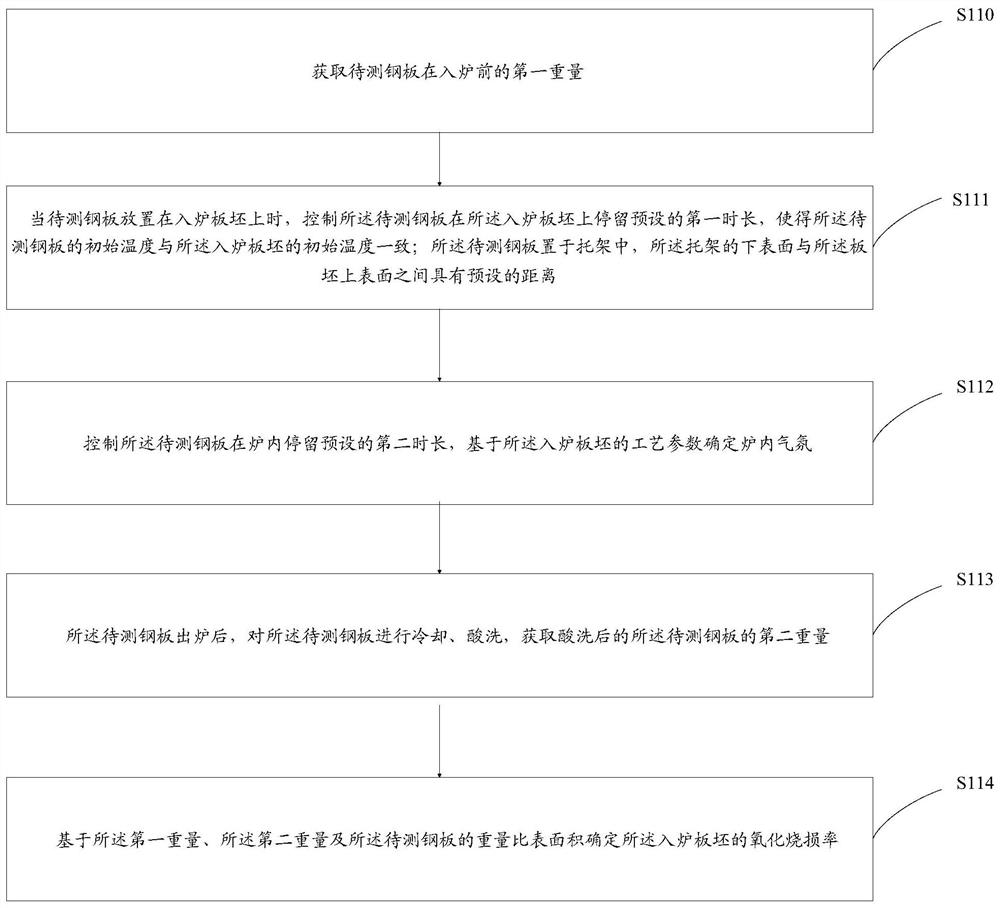

[0039] Therefore, this embodiment provides a method for determining the oxidation loss rate of slabs, which is applied to short-flow roller hearth heating furnaces in continuous casting production lines, such as figure 1 As shown, the methods include:

[0040] S110, ob...

Embodiment 2

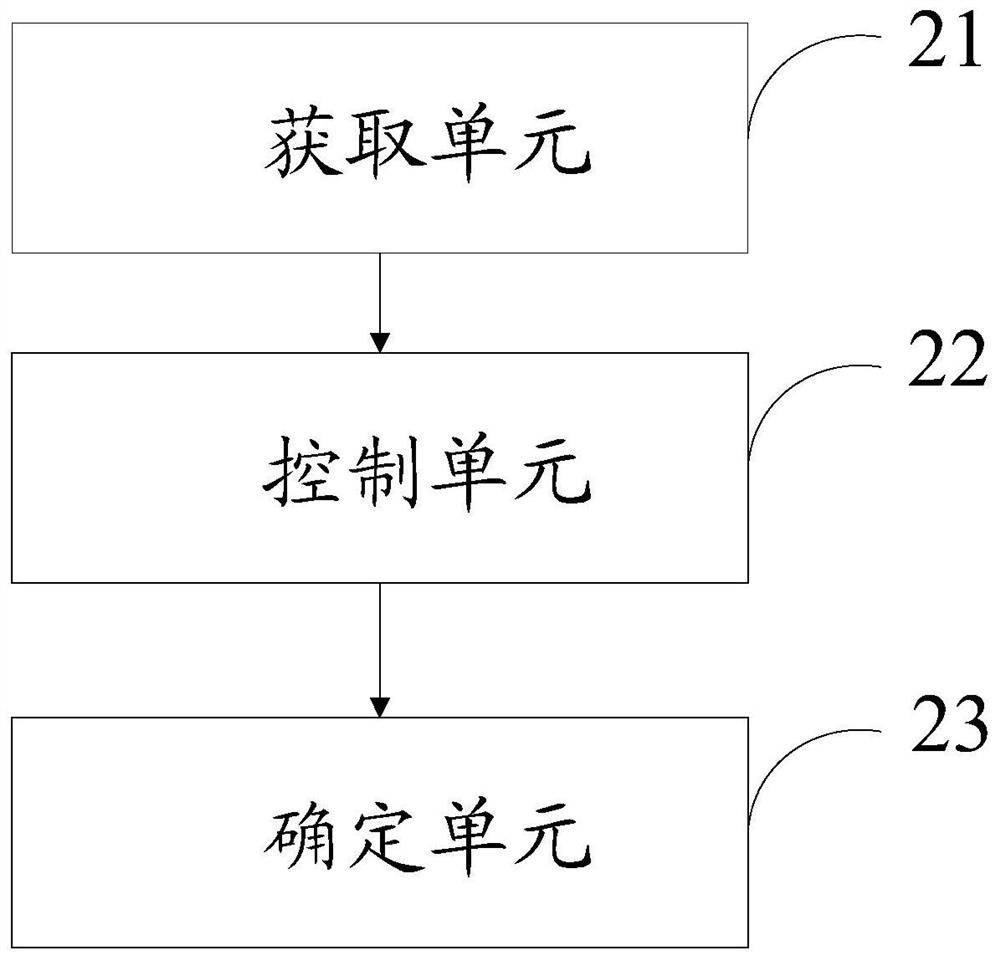

[0063] This embodiment provides a device for determining the oxidation loss rate of slabs, such as figure 2 As shown, the device includes: an acquisition unit 21, a control unit 22 and a determination unit 23;

[0064] The acquisition unit 21 is configured to acquire the first weight of the steel plate to be tested before being put into the furnace; after the steel plate to be tested is released from the furnace, the steel plate to be tested is cooled and pickled, and the weight of the steel plate to be tested is obtained after pickling. second weight;

[0065] The control unit 22 is configured to control the steel plate to be tested to stay on the furnace slab for a preset first time when the steel plate to be tested is placed on the furnace slab so that the initial temperature of the steel plate to be tested is It is consistent with the initial temperature of the slab entering the furnace; the steel plate to be tested is placed in a bracket, and there is a preset distance ...

Embodiment 3

[0086] In practical application, when using the method provided in Example 1 and the device provided in Implementation 2 to measure the oxidation loss rate of the slab, the specific implementation is as follows:

[0087] Take 3 steel plates with a width of 200-250mm, a length of 300-350mm, and a thickness of 1.5-2mm, and 3 stainless steel brackets. Bind to the stainless steel bracket with flammable materials such as plastic rope.

[0088] The tail billet of continuous casting stops after pendulum shearing, and the bound steel plate is placed on the upper surface of the slab. The stainless steel bracket can ensure that the steel plate to be tested is 30mm away from the slab, and after staying for 2 minutes, the continuous casting tail billet is put into the furnace. Set the forward speed of the slab to 3.5 m / min, and the tail billet slowly advances to the traverse section of the continuous casting machine. , After the slab is always in the furnace for 18 minutes, the slab is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com