Quenching apparatus for tool edge

A technology of quenching device and cutting edge, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., to achieve the effect of convenient use, improved accuracy and accurate heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

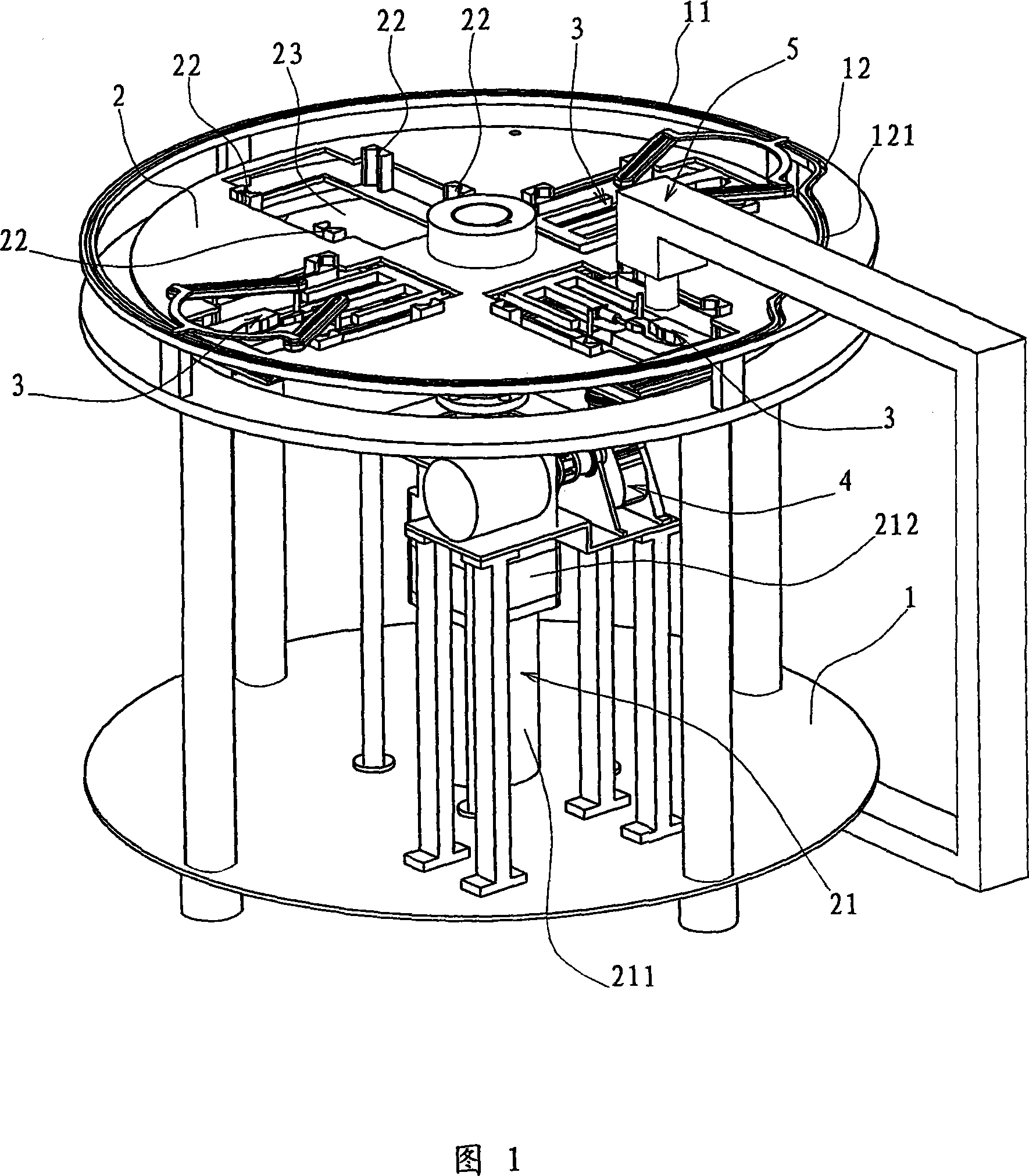

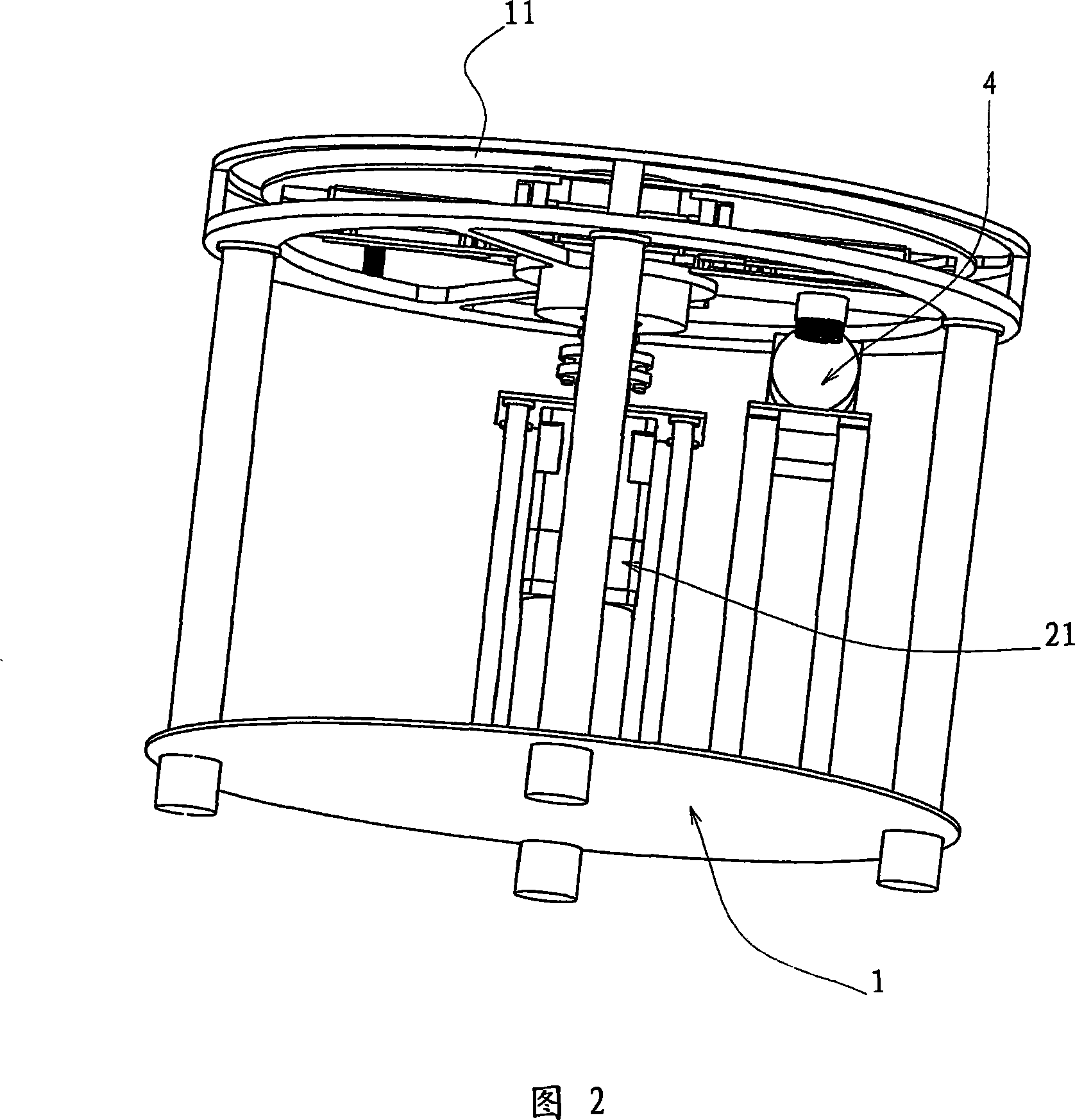

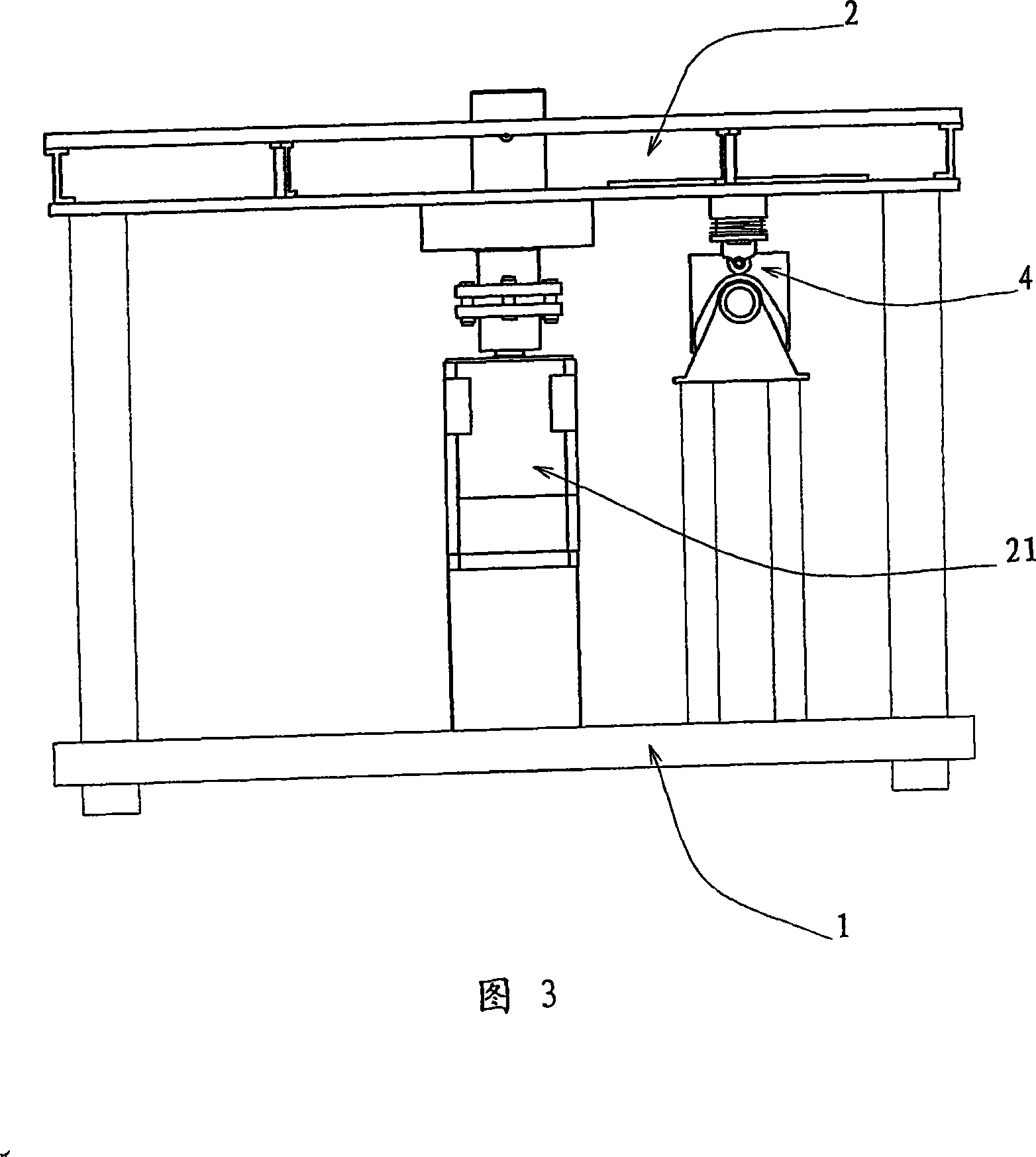

[0024] see figure 1 , figure 2 and image 3 , in an embodiment given by the present invention, comprising a frame 1, a rotary table 2 installed on the frame 1 and a plurality of clamps 3 installed on the rotary table 2, the A high-frequency quenching device 5 is installed on the frame 1, and the rotary table 2 is driven by a driving device 21 to move intermittently. The high-frequency quenching device 5 can correspond to each fixture 3 according to a certain period, so that all The high-frequency quenching device 5 quenches the workpiece in each fixture 3 . The high-frequency quenching device 5 is located above the rotary table 2, and its specific structure belongs to relatively mature prior art, so its specific structure and working principle will not be repeated here.

[0025] see figure 1 and image 3 , in the above embodiments of the present invention, the frame 1 is provided with a lifting mechanism 4, and the lifting mechanism 4 drives the clamp 3 to reciprocate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com