Patents

Literature

101results about How to "Control heating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

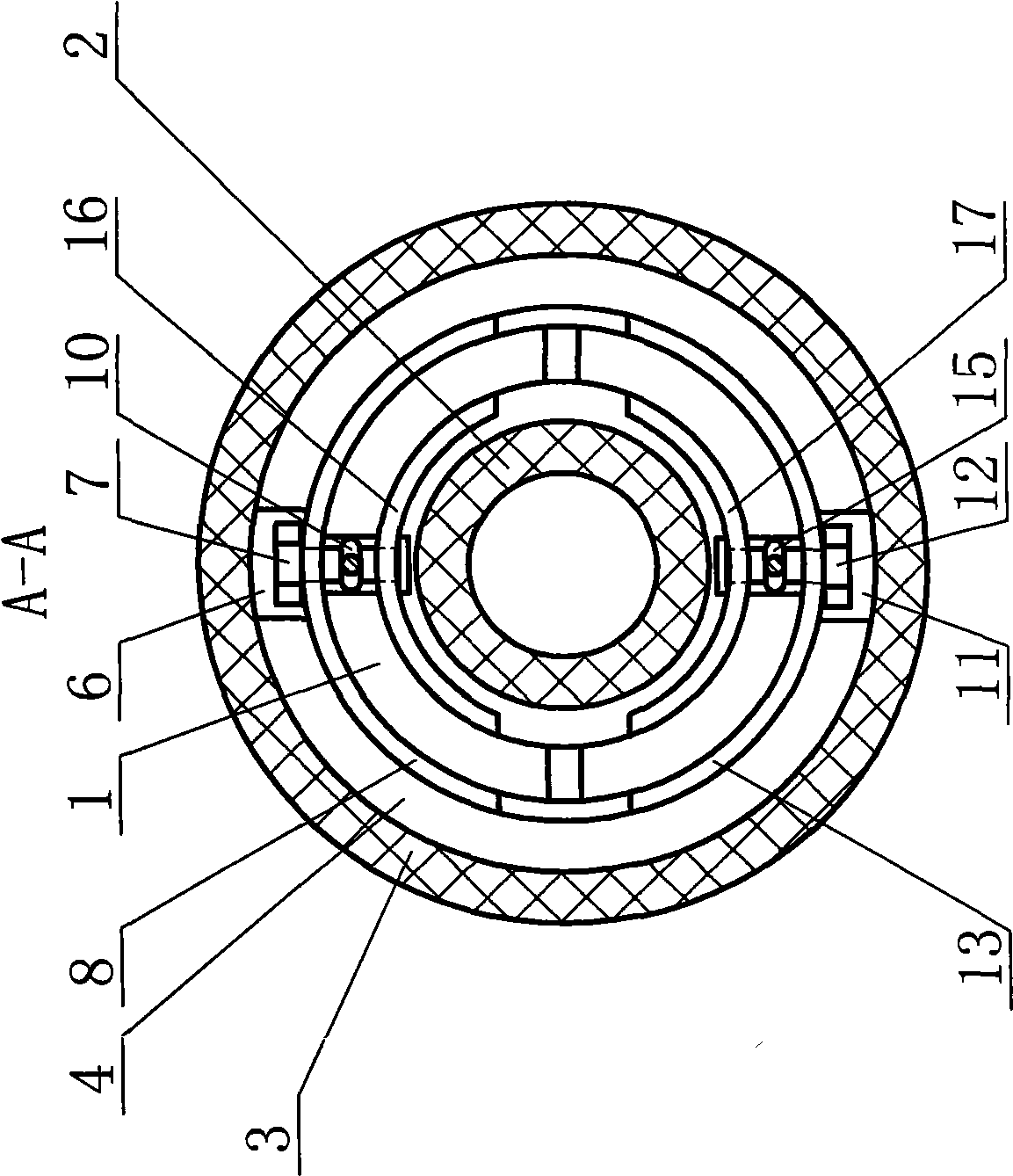

Solid energy storage electric boiler and heat exchanging structure thereof

InactiveCN102175018AUniform and effective conductionRuntime controlSteam generation heating methodsHeat storage plantsBrickExothermic process

The invention aims to overcome the defects of the existing heating plants, such as a boiler, and to provide a solid energy storage electric boiler and a heat exchanging structure thereof. A heat storage brick is utilized as a heat storage medium for the solid energy storage electric boiler, and a high-capacity heat exchanging structure with a controllable exothermic process. Particularly, the heat exchanging structure comprises a heat storage structure, a heat insulation material layer, a heat insulation wall with holes, a heat exchanger and an outer shell; two ends of the outer shell are provided with air openings; the heat storage structure, the heat insulation wall with holes and the heat exchanger are arrayed in the outer shell; the heat insulation material is placed among the heat storage structure, the heat insulation wall with holes and the outer shell; and the heat exchanging structure also comprises an air door, a fan and a circulation outer air duct.

Owner:北京蓝景圣诺尔能源科技有限公司 +1

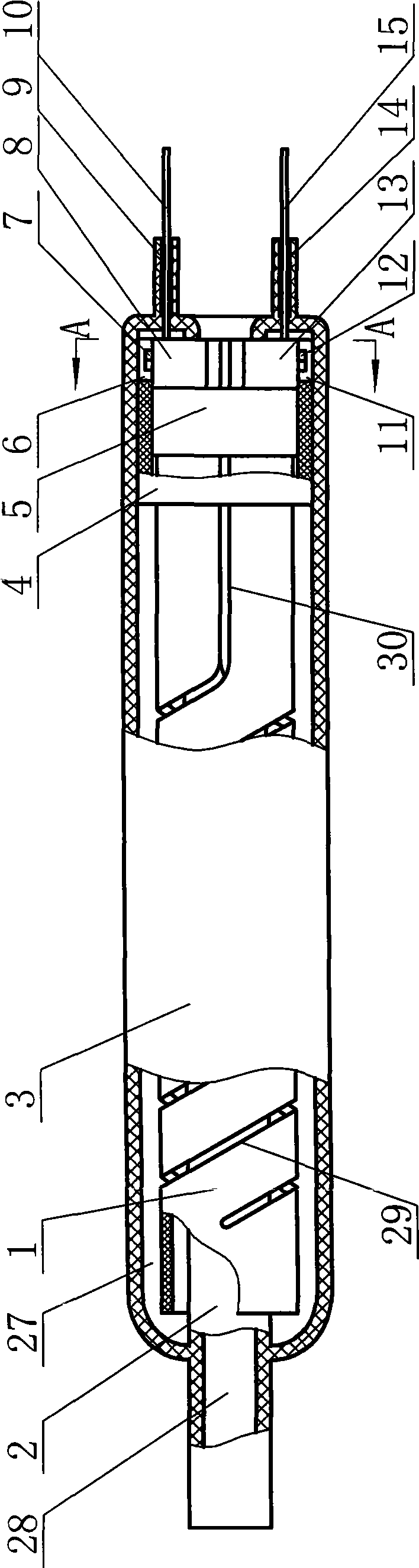

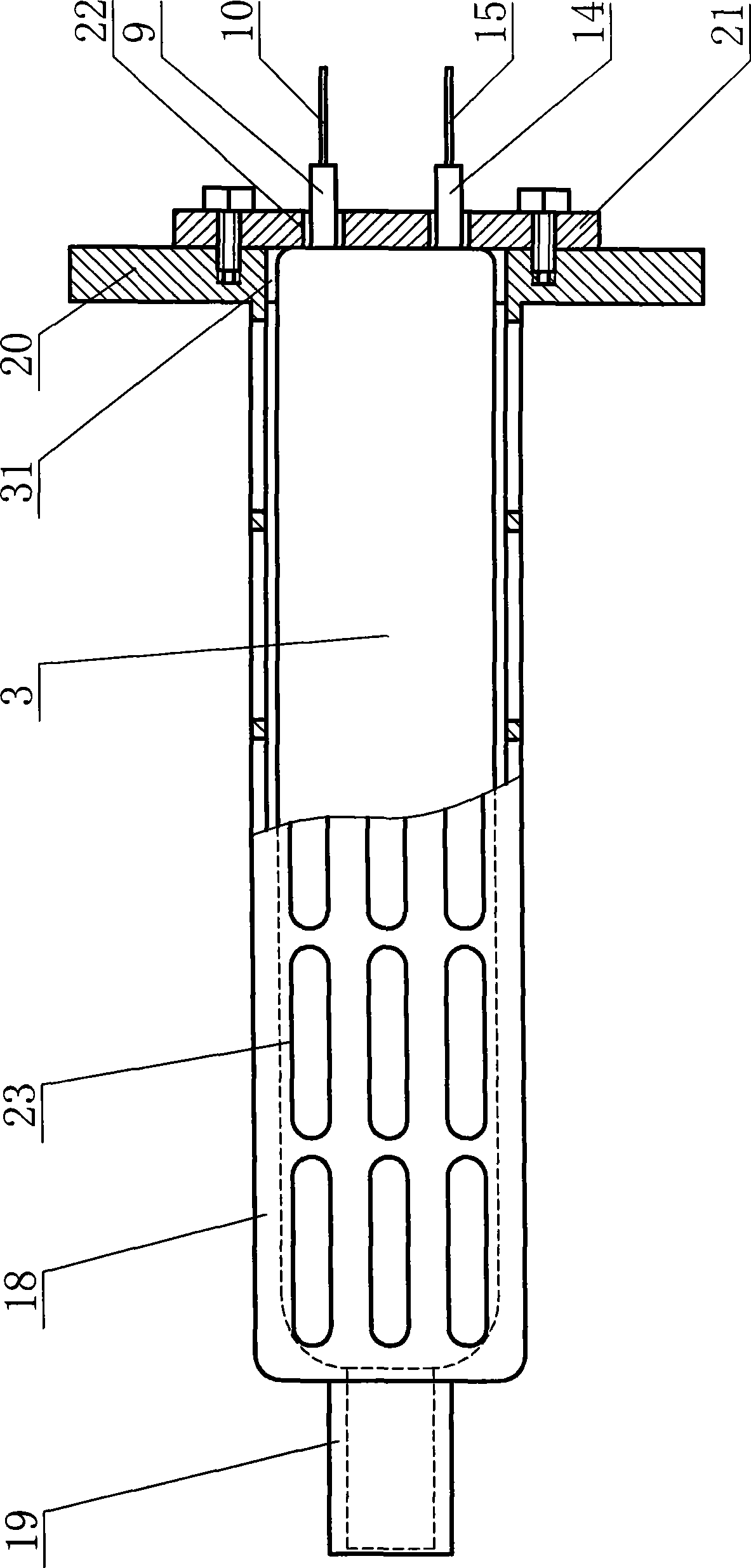

Infrared radiation ceramic heater

InactiveCN101505554AHeating up fastReduce consumptionImmersion heating arrangementsHeating element shapesFiberCarbon fibers

The invention discloses an infrared radiation ceramic heater, which comprises a quartz outer tube and a quartz inner tube, wherein two ends of the quartz outer tube and two ends of the quartz inner tube are connected in a melted and closed mode respectively; a cavity is arranged between the inner wall of the quartz outer tube and the outer wall of the quartz inner tube and provided with a silicon carbon rod inside; the diameter of a through hole in the middle of the quartz inner tube is more than or equal to the length of the quartz outer tube; electrodes are arranged at the ends of the silicon carbon rod; and a silicon dioxide pad is arranged on the outer wall or the inner wall of the ends of the silicon carbon rod. The infrared radiation ceramic heater is mainly used for medium heating of heaters, can also be used for heating in industrial production, and is particularly applicable to heaters adopting water circulation. The product can directly heat water to make the water temperature rise rapidly, water absorbs heat through the quartz outer tube and the quartz inner tube, the heat efficiency is high, because the infrared radiation rate is larger than 97 percent, the energy consumption is low, and compared with the prior silicon fiber wire heating and electrothermal tube heating, the heating mode saves energy by 38 to 45 percent. The infrared radiation ceramic heater has the advantages of long service life along with thoroughly overcoming the defect of easy failures of electric heating and carbon fiber heating.

Owner:周存文

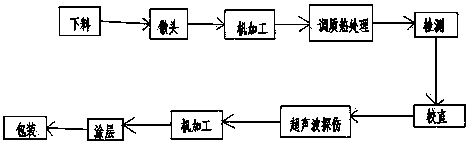

Processing technology for improved drill stems

InactiveCN104070330AIncreased jacking forceHeading Quality AssuranceDrilling rodsDrilling casingsSteel tubePetroleum

The invention discloses a processing technology for improved drill stems. The processing technology comprises the following steps of: cutting out tubes which are identical in length from a seamless steel tube; upsetting heads, including thickening upsetting heads at two ends of the tubes produced in the step A; machining, including rough machining the two ends of the tubes; quenching and tempering; detecting, including performing mechanical property detection on the drill stem which has been subjected to quenching and tempering; straightening; detecting flaws ultrasonically; secondary machining, including cutting an external thread and an internal thread respectively at two ends of the drill stem by a petroleum pipeline threading tool, and measuring taper, thread pitches, screw tightness and thread angles of the threads by a petroleum pipeline measuring instrument; coating; packaging. By adopting the processing technology, the cut threads are small in thread pitch and the surfaces of the threads meets requirements on smooth finish; the processing technology can effectively control heating time and increase of impurities, increases applicability and greatly improves productivity..

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

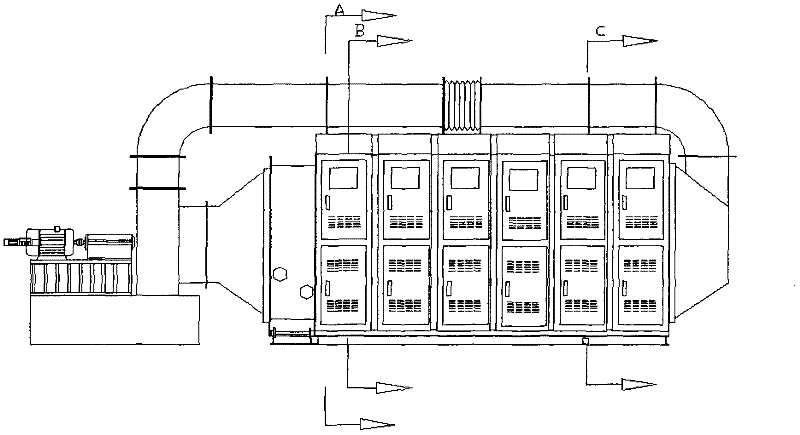

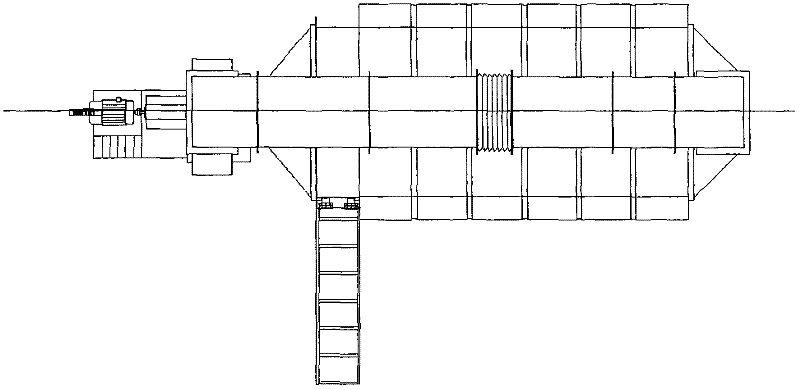

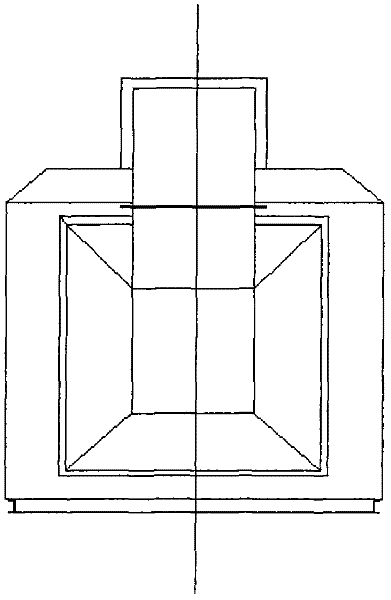

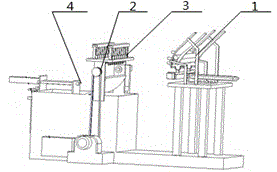

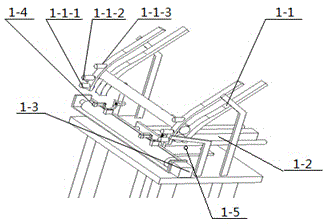

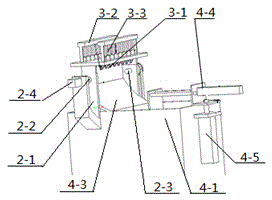

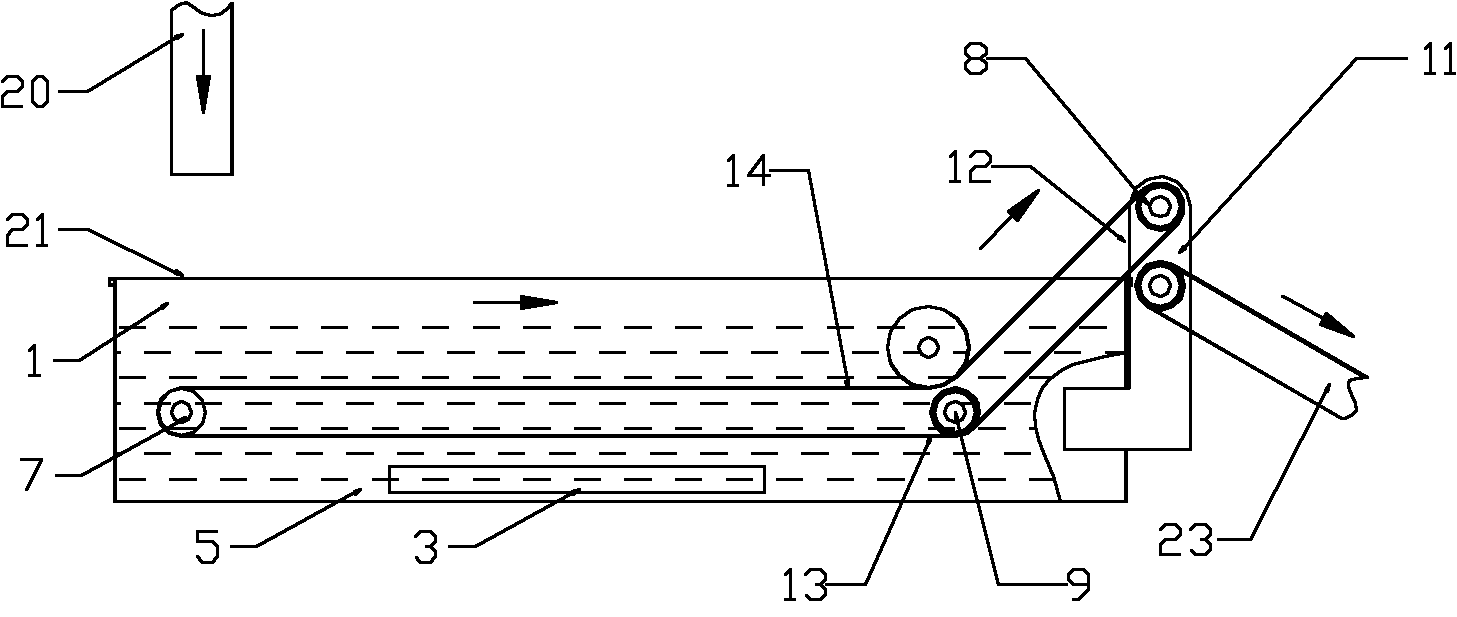

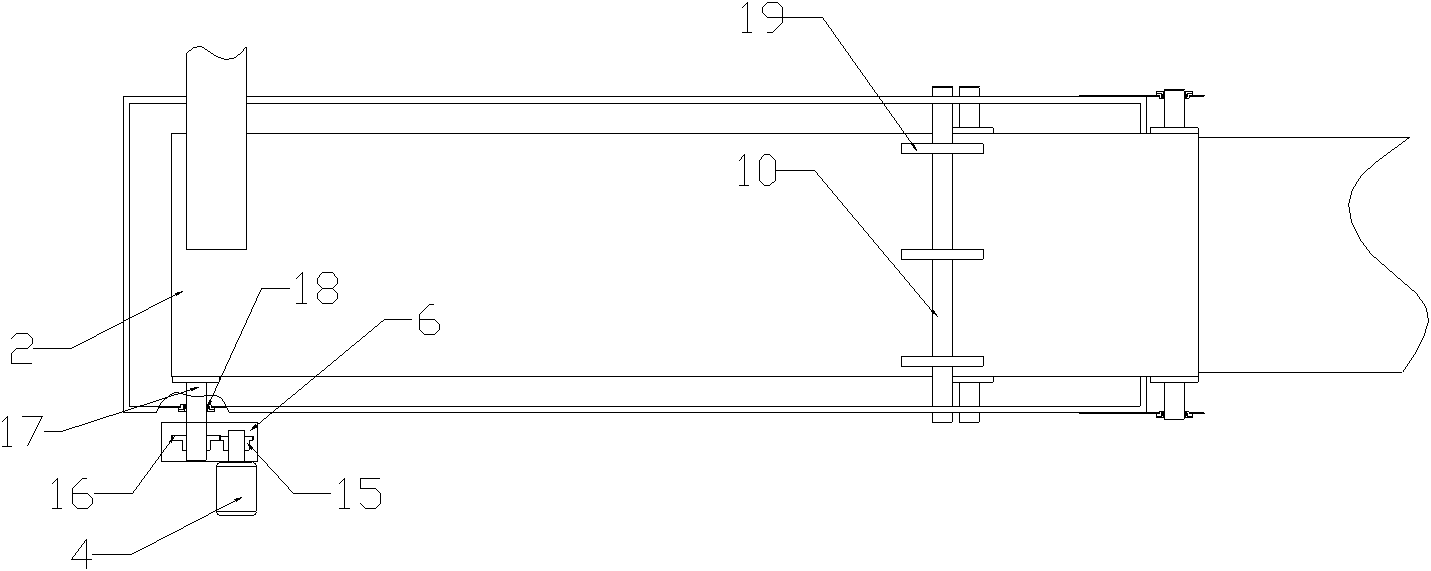

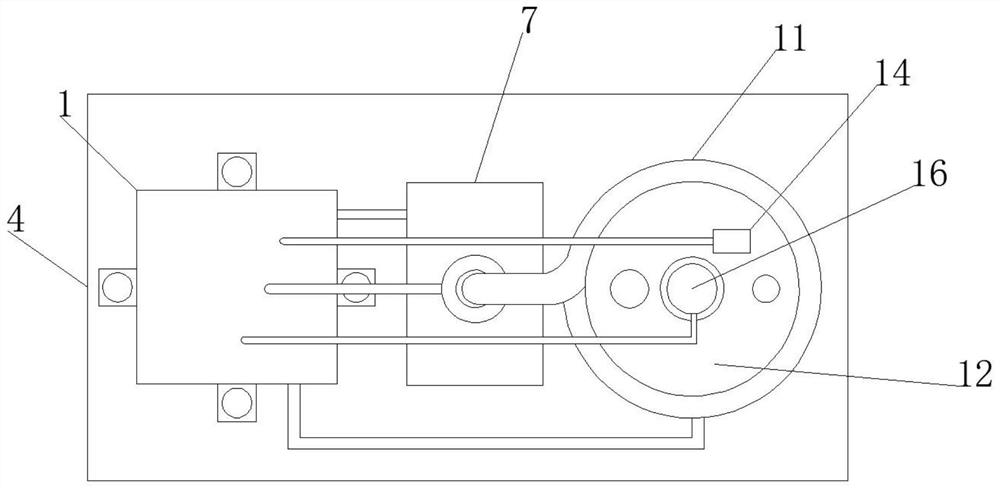

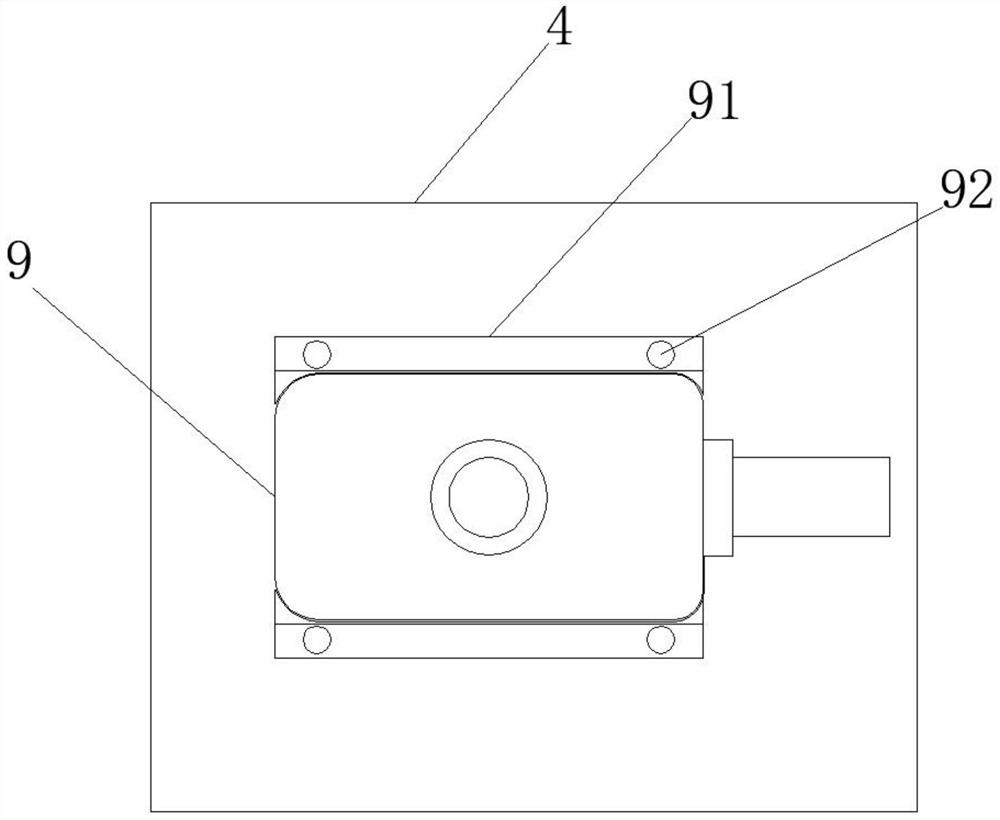

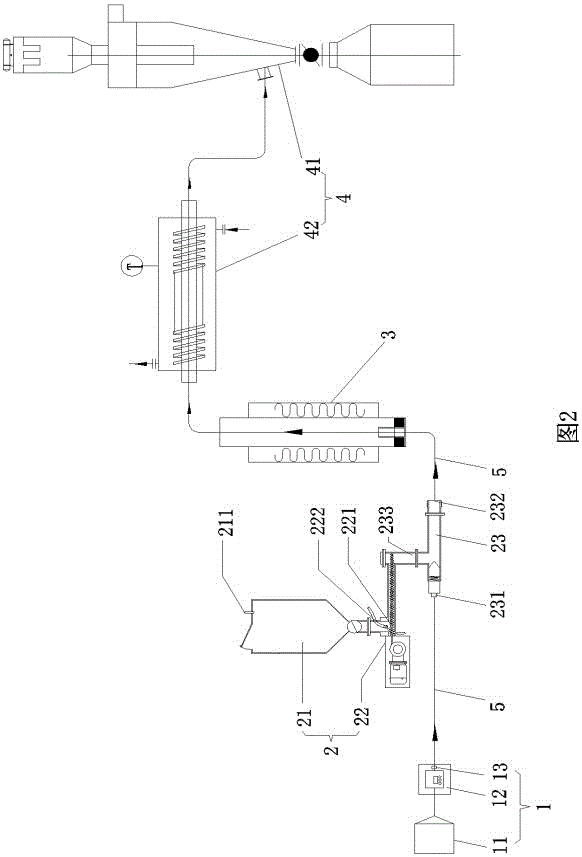

Cam shaft flame hardening automatic heat treatment machine tool and technology

ActiveCN104928458ASimple structureImprove versatilityFurnace typesHeat treatment furnacesEngineeringCam

The invention relates to a cam shaft flame hardening automatic heat treatment machine tool. The machine tool comprises a feeding mechanism, a rotating mechanism, a heating mechanism, a cooling mechanism and a control mechanism controlling all the mechanisms of the machine tool to run cooperatively, wherein the feeding mechanism, the rotating mechanism, the heating mechanism, the cooling mechanism and the control mechanism are arranged on the machine tool in sequence. The invention further discloses a cam shaft flame hardening automatic heat treatment technology. The technology specially comprises the steps of automatic feeding, flame heating and cooling. By the adoption of the cam shaft flame hardening automatic heat treatment machine tool and technology, the technical problem of conducting automatic heat treatment on a cam shaft with the flame hardening heat treatment technology is solved, automatic precise operation is achieved during cam shaft flame hardening, hardening quality and stability are guaranteed, a feeding system and a discharging system of the cam shaft flame hardening automatic machine tool are high in automation degree, and production efficiency and economic effectiveness are further improved.

Owner:HEBEI UNIV OF ENG

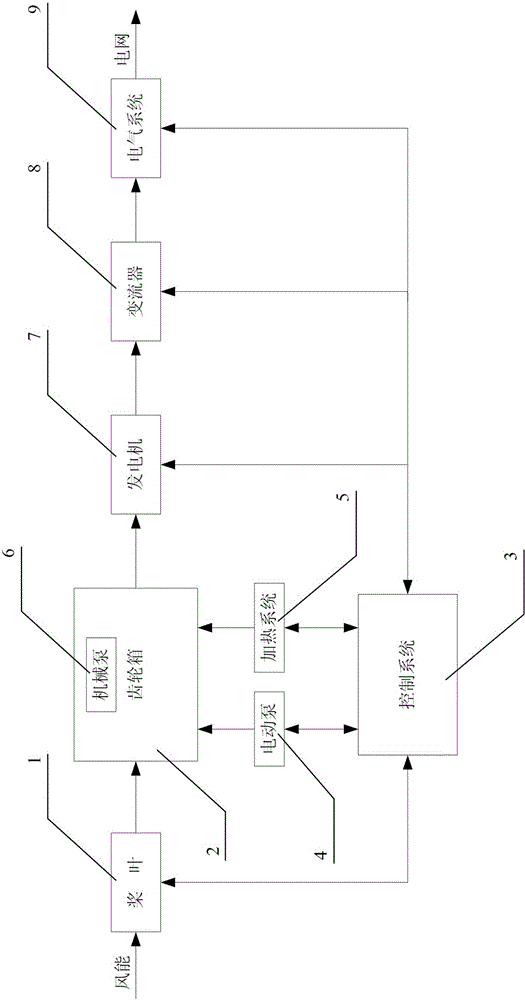

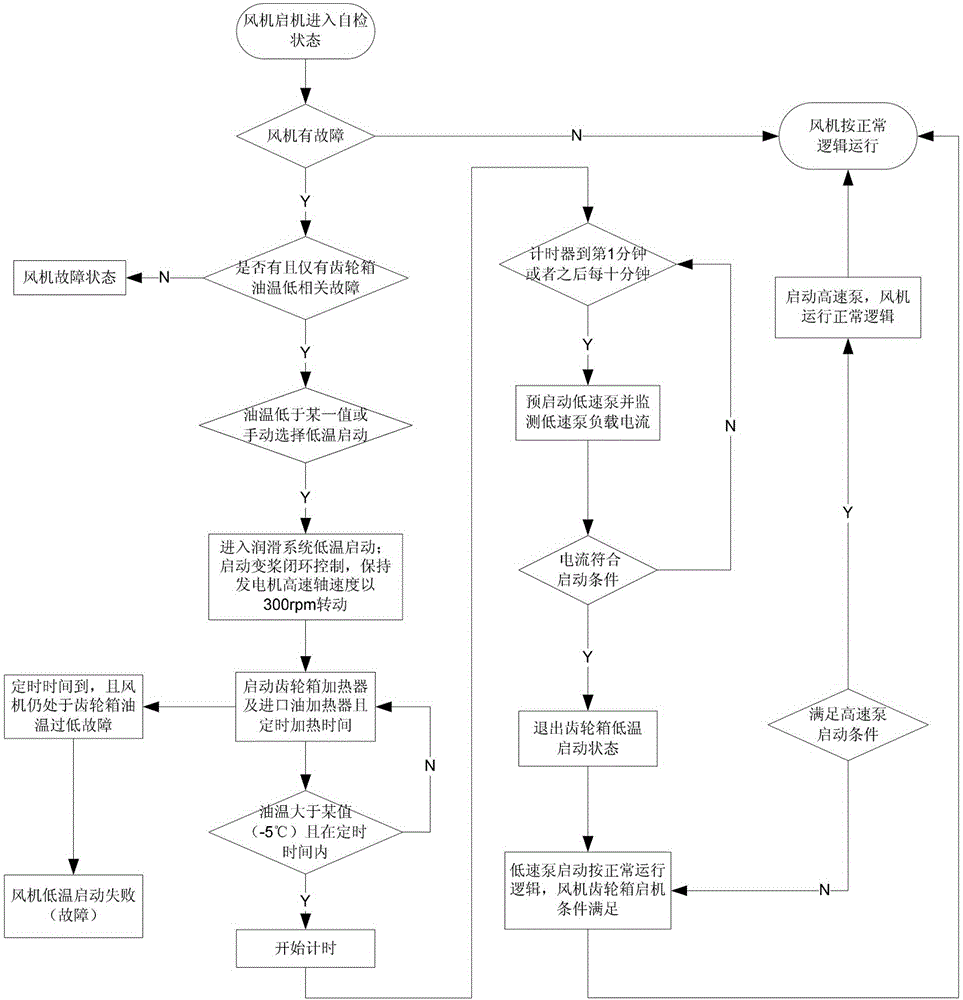

Low-temperature idle running heating control system and method of wind generating set

ActiveCN105526046AGuaranteed heating effectControl heating timeWind motor controlMachines/enginesElectricityLow speed

The invention discloses a low-temperature idle running heating control system and a method of a wind generating set. The system comprises a control system, an electric pump and a heating system. When the oil temperature of a gear box is below a certain value, a gear box lubricating system enters a low-temperature starting state, then the control system controls a propeller to change the pitch to a certain angle, gear box idle rotation is maintained so as to mix lubricating oil, the oil temperature of the gear box rises uniformly, and the control system does not start the heating system until the rotating speed of a high speed shaft is maintained at a set value. After the oil temperature of the gear box reaches the minimum machine starting oil temperature, the control system pre-starts the electric pump to a low-speed state, and monitors a load current of the electric pump; when the load current of the electric pump can not meet the starting condition of the gear box lubricating system, the wind generating set carries out idle rotation continuously and the gear box is kept heated. According to the system and the method, safe operation of the low-temperature starting process of the wind generating set can be guaranteed, the starting process on the low-temperature condition is accelerated, the labor intensity of workers is lowered, and the generated energy of the wind generating set is increased.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

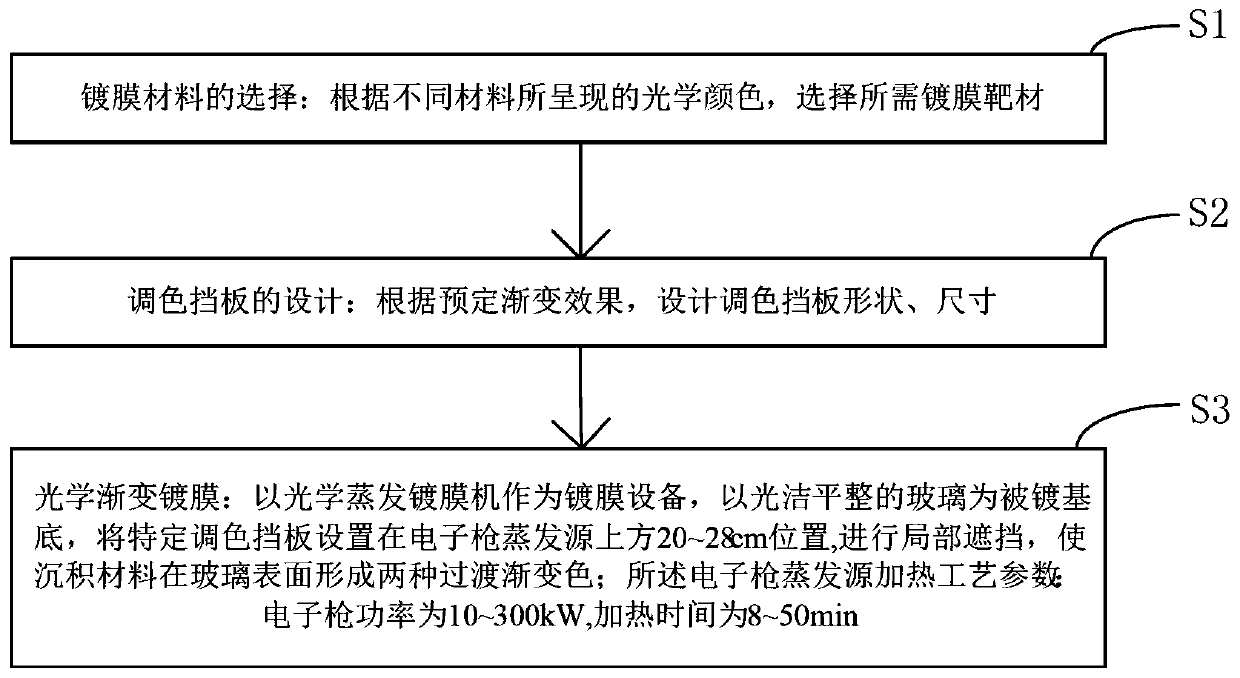

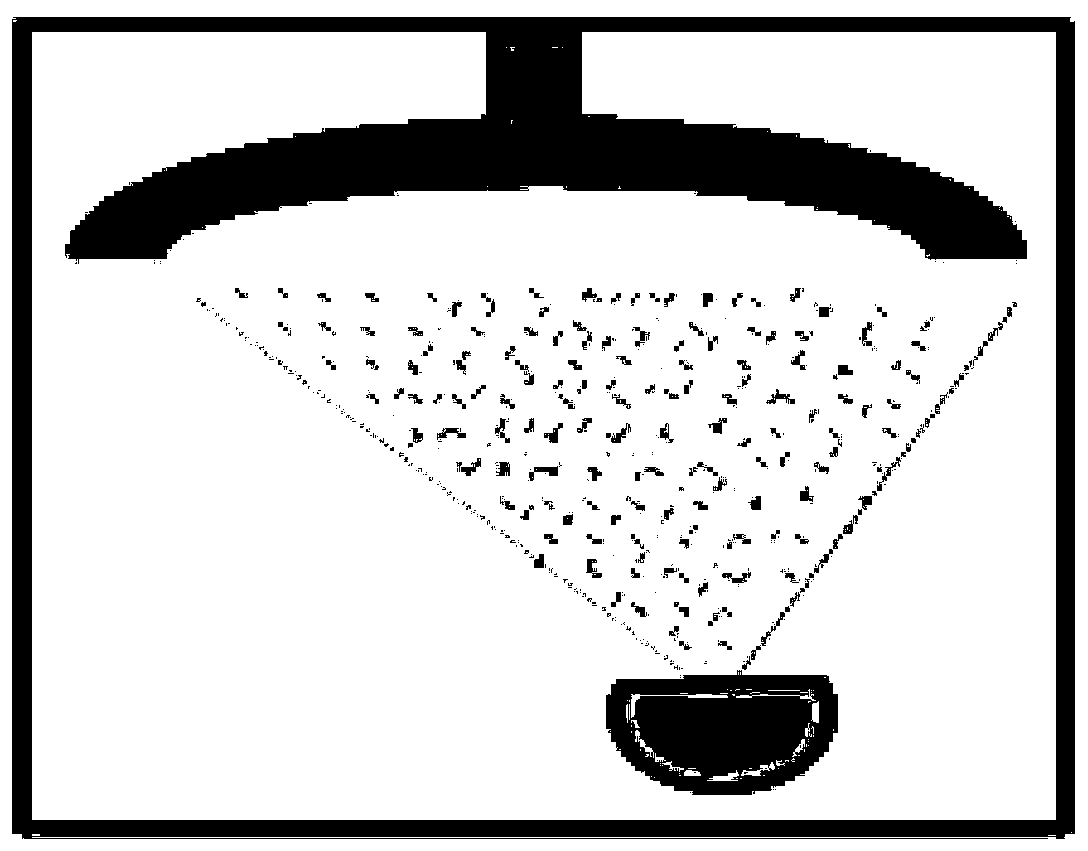

Film-coating method for forming gradient colors on glass surface

The invention discloses a film-coating method for forming gradient colors on a glass surface. According to the method, partial shielding is performed at an upper position of an evaporation source of an electron gun by using a specific color-matching baffle plate, so that two transition gradient colors are formed by a deposition material on the glass surface, and a plurality of gradient effects are formed by adjusting a shape, a size and a shielding position of the color-matching baffle plate. The film-coating method specifically comprises the following steps: S1, selection of a film-coating material; S2, design of a color-matching baffle plate; and S3, optical gradient film-coating. Compared with a traditional gradient color film-coating process, the method is simple and easy to control, and a coating film with a predetermined gradient effect can be formed by only needing to adjust a shape, a size and a shielding position of the color-matching baffle plate, controlling a heating power of the electron gun and a heating time.

Owner:ANHUI BENGBU HUAYI CONDUCTIVE FILM GLASS

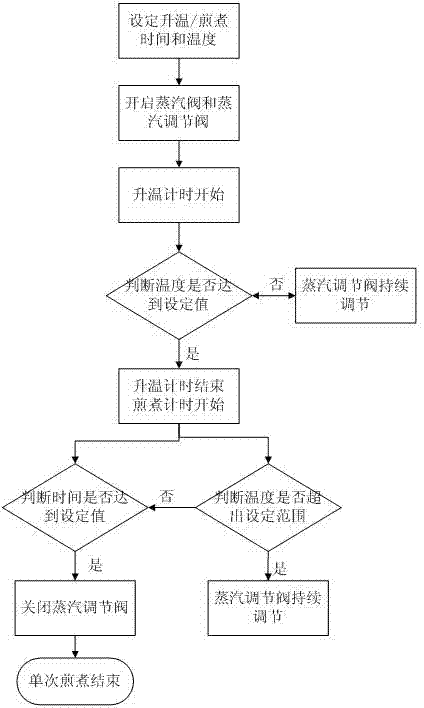

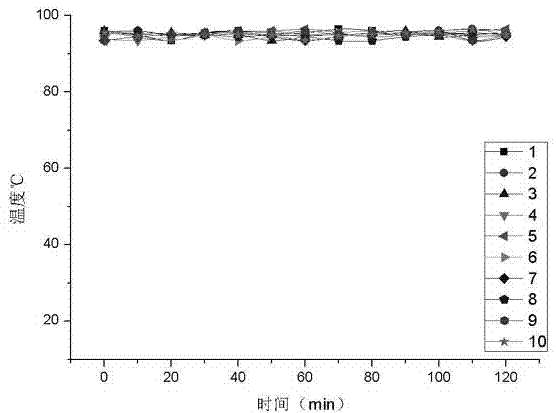

Temperature stability control method during the extraction process of traditional Chinese medicines

ActiveCN105446394AControl heating timeTemperature controlAuxillary controllers with auxillary heating devicesEngineeringRise time

The invention discloses a temperature stability control method during the extraction process of traditional Chinese medicines. The temperature stability control method comprises the steps: starting a steam inlet valve on an extraction pot, and adjusting the opening degree of a steam adjusting valve according to a function K=0.18(T-T0) / t*100% so as to guarantee the stability of the temperature rise time; entering an insulation and decoction phase when the temperature in the extraction pot achieves a set extraction temperature, and adjusting the opening degree of the steam adjusting valve according to the difference between the detection temperature TS in the pot and a set insulation and decoction temperature T1 so as to guarantee the temperature stability during the insulation and decoction phase; and finishing decoction when the time of insulation and decoction achieves a set insulation and decoction time t1. Through the above mode, the temperature stability control method during the extraction process of traditional Chinese medicines realizes accurate control of the temperature rise time and the temperature during the extraction process of traditional Chinese medicines, and reduces the difference between batches during the extraction process of traditional Chinese medicines, and can provide a new technology for improvement of quality stabilization of traditional Chinese medicine products and modernization of traditional Chinese medicines.

Owner:SUZHOU ZEDAXINGBANG MEDICAL TECH

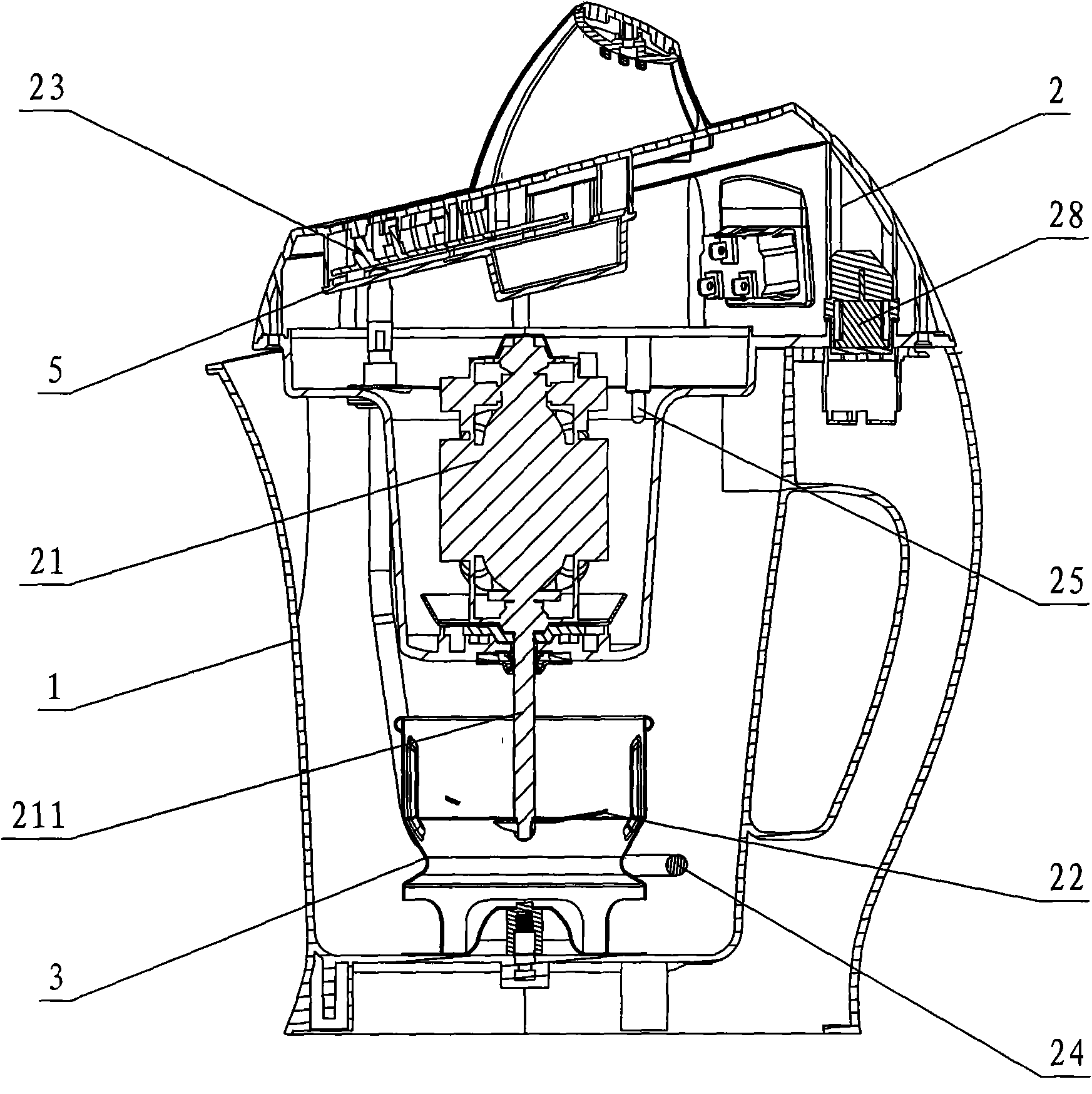

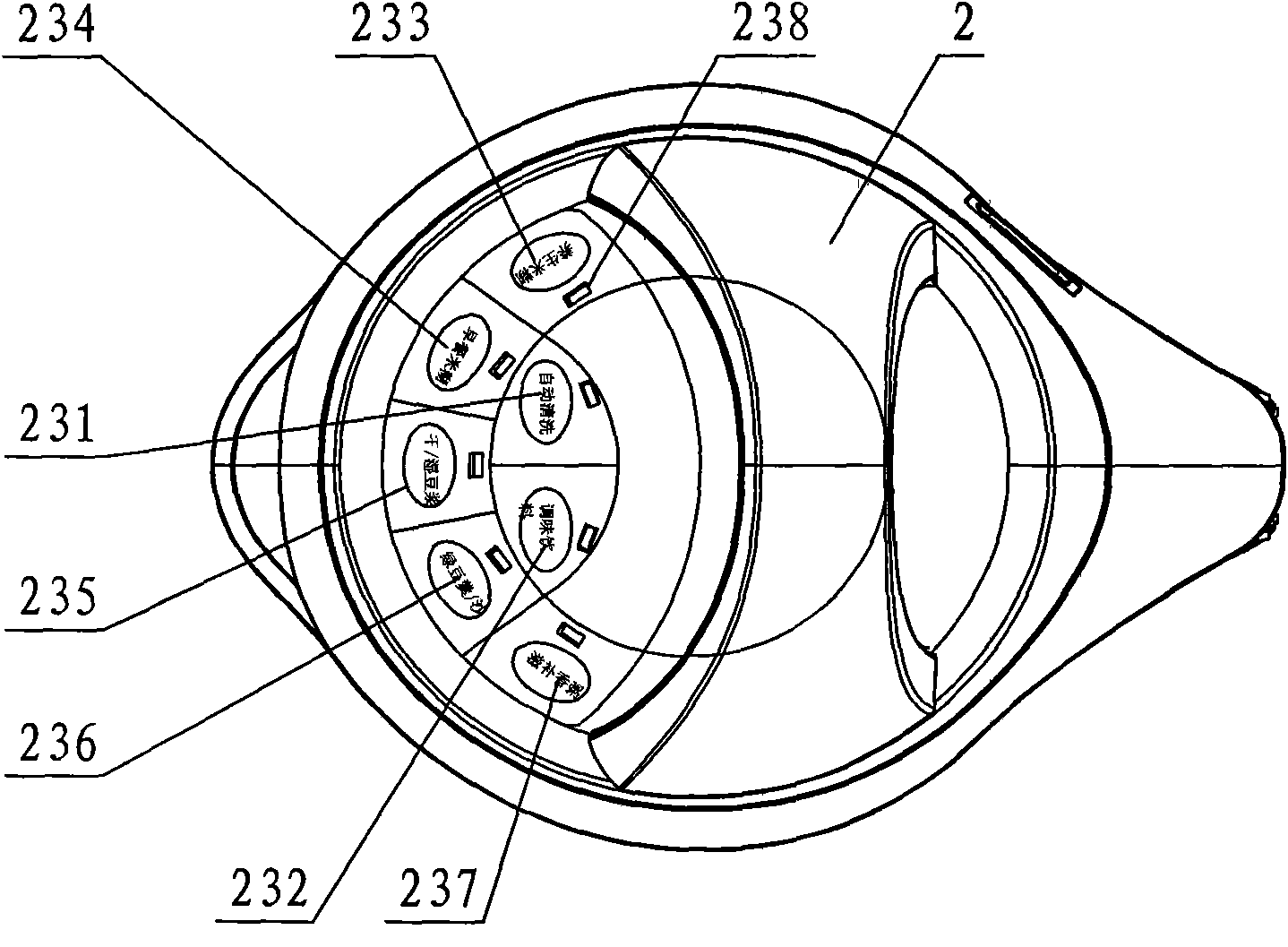

Liquid food machine and method for making liquid food

InactiveCN101569502ALiquid food tastes goodGood color and fragranceBeverage vesselsProgramme control in sequence/logic controllersElectric machineryEngineering

The invention provides a liquid food machine, comprising an upper head cover arranged on the upper part of a barrel; wherein, an electric motor is arranged on the upper head cover; an output shaft of the electric motor extends toward the inside of the barrel and a blade is fixed at the end of the output shaft; a control switch is arranged on the upper head cover, and an anti-dry-heating electrode, an anti-overflow electrode and an electrothermal tube are arranged on the lower end face, wherein, the electrothermal tube extends toward the bottom of the barrel; the electric motor, the control switch and the electrothermal tube are all connected on and controlled by a control board, the control board is arranged on the upper head cover and is internally provided with chips having over four types of function control programs, corresponding chips on the upper head cover are provided with over four control switches, each control switch takes charge of starting a function control program. The invention is characterized in that in consideration of a great variety of food, trivial procedure of making the liquid food and the troublesome cleaning, the chip is provided with a plurality of function control programs and cleaning function control programs in making the liquid food; a corresponding control switch takes charge of the start of each program; the machine is simple and reasonable in structure and easy in operation.

Owner:ZHANGZHOU WANLIDA ELECTRICAL APPLIANCE

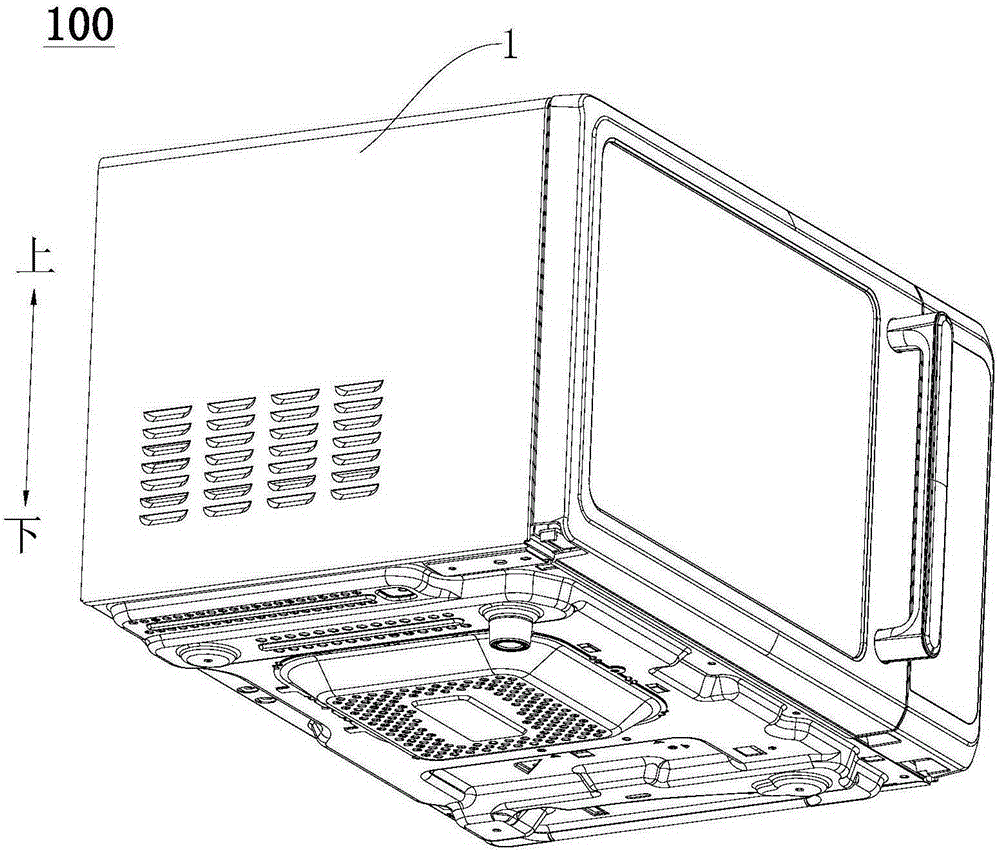

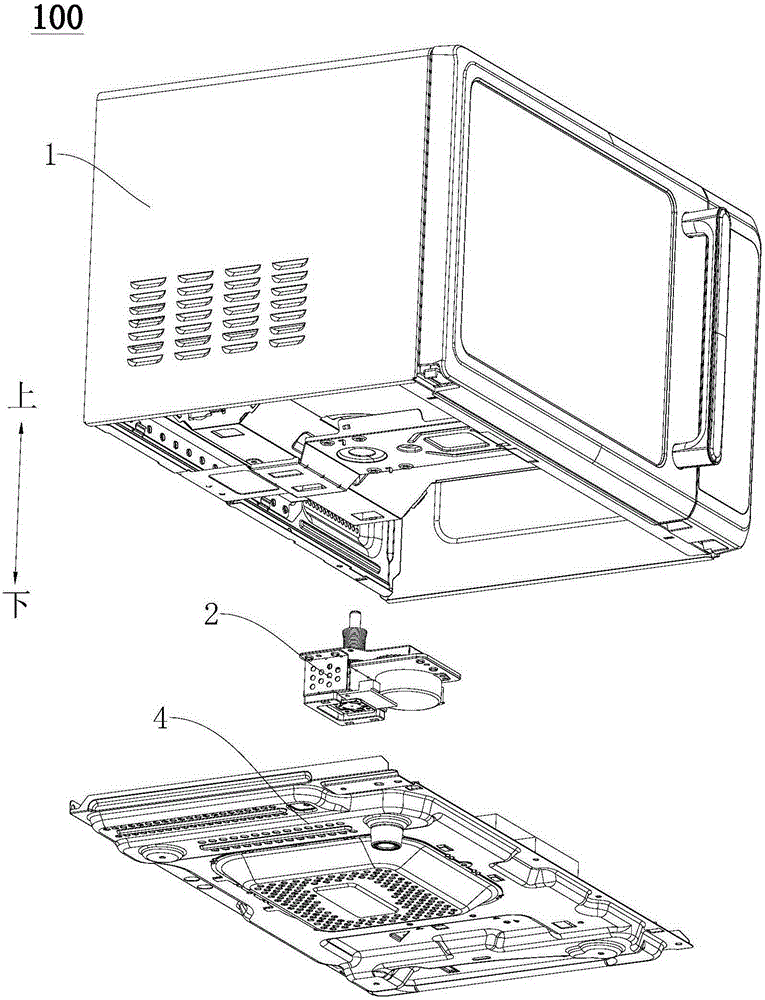

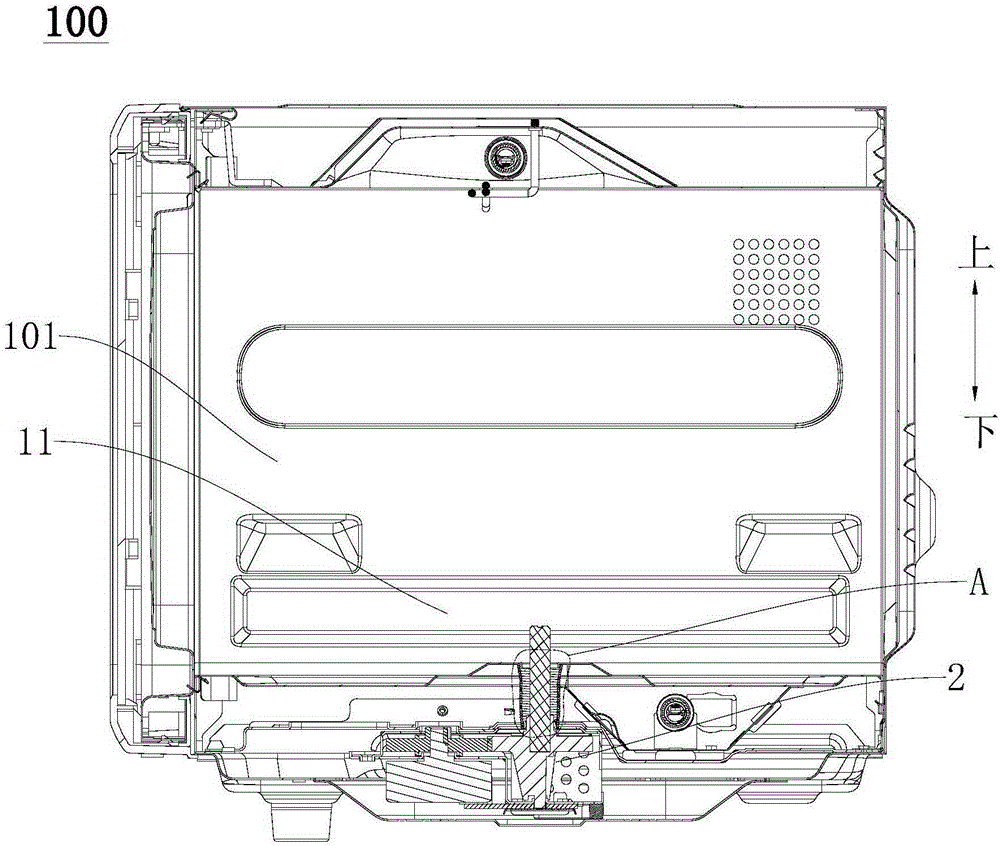

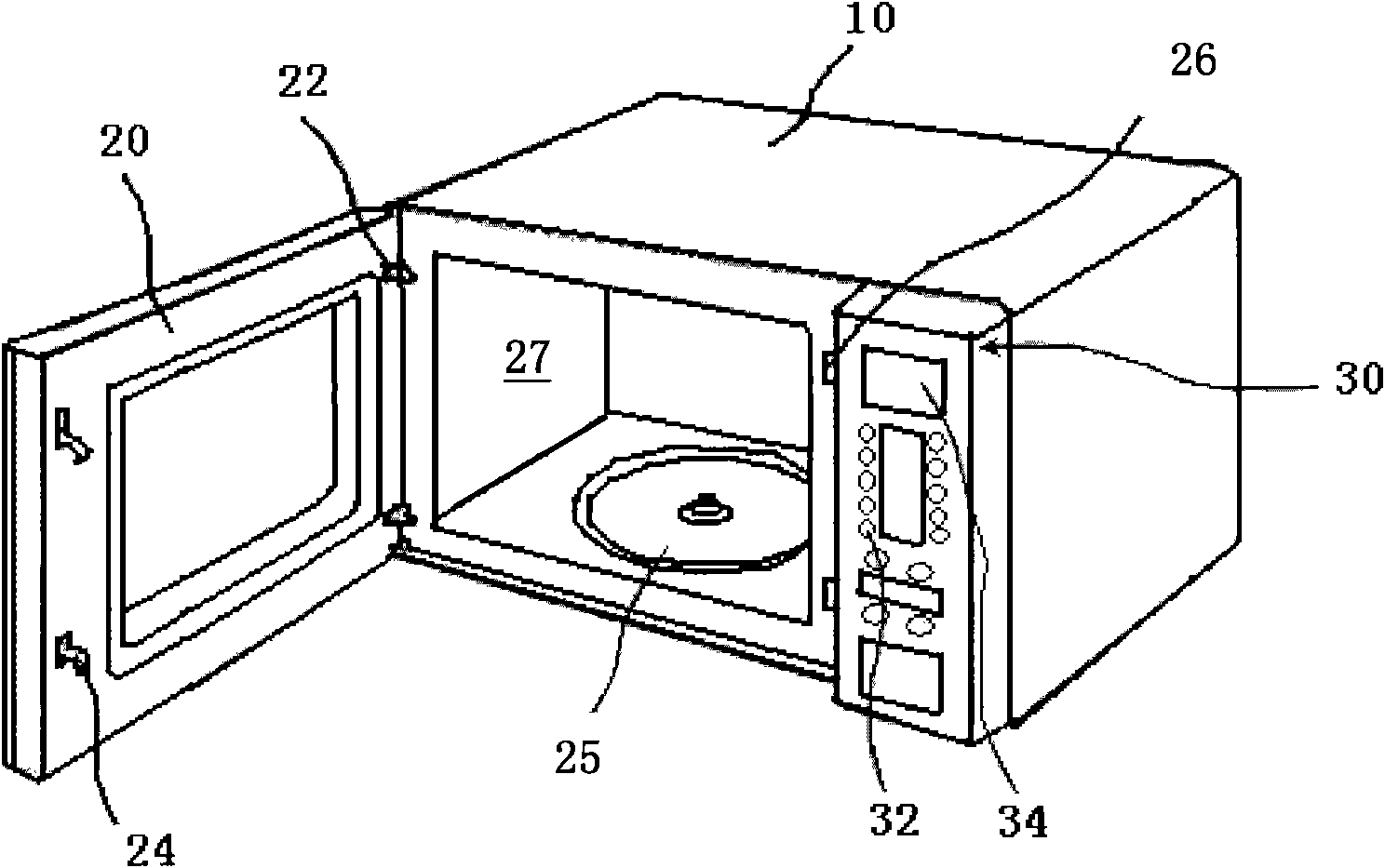

Control method for microwave oven

ActiveCN105222185AReduce complaintsImprove satisfactionDomestic stoves or rangesLighting and heating apparatusMicrowave ovenHeating time

The invention discloses a control method for a microwave oven. The control method comprises the steps that heating time T is determined in a sectional mode according to the weight W of objects to be cooked, and if the weight W of the objects to be cooked is not larger than first preset weight W1, the objects to be cooked are heated for first preset time T1; if the weight W of the objects to be cooked is not smaller than second preset weight W2, the objects to be cooked are heated for second preset time T2; and if the weight W of the objects to be cooked is within the range of the first preset weight W1 and the second preset weight W2, the heating time is determined according to the weight W of the objects to be cooked. According to the control method for the microwave oven, the heating time is determined in the sectional mode according to the weight of the objects to be cooked, accordingly, the heating time can be reasonably controlled, and it is guaranteed that the temperature of the objects to be cooked is proper after the objects are heated.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

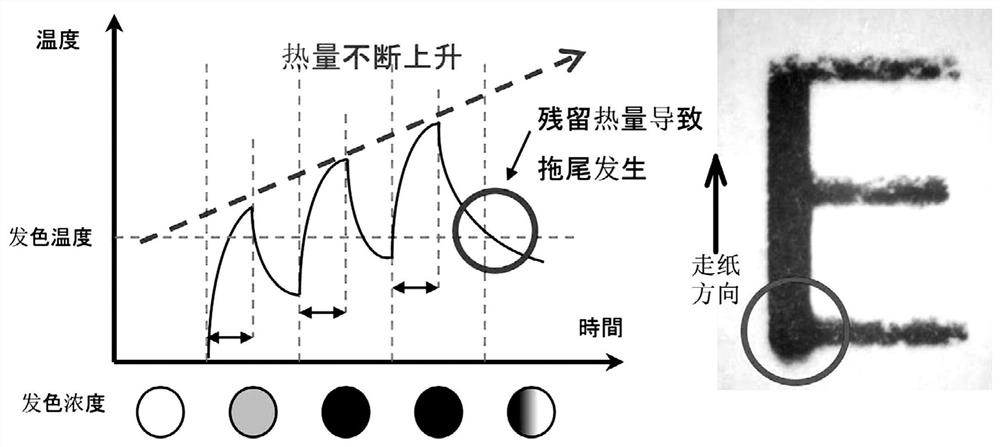

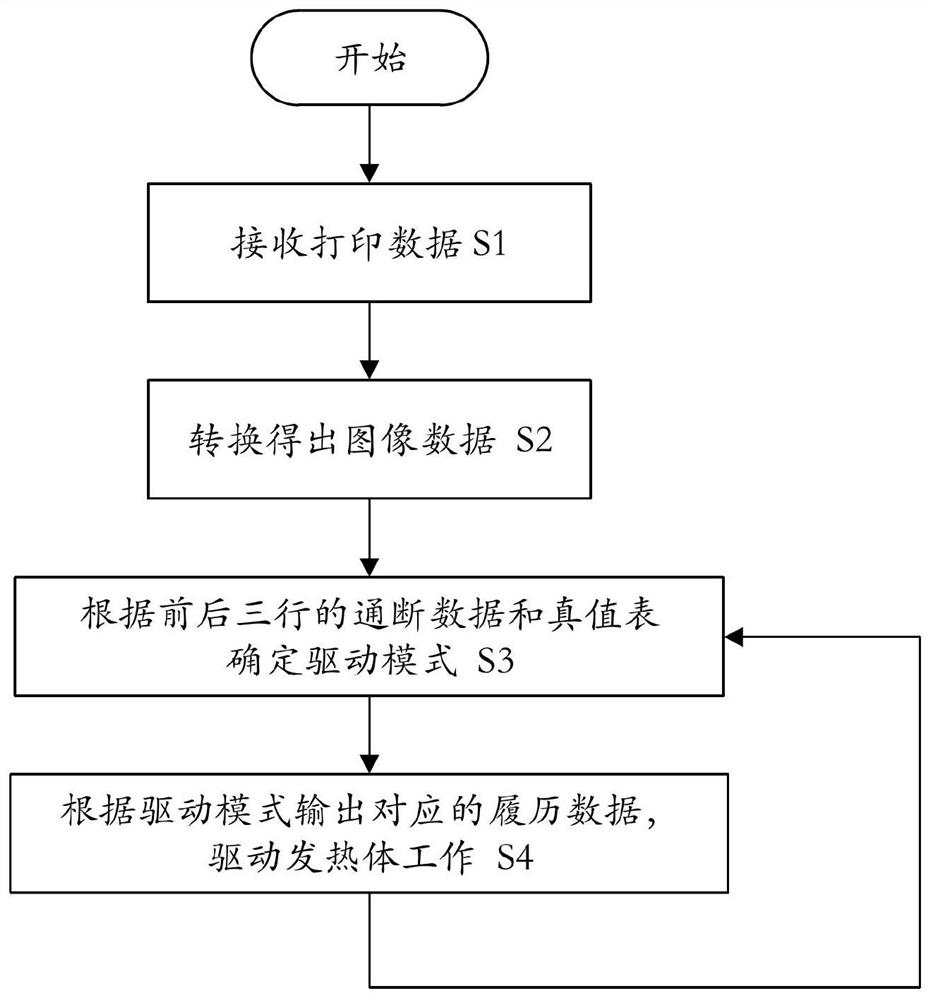

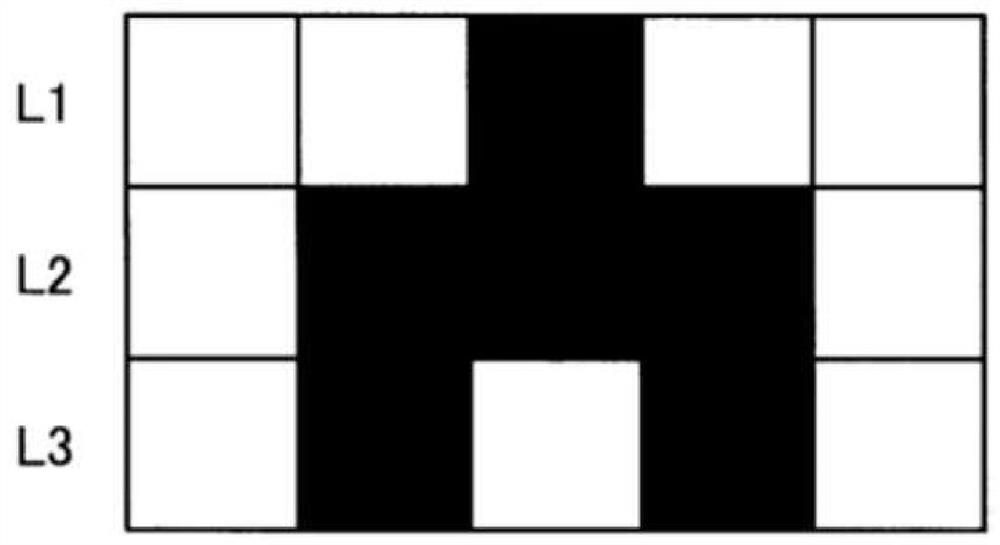

Thermal history control method for thermal printing head, thermal printer and computer-readable storage medium

ActiveCN111688362AControl heating timeImprove printing qualityImage codingPrintingThermodynamicsComputer printing

The invention provides a thermal history control method for a thermal printing head, a thermal printer and a computer-readable storage medium. The thermal history control method comprises the steps ofreceiving printing data, obtaining image data according to the printing data, obtaining on-off data of a current printing row, a previous printing row and a next printing row of a heating body of thethermal printing head from the image data, determining a driving mode of the heating body according to the on-off data and a truth-value table, and outputting the history data corresponding to the driving mode to the thermal printing head to drive the heating body to operate. By predicting and judging the accumulated heat of a heating element of the printing head in advance and setting and inquiring the truth-value table, the heating time of the heating body can be effectively controlled, so that the printing quality is improved by smooth heating and smooth heat dissipation, a printed font orimage is clearer, and trailing smear is avoided.

Owner:珠海柏印自动化设备有限公司

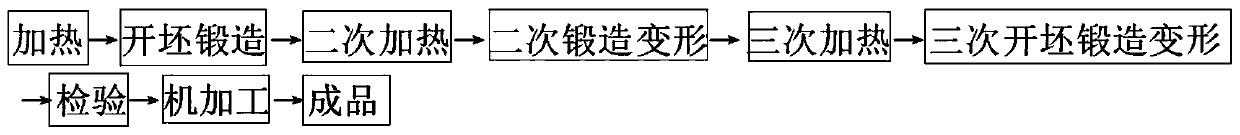

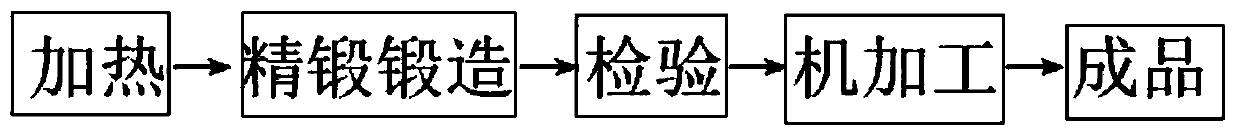

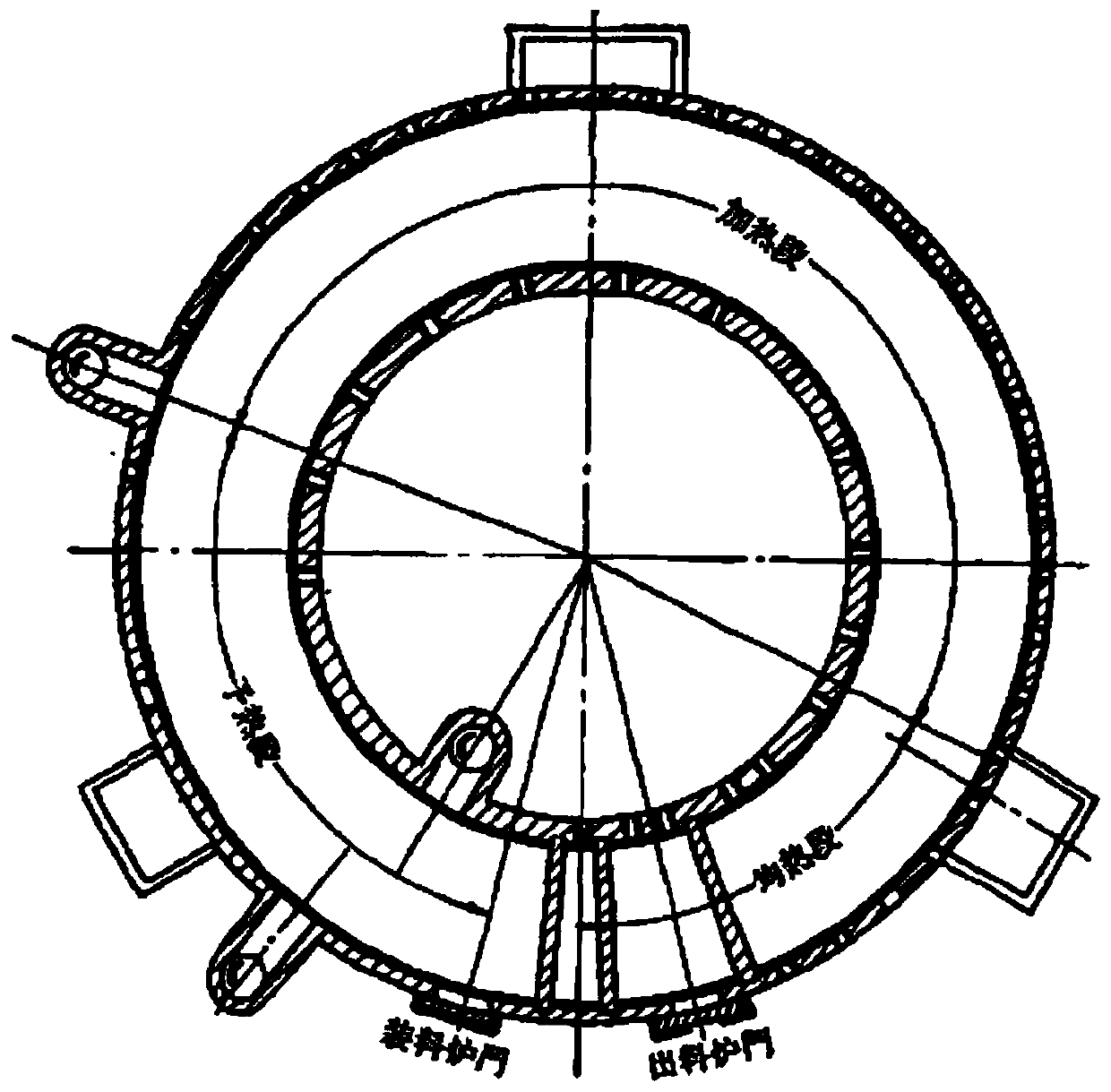

Efficient titanium and titanium alloy cast ingot short-process precision-forging blank forging process

ActiveCN110605353AControlled atmosphereControl heating temperatureForging/hammering/pressing machinesForging press detailsHeating timeThree stage

The invention provides a efficient titanium and titanium alloy cast ingot short-process precision-forging blank forging process. The process comprises a heating process, a precision forging machine precision forging deformation treatment, an inspection process and a machining process, then a titanium alloy bar material is obtained, wherein the heating process adopts an annular heating furnace, heating of titanium and titanium alloy ingot blanks is achieved through flame heating, three stages of preheating, heating and soaking are adopted to achieve heating in the heating process, the heating temperature of the preheating section is 800+ / -50 DEG C, the heating time is 60-70 min, the heating temperature of the heating section is 900-1150DEG C, the heating time is 70-90 min, the heating temperature of the soaking section is equivalent to the heating temperature of the heating section, the soaking time is 60-90 min, the precision forging machine precision forging deformation treatment comprises the steps of carrying out precision forging through a hydraulic precision forging machine and carrying out hammering forging by using four hammers, and the forging time is 10-30 min. According to the process, by adopting the annular heating furnace with an improved heating mode, an annular sectional heating mode is adopted, and the precision forging machine forging deformation treatment is combined, so that the fast, efficient and short-process preparation of the titanium and titanium alloy cast ingots is achieved.

Owner:江苏天工科技股份有限公司

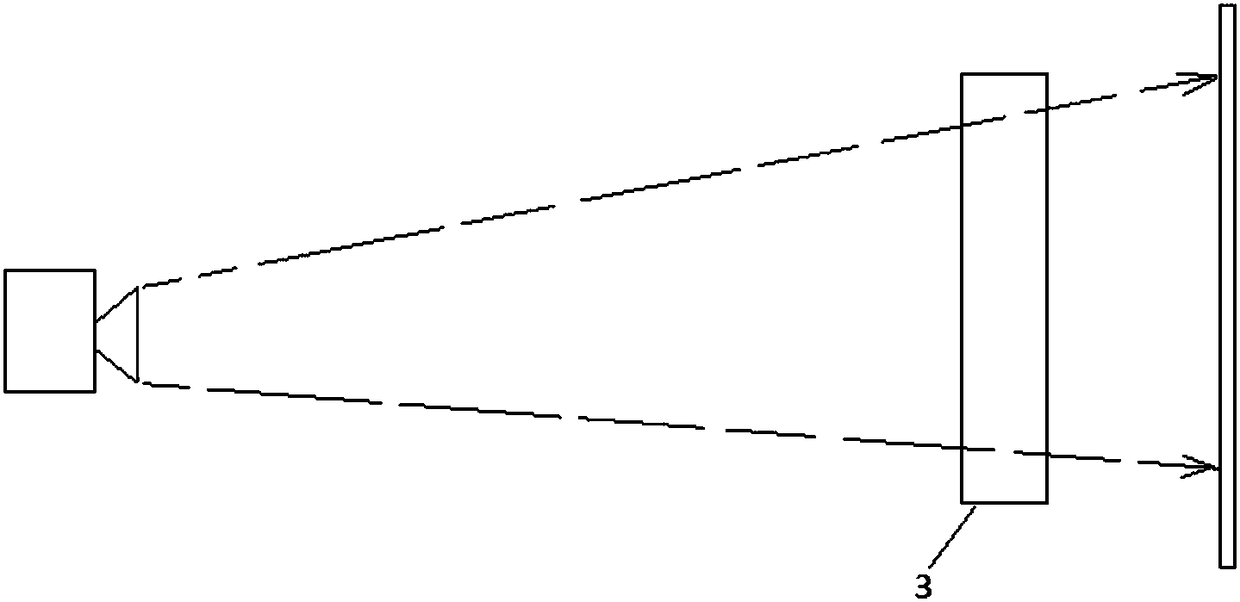

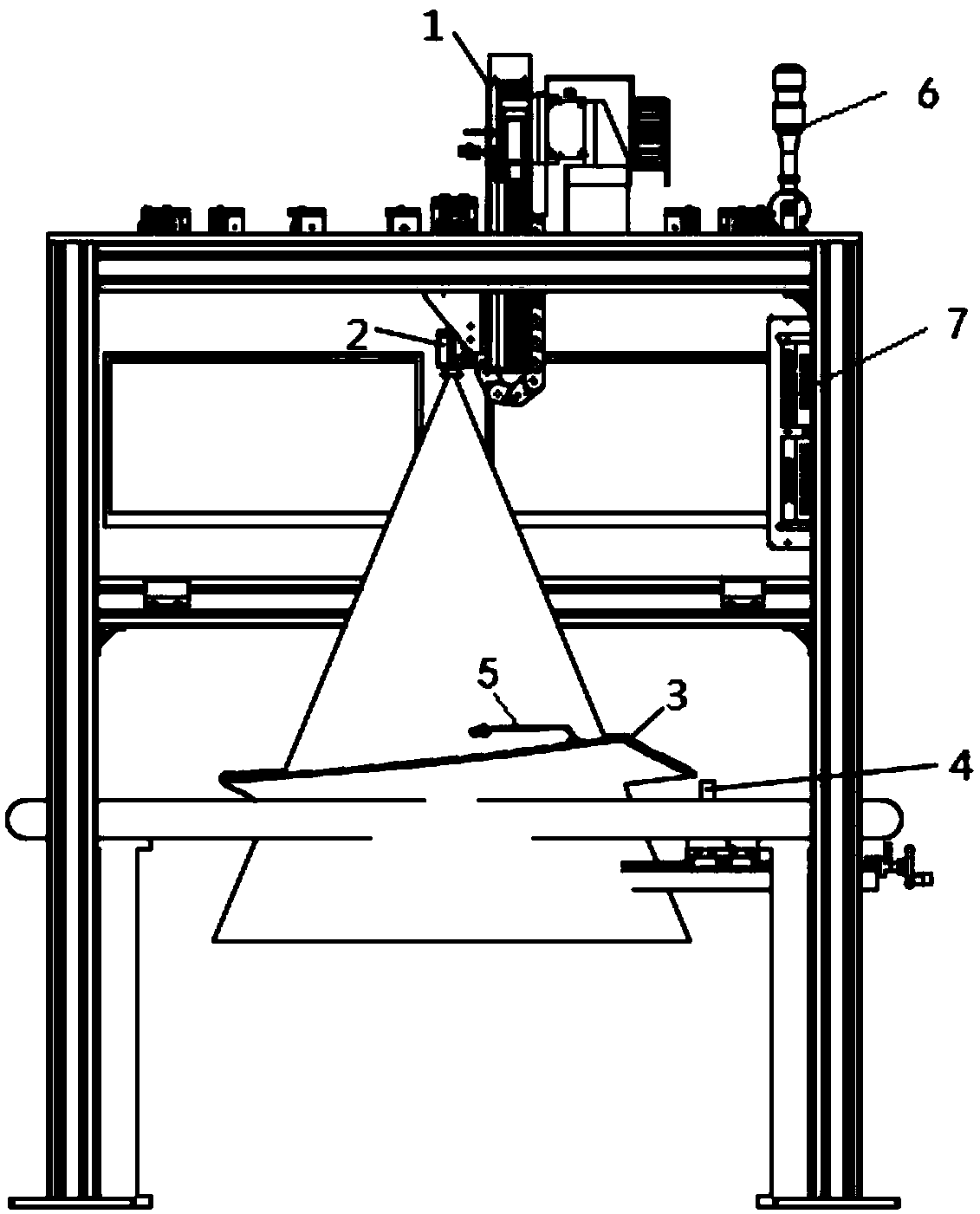

Automatic detection method for broken wires of automobile front windshield wired glass

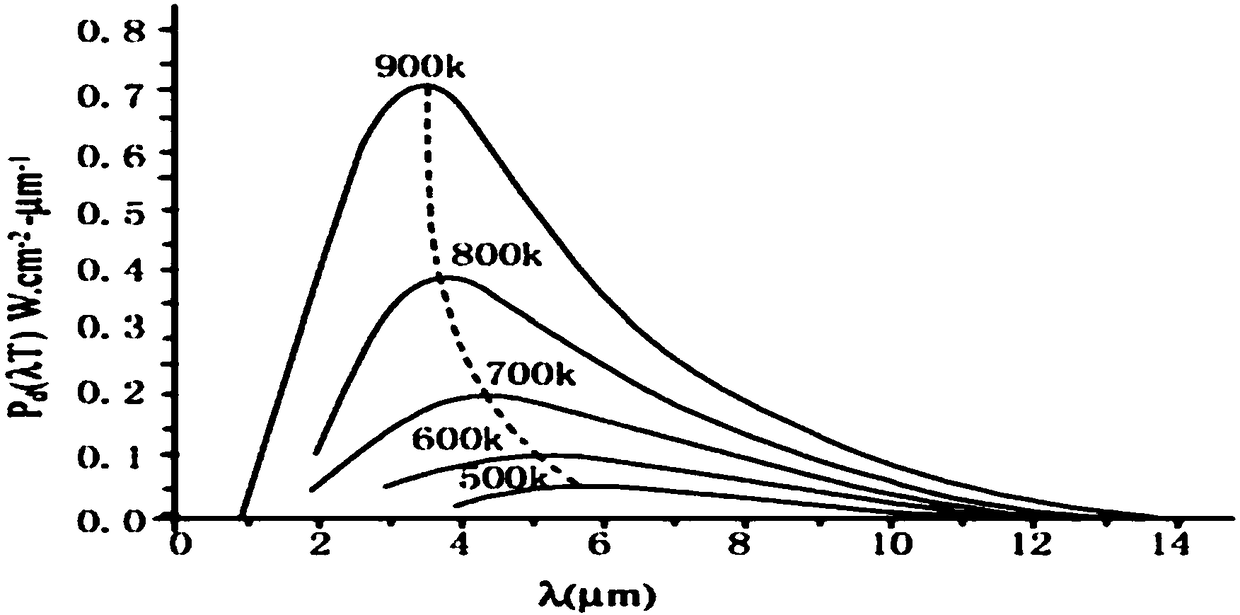

InactiveCN108490305AImprove detection efficiencyReduce the number of missed inspectionsRadiation pyrometryElectrical testingTemperature differenceEngineering

The invention relates to an automatic detection method for broken wires of automobile front windshield wired glass. The method comprises the steps that metal wires in the wired glass are electrified and heated; the surface temperature of the wired glass is measured; and the number of broken metal wires is determined according to the regional temperature difference of the surface. Compared with theprior art, the method provided by the invention has the advantages that the method of surface temperature difference detection is used to infer the number of broken wires; a user does not need to carry out macroscopic observation one by one; the detection efficiency is improved; and the number of missed inspections is reduced; an infrared thermal imager measures the surface temperature of the wired glass; and industrial automatic detection is realized.

Owner:EAST CHINA UNIV OF SCI & TECH

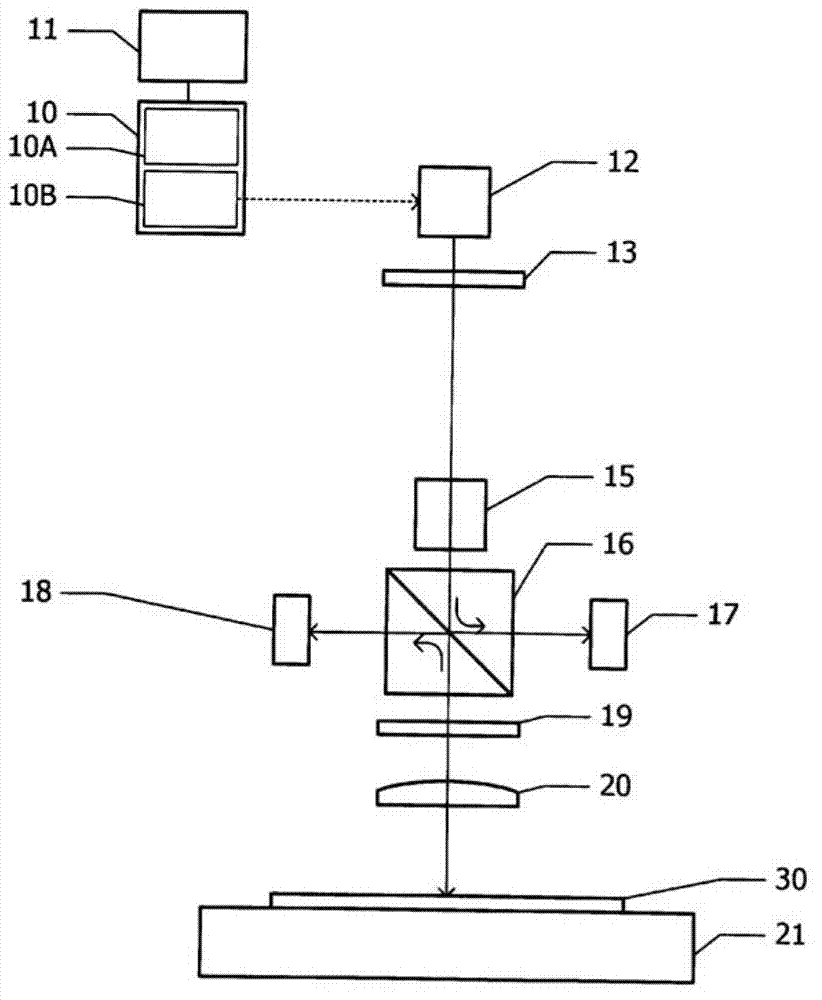

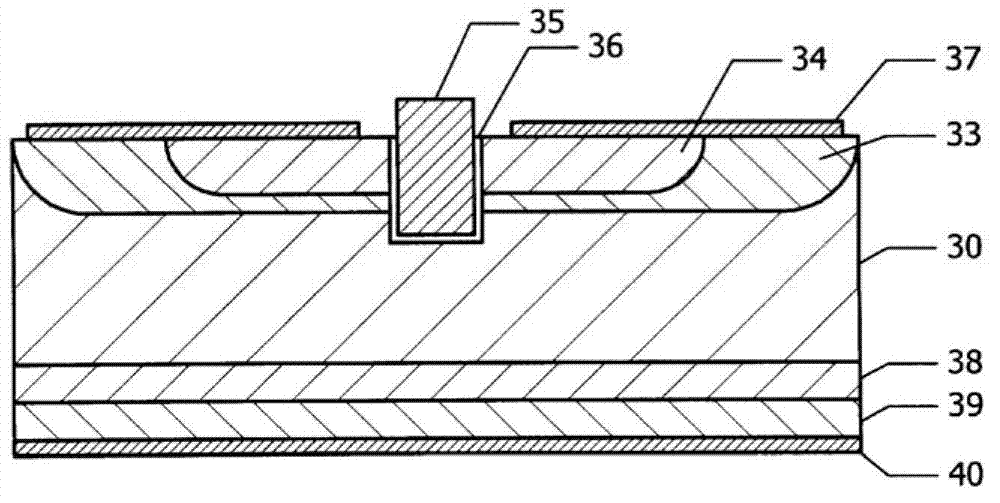

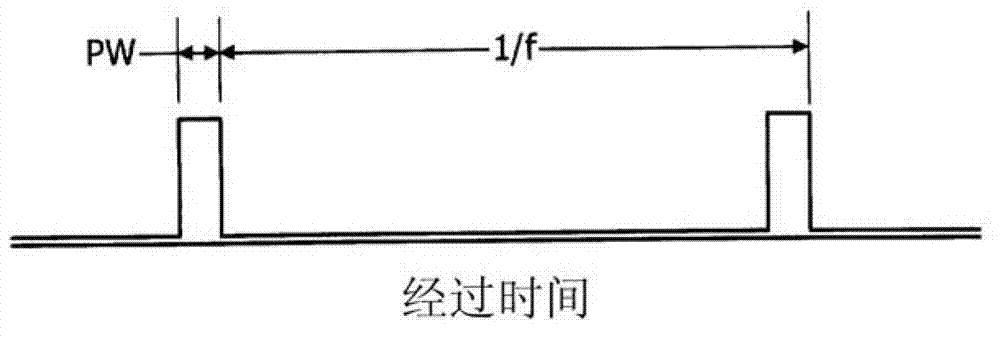

Laser annealing device and laser annealing method

ActiveCN103021826AFully annealedControl heating timeSemiconductor/solid-state device manufacturingMetal working apparatusLaser annealingStart time

Provided are a laser annealing device and a laser annealing method. A general pulse waveform rises sharply from a starting time point of oscillation, shows a peak, and thereafter, decreases gently. At the time point when power shows a peak, the surface of an annealing object is sharply heated and reaches a high temperature. Since time showing the peak is an instant, it is difficult to sufficiently heat a deep region of an annealing object. A laser pulse is emitted from a laser diode when a pulse current is input. An optical system that guides a laser beam emitted from the laser diode to an annealing object. A driver supplies a pulse current that has a time waveform of a top flat and a pulse width of 1 [mu]s to 100 [mu]s to the laser diode.

Owner:SUMITOMO HEAVY IND LTD

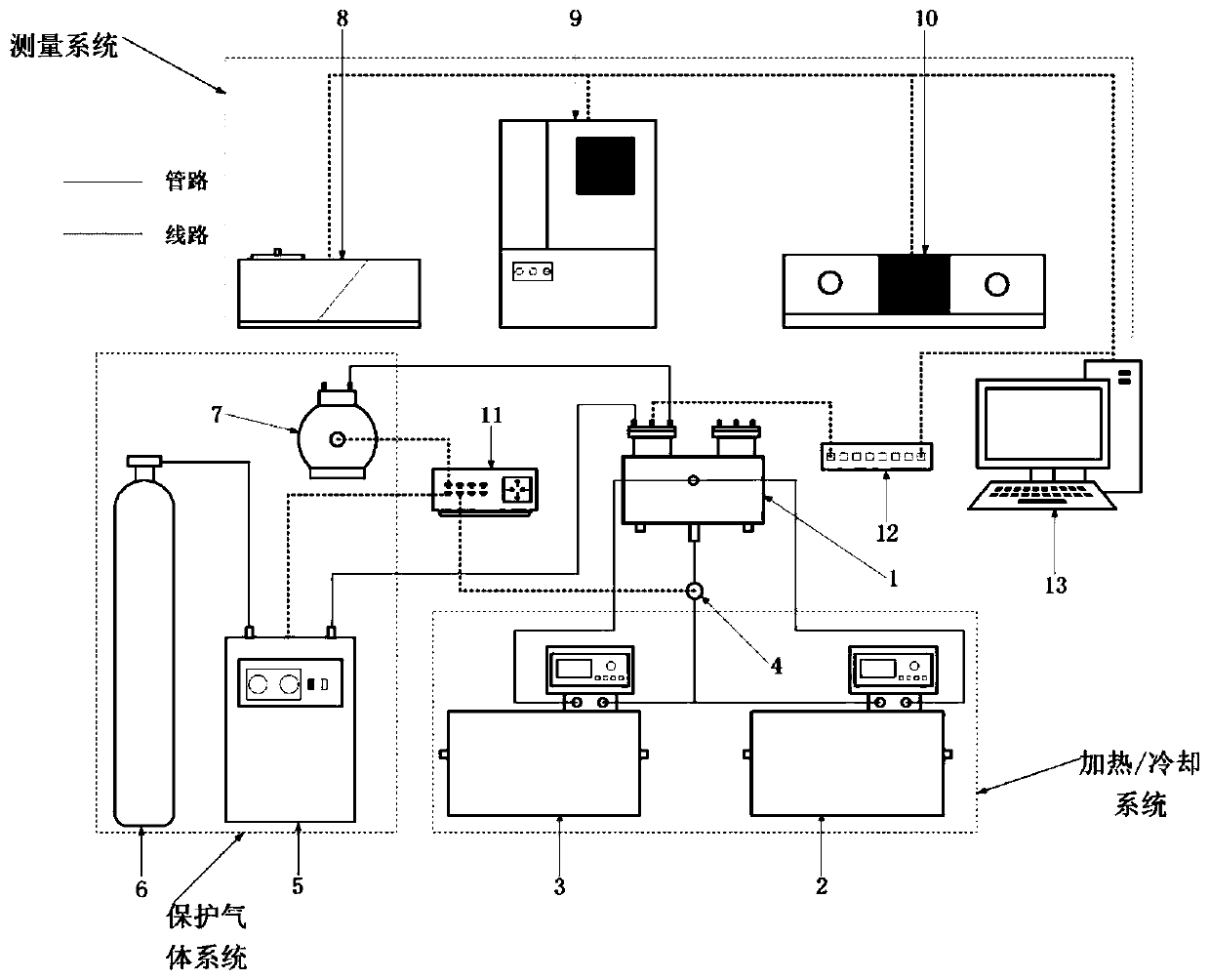

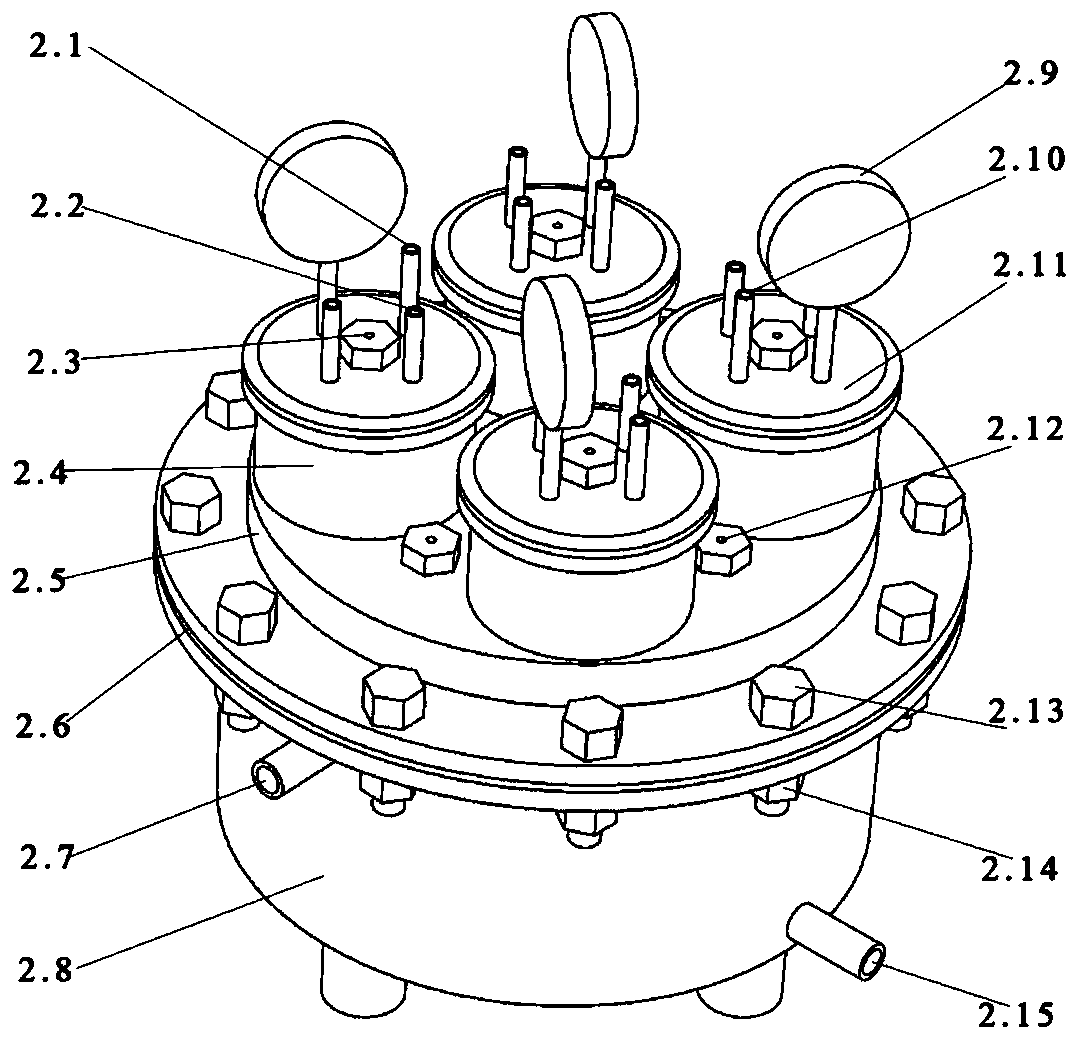

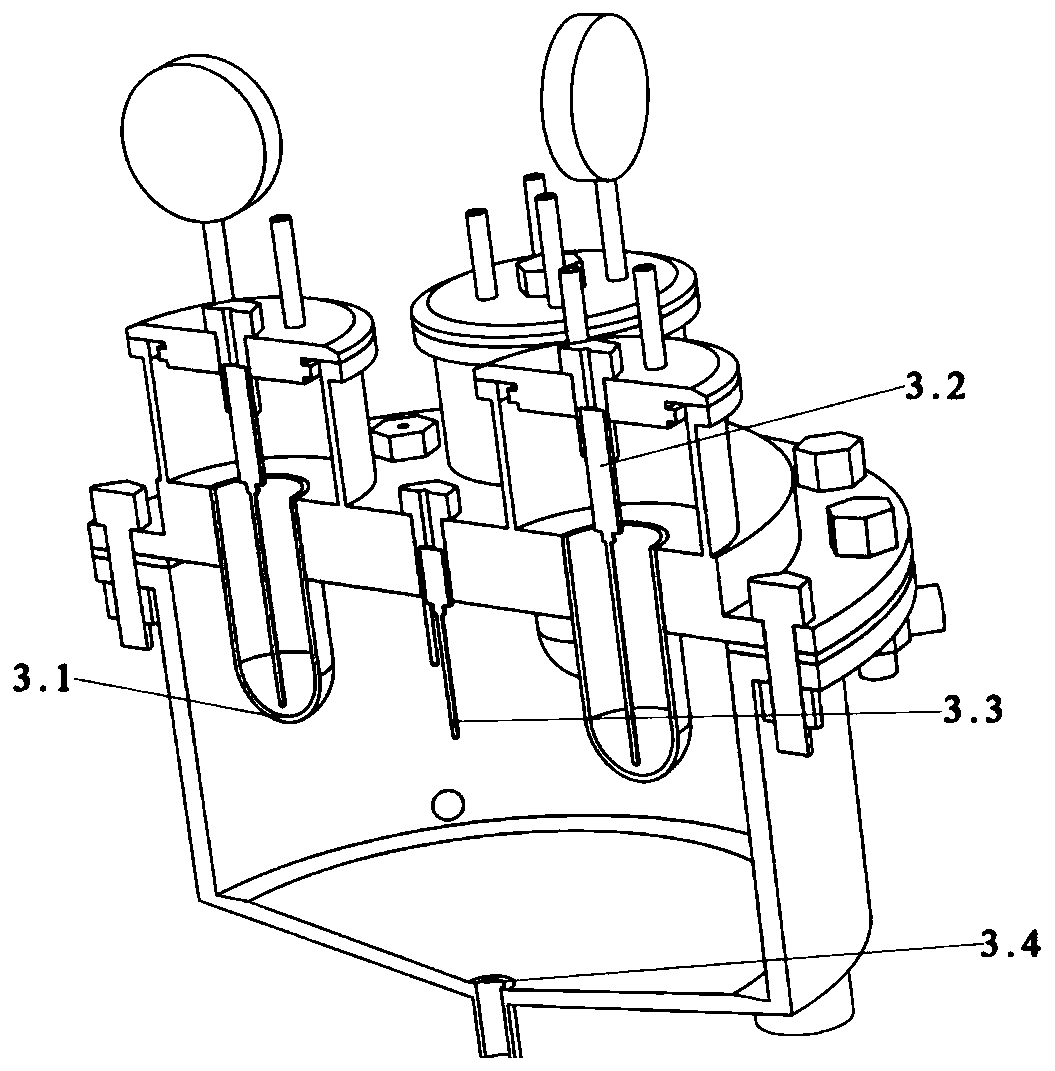

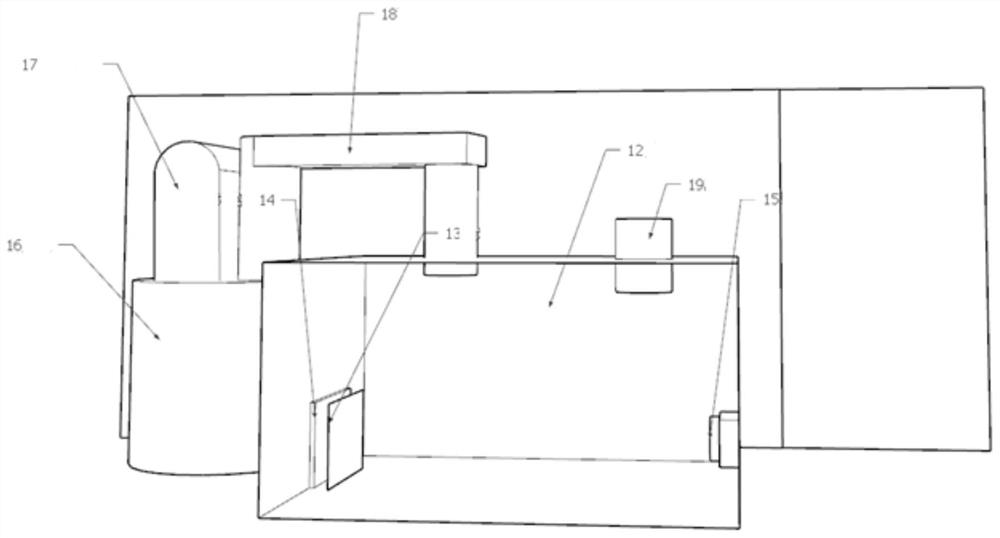

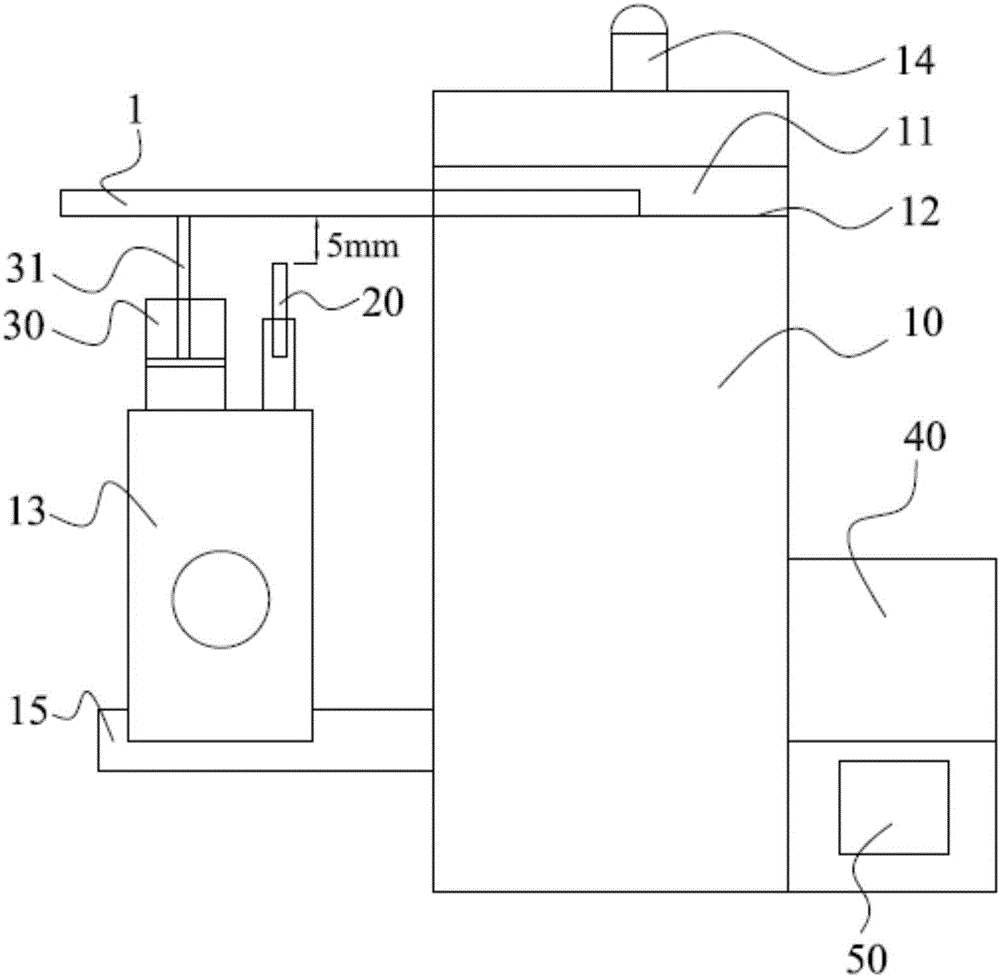

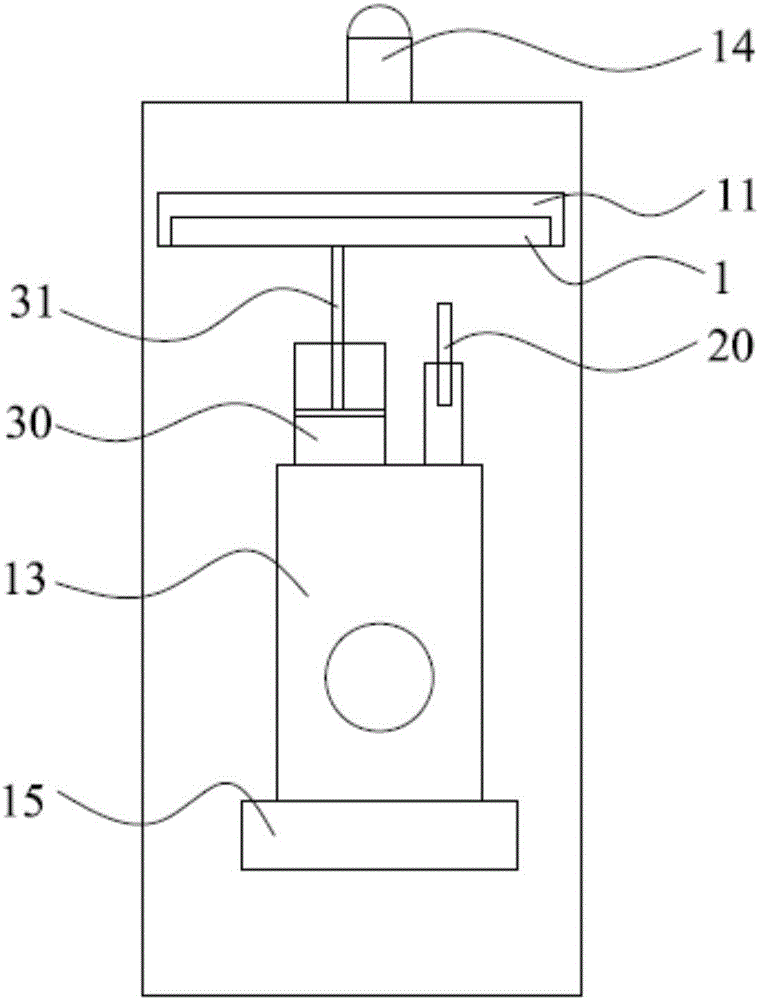

Integrated device for testing stability of phase change thermal storage material as well as method

ActiveCN109738476AControl heating temperatureControl cooling temperatureInvestigating phase/state changeMeasurement deviceProcess systems

The invention discloses an integrated device for testing stability of a phase change thermal storage material as well as a method. The device is applied to testing of the stability of the phase changethermal storage material. The device comprises a reaction kettle, a heating / cooling oil bath, an electromagnetic valve, a vacuum pump, a protective gas circulating pump, a protective gas tank, a DSC(differential scanning calorimeter), an X ray polycrystalline diffraction instrument, an infrared spectrometer, a console, a temperature acquisition card and a data acquisition and processing system.The reaction kettle is utilized for providing a test space; the heating / cooling oil bath is utilized for circularly melting and solidifying a material at a constant temperature; the vacuum pump, the protective gas circulating pump and the protective gas tank are utilized for providing a protective gas environment; the console is utilized for controlling a test cyclic process; the temperature acquisition card is utilized for recording temperature variation of the material in the cyclic process; a measuring device is utilized for measuring enthalpy of phase change, a phase change temperature, acrystal structure, a molecular structure and chemical composition of the material after being cycled for multiple times; and the data acquisition and processing system is utilized for processing datainformation returned back by a temperature information acquisition card and the measuring device.

Owner:ZHEJIANG UNIV

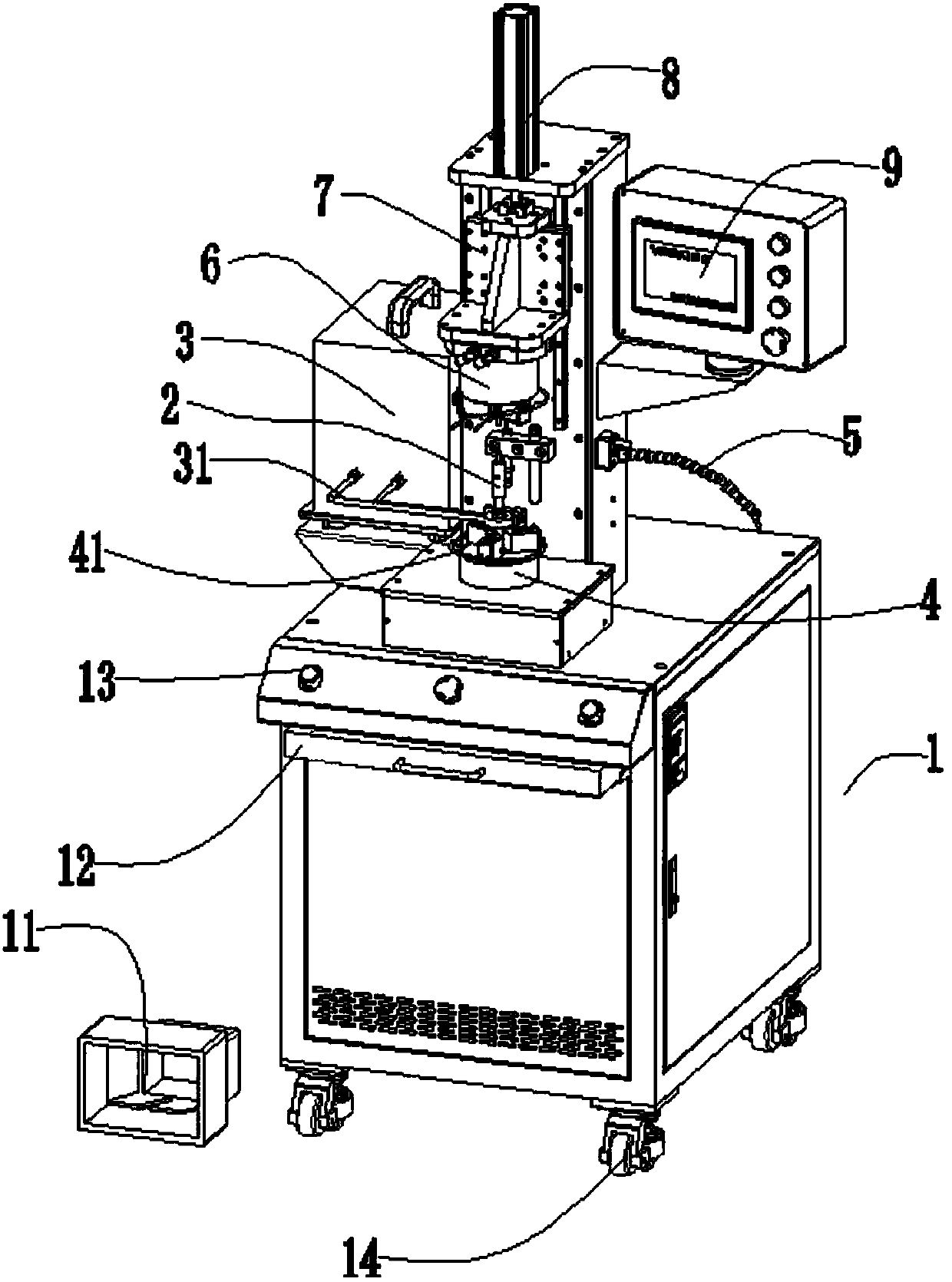

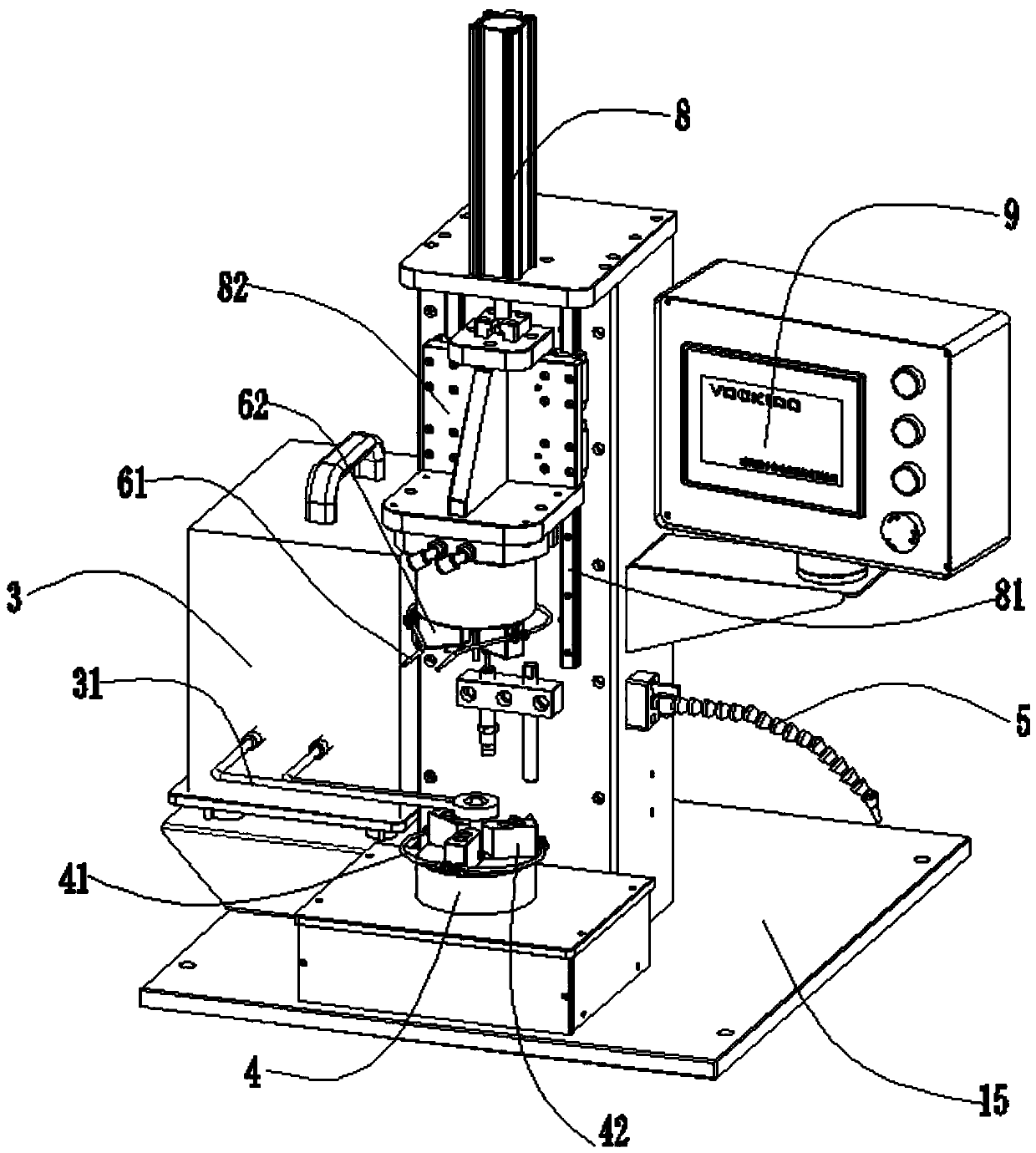

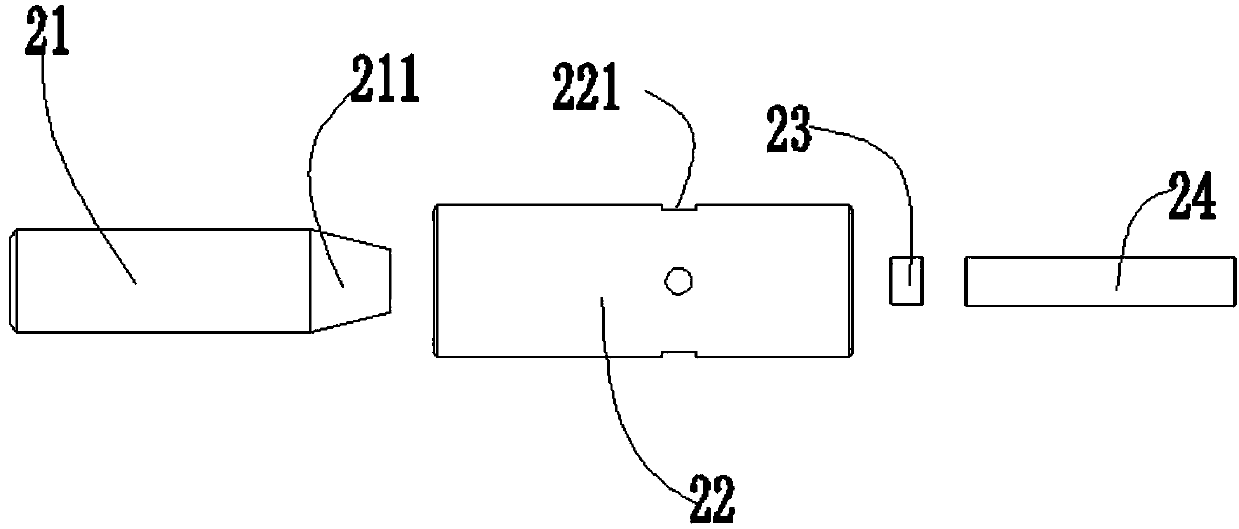

Semi-automatic knife handle brazing machine

PendingCN107855621AImprove cohesionEvenly heatedMetal working apparatusSoldering auxillary devicesTool bitSemi automatic

The invention discloses a semi-automatic knife handle brazing machine which comprises a control display unit, an upper clamp head, a lower clamp head, a welding unit, a high-frequency heating machineand a drive unit controlling the upper clamp head to move up and down. The control display unit and the high-frequency heating machine are in signal connection. The welding unit comprises welding flux, a knife handle and a knife head. The knife head is clamped by the upper clamp head, the knife handle is clamped by the lower clamp head, and the welding flux is arranged at the upper end of the knife handle. A high-frequency induction coil of the high-frequency heating machine is arranged at the combined position of the knife head and the knife handle. The concentricity of the upper clamp head and the lower clamp head is smaller than or equal to 0.05 mm. Compared with the prior art, the semi-automatic knife handle brazing machine has the beneficial effects of being good in welding quality, high in production efficiency and the like.

Owner:珠海市威卡自动化设备有限公司

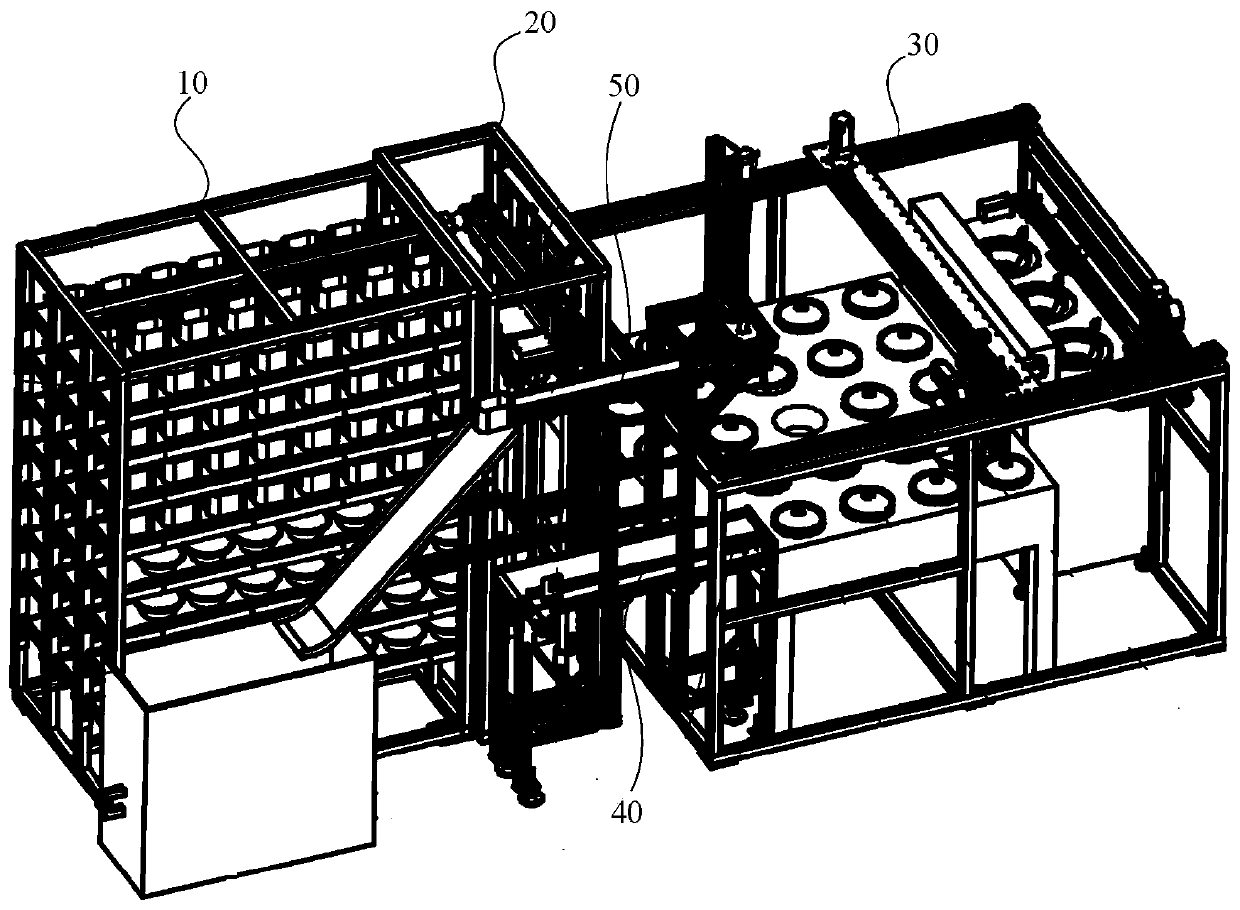

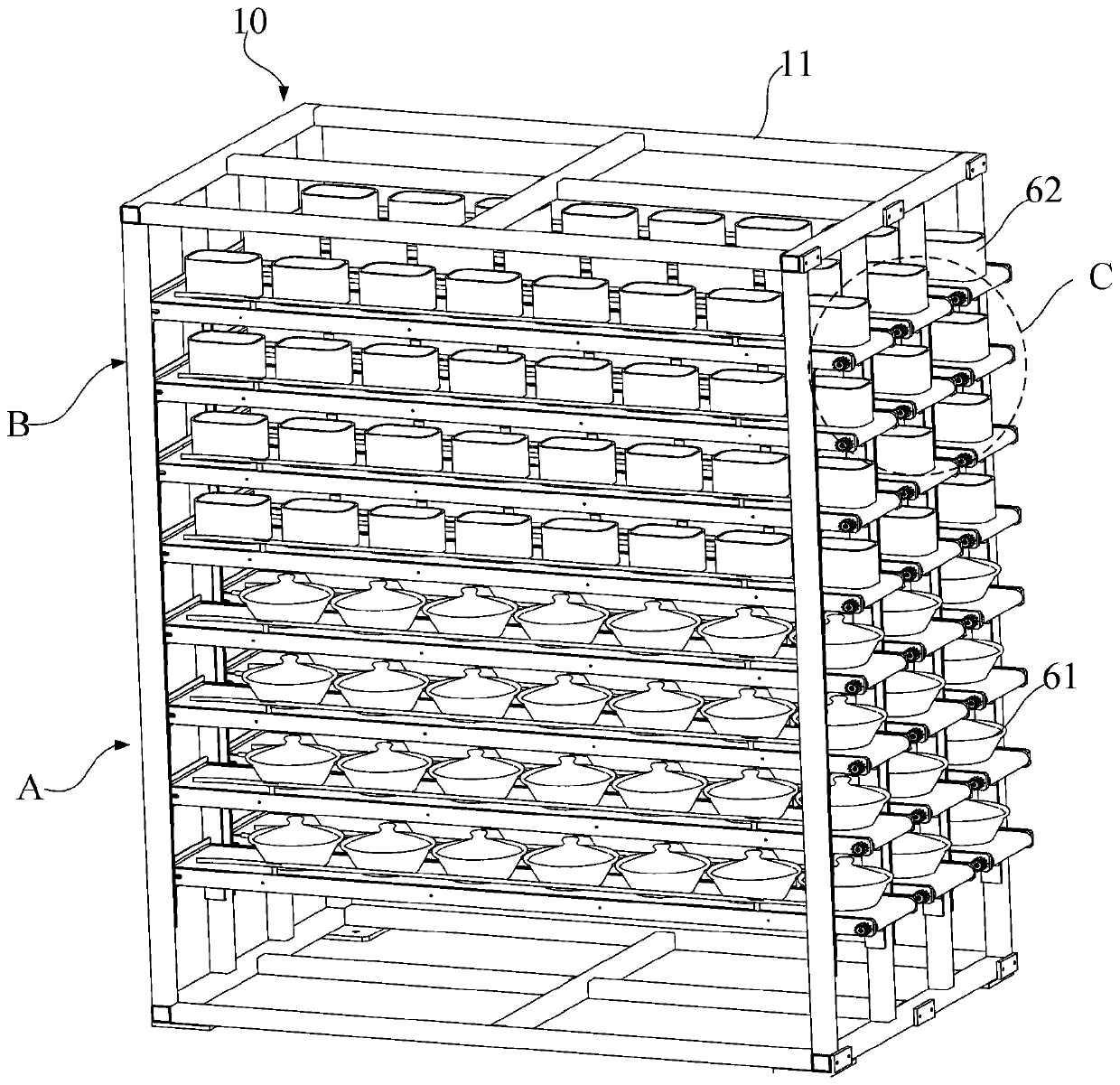

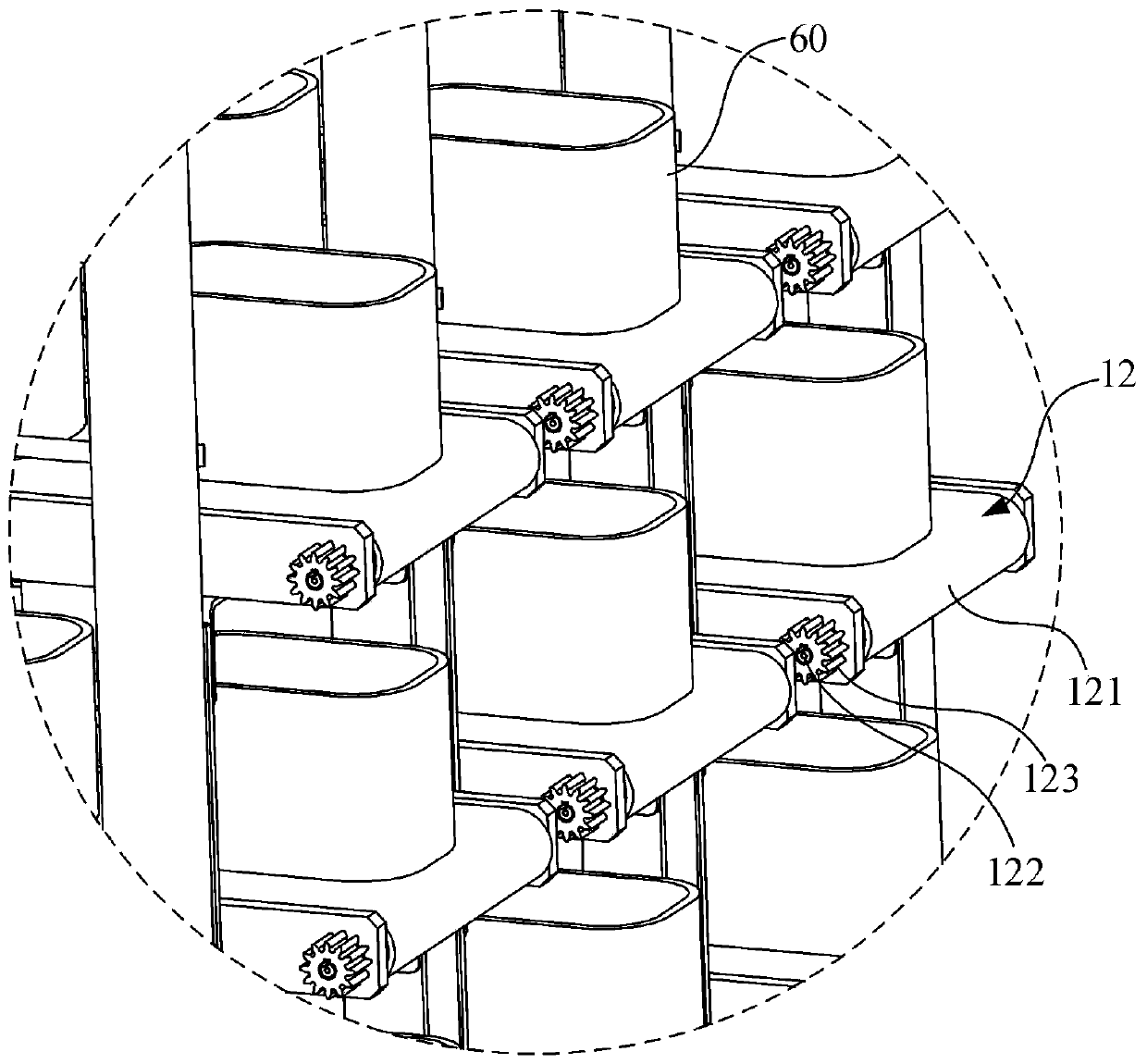

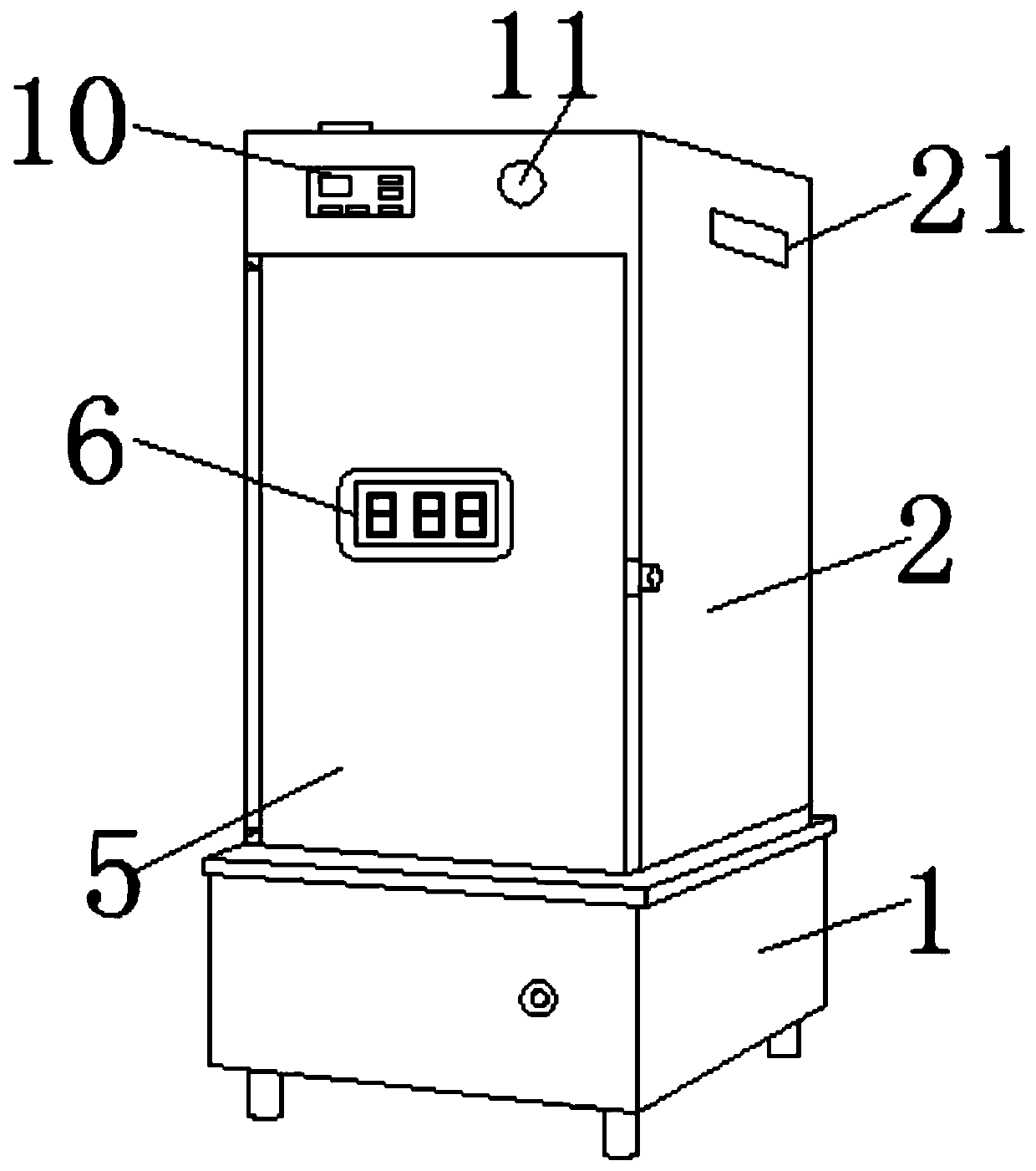

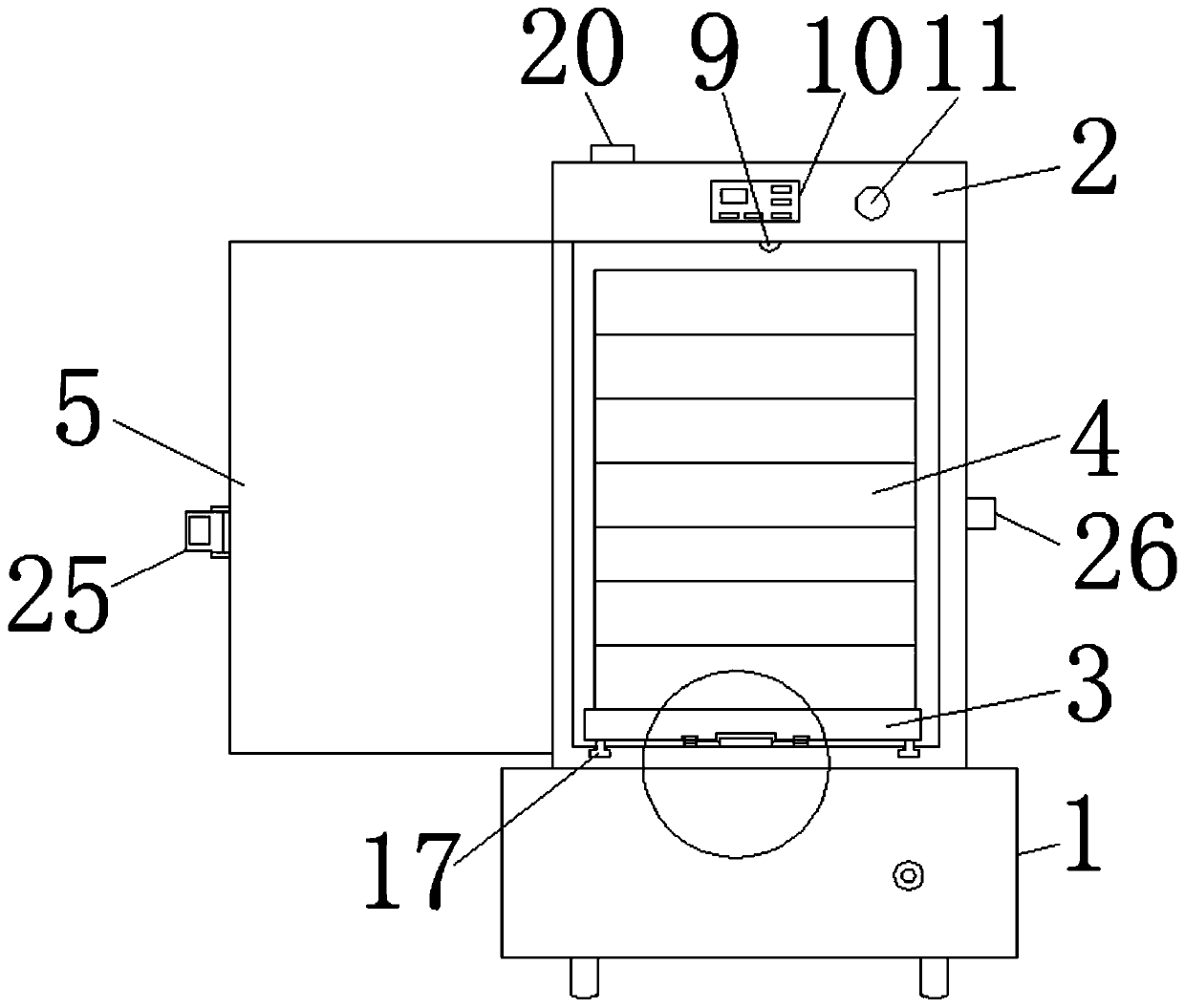

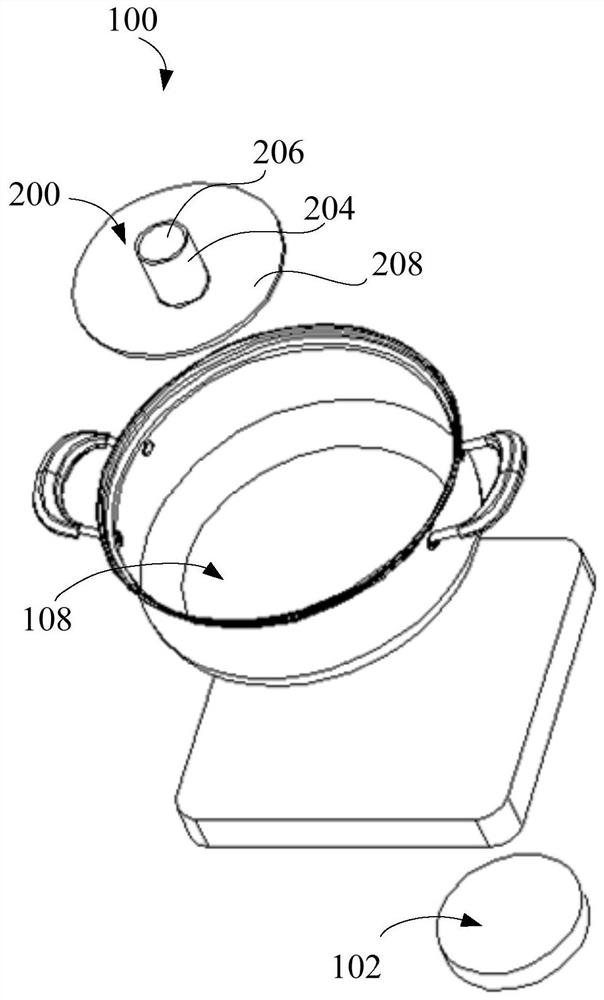

Cooking device and cooking method

ActiveCN111281117AIncrease productivityRealize automatic cookingCooking vessel constructionsProcess engineeringFood material

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Heating device for tea processing technology and working method thereof

PendingCN110274446AAutomatic separationNo dropDrying solid materials with heatPre-extraction tea treatmentEngineeringSlide plate

The invention discloses a heating device for a tea processing technology. The heating device for the tea processing technology comprises an electric heating kettle and a heating device body arranged on the electric heating kettle; the heating device body comprises a heating box body, a sliding plate which is arranged at the bottom end of the heating box body and slidably connected with the heating box body and multiple boiling drawers distributed in the heating box body at intervals from top to bottom; the bottom end faces of the left side and the right side of each boiling drawer are provided with limiting clamping strips in the width direction, and the upper end faces of the left side and the right side of each boiling drawer are provided with limiting clamping grooves matched with the limiting clamping strips in the width direction; a temperature sensor is arranged at the top end of the interior of the heating box body; a controller and a timer are arranged on the outer wall of the top end of the heating box body; a sliding mechanism is arranged at the bottom end of the interior of the heating box body; and the end, located in a fixing groove, of the heating box body, is provided with a vent groove in the length direction of the heating box body. According to the heating device for the tea processing technology, heated tea can be automatically and quickly separated from a heat source, the heated boiling drawers are taken out of the heating box body and do not need to be directly taken out by workers, and the condition that the workers are scalded by high-temperature steam is avoided.

Owner:李学升

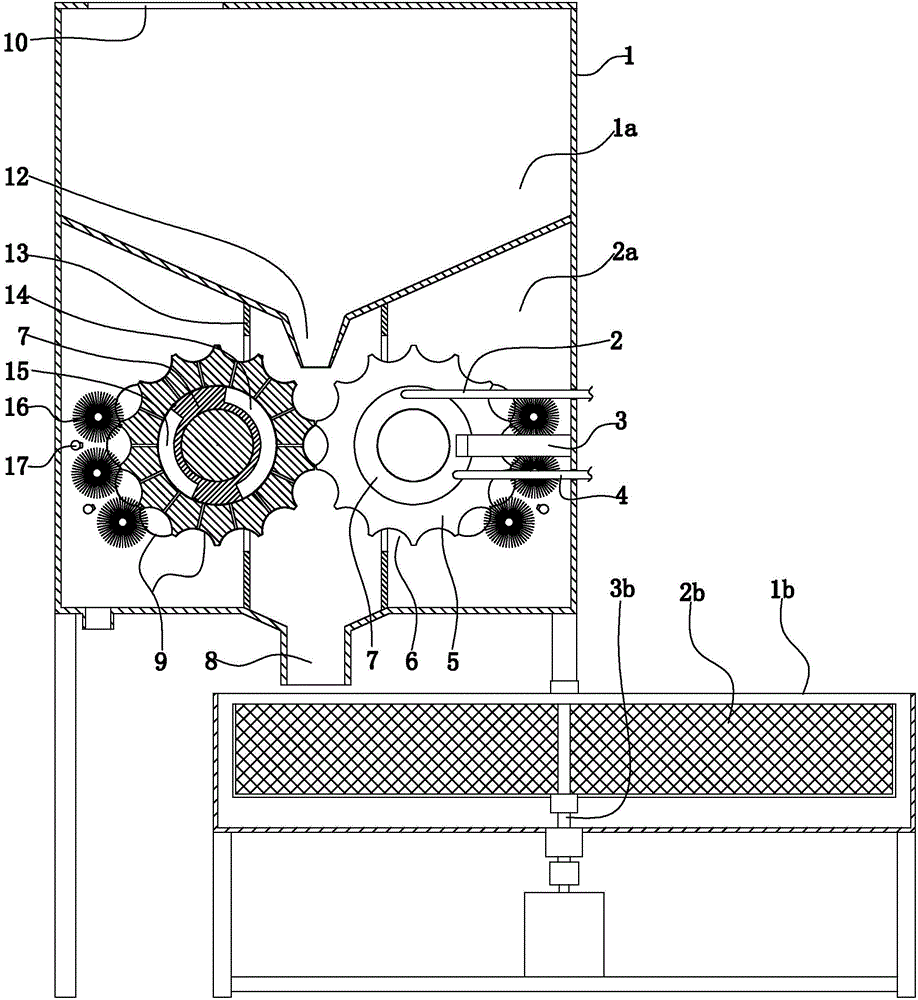

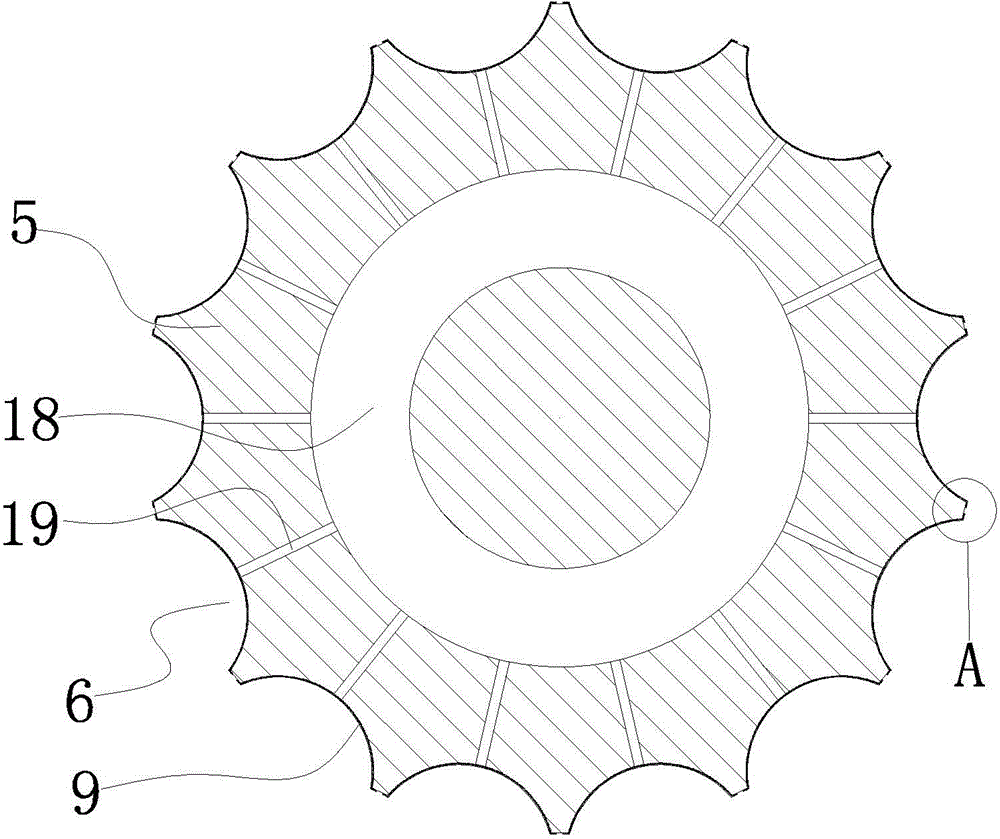

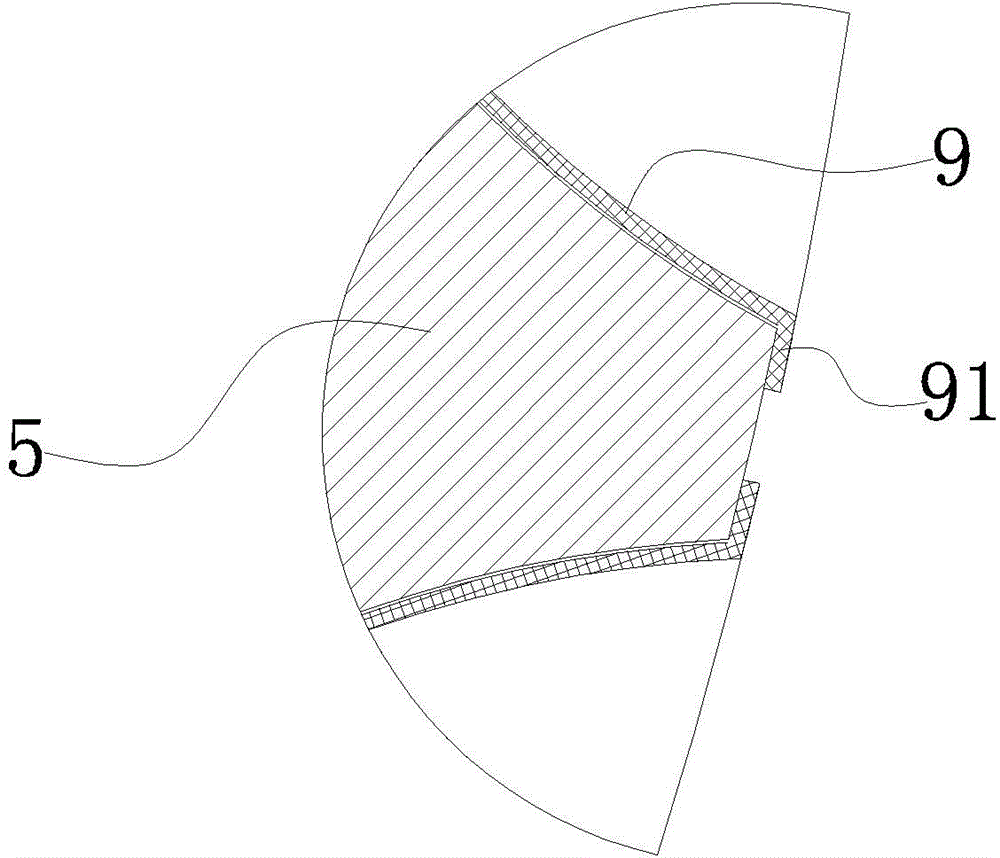

Peeled squid processing device

The invention discloses a peeled squid processing device. The peeled squid processing device is a squid pill production device which realizes fish ball continuous production and can effectively remove fish ball slurry adhering to the inner walls of molding grooves. The peeled squid processing device comprises a cabinet, a boiling device, an air feeding chamber, a negative pressure chamber, a feeding basin arranged at the upper part of the cabinet, a pelletizing basin arranged at the lower part of the cabinet and left and right synchronous relative rotation discs in the pelletizing basin. The bottom of the feeding basin is provided with a feeding inlet, the bottom of the pelletizing basin is provided with a discharge outlet, and the peripheral surfaces of the two rotation discs are provided with the matching molding grooves for fish ball molding. The boiling device comprises a circular boiling tank arranged below the discharge outlet and a heating device arranged in the circular boiling tank.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

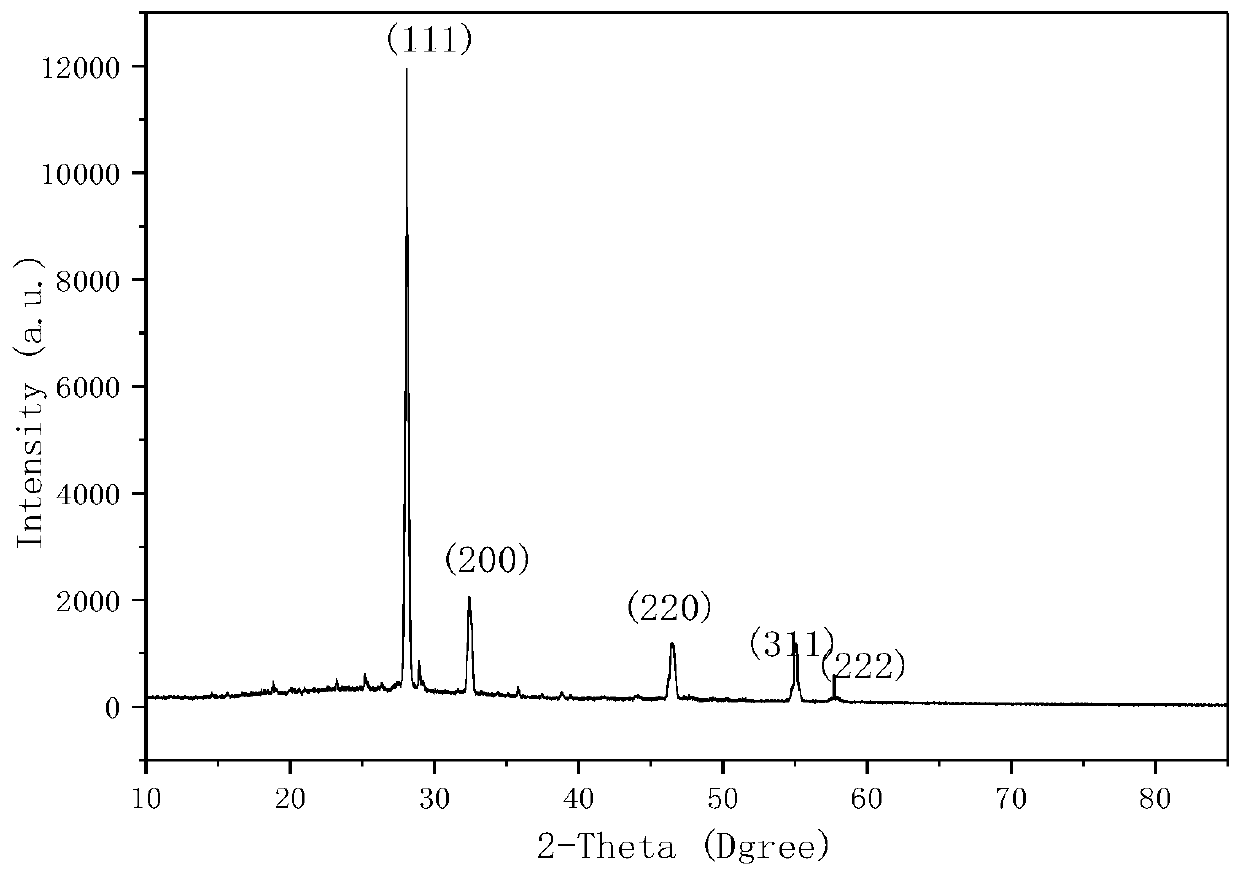

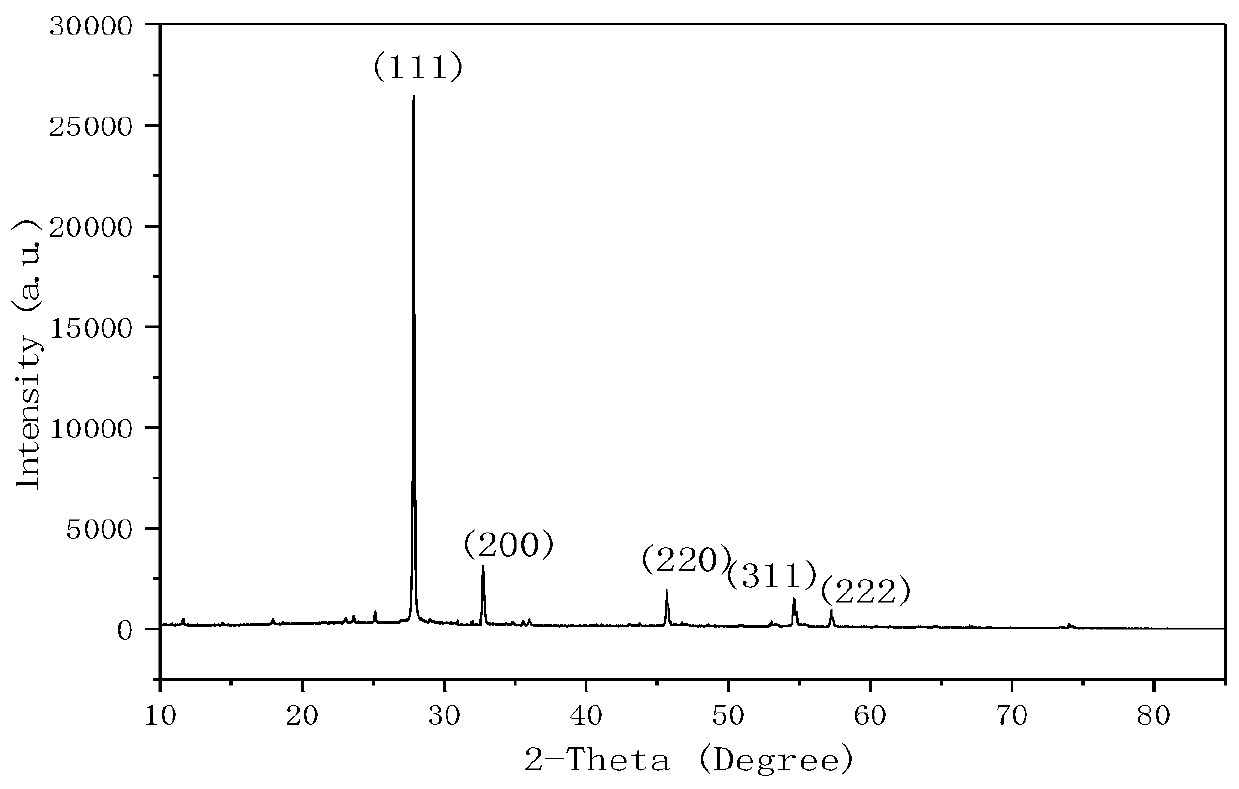

Method for preparing bismuth oxide-based electrolyte material Bi<1-x>A<x>O<1.5-delta> by utilizing microwave combustion-supporting method

InactiveCN109713348AHeating evenly and quicklyQuickly and comprehensively stimulate the combustion reactionMaterial nanotechnologyFuel cellsMicrowave methodCalcination

The invention relates to a method for preparing a bismuth oxide-based electrolyte material Bi<1-x>A<x>O<1.5-delta> by utilizing a microwave combustion-supporting method, and relates to the technical field of preparation of bismuth oxide-based electrolyte materials. The chemical formula of bismuth oxide-based electrolyte material is Bi<1-x>A<x>O<1.5-delta>, and the preparation method comprises thefollowing steps: taking bismuth nitrate, nitrate of elements corresponding to A and a complexing agent as reaction raw materials, performing heating and evaporating to form sol, spraying the sol through a spraying machine to form a nano-scale precursor, putting the nano-scale precursor into a microwave oven, carrying out microwave heating and combustion to prepare nano-powder, and finally performing tabletting and sintering to obtain the material. A microwave method and a self-combustion method are combined, and the interior of a reaction system is heated uniformly and rapidly through wave radiation energy during microwave heating combustion supporting, and a combustion reaction can be excited rapidly and comprehensively. The precursor uniformly and quickly generates a combustion reaction,powder can be synthesized at a high temperature in one step, the yield in unit time is high, and a later high-temperature calcination process of a common method is avoided.

Owner:HEFEI UNIV

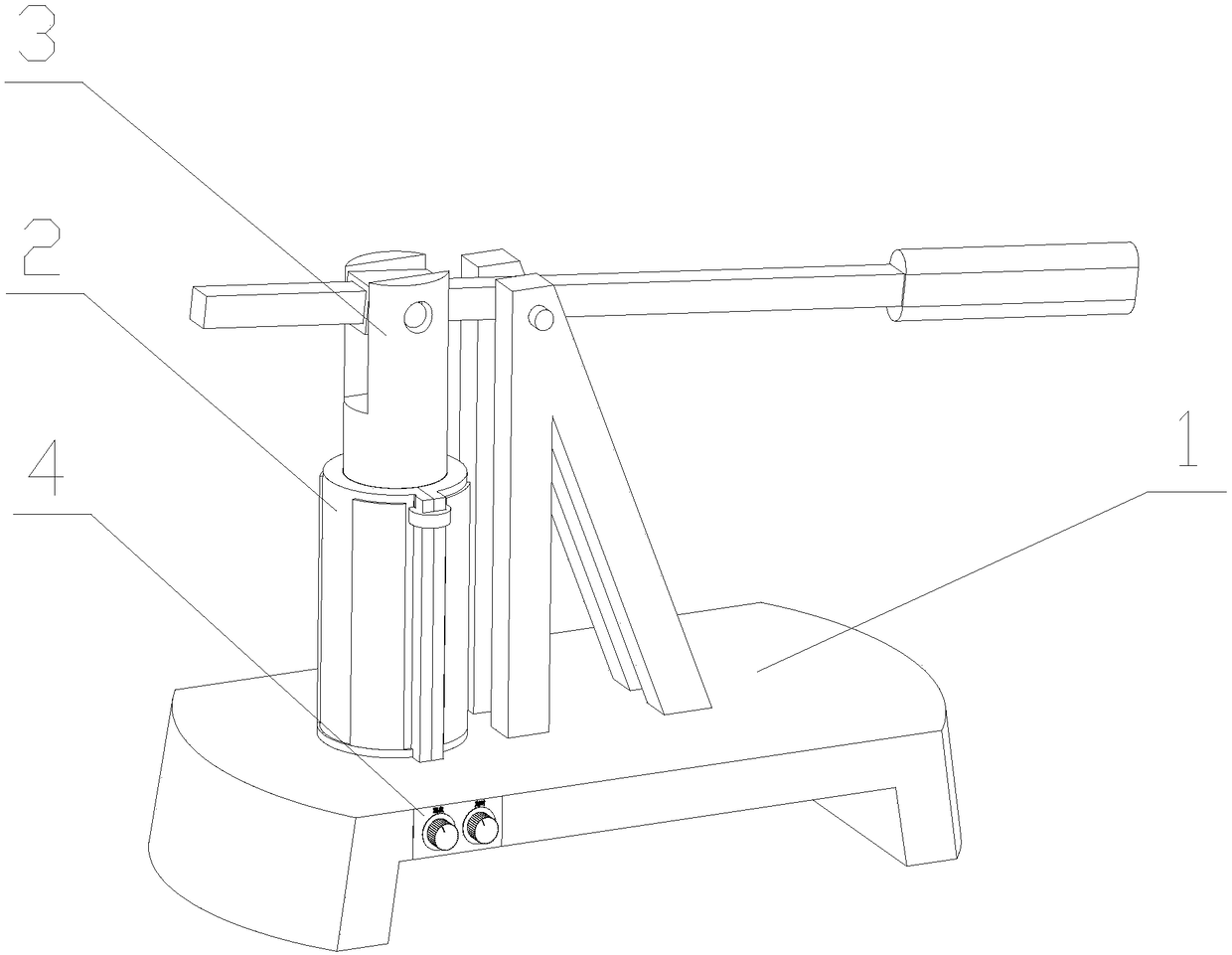

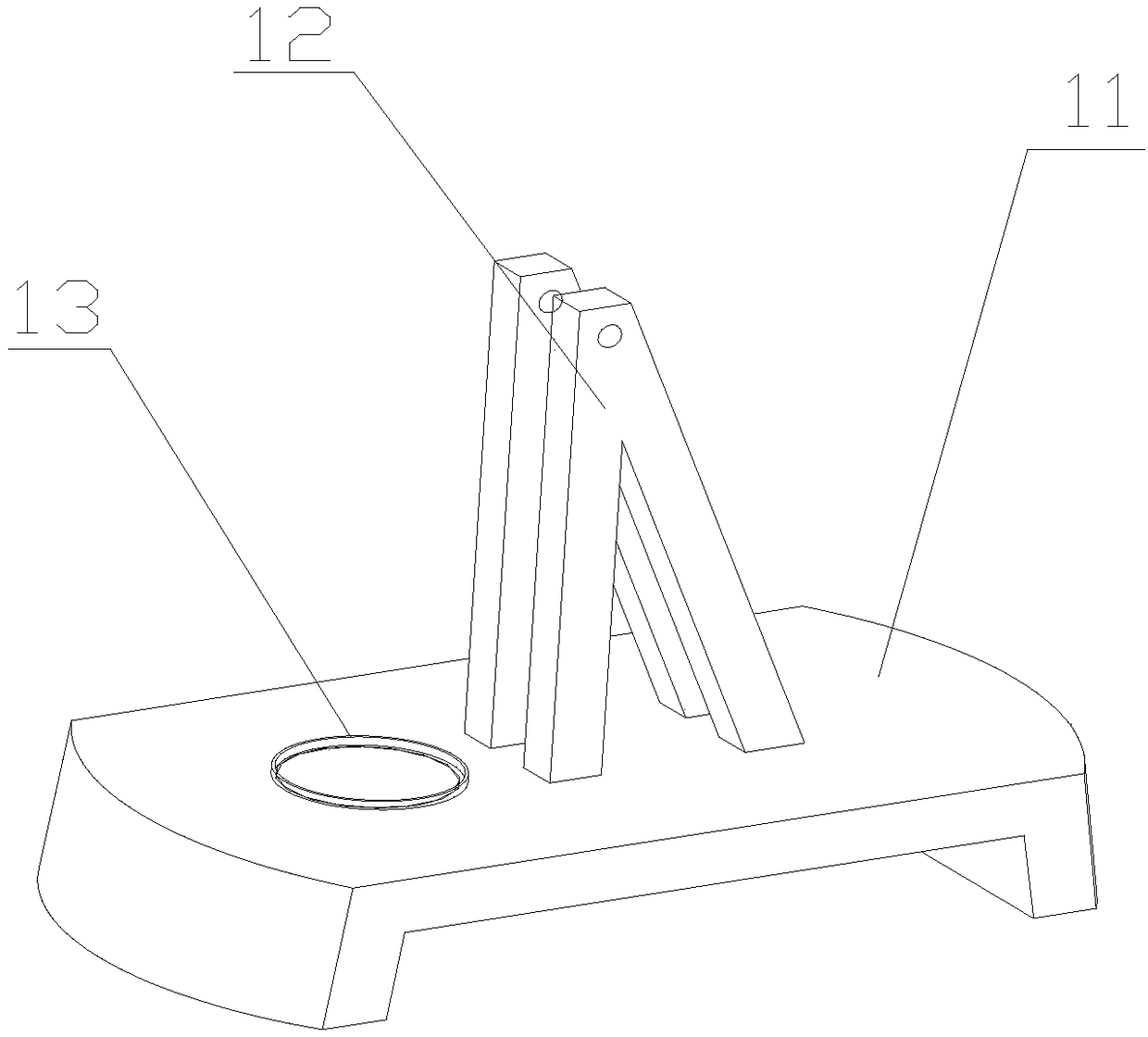

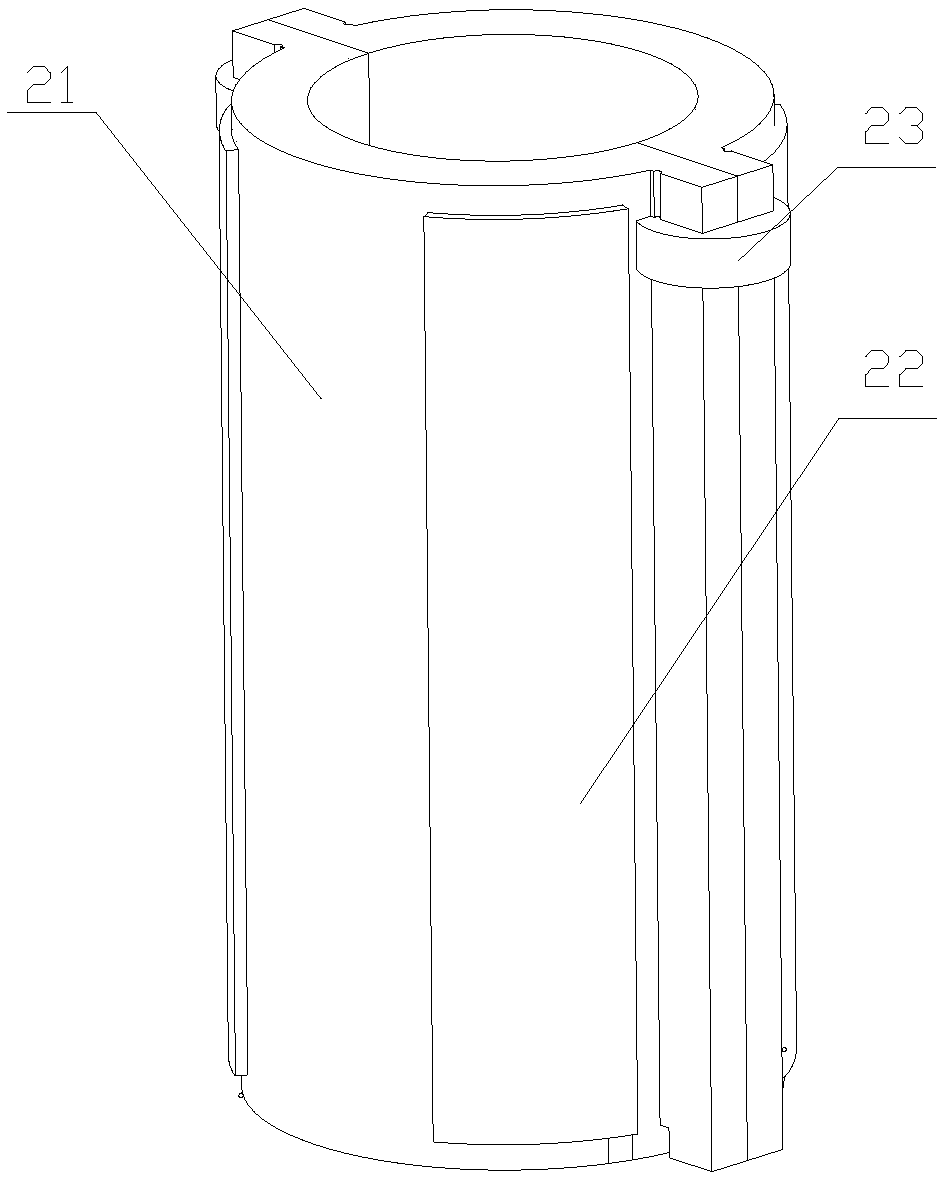

Device for producing cylindrical test piece for rock and soil test

InactiveCN109470536AAchieve supportAchieve fixed supportPreparing sample for investigationTemperature controlEngineering

The invention discloses a device for producing a cylindrical test piece for a rock and soil test, aims to achieve rapid production of the cylindrical test piece for the rock and soil test through a lever compacting device and an electric heating matched mould device integrating electric heating sheets, overcomes the defects of high labor consumption, long drying time, low production efficiency andthe like during the conventional smashing hammer knocking compaction, and achieves test piece production with high efficiency and low labor consumption. The device for producing the cylindrical testpiece for the rock and soil test comprises a machine frame device, the electric heating matched mould device, the lever compacting device and a timing and temperature control device. The device for producing the cylindrical test piece for the rock and soil test is convenient to operate and easy to maintain, and has a broad application prospect in the production of rock and soil test pieces.

Owner:QINGDAO UNIV OF SCI & TECH

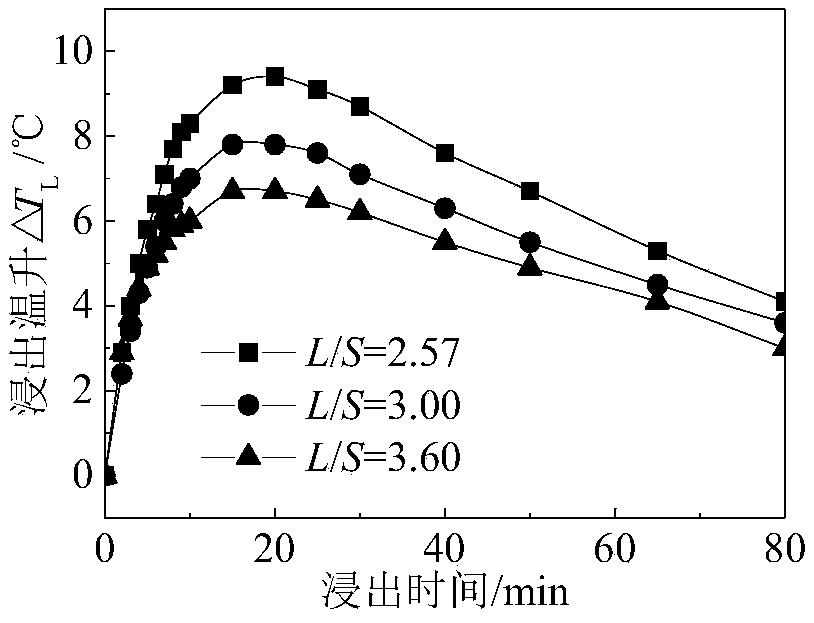

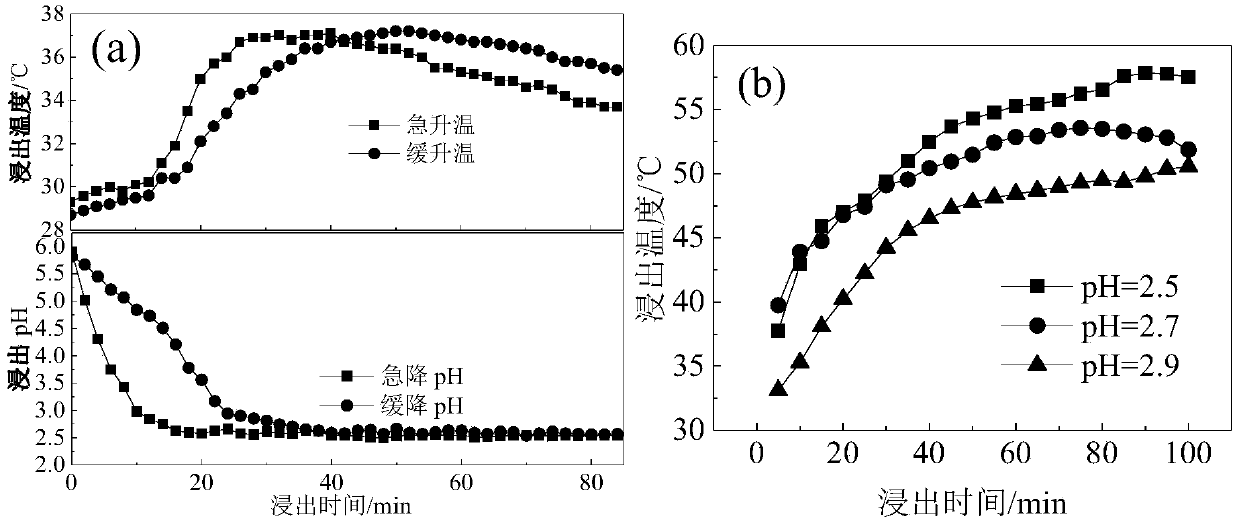

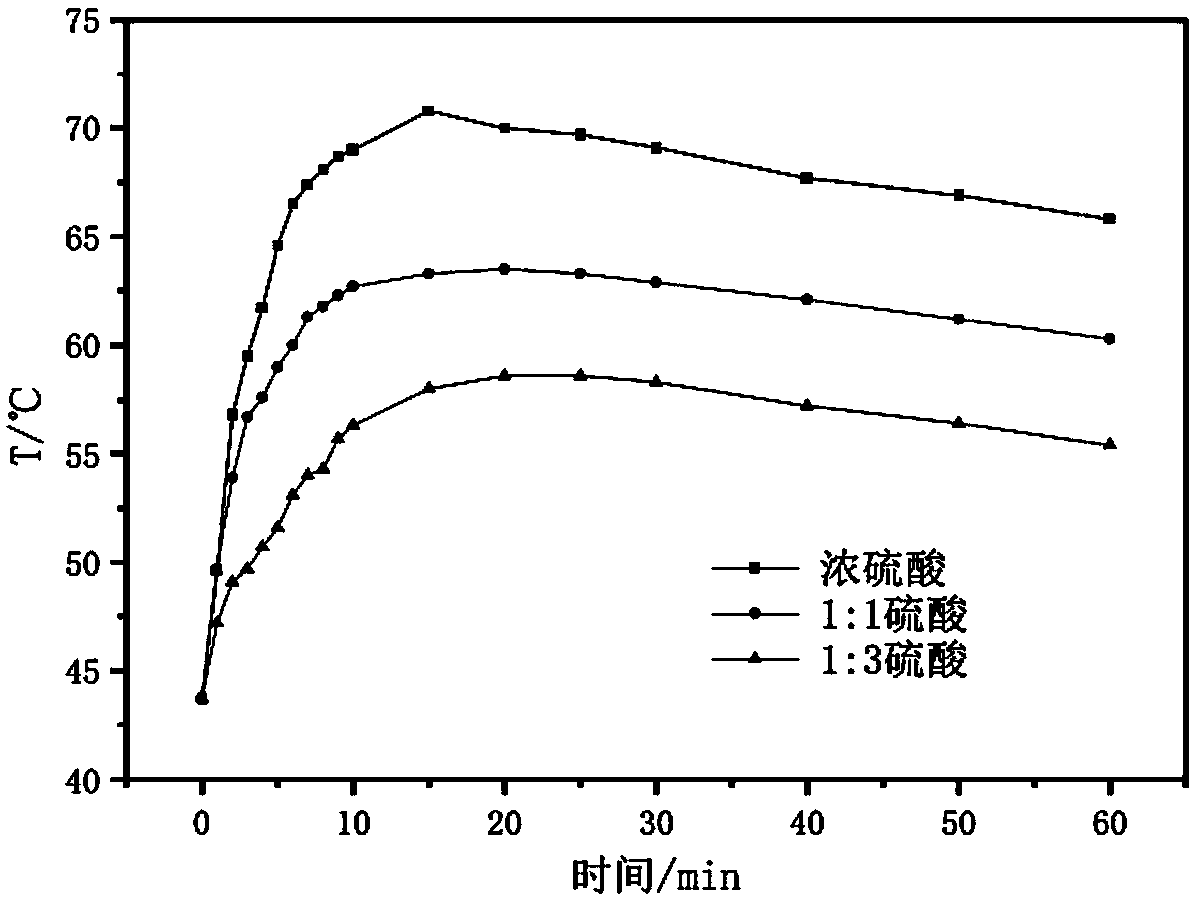

Acid pickling method of calcified clinker

ActiveCN109252047AGuaranteed dissolution rateGeneration of controlProcess efficiency improvementHydrogenRise rate

The invention belongs to the field of metallurgy, and particularly relates to an acid pickling method of calcified clinker. Aiming at solving the technical problem, the invention provides the acid pickling method of the calcified clinker. In the acid pickling method, according to the different specific values of acid-soluble vanadium amounts to total vanadium amounts in roasted clinker and ambienttemperatures, the proper temperature rise rate is controlled; thus, the proper liquid-solid ratio of a mother liquor amount to a clinker amount is further controlled and the factors of a pH (potential of Hydrogen) change rate and the like are controlled; and therefore, the acid pickling rate of calcified and roasted clinker is enabled to be up to 95% or above.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

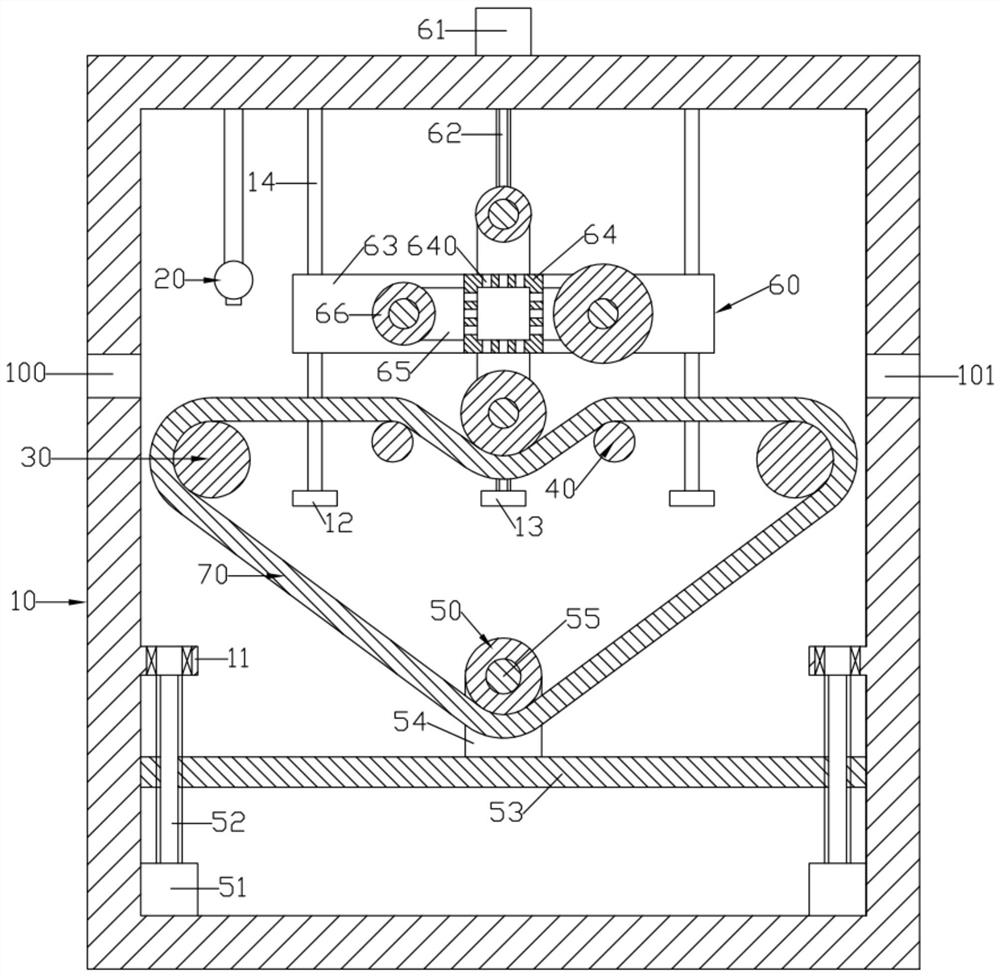

Automatic transporter with high-temperature water channel for sterilization

InactiveCN101920802AReduce labor intensityIncrease productivityPackage sterilisationCharge manipulationHeating timeWater channel

The invention discloses an automatic transporter with a high-temperature water channel for sterilization, which comprises a water channel, a transmission conveyer belt, a heater and a motor. The transporter is characterized in that the heater is arranged at the inside bottom the water channel, the water channel is provided with a transmission main shaft, a driven shaft, a steering shaft, a compacting spindle and a fixed support, the external side surface of the water channel is provided with a motor and a transmission system, and the transmission main shaft is connected with the motor by the transmission system. The automatic transporter with a high-temperature water channel for sterilization can perform automatic sterilization and transport on the packed products in the high-temperature water channel; simultaneously, the automatic transporter with the high-temperature water channel for sterilization can improve quality and quantity of the products due to using an automatic transporter to effectively control heating time and temperature.

Owner:浙江亲亲食品有限公司

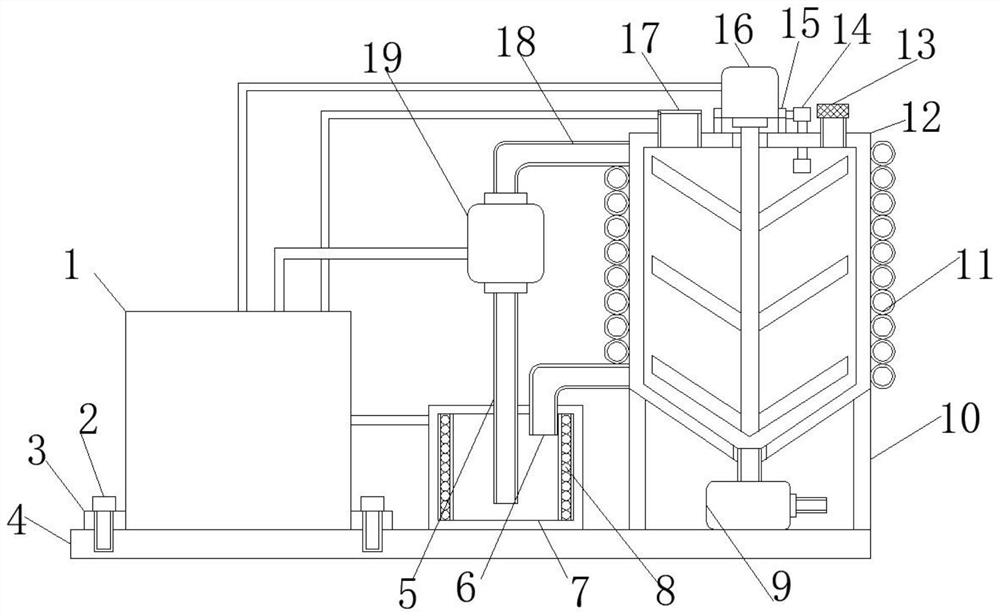

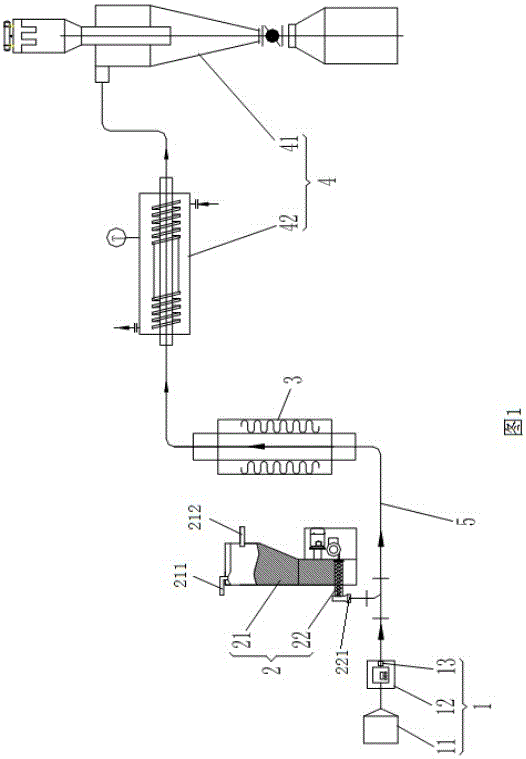

Heating circulation device of crack pouring machine for road repair

InactiveCN112323591AHeating evenlyControl heating timeRoads maintainenceElectric machineryEngineering

The invention discloses a heating circulation device of a crack pouring machine for road repair The heating circulation device comprises a heating circulation control box, a bottom plate is arranged at the bottom of the heating circulation control box, a hot oil heating box is arranged on the right side of the heating circulation control box, a return pipe is arranged on the right side of the topof the hot oil heating box, and a hot oil coil pipe is arranged on the right side of the return pipe; a crack pouring glue heating cylinder is arranged on the inner side of the hot oil coil pipe, a glue pump is arranged at the bottom of the crack pouring glue heating cylinder, an exhaust cylinder is arranged on the right side of the top of the crack pouring glue heating cylinder, a driving motor is arranged in the center of the top of the crack pouring glue heating cylinder, and a temperature sensor is arranged in front of the driving motor; and a temperature probe of the temperature sensor extends into the crack pouring adhesive heating cylinder, and a feeding pipe is arranged on the left side of the driving motor. According to the heating circulation device of the crack pouring machine for road repair, the heating time of crack pouring glue is controlled, energy is saved, the crack pouring glue is heated uniformly, and crack pouring is facilitated.

Owner:安徽宜瑞达纸业有限公司

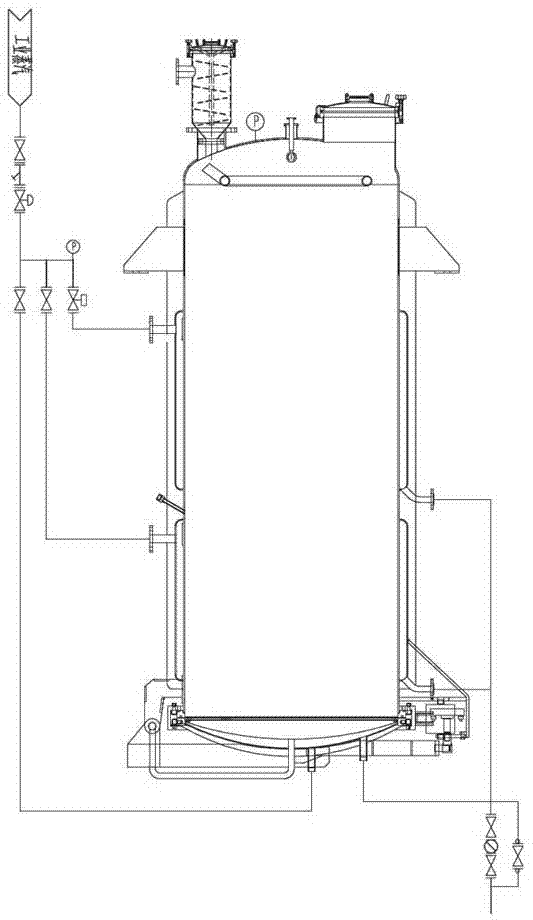

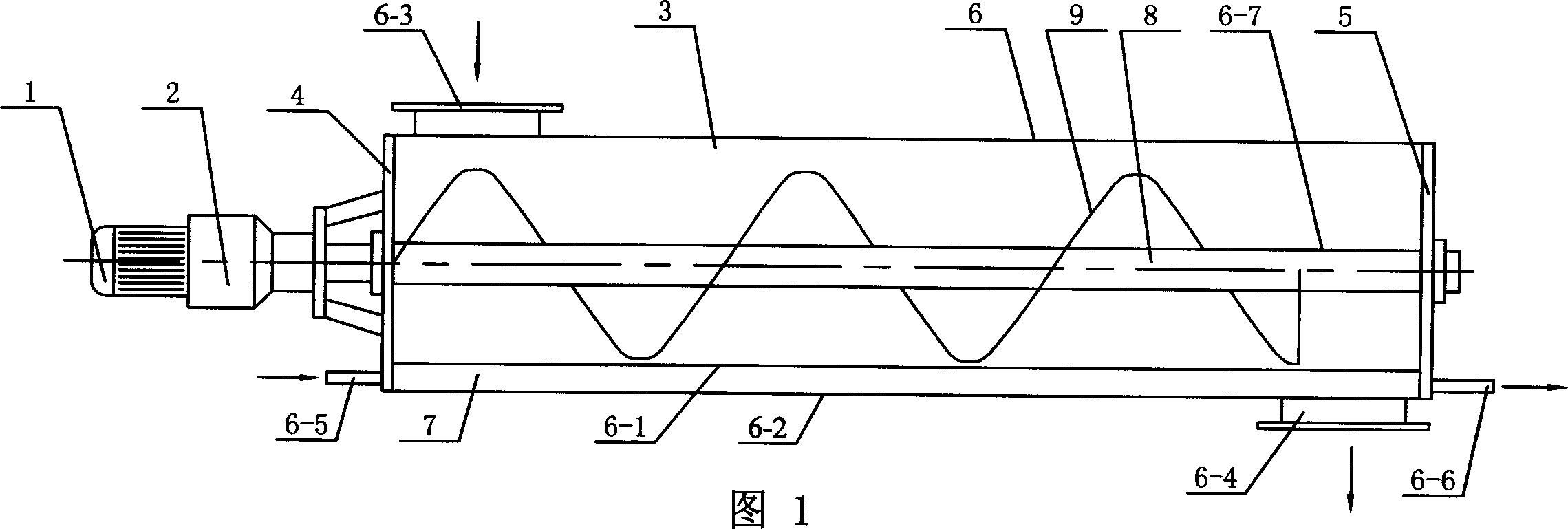

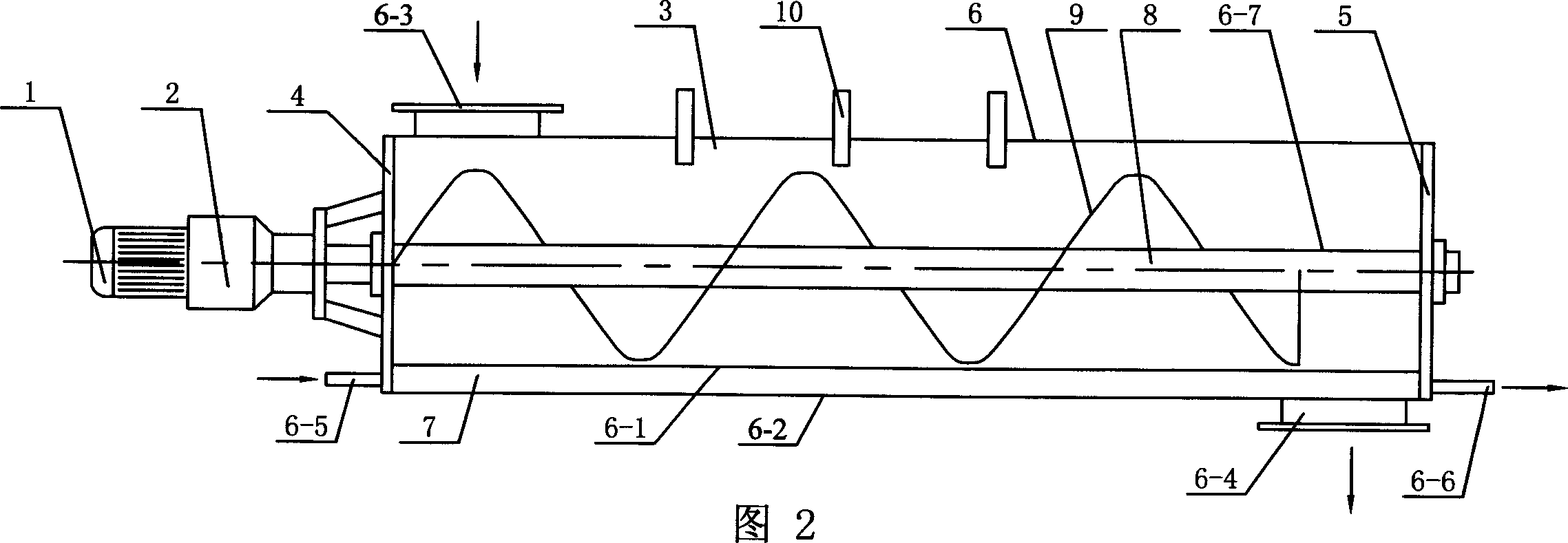

Oxygen stewing separation method and equipment used therefor

InactiveCN1594726ANo pollutionStrong penetrating powerPulping with inorganic basesReaction temperatureSlurry

Oxygen stewing separation method and equipment used therefor relates to a method of processing the stalk thread into stalk slurry and the equipment used therefor. The method comprises following steps: a. adding the stalk thread into the oxygen stewing separation equipment; b. preparing auxiliary, which is composed of following components by weight percent: 3-10% of alkali, 70-85% of alkaline hydrogen dioxide, 3-10 of sodium silicate, 0.5-1.5% of grafting starch, 0.5-2% of magnesium sulfate, 5-15% of chlorine-oxygen; c. adding the prepared auxiliary into the Oxygen stewing separation equipment, mixing with the stalk thread uniformly, raising the temperature to boil the stalk thread, making the stalk thread become stalk slurry, in which the reacting temperature is 150-200 DEG C, the reaction time is 100-140 mins / ton, the quantity of the auxiliary is 40-50% of the total weight.

Owner:朱晓平

High-temperature reaction device and graphene material production system

ActiveCN106006627AChange speedChange concentrationProcess control/regulationGrapheneSide reactionAirflow

The invention discloses a high-temperature reaction device which comprises a gas control unit, a powder control unit, a high-temperature reaction unit and a receiving unit. The gas control unit controls the speed of gas flow at an inlet of the high-temperature reaction unit. The powder control unit controls the speed of powder entering the air flow. The receiving unit communicates with an outlet of the high-temperature reaction unit to carry out gas-solid separation on reacted materials. Compared with the prior art, the high-temperature reaction device can achieve high-temperature atmosphere continuous heat treatment for powder materials. The gas control unit can adjust the air intake amount in the whole process and then controls the heated time of the powder in the high-temperature reaction unit. After the reaction, the powder enters the receiving unit, receiving is achieved without halting or cooling, and continuous reaction is achieved. In addition, gas generated after the reaction is finished can be rapidly separated from the powder materials through the receiving unit, side reaction can be avoided, and the purity of the powder materials is further improved. The invention further discloses a graphene material production system.

Owner:湖北高地石墨烯科技有限公司

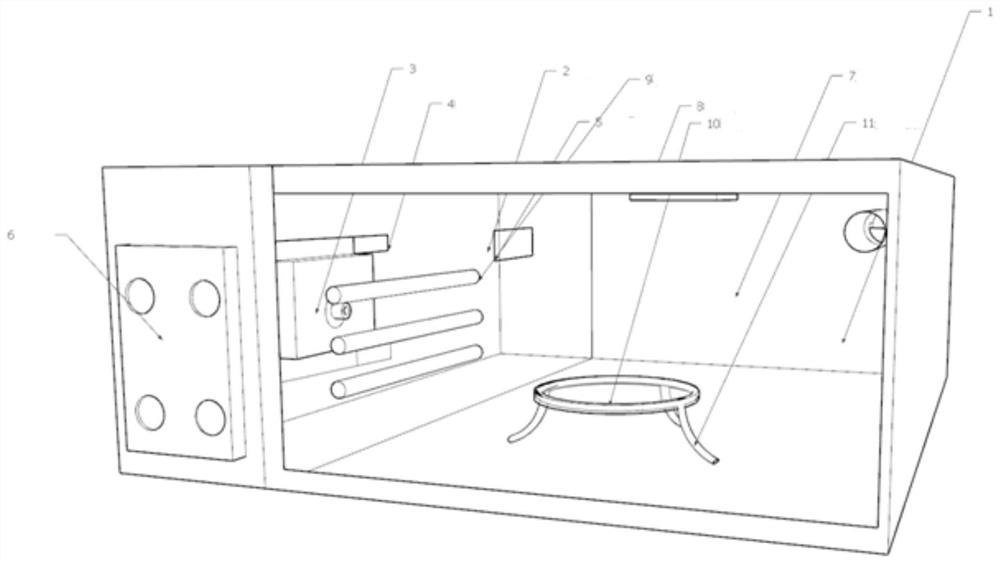

Device for detecting carbon emission of mixture based on microwave induction

PendingCN112595688AHeating fastHeating evenlyPreparing sample for investigationMaterial analysis by optical meansEngineeringLight filter

The invention provides a device for detecting the carbon emission of a mixture based on microwave induction, which belongs to the technical field of measurement, and the device comprises a main body,a heating system, a heat system, a measuring system and a ventilating system, and a heating chamber is arranged on the inner wall of the main body; the heating system comprises a heating chamber, a magnetron, an electrical circuit, a waveguide port and a control panel, energy is transmitted to the heating chamber through the waveguide port, the heat system comprises a temperature sensor, a quartzheating tube, an electric glass turntable and a metal net rack, and the measuring system comprises a measuring chamber, an optical filter, an infrared detector and an infrared light source. The ventilating system comprises a draught fan, a first pipeline, a second pipeline and an air outlet pipeline, the two ends of the first pipeline are connected with the draught fan and the heating chamber respectively, the two ends of the second pipeline are connected with the draught fan and the measuring chamber respectively, the air outlet pipeline is formed in the outer wall of the top of the measuringchamber, and the optical filter is a self-disassembling device. The device is fast in heating, accurate in measurement, convenient to use and suitable for measurement of various gases, and data are recorded and the temperature is controllable.

Owner:YANGZHOU UNIV

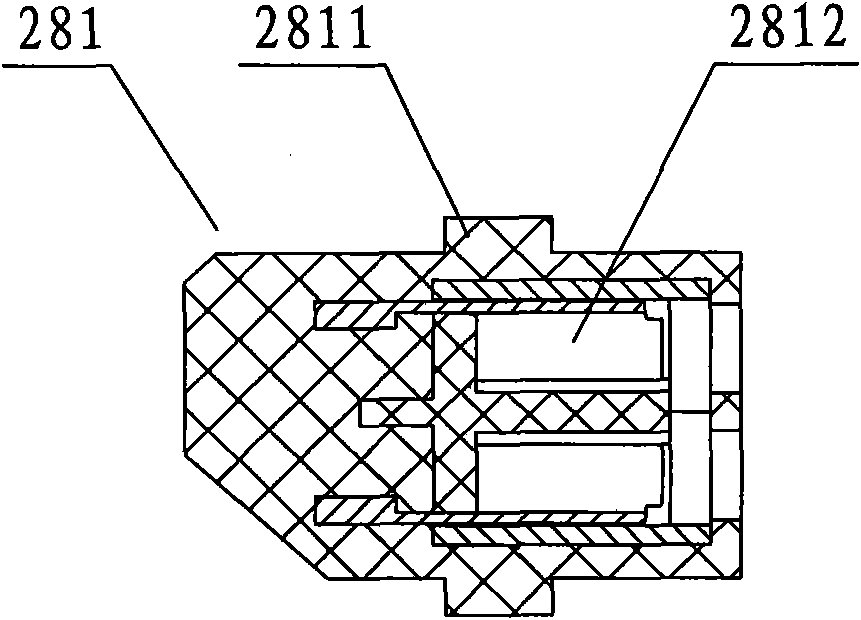

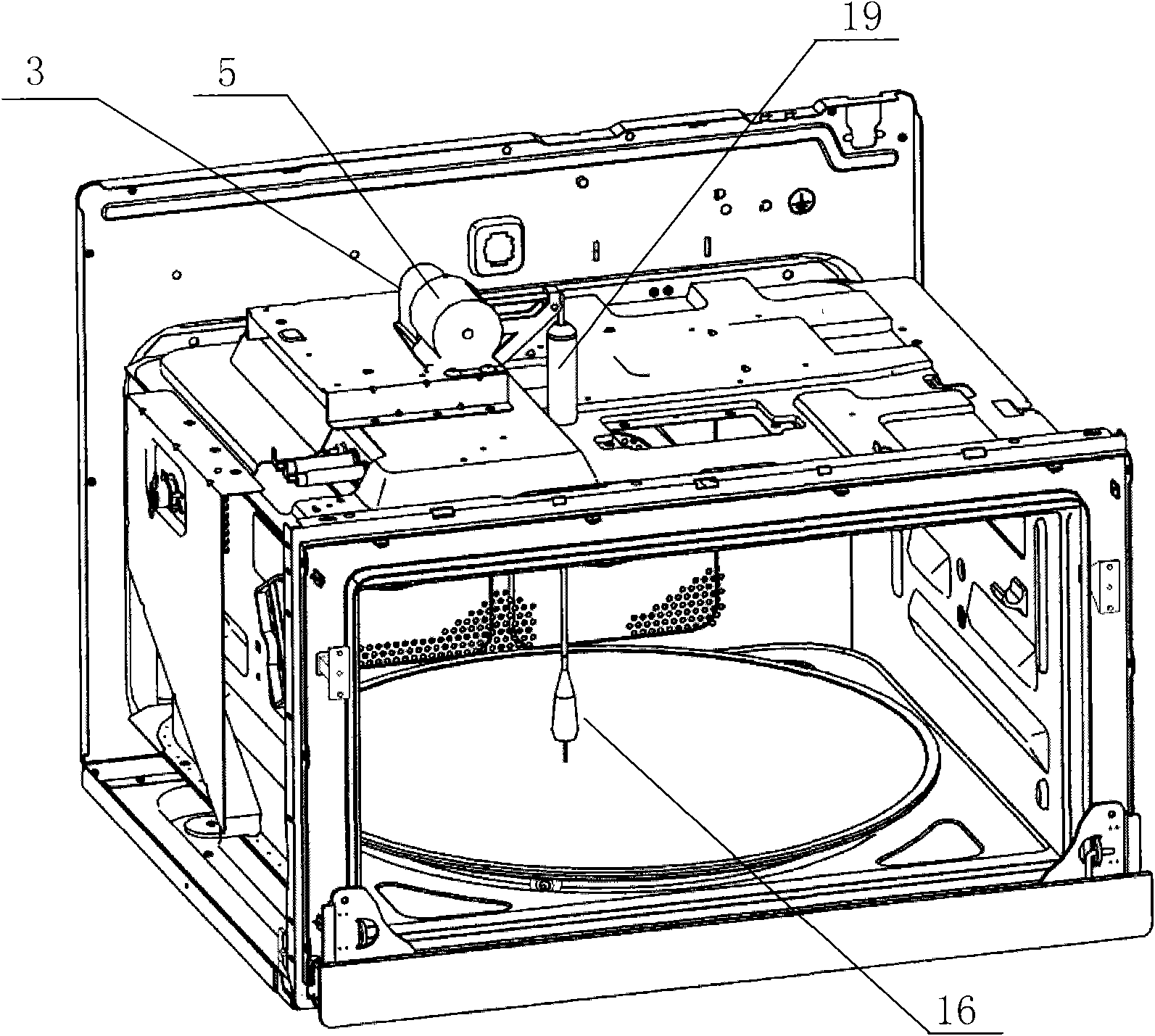

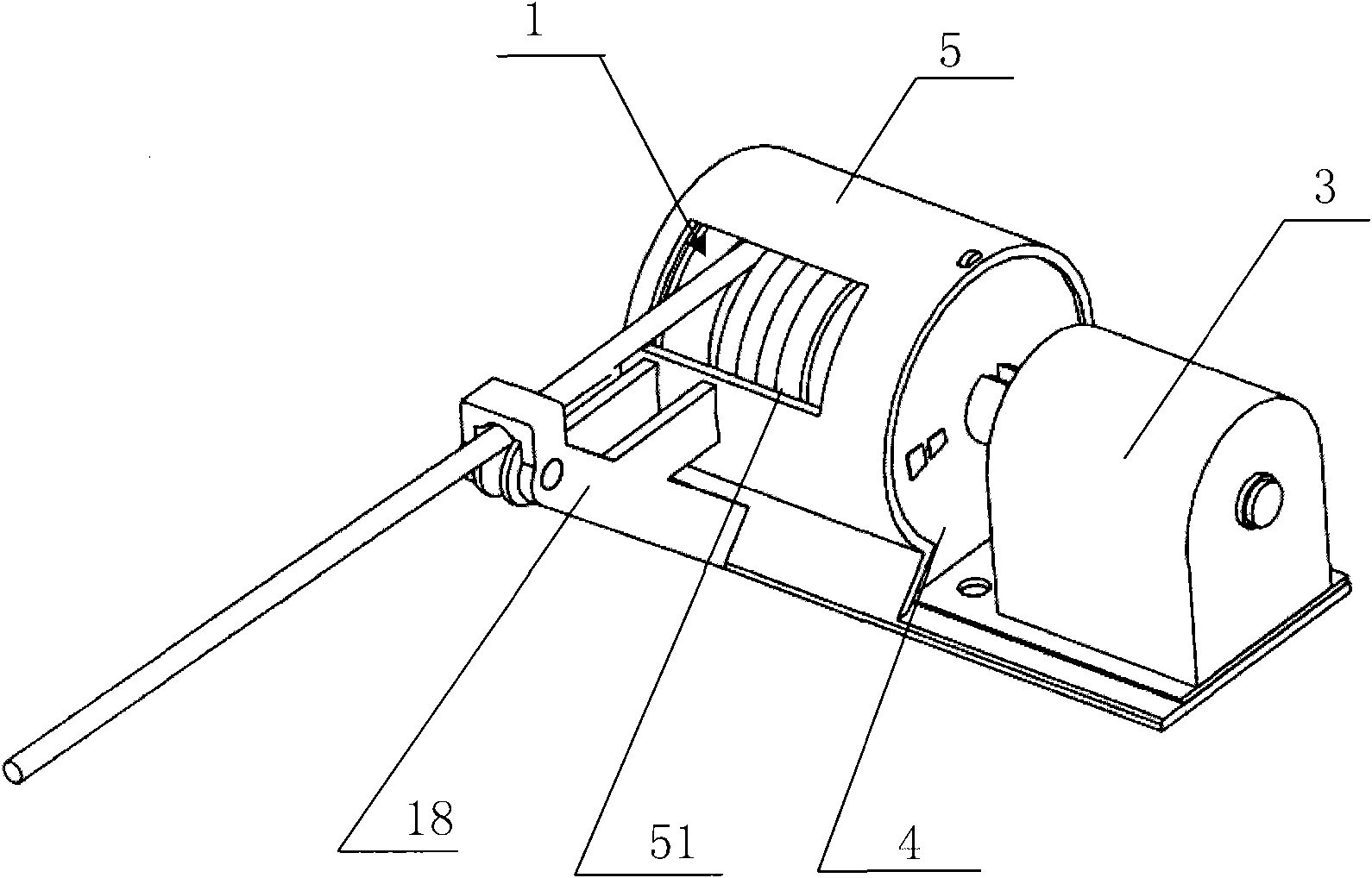

Mounting structure of telescopic contact pin temperature sensor

InactiveCN102297462BControl heating timeImprove work efficiencyDomestic stoves or rangesLighting and heating apparatusMicrowave ovenHeating time

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

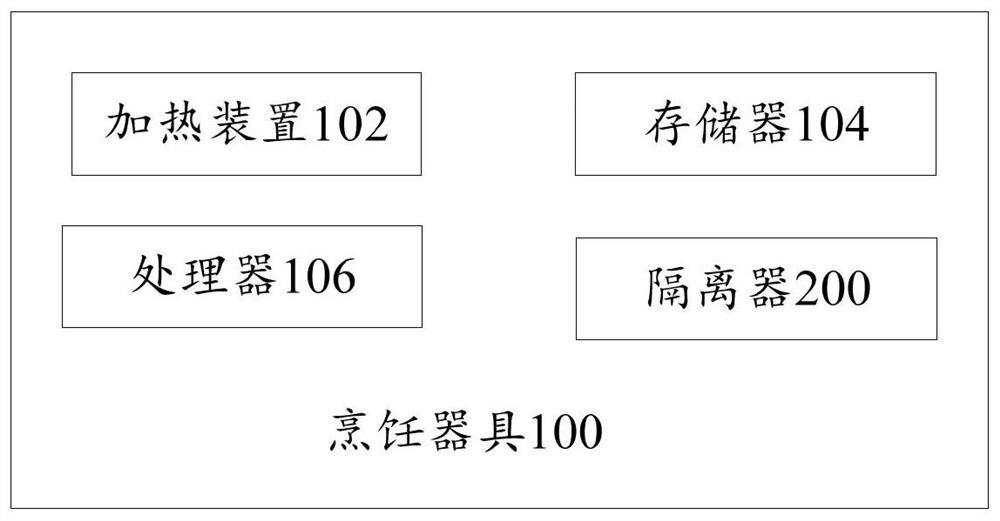

Cooking utensil, control method of cooking utensil and computer readable storage medium

ActiveCN113142968AGuaranteed cooking effectLittle influence of temperatureCooking insertsTime-controlled ignitorsIsolatorSteam cooking

The invention provides a cooking utensil, a control method of the cooking utensil and a computer readable storage medium. The cooking utensil comprises a pot; an isolator which is contained in the cookware, and the isolator and the cookware are matched to define a first chamber; a heating device configured to supply heat to the first chamber; a memory configured to store a computer program; and a processor which is configured to execute a computer program to implement so as to obtain cooking parameters, and determines first heating power and second heating power of the heating device according to the cooking parameters; and after the heating device is controlled to operate at the first heating power, the heating device is controlled to operate at the second heating power. According to the cooking utensil provided by the invention, quick steam discharging and segmented heating of the heating device are realized, a good steam cooking effect is favorably ensured, requirements of special cooking functions can be met, and the application range of the product is expanded.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Pre-shrinking machine capable of rotationally switching heating rollers

The invention discloses a pre-shrinking machine capable of rotationally switching heating rollers. A tensioning roller is arranged on the lower portion in a machine box in a lifting manner. A pair ofauxiliary rollers is positioned between a pair of conveying driving rollers. A rubber blanket is arranged on the pair of auxiliary rollers, the pair of conveying driving rollers and the tensioning roller. A switching device comprises a pair of front and back supporting plates which are symmetrically arranged front and back. The pair of front and back supporting plates is arranged at the upper partin the machine box in a lifting manner. The pair of front and back supporting plates is positioned on the front and back sides of the rubber blanket. A hollow central connecting column in a regular polygon column shape is rotationally arranged between the pair of front and back supporting plates. Rotary supporting plates are formed at the front end and the back end of each end face of the centralconnecting column correspondingly. A heating roller is rotationally arranged between each pair of rotary supporting plates on the same side. The diameters of the heating rollers are different. The heating roller at the lowermost end downwards presses the part, between the pair of auxiliary rollers, of the rubber blanket.

Owner:TAIZHOU ZHONGGANG CHEM & CONSTR CO LTD

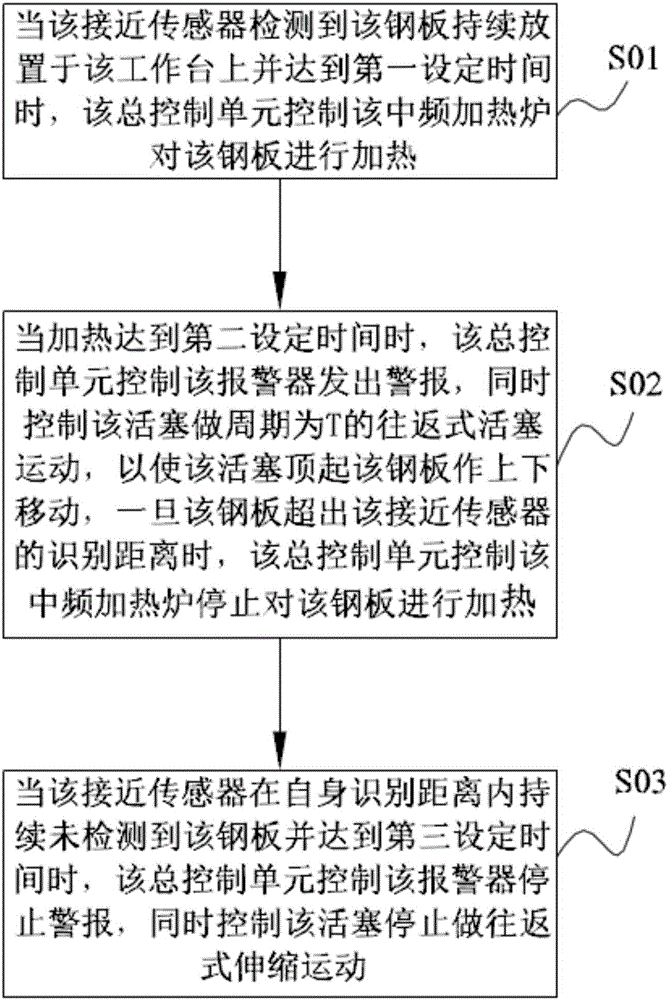

Steel plate heating control method and steel plate heating control device

InactiveCN106011406ASolve heatingAvoid heatingFurnace typesIncreasing energy efficiencyProximity sensorHeating time

The invention provides a steel plate heating control method and a steel plate heating control device. The steel plate heating control device comprises a master control unit, an intermediate frequency heating furnace, a proximity sensor and a cylinder, wherein the intermediate frequency heating furnace comprises a working table used for placing a steel plate. The steel plate heating control method comprises the steps: when the steel plate is continuously detected to be placed on the working table for a certain period of time by the proximity sensor, automatically heating the steel plate; when heating is carried out for a certain period of time, controlling a piston to make reciprocating type telescopic movement to enable the steel plate to go beyond the identification range of the proximity sensor, and automatically stopping heating; when the steel plate is continuously not detected for a third set period of time by the proximity sensor, using the master control unit to control the piston to stop making the reciprocating type telescopic movement so as to restore the piston to the original position, and waiting for a next steel plate. The steel plate heating control method and the steel plate heating control device can be used forautomatically heating the steel plate and controlling the heating time.

Owner:JIANGXI KEBUKE AUTOMOTIVE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com