Laser annealing device and laser annealing method

A technology of laser annealing and laser pulse, which is applied in the direction of laser welding equipment, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

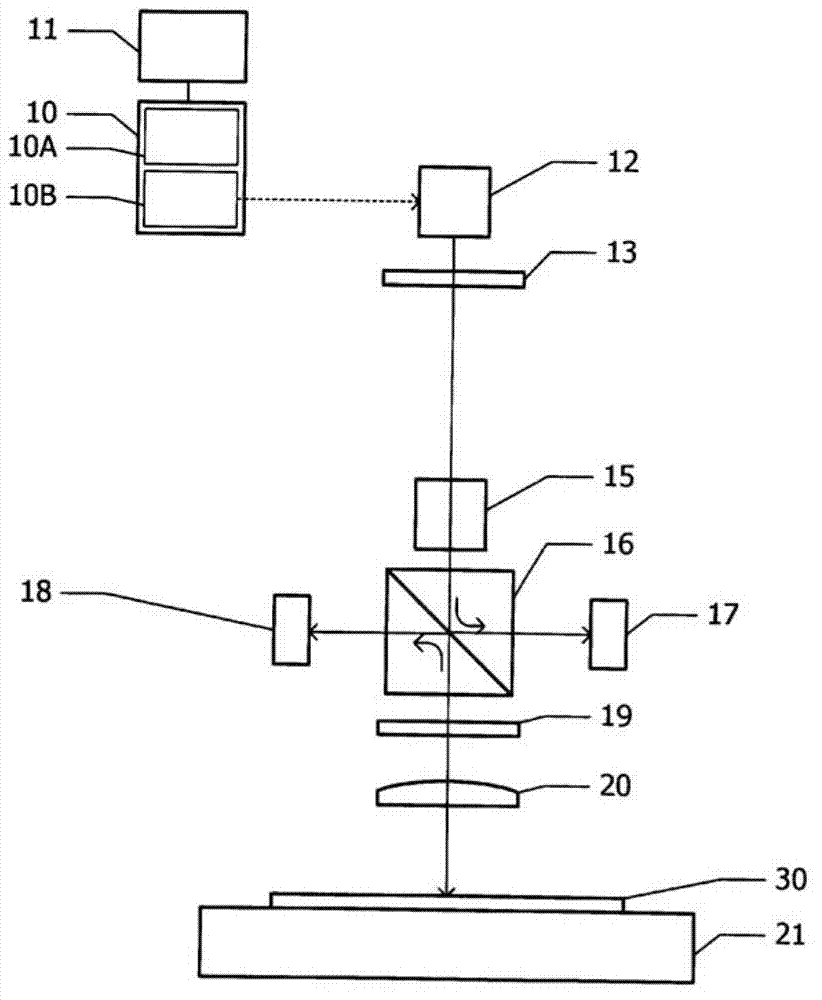

[0026] figure 1 A schematic diagram of a laser annealing apparatus based on an embodiment is shown in . The laser light source 12 is driven by the driver 10 . The laser light source 12 uses, for example, a laser diode with an oscillation wavelength of 690 nm to 950 nm. In this embodiment, a laser diode with an oscillation wavelength of 800 nm is used.

[0027] The laser light source 12 has a plurality of horizontally long light emitting points. The plurality of light emitting points are arranged in a row in the direction of the long sides. The size ratio of the major axis direction and the minor axis direction of each light emitting point is, for example, 100:1. The dimension in the long-axis direction of the light-emitting points is almost equal to the interval between two adjacent light-emitting points. In other words, the luminous points and non-luminous regions are alternately arranged at equal intervals.

[0028] Generally, the spread angle of the laser beam in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com