Quantum dot light emitting diode bottom electrode and preparation method thereof

A quantum dot light-emitting and bottom electrode technology, which is applied to circuits, electrical components, and electrical solid devices, can solve problems such as complicated steps, and achieve the effects of avoiding negative effects, improving performance, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

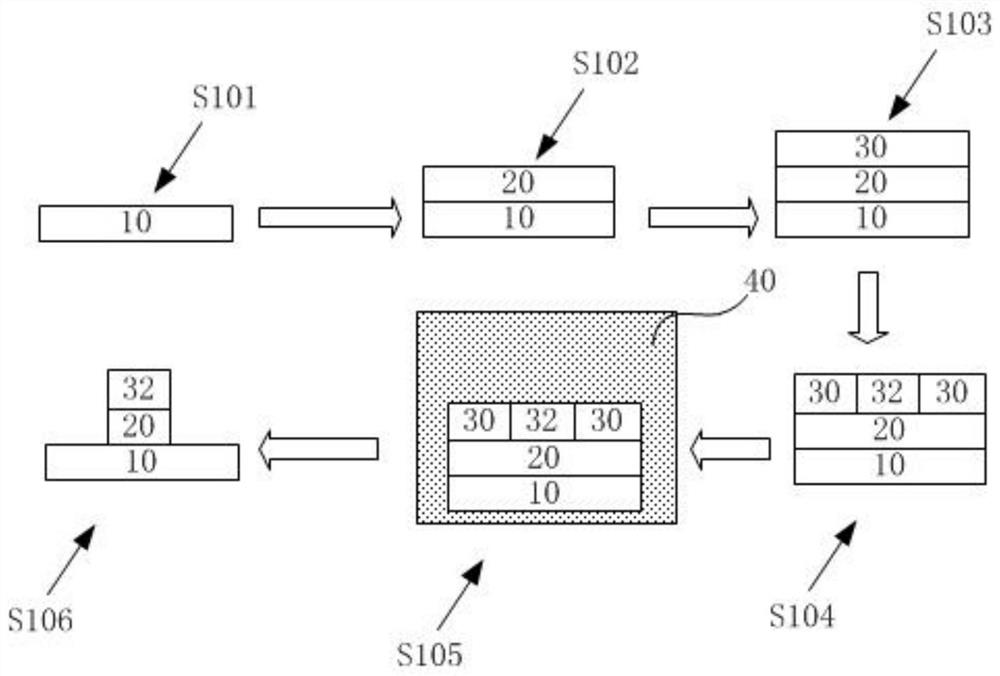

[0024] An embodiment of the present invention provides a method for preparing a bottom electrode of a quantum dot light-emitting diode, which includes the following steps:

[0025] S1. Provide a substrate, and prepare a reflective layer on the surface of the substrate;

[0026] S2, preparing an electrode layer on the surface of the reflective layer away from the substrate, and performing crystallization treatment and etching treatment on the electrode layer to obtain a bottom electrode of a quantum dot light-emitting diode.

[0027] In the method for preparing the bottom electrode of a quantum dot light-emitting diode provided by the embodiment of the present invention, firstly, the electrode layer can be crystallized by crystallizing the electrode layer, which is originally in an amorphous state, and then the conductive metal oxide in the electrode layer can be crystallized. Etching removes the uncrystallized part, which not only achieves the purpose of full annealing, improv...

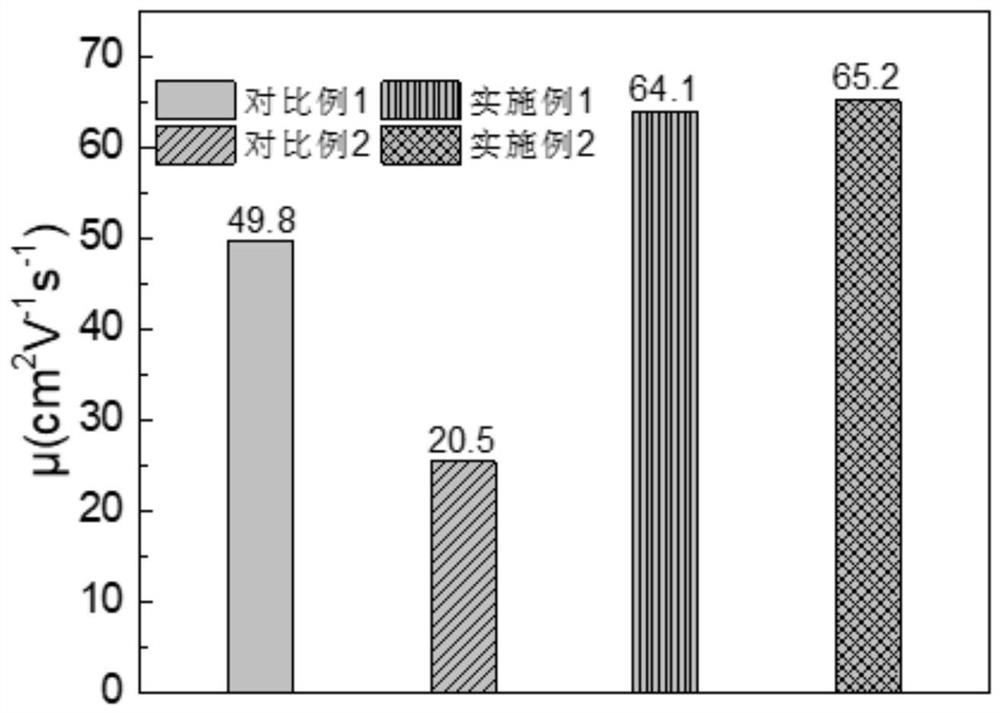

Embodiment 1

[0060] A method for preparing a bottom electrode of a top emission quantum dot light-emitting diode, comprising the following steps:

[0061] (11) Provide blank glass substrate;

[0062] (12) On a blank glass substrate, through thermal evaporation, the vacuum degree is not higher than 3×10 -4 Pa, Ag was evaporated, the speed was 1 angstrom / second, and the time was 1000 seconds to obtain a reflective layer with a thickness of 100 nm;

[0063] (13) Spin coating the ITO precursor solution, rotating speed 3000, time 30 seconds, using electron beam to scan the film 10 -2 Second, the film is thermally annealed, and this process is repeated ten times with an interval of 2 s each time to crystallize the ITO film layer. Wherein, the area of annealing is the desired shape of the ITO electrode layer. The accelerating voltage of the electron beam is 10 2 kV, the energy density of the electron beam is 0.825J / cm 2 , after annealing, let it cool for 5 minutes;

[0064] (14) preparing...

Embodiment 2

[0068] A method for preparing a bottom electrode of a top emission quantum dot light-emitting diode, comprising the following steps:

[0069] (21) Provide blank glass substrate;

[0070] (22) On a blank glass substrate, through thermal evaporation, the degree of vacuum is not higher than 3×10 -4 Pa, Ag was evaporated, the speed was 1 angstrom / second, and the time was 1000 seconds to obtain a reflective layer with a thickness of 100 nm;

[0071] (23) Spin-coating ITO precursor solution, rotating speed 3000, time 30 seconds, using femtosecond laser irradiation for 10 seconds -2 Second, the film is thermally annealed, and this process is repeated ten times with an interval of 2 s each time to crystallize the ITO film layer. Wherein, the area of annealing is the desired shape of the ITO electrode layer. The laser beam diameter is 3mm, the wavelength is 1053nm, the pulse width is 120fs, the repetition frequency is 1kHz, and the beam quality factor is 1.2. After annealing, it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com