Patents

Literature

92results about How to "Realize automatic cooking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

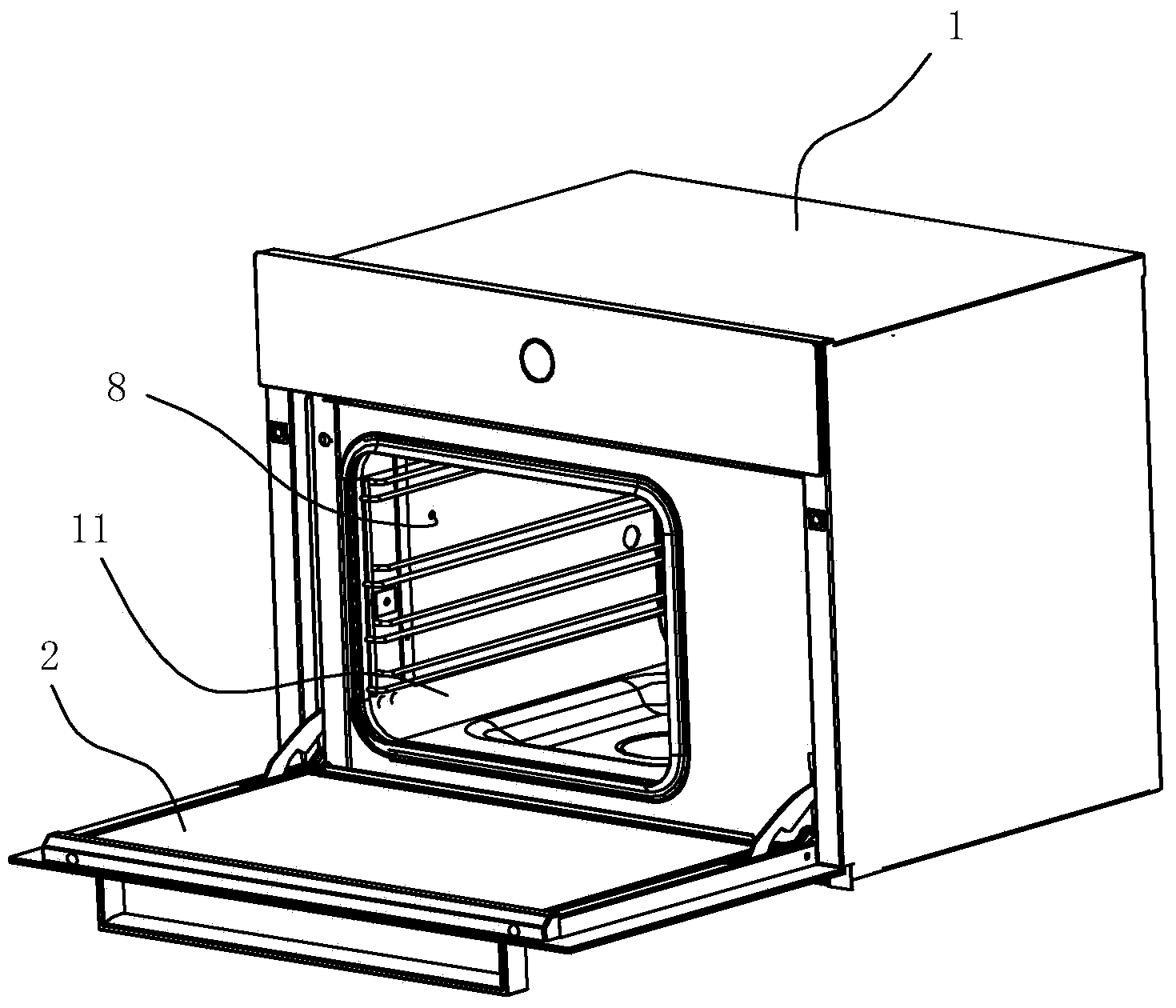

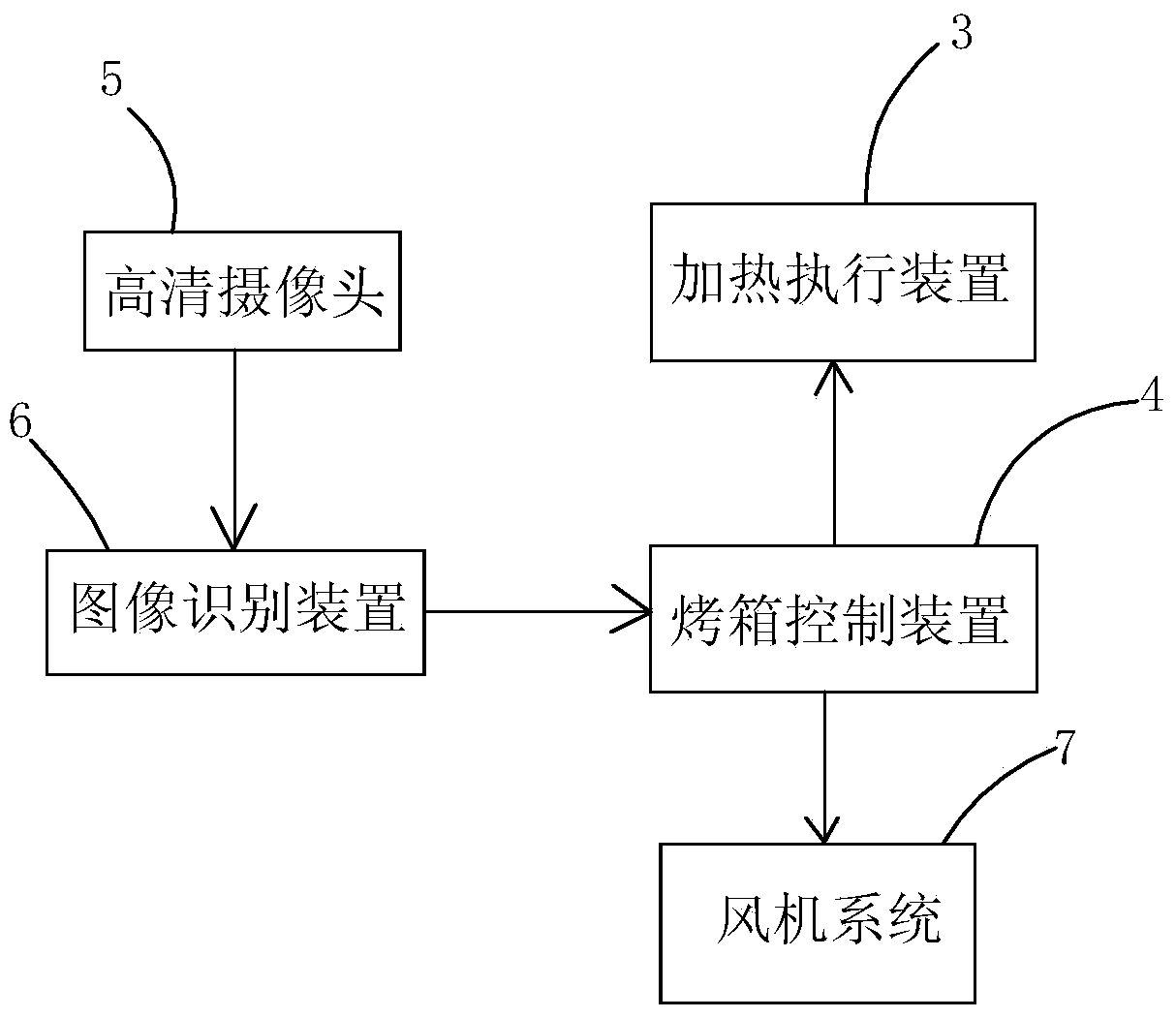

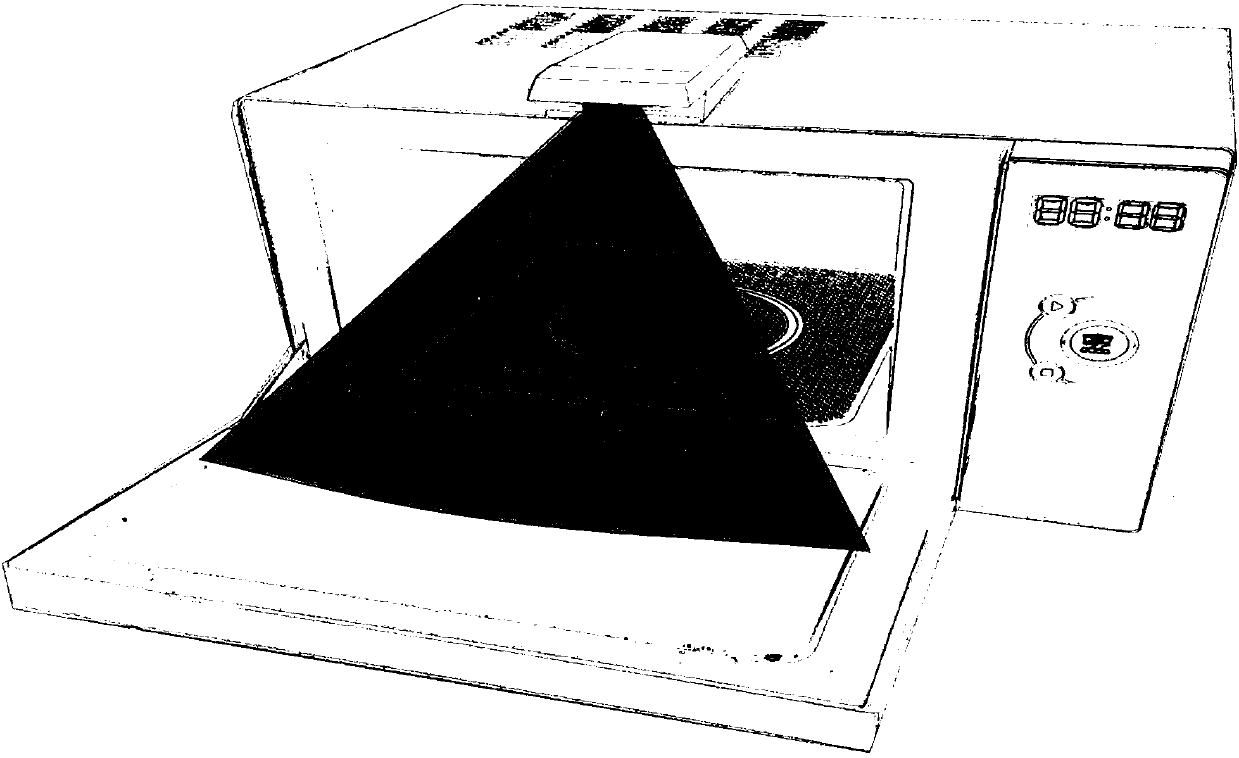

Intelligent oven and work control method thereof

ActiveCN104042124ARealize automatic cookingTemperatue controlRoasters/grillsProcess engineeringRunning time

The invention relates to an intelligent oven and a work control method thereof. The intelligent oven comprises a box body; a cooking cavity, a heating execution device for heating food in the cooking cavity, and an oven control device for controlling the heating execution device to operate are arranged in the box body; the intelligent oven is characterized in that an image collection device for collecting images of food in the cooking cavity is arranged in the cooking cavity; the output end of the image collection device is connected with the input end of an image identification device; the image identification device is used for identifying and judging images collected by the image collection device so as to obtain the category of the food in the cooking cavity; the output end of the image identification device is connected with the oven control device; the oven control device controls the operation time of the heating execution device according to the category of the food, identified by the image identification device, in the cooking cavity. Compared with the prior art, the intelligent oven has the advantage of realizing automatic food cooking.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Cooking method and cookware

ActiveCN105708306AGood cooking effectRealize automatic cookingCooking vesselsRelevant informationEngineering

The invention discloses a cooking method and cookware. The cooking method comprises the following steps: irradiating food to be cooked with preset light rays to make the food to be cooked reflect emergent light rays, and detecting spectrum information of the emergent light rays; setting a corresponding cooking procedure and / or adjusting a set cooking procedure according to the spectrum information. According to the cooking method disclosed by the invention, relevant information of the food to be cooked can be analyzed by a spectrum detection method, and the food to be cooked can be cooked in a targeted manner according to an analysis result, so that an optimal cooking effect can be achieved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Rice cooking method and device of electric cooker

InactiveCN107343740AHigh degree of intelligenceLower the altitudeWarming devicesVessels with intergral heatingCookerEngineering

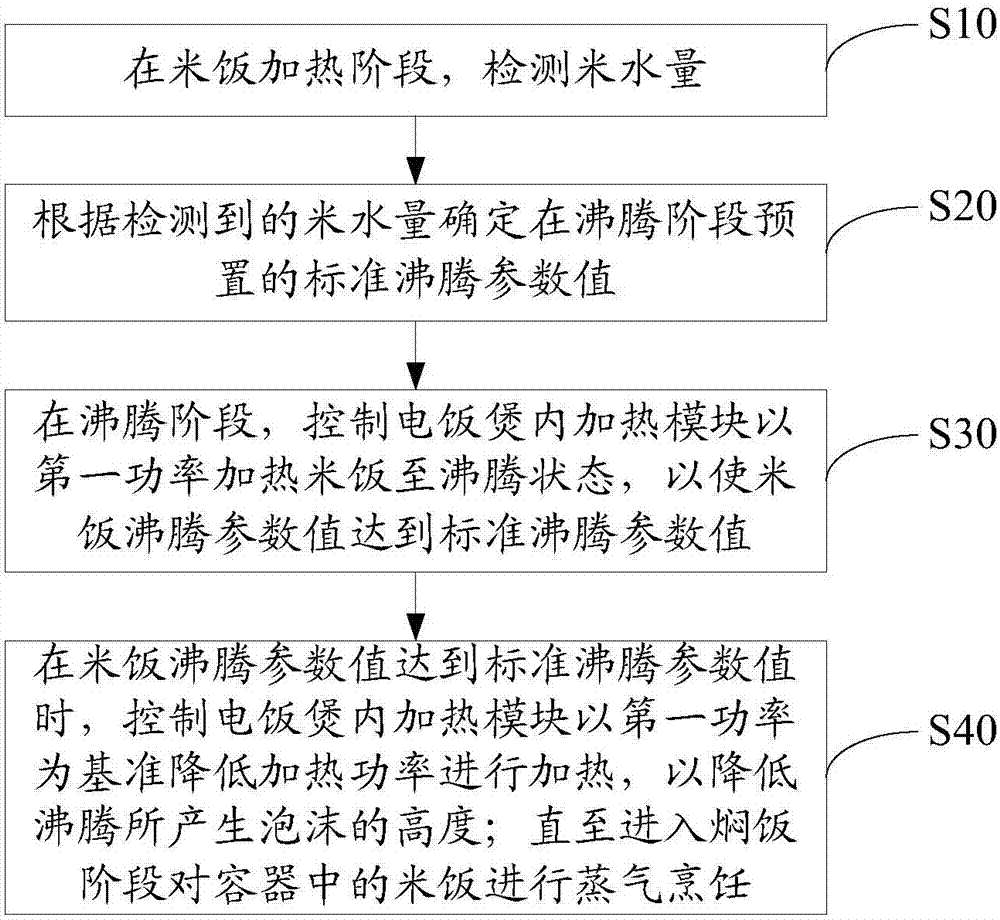

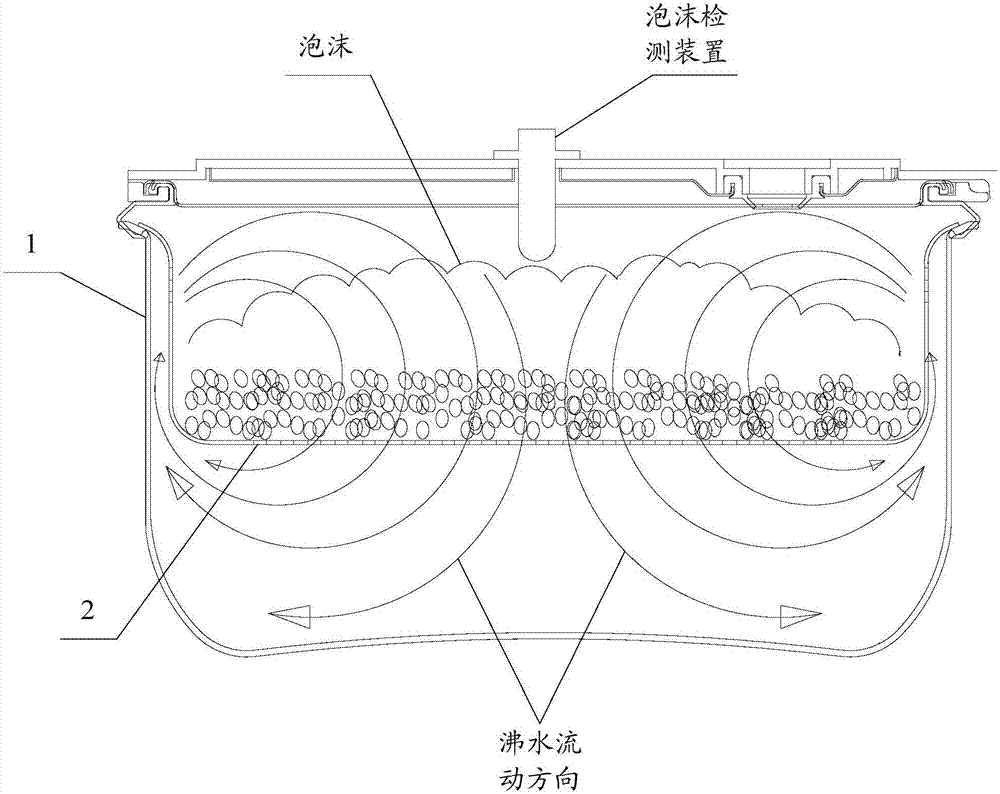

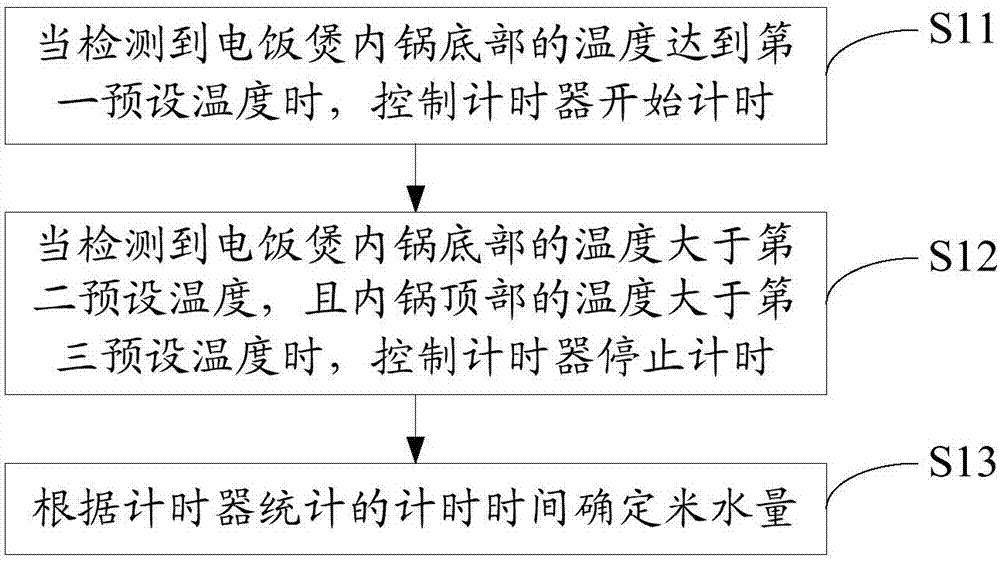

The invention discloses a rice cooking method and device of an electric cooker. The rick cooking method of the electric cooker comprises the following steps: detecting the volume of rice and water during a heating phase of rice; determining a standard boiling parameter value preset in a boiling phase according to the detected volume of the rice and the water, and controlling a heating module in the electric cooker to heat the rice to a boiling state with a first heating powder in the boiling phase, to enable the rice boiling parameter value to reach the standard boiling parameter value; controlling the heating module in the electric cooker to reduce the heating powder to heat by taking the first heating powder as a reference when the rice boiling parameter value reaches to the standard boiling parameter value so as to reduce the height of foam generated by boiling; cooking the rice in the container by vapour when entering into a braised rice phase. The invention discloses rice cooking device of the electric cooker. The method and the device of the invention realizes the automatic cooking including rice draining and improves the intelligence degree of the electric cooker.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

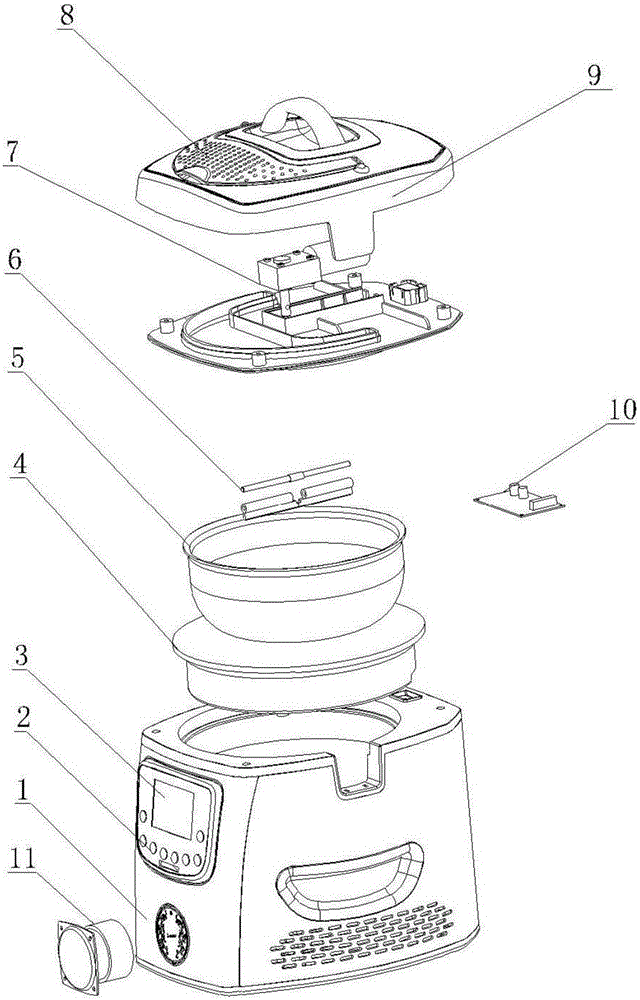

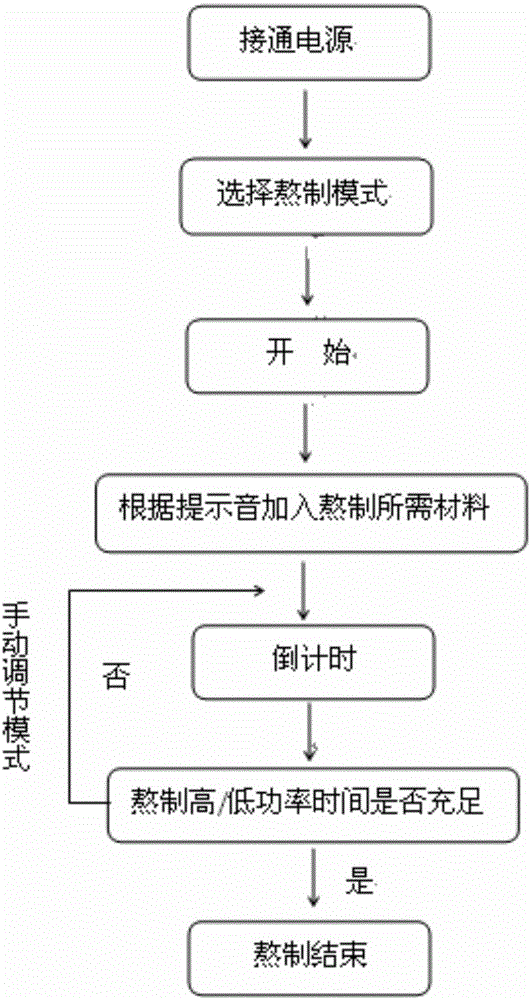

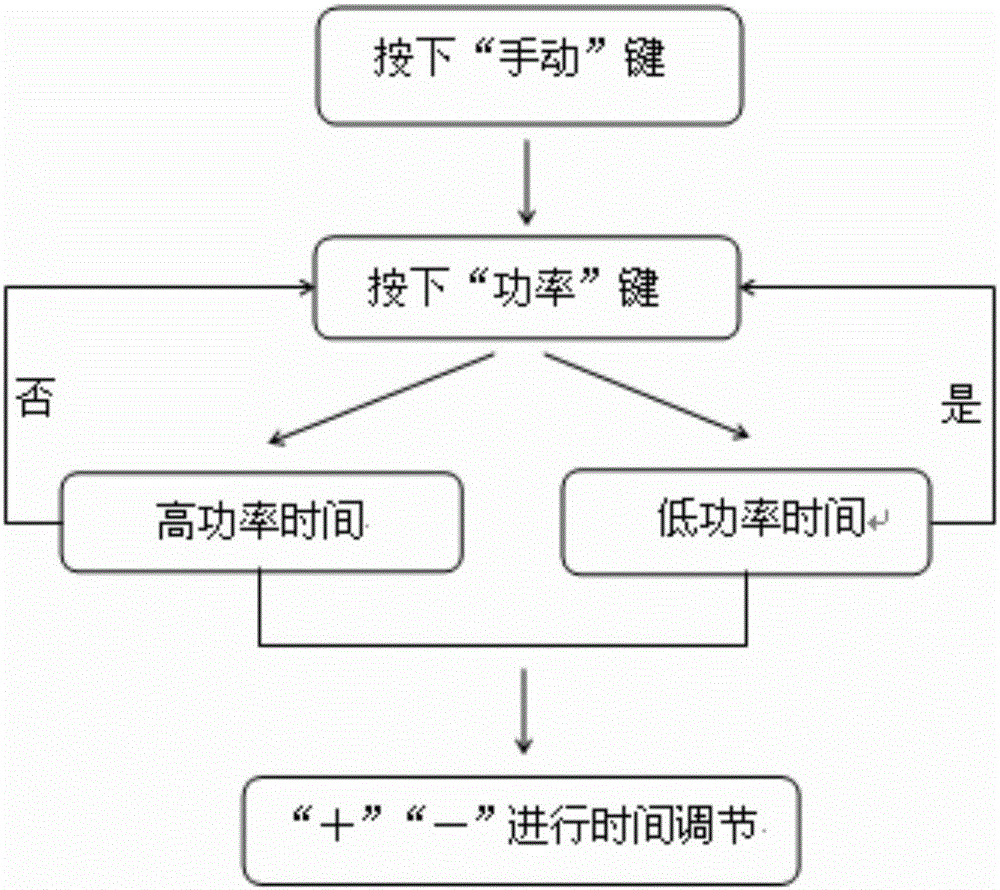

Intelligent program-controlled multipurpose pot and control method thereof

InactiveCN104523133AMeet culinary needsRealize automatic cookingCooking vesselsProgrammable logic controllerEngineering

The invention discloses a program-controlled multipurpose pot and a control method of the program-controlled multipurpose pot. A plurality of heating devices are arranged on the lower side and the side face of the inside of the program-controlled multipurpose pot, and an intelligent programmable controller is installed in the program-controlled multipurpose pot and comprises an operation function body, a displayer and a programmable controller body. The programmable controller body can be connected with external equipment or a cloud server through a wire interface or a wireless interface, is used for downloading, storing, backing up and uploading a plurality of cooking procedures and controls the multipurpose pot to operate according to temperatures and pressure curves set through the procedures, and a cooking process is completed automatically. A manual operation process can be automatically recorded, and the corresponding cooking procedure can be automatically generated; inner containers made of different materials can be recognized and used, and the corresponding procedures are selected; the intelligence degree is high, operation is simple and convenient, and the functions and the application range of the multipurpose pot are greatly widened.

Owner:张海舡

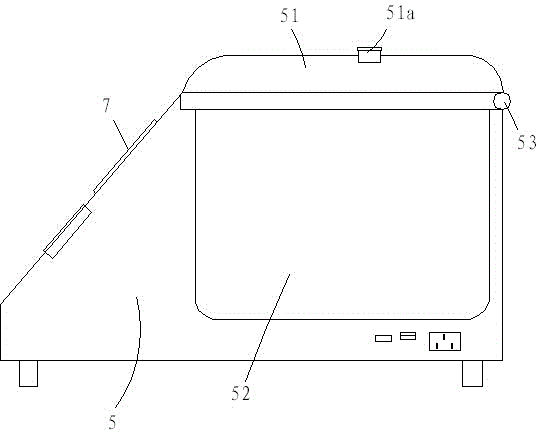

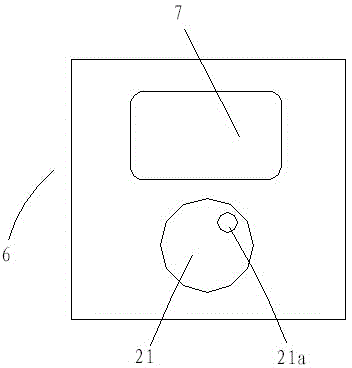

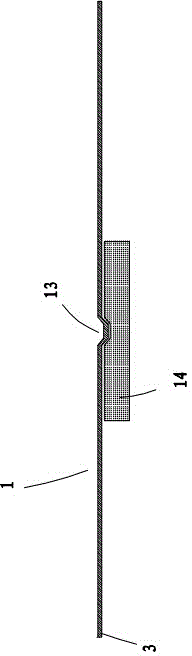

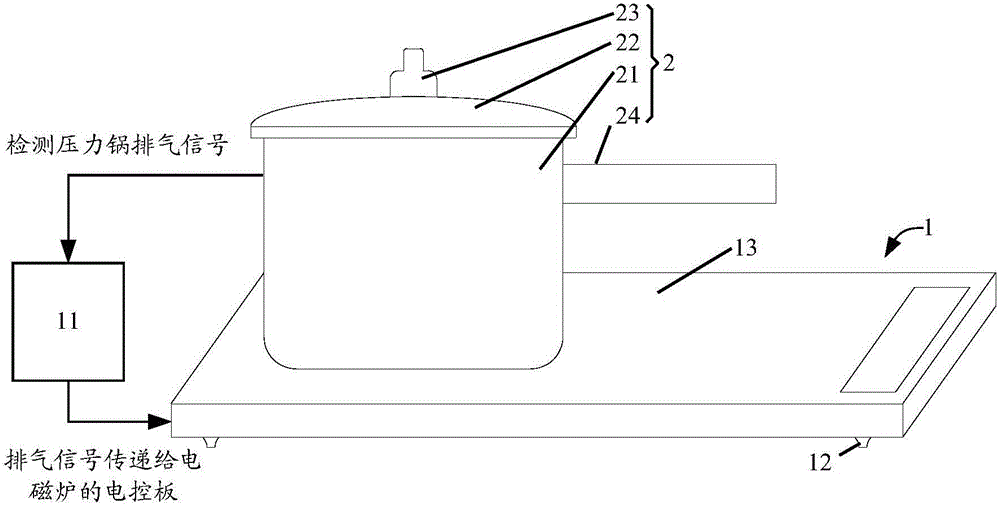

Heating equipment, cooking device and cooking method of heating equipment

ActiveCN105832133AReduce cooking timeImprove user experienceDomestic stoves or rangesLighting and heating apparatusProcess engineeringFood material

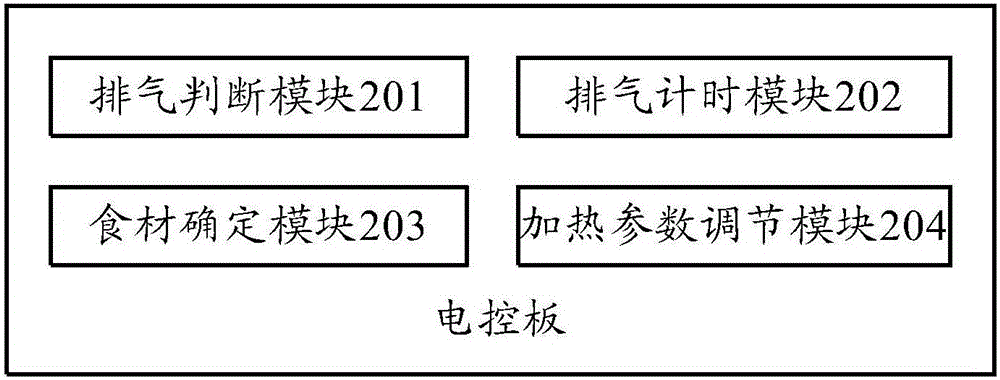

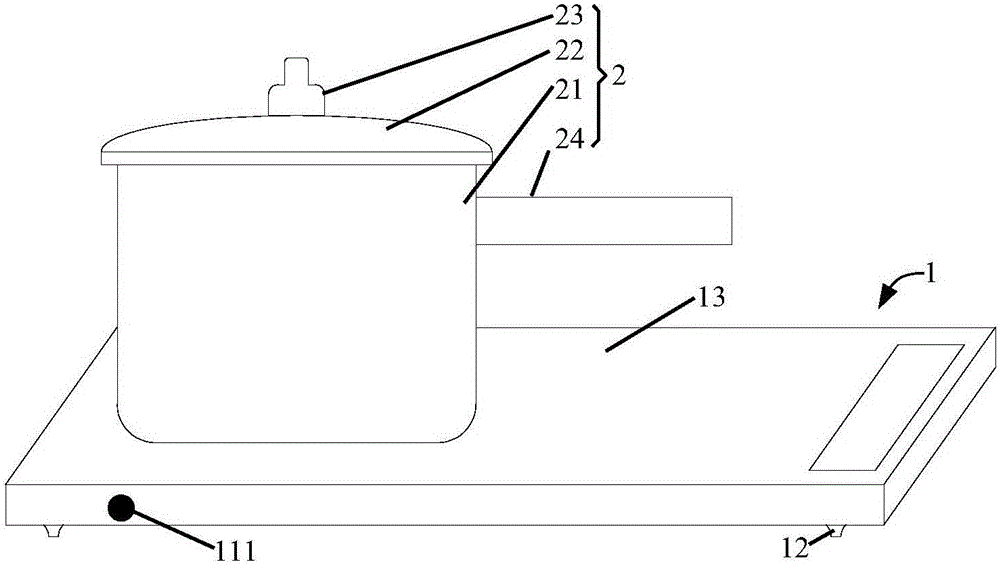

The invention provides heating equipment, a cooking device and a cooking method of the heating equipment. The heating equipment comprises a heating component, an exhaust detection component and an electric control board. The heating component is used for heating a cooking utensil; the exhaust detection component is used for detecting exhaust signals of the cooking utensil; the electric control board is connected to the heating component and the exhaust detection component and used for determining quantity of food materials in the cooking utensil according to exhaust signals detected by the exhaust detection component and regulating heating parameters of the heating component according to the quantity of the food materials. By the technical scheme, the heating equipment is capable of automatically detecting the quantity of the food materials in the cooking utensil and regulating the heating parameters of the heating component accordingly, an automatic cooking function is realized, and user experience is greatly improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

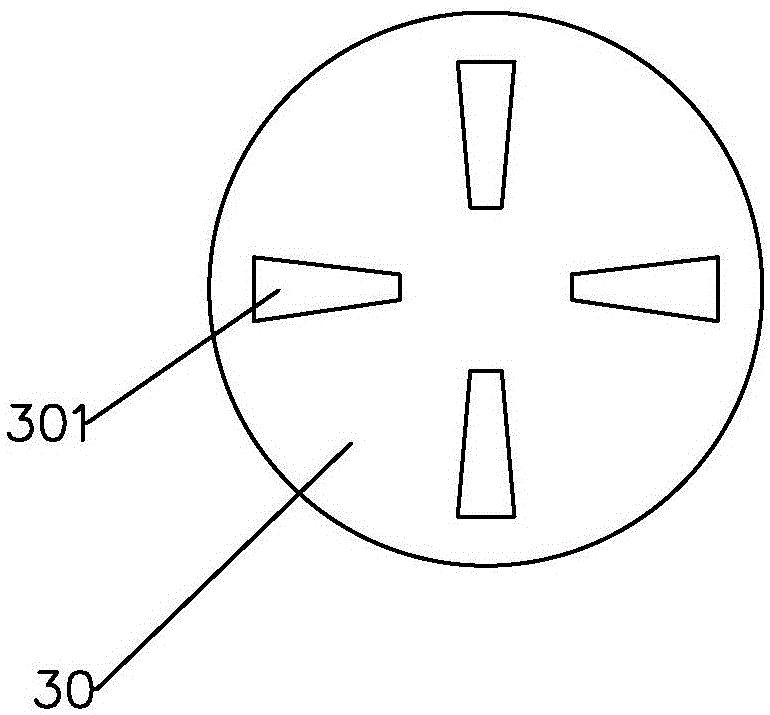

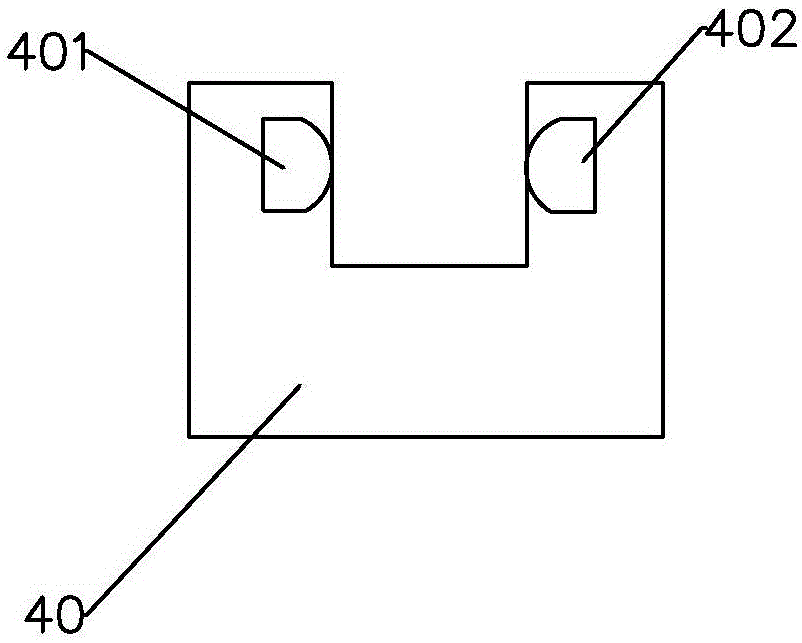

Automatic cooker for kitchen

ActiveCN109730523AFunction as a switchImprove adsorption capacityCooking-vessel lids/coversCooking insertsEngineeringCooked food

The invention relates to an automatic cooker for a kitchen, comprising a cabinet, wherein a disk feeding unit, a dish processing unit, a seasoning feeding unit and a cooked food delivering unit are arranged on the cabinet; the feeding unit comprises a rotary rod, a motor A, a dish box and an adsorbing device, and the adsorbing device is arranged on the rotary rod; the dish processing unit comprises a heating device, a stir pan and a stir-frying mechanism used for stirring and frying the dish in the stir pan, the stir pan is located above the heating device, and the stir-frying mechanism is located above the stir pan; the seasoning feeding unit comprises a solid seasoning feeding unit and a liquid seasoning feeding unit; the cooked food delivering unit comprises a stir pan delivering mechanism and a stir pan dumping mechanism, so as to realize the functions of automatic dish feeding, automatic stirring and frying, automatic and quantitative feeding of seasonings and automatic dumping ofdishes, further realize the aim of automatic cooking dishes, and further reducing the work intensity of personnel of the kitchen and effectively saving human cost.

Owner:张维加

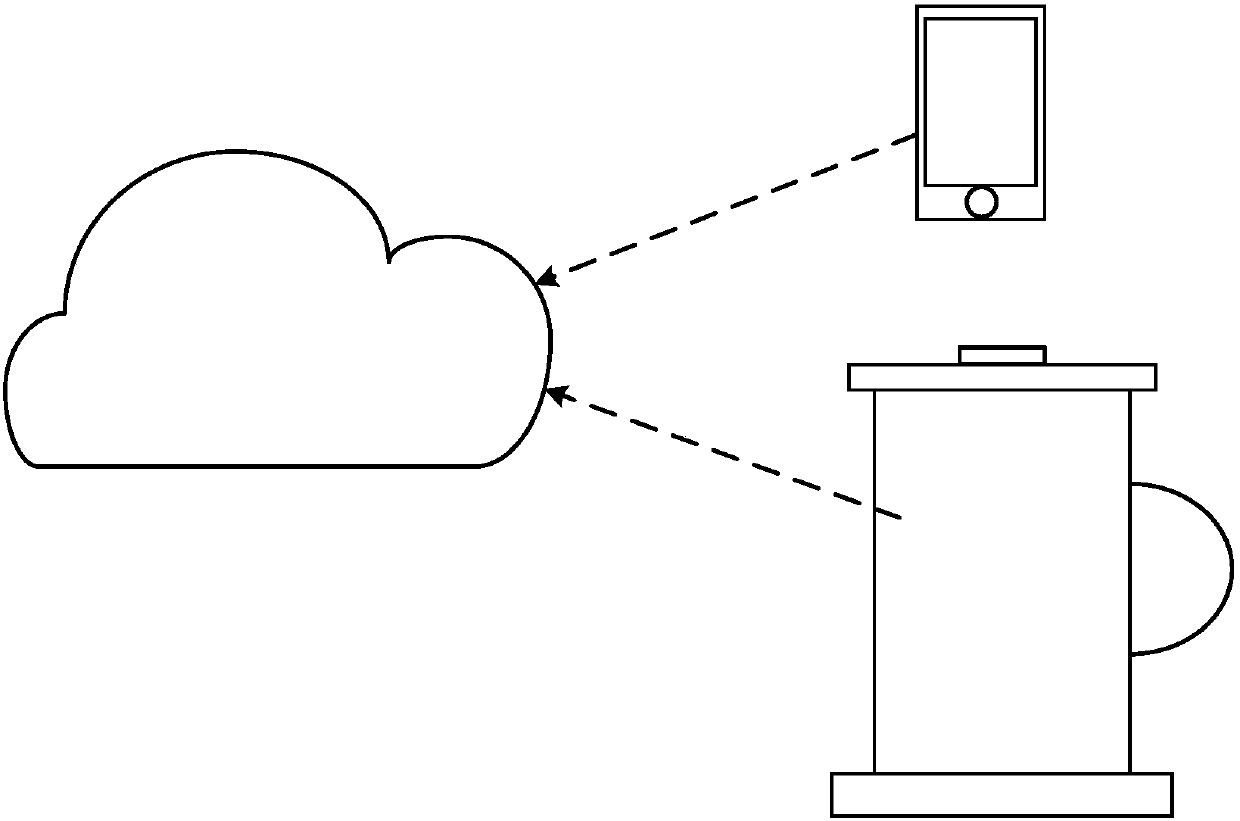

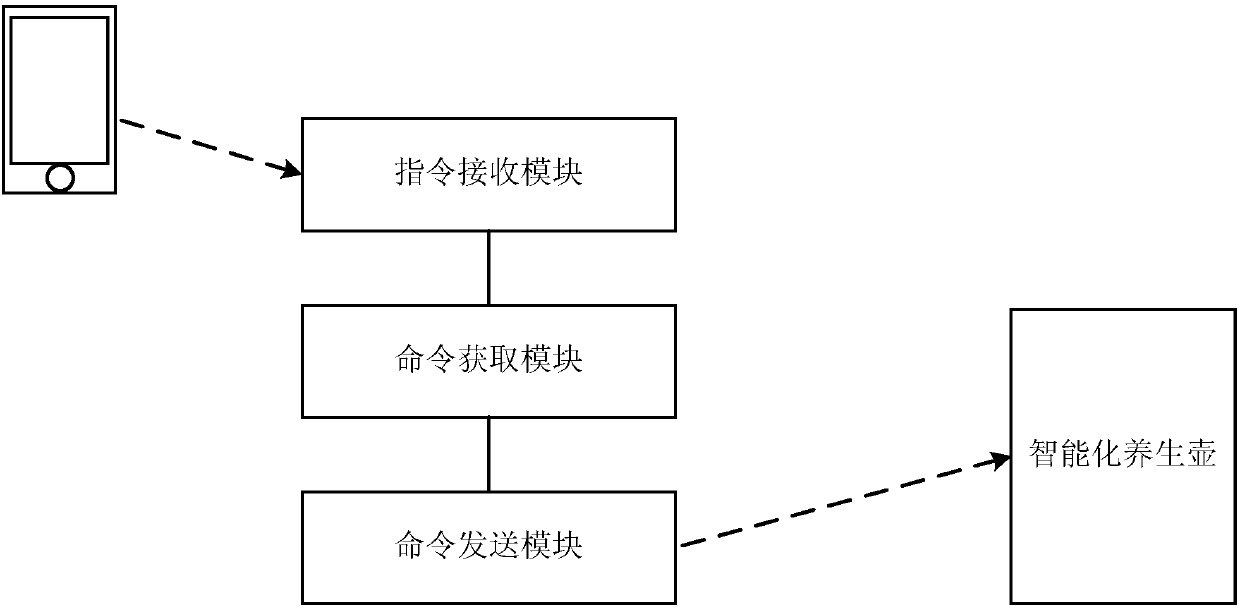

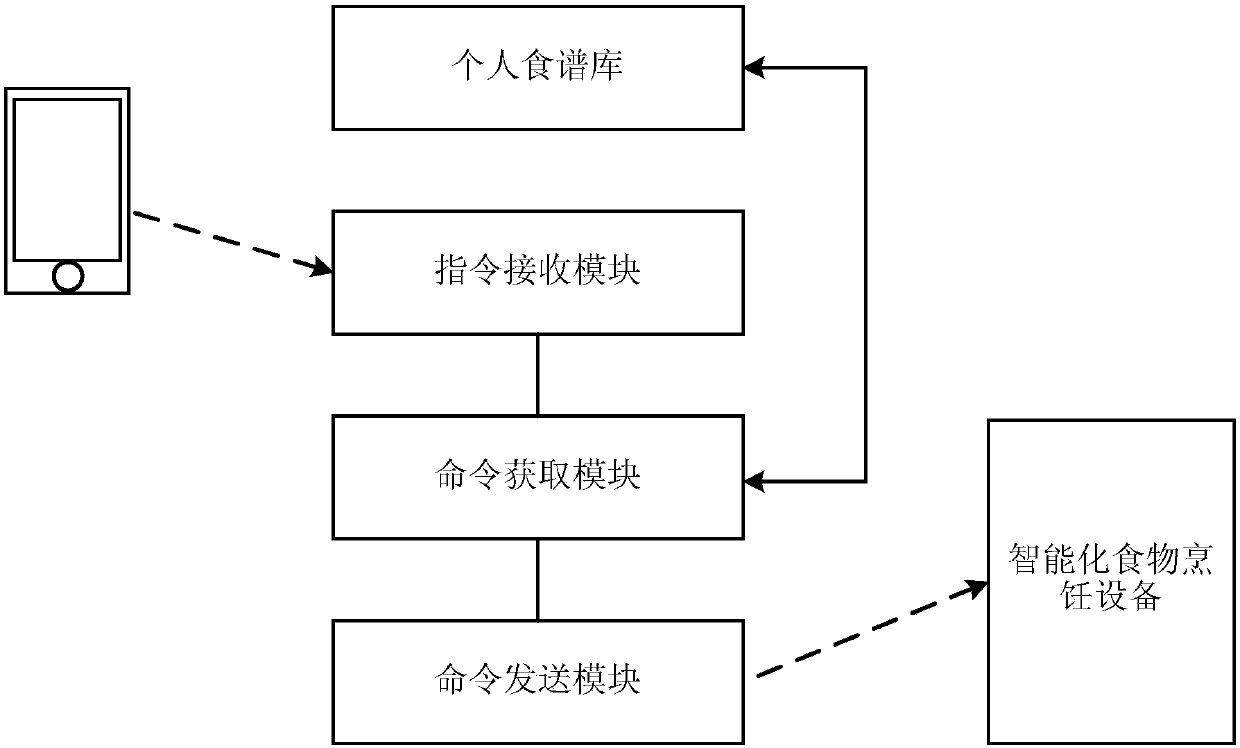

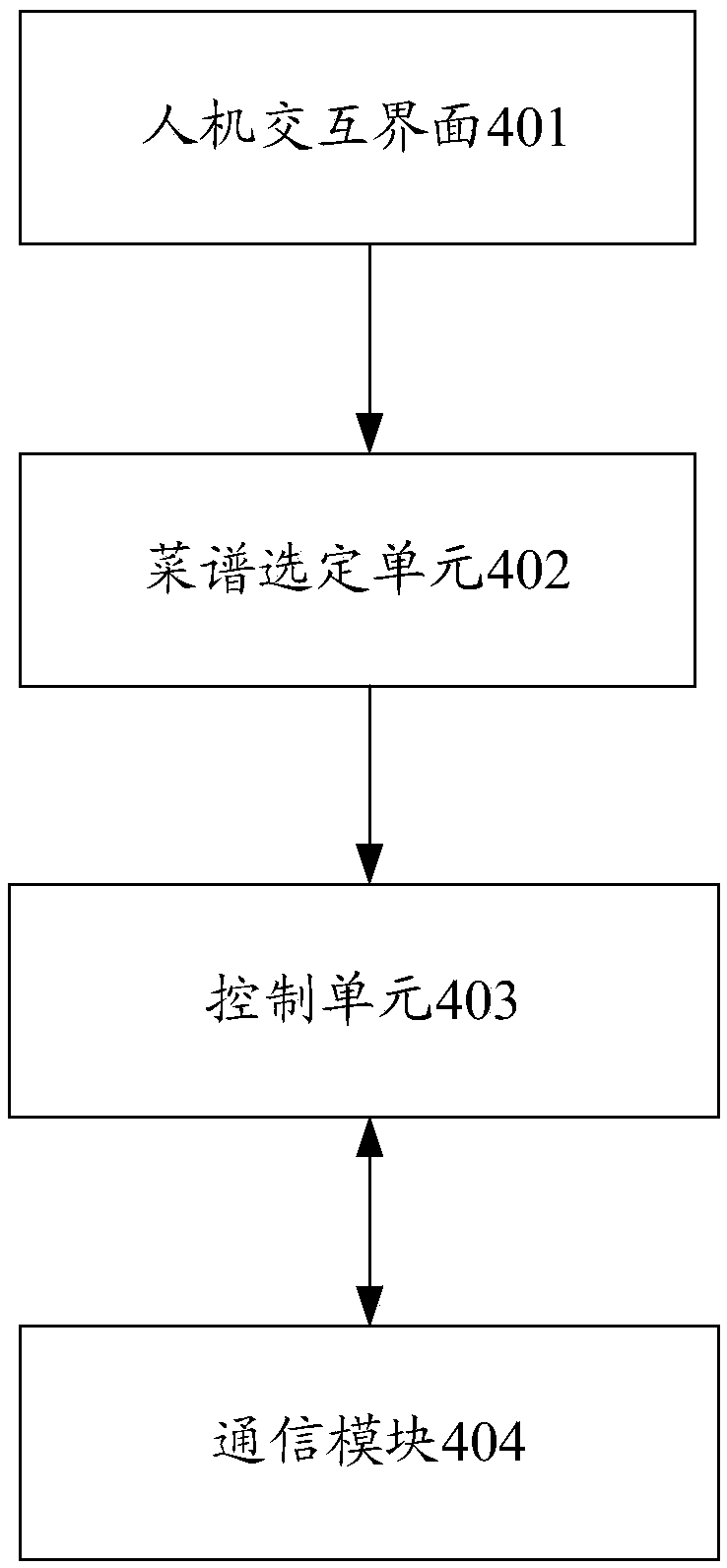

Smart food cooking device remote control cloud server and system

InactiveCN107566448ARealize remote controlRealize automatic cookingData switching by path configurationRemote controlComputer terminal

The invention relates to the field of smart home, and discloses a smart food cooking device remote control cloud server and system. The cloud server, to which a smart food cooking device and a user terminal are connected remotely, includes an instruction receiving module used for receiving a recipe operation instruction of a user from the user terminal, a command acquisition module used for acquiring a control command which can be identified by the smart food cooking device according to the recipe operation instruction, and a command sending module used for sending the control command to the smart food cooking device bound to the user. A smart food cooking device can be remotely controlled, and dishes can be automatically cooked.

Owner:SHANGHAI MXCHIP INFORMATION TECHN

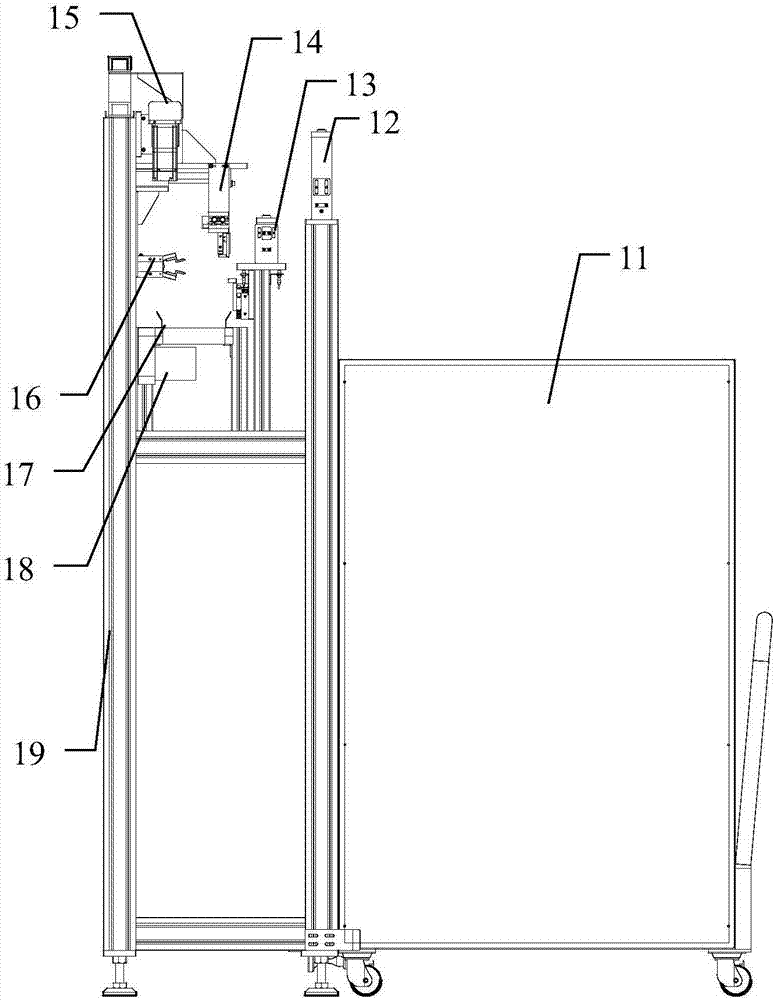

Method for using automatic cooking equipment to prepare food

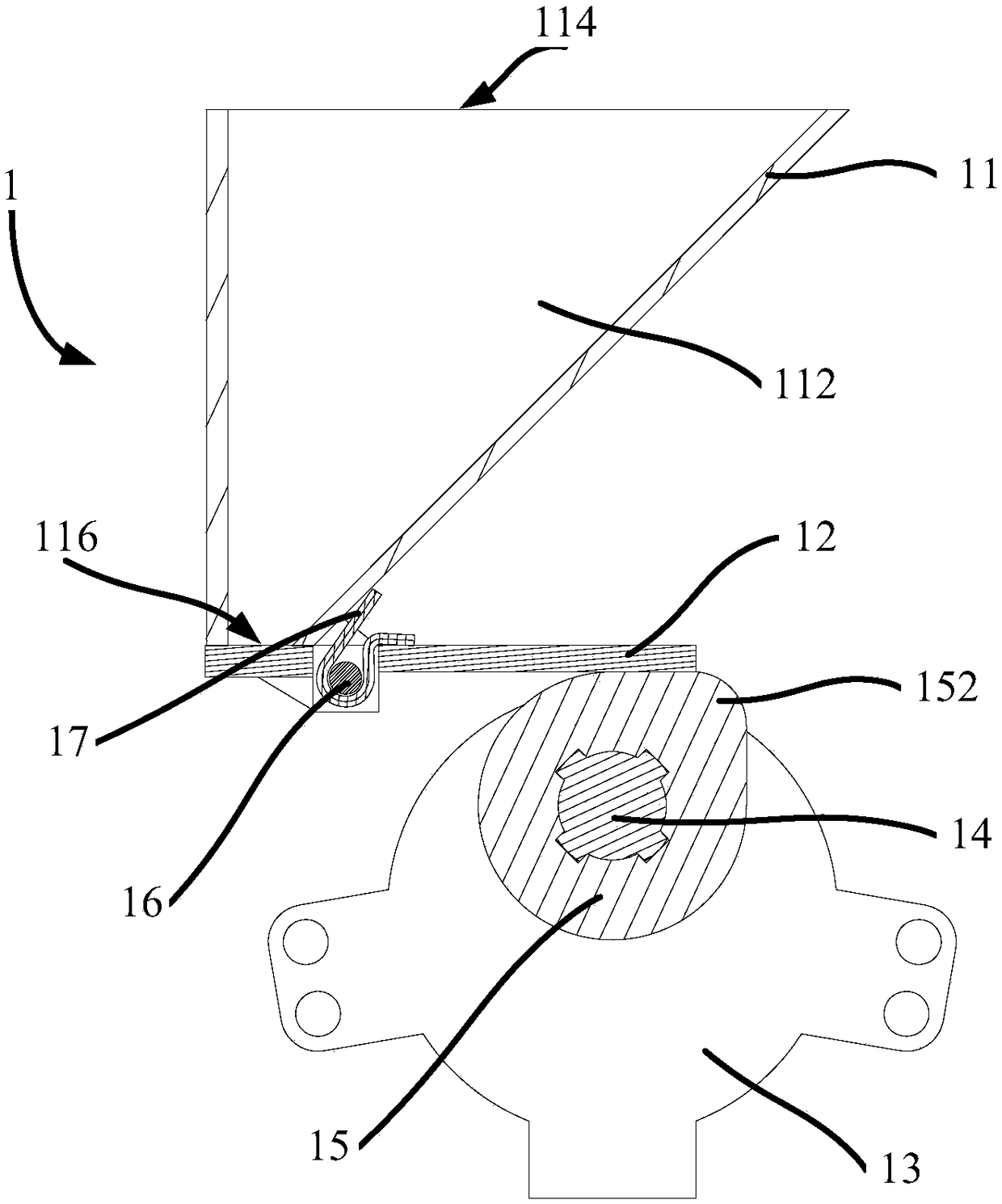

InactiveCN104921582ARealize automatic cookingAccurately achieve cooking resultsCooking vesselsCookerEngineering

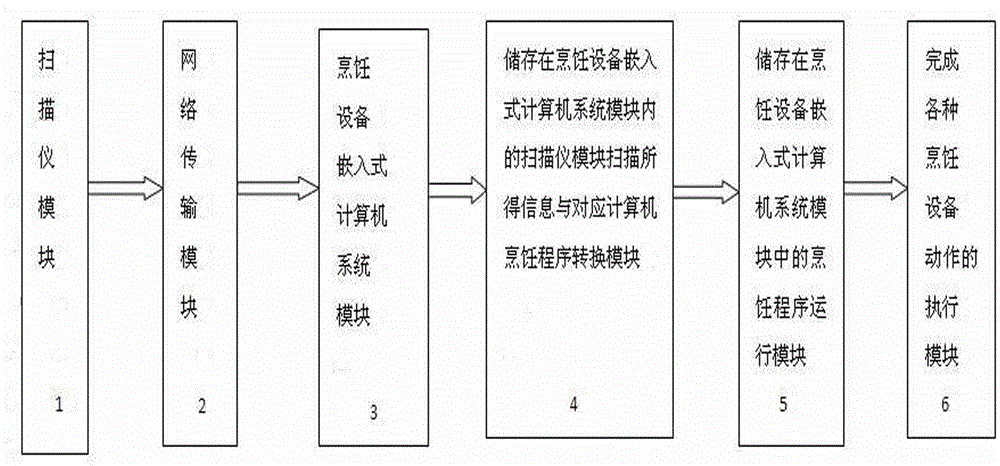

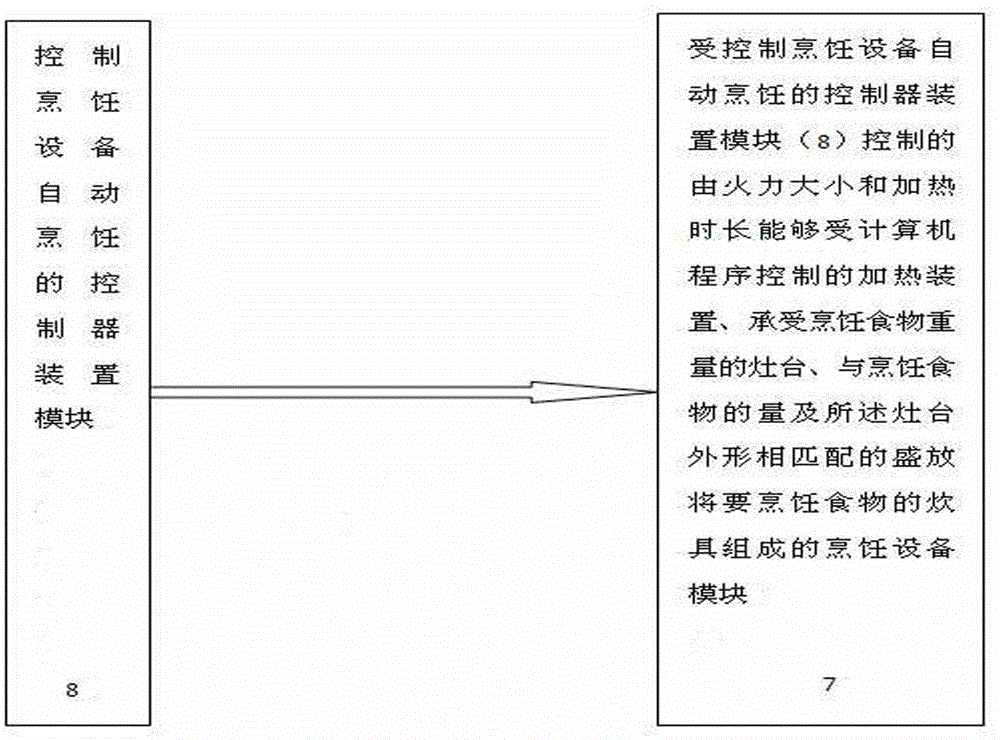

The invention discloses a method for using automatic cooking equipment to prepare food and belongs to the technical field of preparing food with the automatic cooking equipment. According to the technical scheme, the method includes: allowing a scanner module (1) to scan information signs, corresponding to the cooking process, on the outer wrappage of well-wrapped to-be-cooked food; taking apart the wrappage of cooked food after the information signs are input in an embedded computer system module (3) of the cooking equipment through a network transmitting module (2); placing the to-be-cooked food into a cooker, and starting a start cooking switch or automatically starting the cooking process to start cooking through the cooking equipment according to default setting conditions; taking out the cooked food after the cooking equipment sends out signals for completion of cooking to complete the entire cooking of the food. With the method, the food can be prepared by the aid of the automatic cooking equipment, and the cooking effect required by the cooking process can be realized conveniently, easily and accurately.

Owner:江苏华音信息科技有限公司

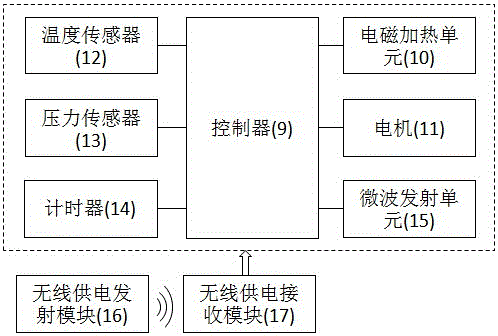

Intelligent cooking device

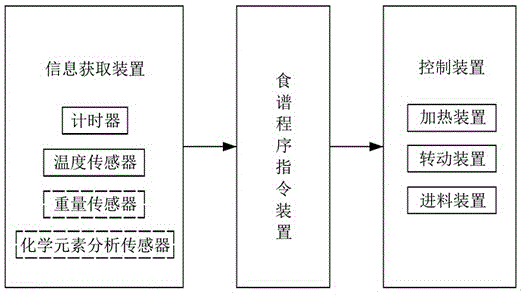

InactiveCN106539483ARealize automatic cookingGuaranteed consistent tasteCooking vesselsStopwatchProgram instruction

The invention discloses an intelligent cooking device. The device comprises an information acquisition device, a recipe program instruction device and a control device. The information acquisition device comprises a timer and a temperature sensor. The recipe program instruction device is used for sending instructions to the control device for controlling or stopping the control device according to information obtained by the information acquisition device. The intelligent cooking device has following beneficial effects: an automatic cooking function is fulfilled according to a recipe and connected with a server for automatically renewing the recipe, thereby bringing much convenience for cooking delicious food of various kinds in families; the automatic cooking function of complicated food is fulfilled according to the recipe, thereby saving a large quantity of work on recipe learning and cooking so that the taste consistency of cooking each time is ensured; users can dynamically adjust the recipe program instruction device through taste of cooking each time, thereby continuously improving the recipe and making taste suitable for users.

Owner:深圳会当科技有限公司

Automatic cooking method, medium and equipment

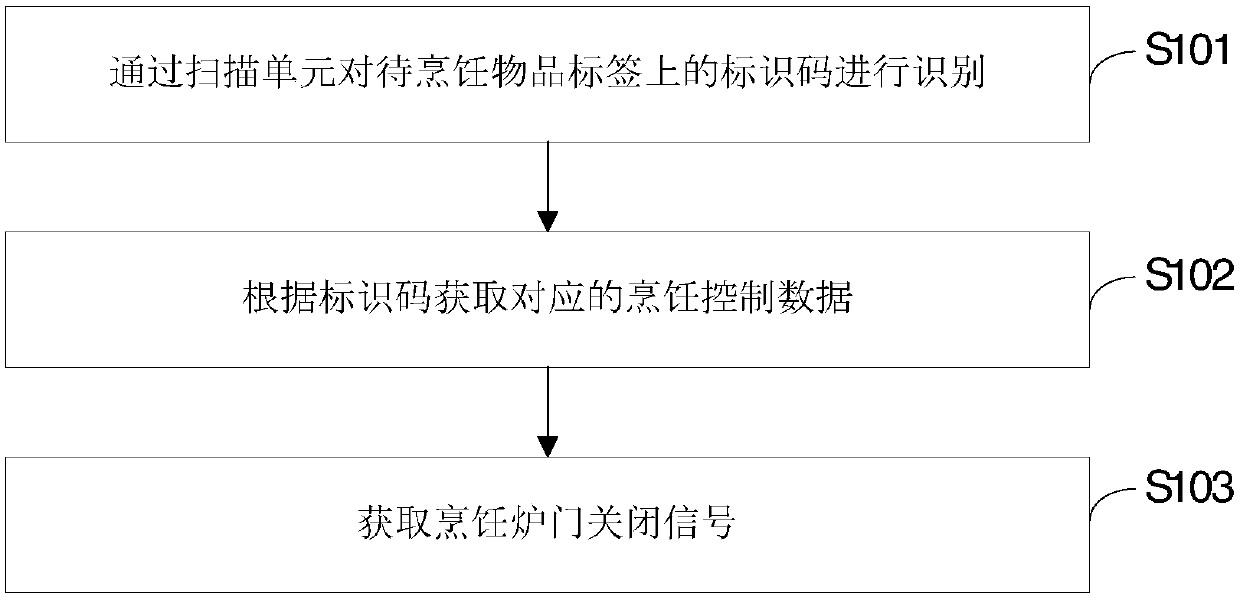

InactiveCN107713721ARealize automatic cookingGood cooking effectCooking vesselsSimulationControl data

The invention discloses an automatic cooking method, a medium and equipment. The method comprises the steps of identifying an identification code on a label of an article to be cooked through a scanning unit; acquiring corresponding cooking control data according to the identification code; then acquiring an off signal, and cooking according to the acquired cooking control data, so that the cooking equipment can be used for cooking automatically. Different cooking control data is correspondingly acquired through scanning and identifying bar codes, and cooking is automatically started, so thata convenient, fast, high-efficient and automatic cooking effect is achieved, and the automatic cooking method, the medium and the equipment have a broad market prospect in the field of cooking utensils.

Owner:FUZHOU GOLDENCHIP POWER SUPPLY TECH

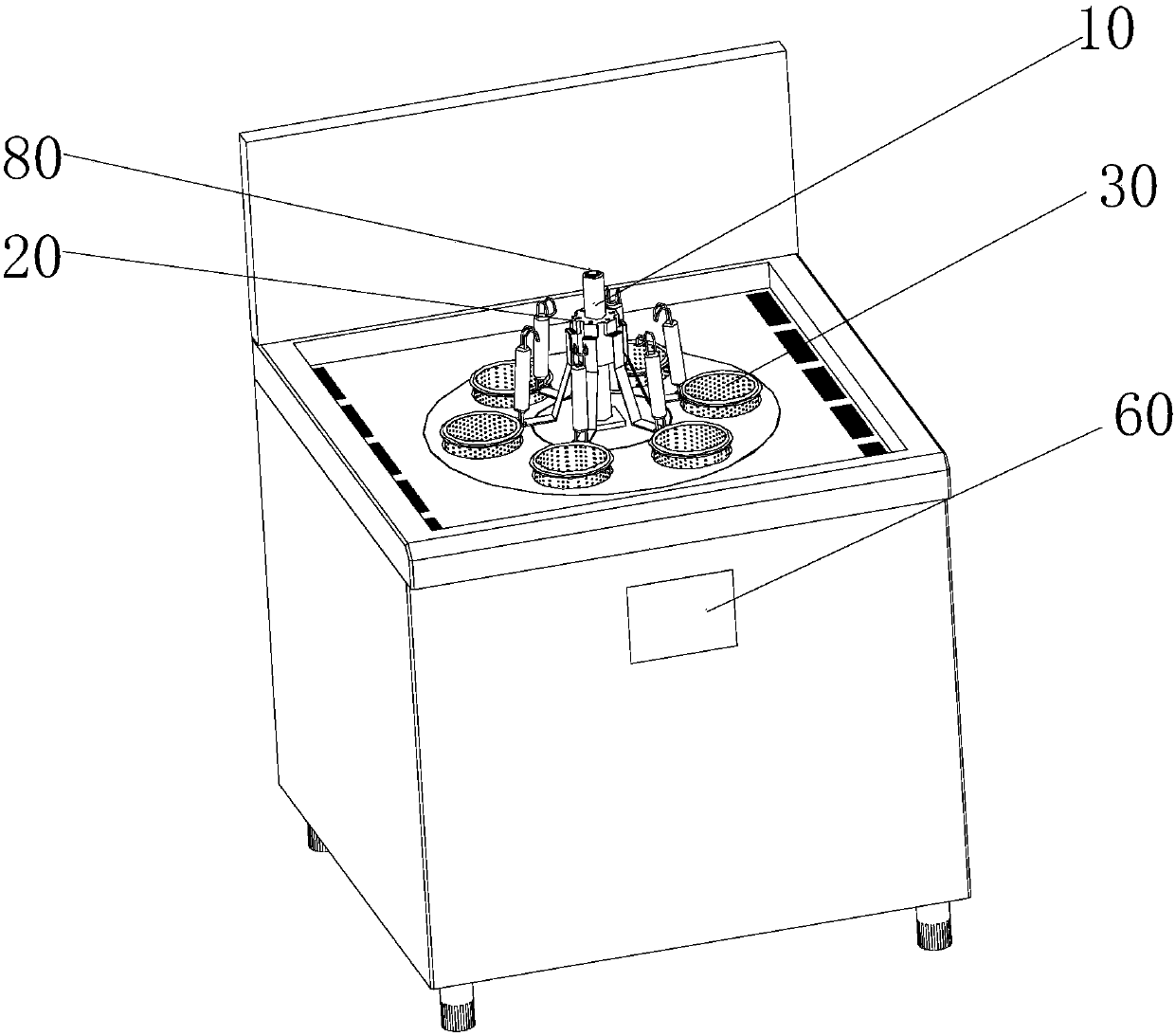

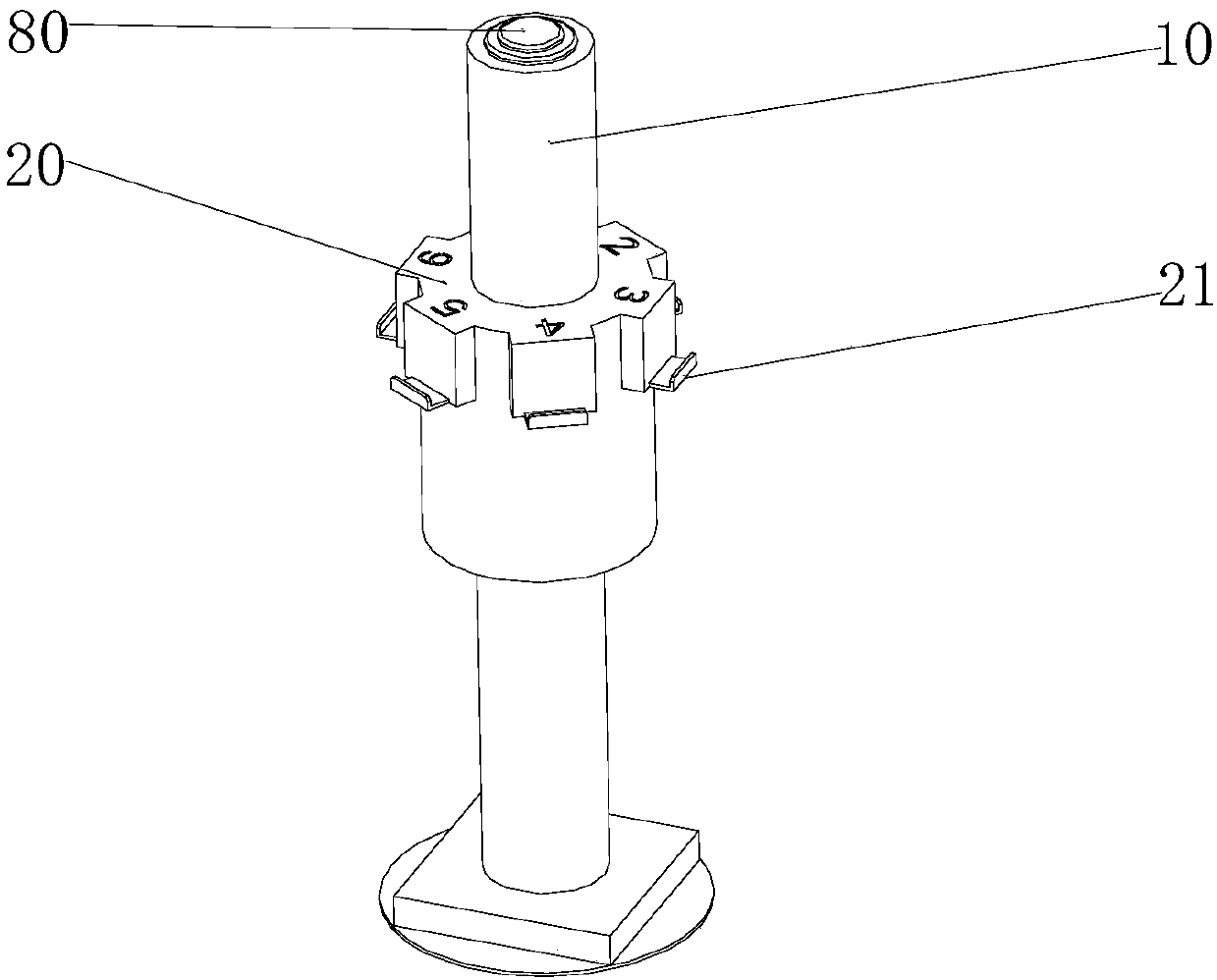

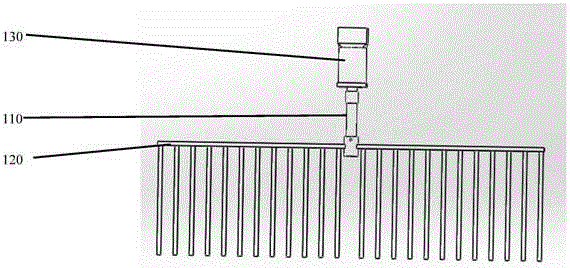

Noodle-cooking stove

ActiveCN107752753AFewer motors and componentsSimple structureWater-bath cooking vesselsCooking insertsPush outEngineering

The invention provides a noodle-cooking stove. The noodle-cooking stove comprises a lifting bar, a hook assembly, multiple noodle frames, a push-out device, and a control device, wherein the lifting bar is provided with the hook assembly, the hook assembly can move up and down along with the lifting bar, the hook assembly comprises multiple hooks, each hook can move relative to the lifting bar andhas a noodle getting state and a reset state, the multiple noodle frames can be suspended on the hooks, the push device enables the hook to switch between the noodle getting state and the reset state, when in the noodle getting state, the push device pushes the hook toward the direction far from the lifting bar, so that the hook is in the noodle getting state to hook the noodle frame, the liftingbar can lift up and down to drive the noodle frame to ascend and descend, when in boiling, the push device is separated from the hook, the hook is in the reset state, so as to separate the noodle frame from the hook, and the control device is connected with the lifting bar and the push device, so as to control the lifting bar to ascend and descend and the push device to act. The noodle-cooking stove overcomes the defect of complex structure of an existing noodle-cooking stove.

Owner:珠海优特智厨科技有限公司

Automatic cooker

InactiveCN106618150AImplement automatic additionThe amount of seasoning added is controllableCooking-vessel lids/coversAutomatic controlEngineering

The invention relates to an automatic cooker which comprises a cooking bench, a conveyor belt, multiple pots, a hopper and pot covers. The two sides of the conveyor belt are provided with side plates; openings are formed in the portions, corresponding to the pots, of the side plates, and side wing grooves are formed in the openings; the lower ends of the side wing grooves are connected to the edges of pot openings of the pots in an abutting mode; a push plate and a first electric push rod for pushing the push plate towards the corresponding opening are arranged on the portion, corresponding to each opening, of the corresponding side plate, and stirring shovels are arranged in the centers of the pot covers. The automatic cooker has the advantages that automatic cooking can be achieved, multiple dishes can be independently cooked simultaneously, and not only can the cooking efficiency be improved, but also the single-pot single-dish delicious taste can be guaranteed; the whole process is automated, operation is easy and practical, both the adding quantity and the adding time of seasonings can be automatically controlled through programs, and the taste can be consistent.

Owner:吴佳涵

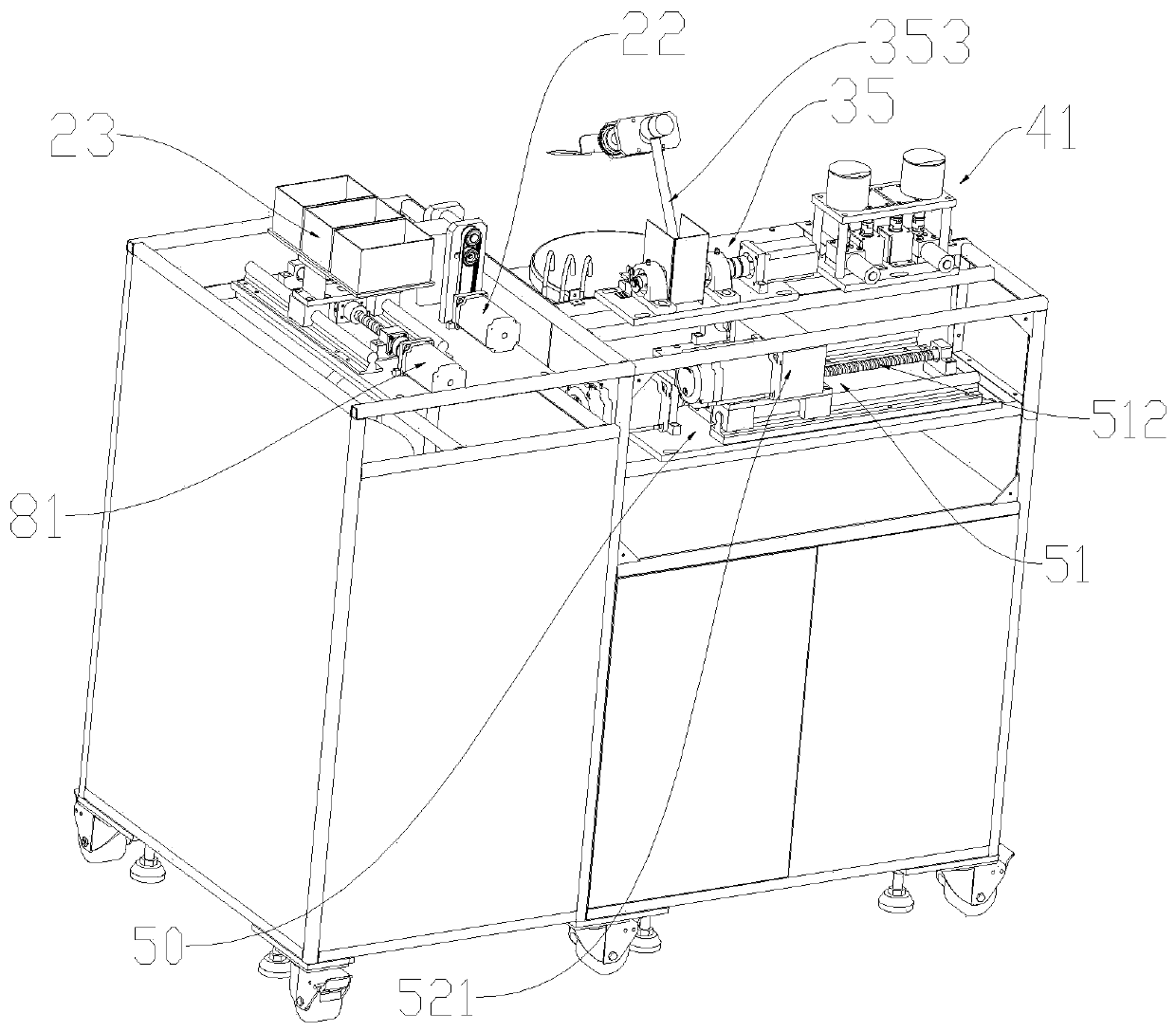

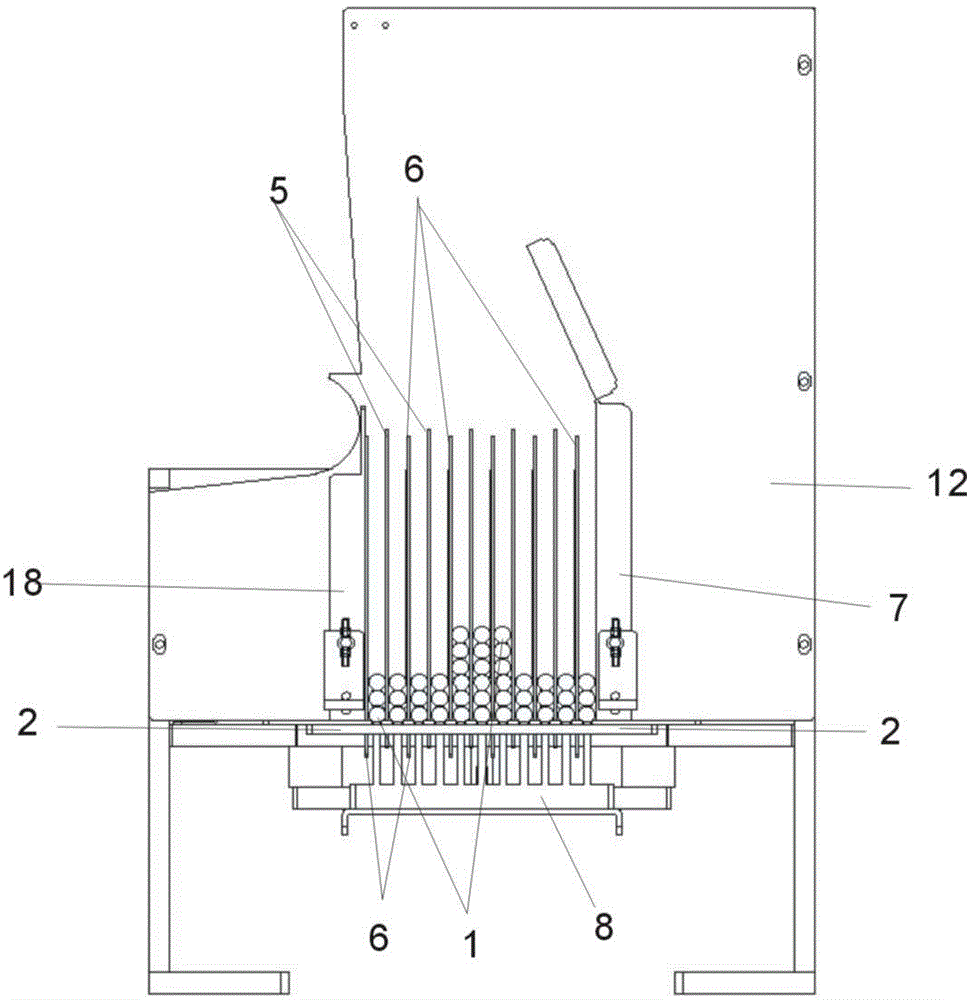

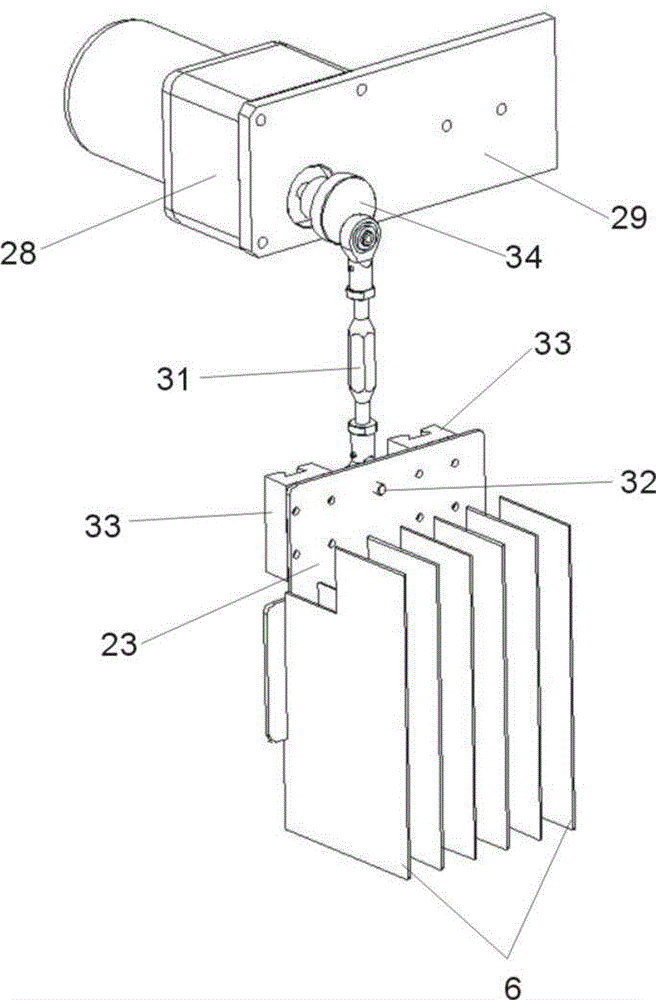

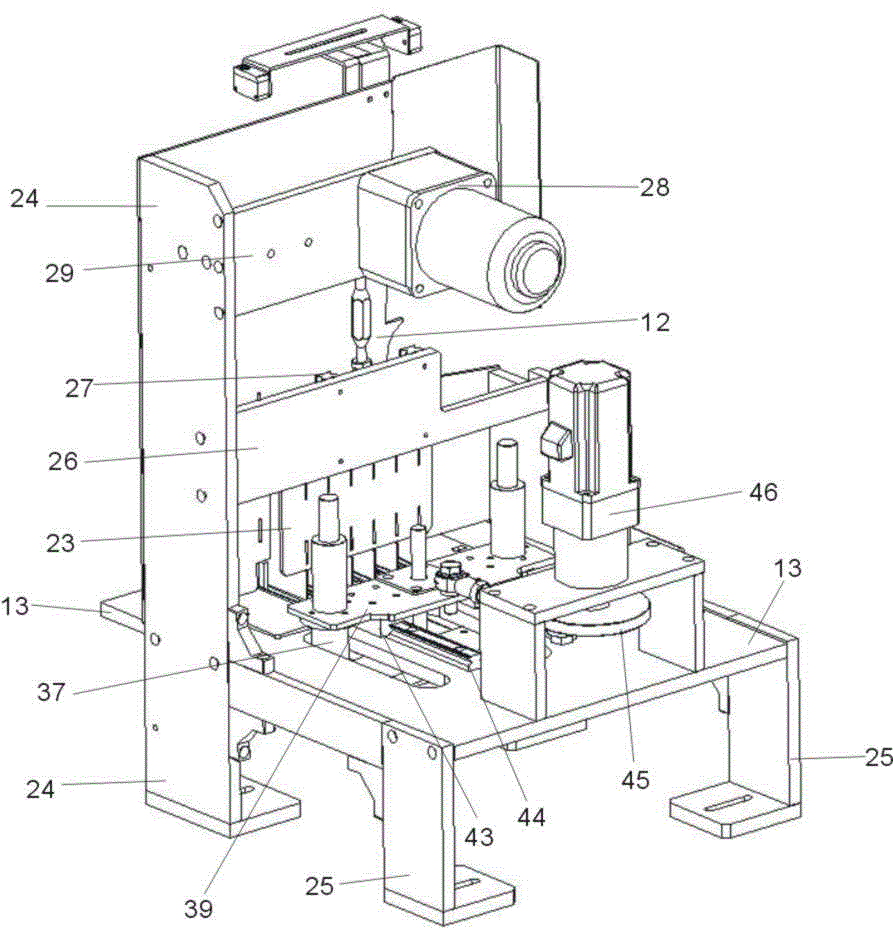

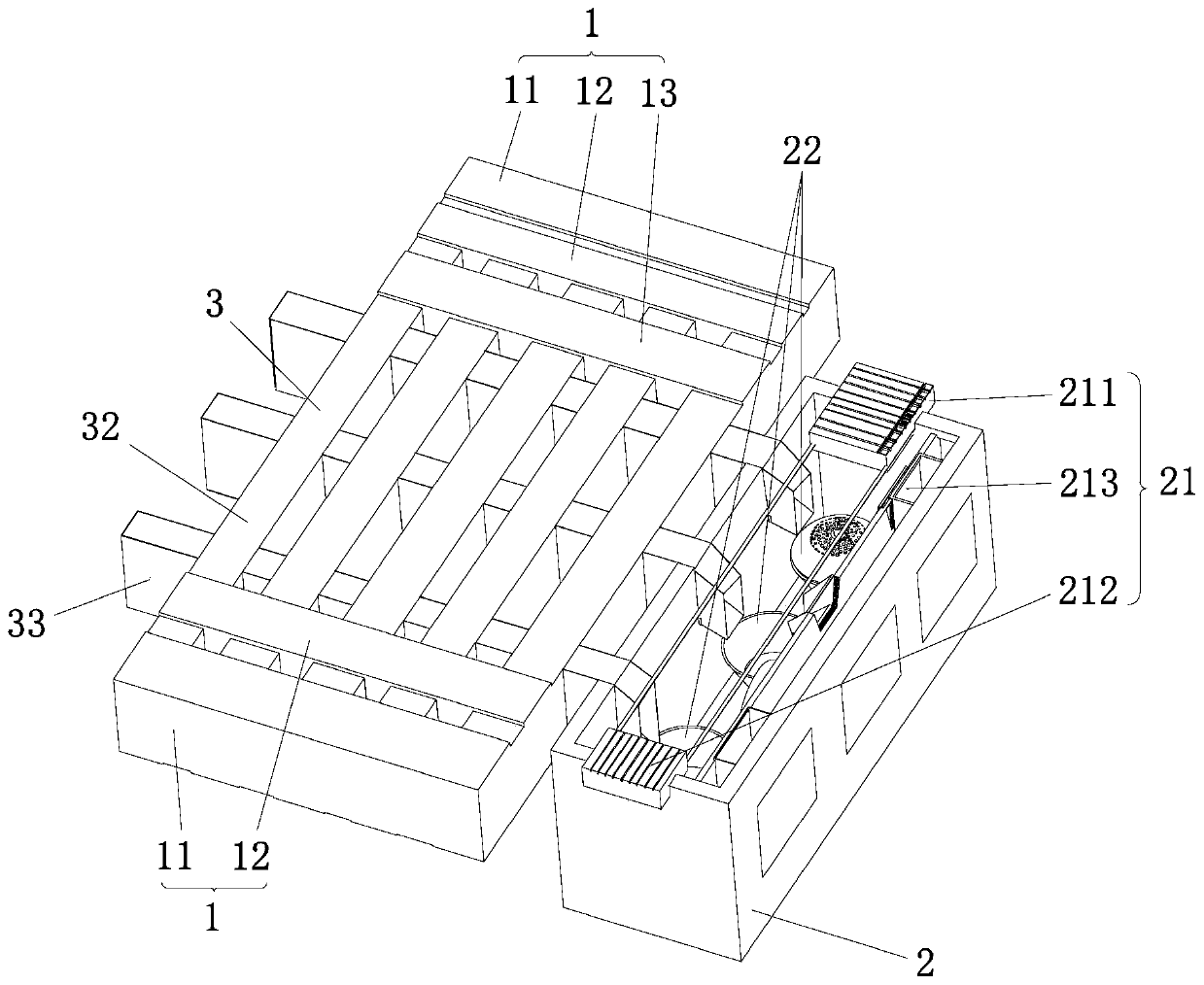

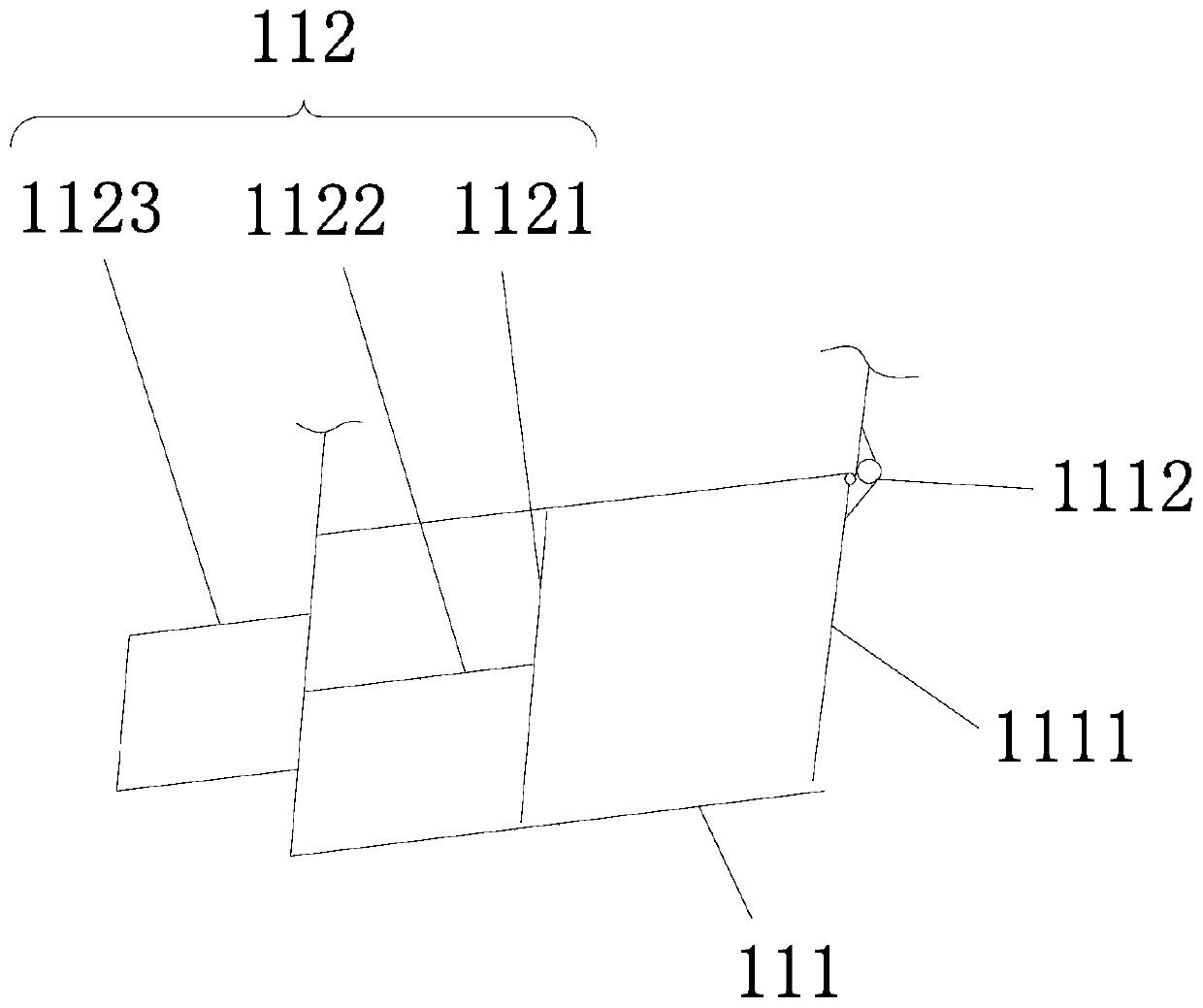

Settling machine for multiple bar-shaped materials

ActiveCN105984603AReasonable structureFully automatedPackaging biscuitsProduction rateVertical vibration

A settling machine for multiple bar-shaped materials comprises a settling bin which comprises a settling bin bottom plate, a settling bin front baffle, a settling bin rear baffle, a settling bin left baffle, a settling bin right baffle, settling bin fixed separating plates, settling bin vibrating plates, a vibration transmission plate and a settling bin push handle. The settling bin bottom plate is provided with supporting strips, and the supporting strips and the settling bin bottom plate are provided with slotted holes. The settling bin rear baffle is provided with grooves and concave openings. The settling bin push handle comprises a push palm and pushing plates. The settling bin fixed separating plates are mounted on the settling bin rear baffle, and the settling bin vibrating plates are mounted on the vibration transmission plate. The settling bin rear baffle is arranged on the supporting strips, and the settling bin fixed separating plates are arranged in the corresponding slotted holes. After the vibration transmission plate is arranged on the settling bin rear baffle, the settling bin vibrating plates penetrate through the grooves of the settling bin rear baffle to be arranged in the corresponding slotted holes for vertical vibration so as to achieve settling. The settling bin front baffle is mounted on the settling bin left baffle and the settling bin right baffle, and the bar-shaped materials can pass through the settling bin front baffle. The push palm is arranged under the settling bin bottom plate, the pushing plates are arranged between the corresponding supporting strips, and the pushing plates push the materials front and back through the concave openings of the settling bin rear baffle. The settling machine is mainly applied to stack the bar-shaped materials one by one and layer by layer for settling, such as bar-shaped biscuits, automation of a production line is achieved by connecting production and packaging, and the productivity is greatly increased.

Owner:佛山市永创智能设备有限公司

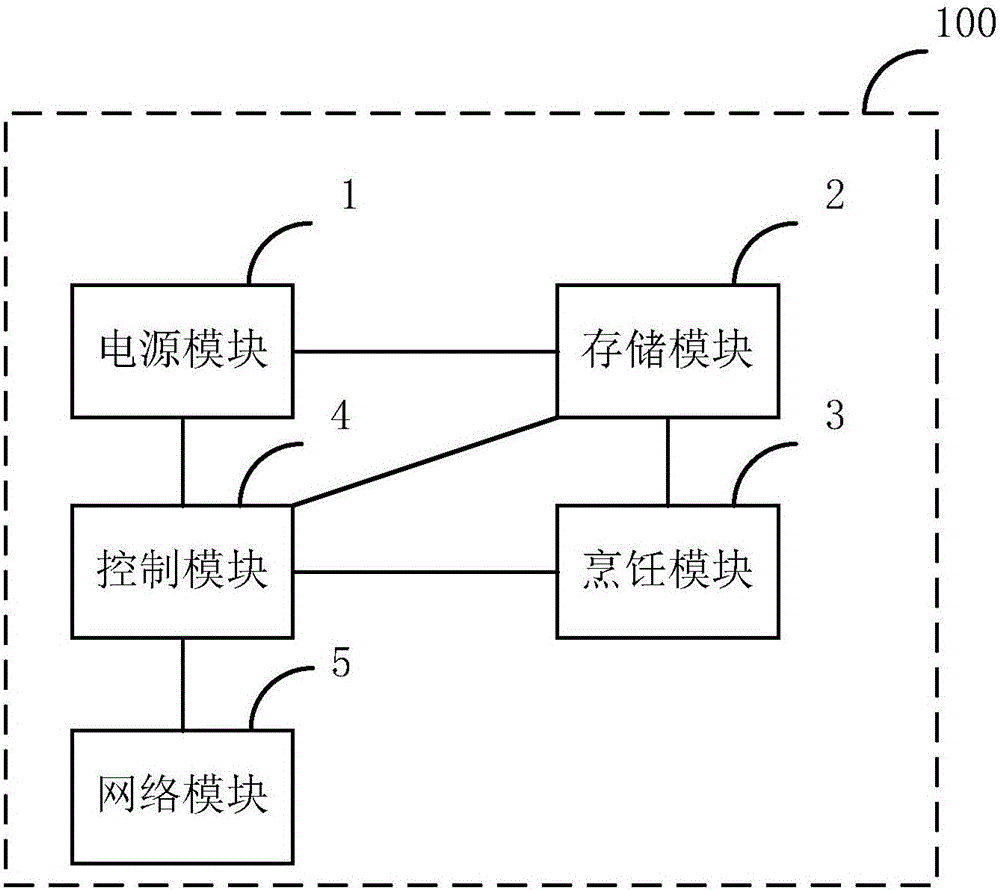

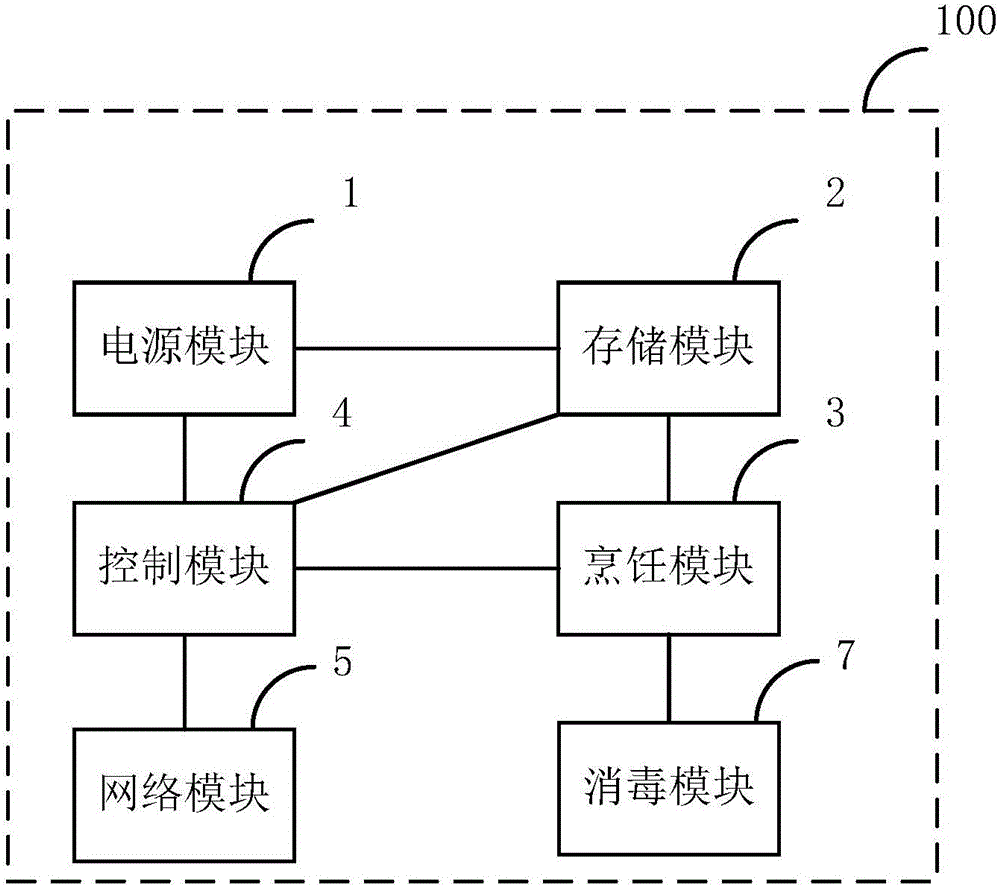

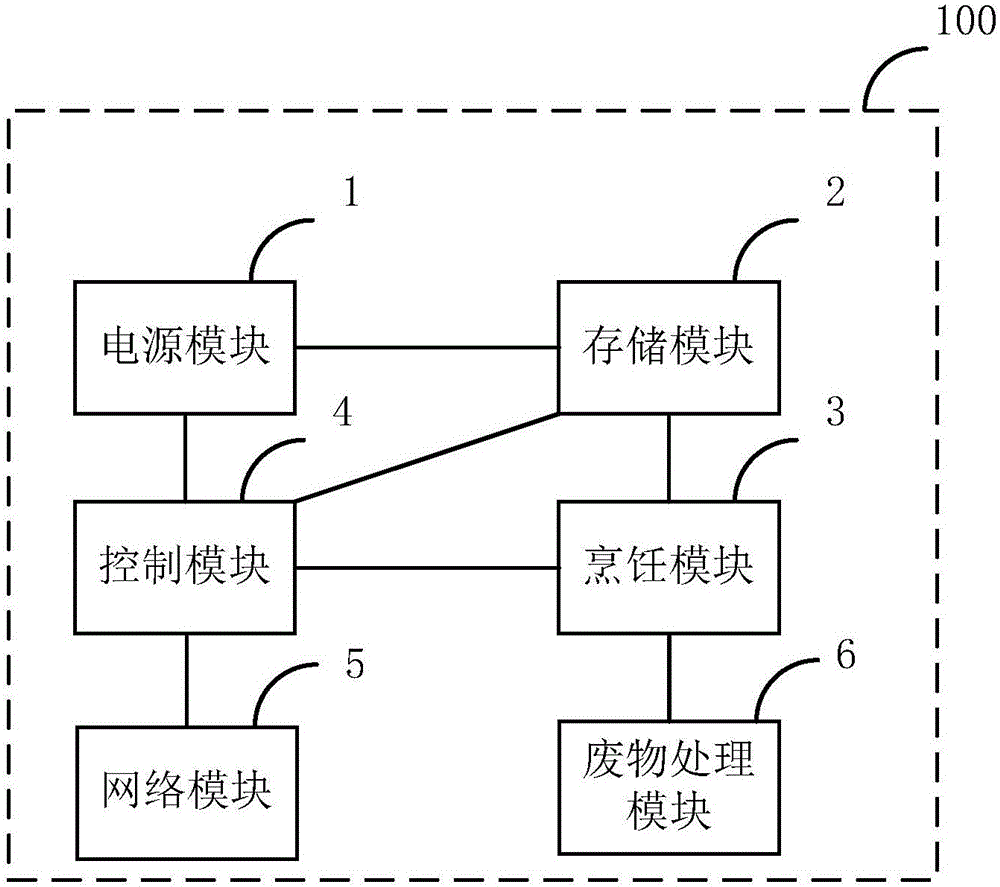

Cooking equipment

InactiveCN105816012AImprove quality of lifeImprove convenienceCooking vesselsRemote controlComputer module

An embodiment of the present invention proposes a cooking device, including: a power module, a storage module, a cooking module, a control module, and a network module; wherein, the power module is connected to the storage module, the cooking module, and the control module; The storage module is connected to the control module and the cooking module; the control module is connected to the cooking module; the network module is connected to the control module. In this way, the automatic cooking equipment is remotely controlled through the network module, and automatic cooking is realized, and the addition of the respective additional modules can also provide users with nutritious and low-cost food, and at the same time save the user from the cumbersome cooking process. The operation is liberated, improving the user's quality of life, and the entire cooking process does not require personal presence, which improves the user's life convenience and life experience.

Owner:肖梁坚

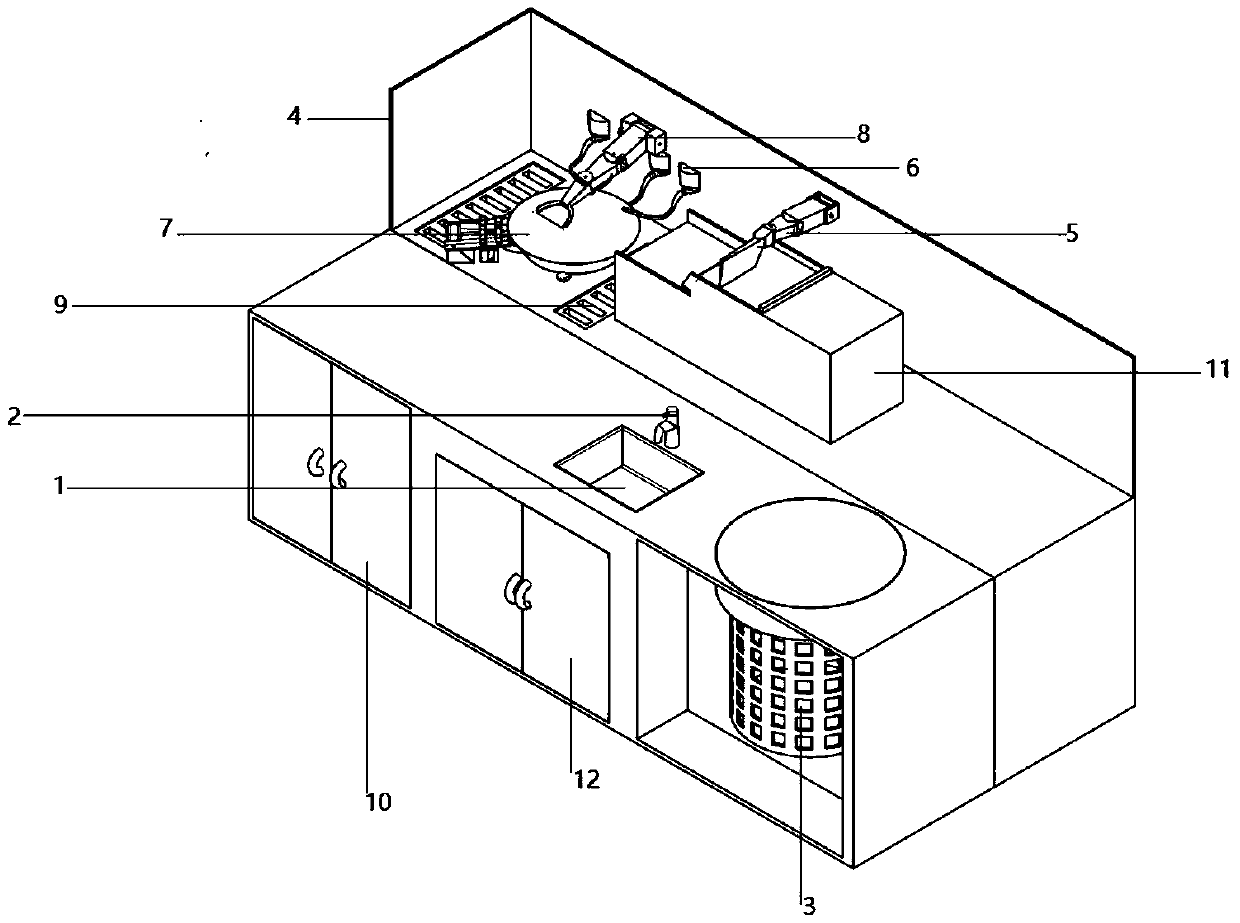

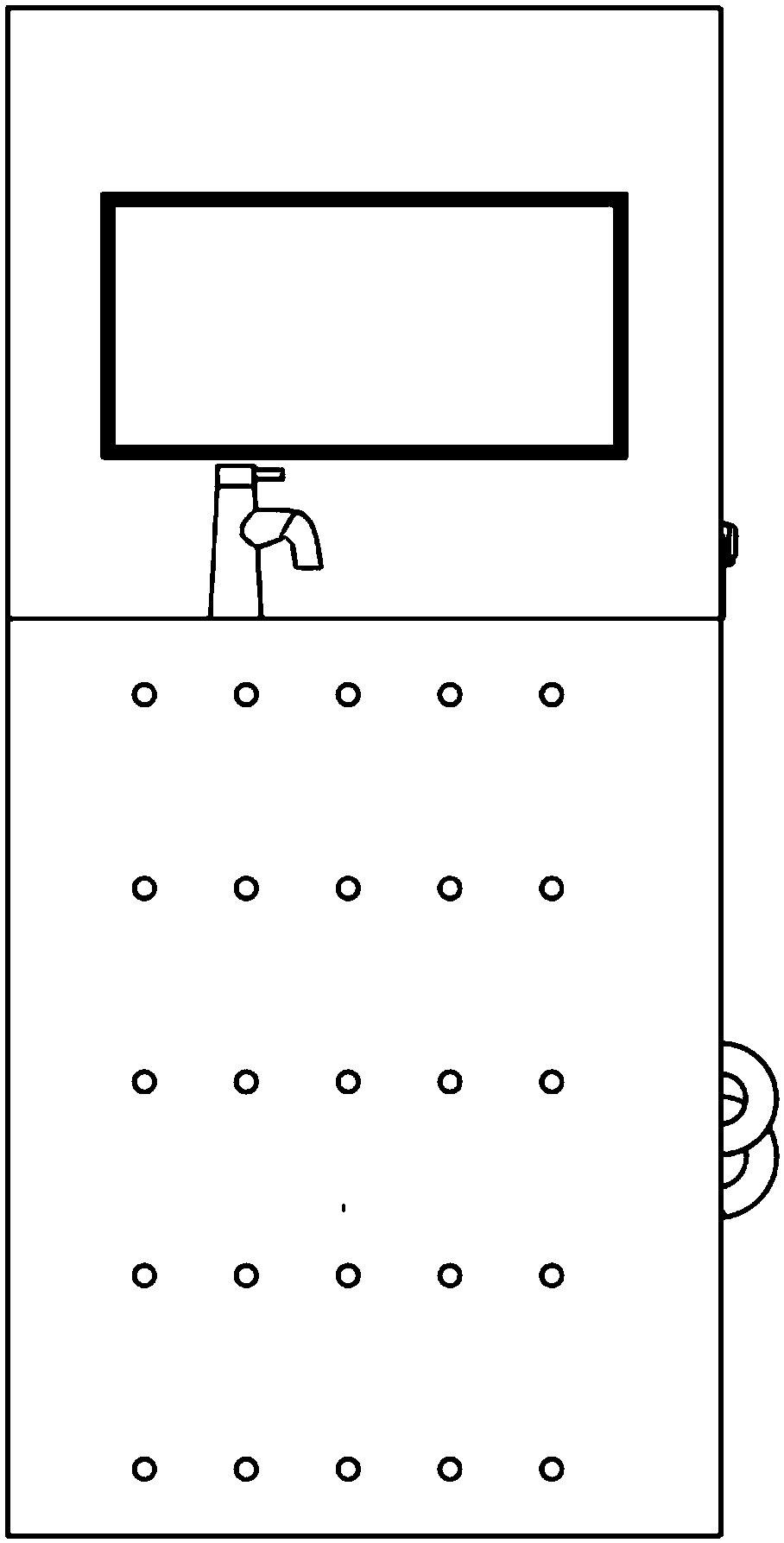

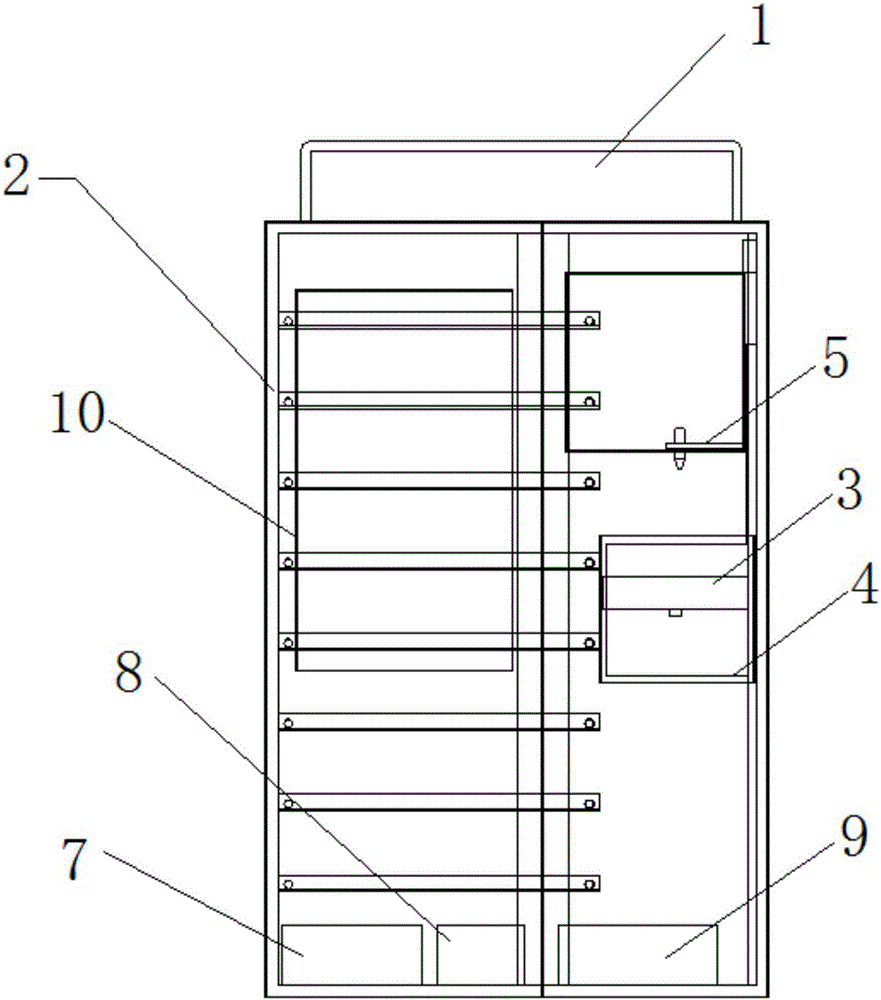

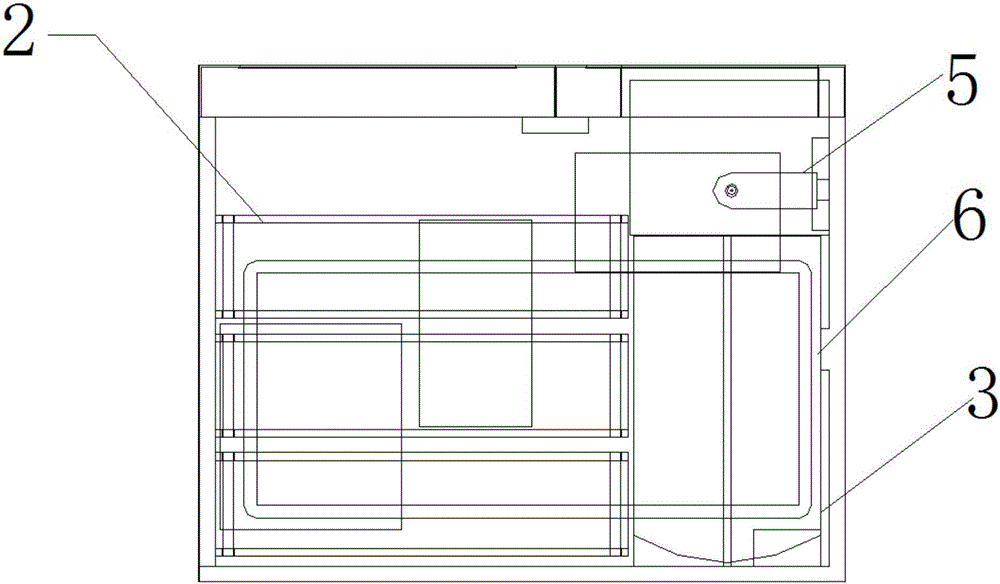

Integrated kitchen robot and control method thereof

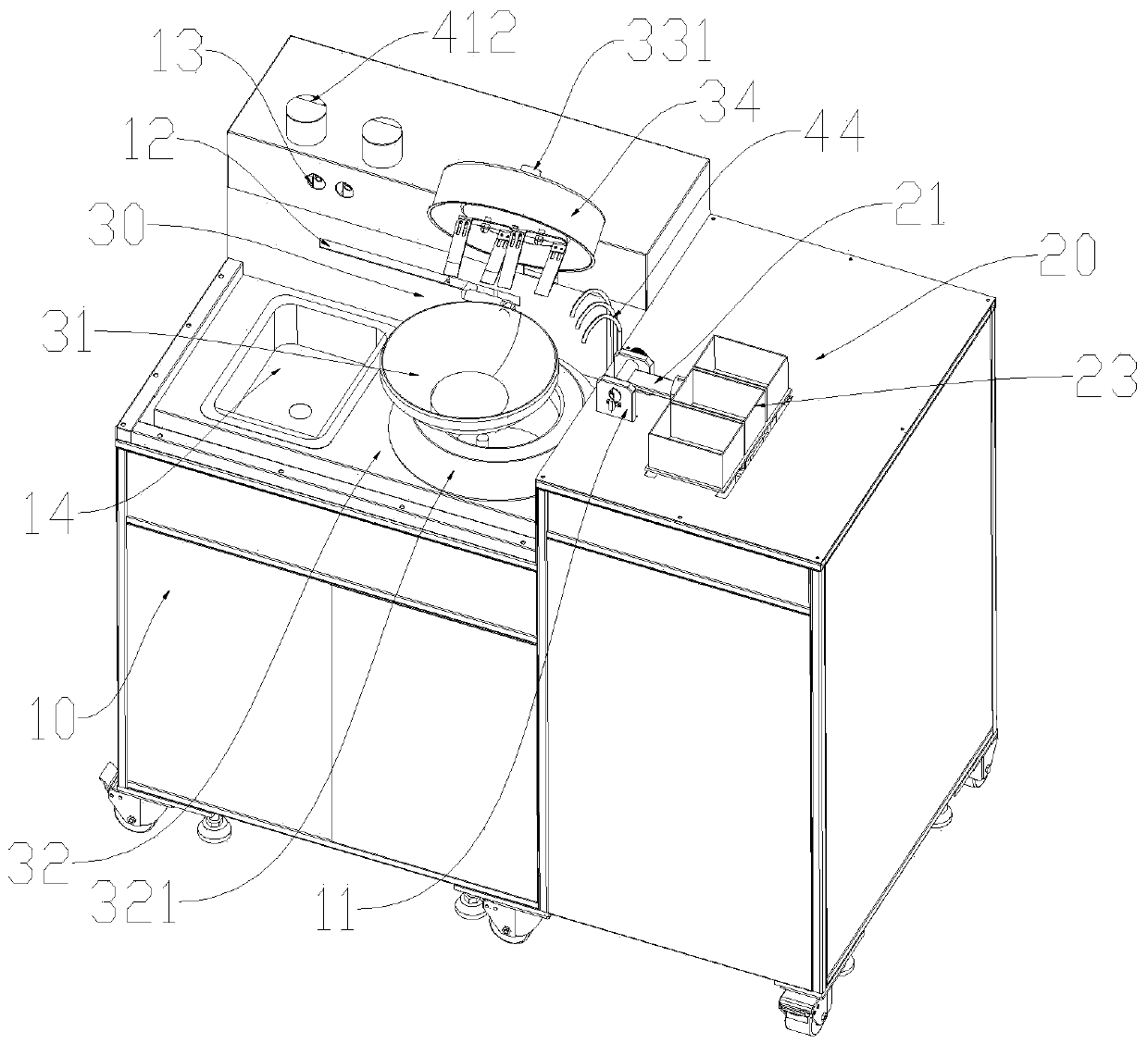

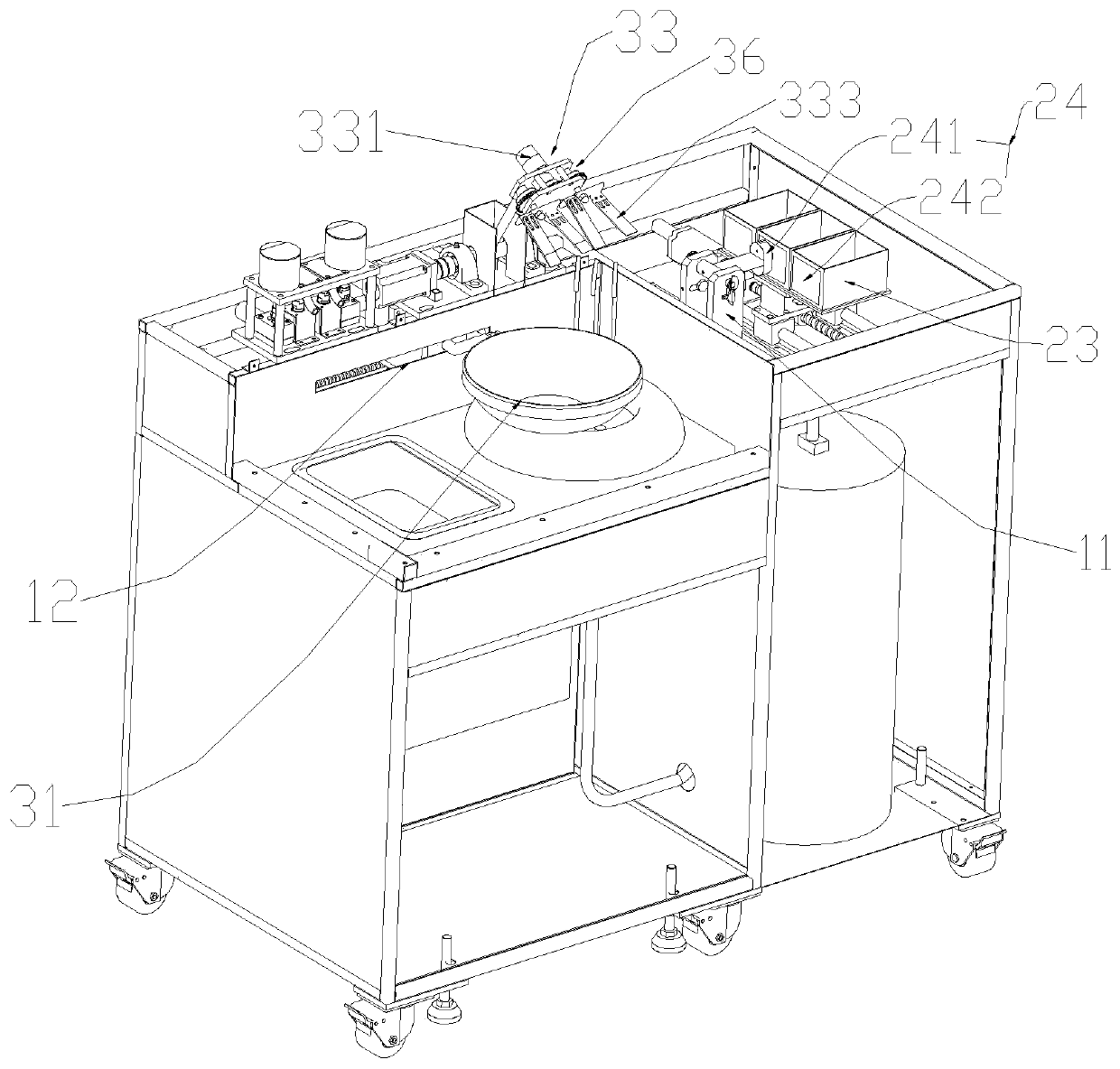

InactiveCN109623842ARealize automatic cookingRealize the purpose of automatic cookingProgramme-controlled manipulatorCookerMaterial transfer

The invention provides an integrated kitchen robot and a control method thereof. The robot comprises a cabinet body (100), wherein a water tank (1), a vegetable washing and disinfecting device (3), anautomatic discharging air exhaust ventilator (9), an automatic material transferring device (11) and man-machine interaction equipment (4) are arranged on the cabinet body (100), a water faucet (2) is arranged above the water tank (1), the automatic discharging air exhaust ventilator (9) is provided with an automatic stir-frying pan device (7), and an automatic cooker shovel (8) and a feeding container (6) are arranged above the automatic stir-frying pan device (7); the automatic material conveying device (11) is close to the automatic stir-frying pan device (7) to automatically convey food materials to the automatic stir-frying pan device (7); and the automatic material conveying device (11) is provided with a cutting device (5), so that the food materials which are conveyed to the position of the man-machine interaction equipment (4) are cut, the man-machine interaction is provided by the man-machine interaction equipment (4), and the purpose of automatic cooking of dishes can be achieved.

Owner:GUANGZHOU UNIVERSITY

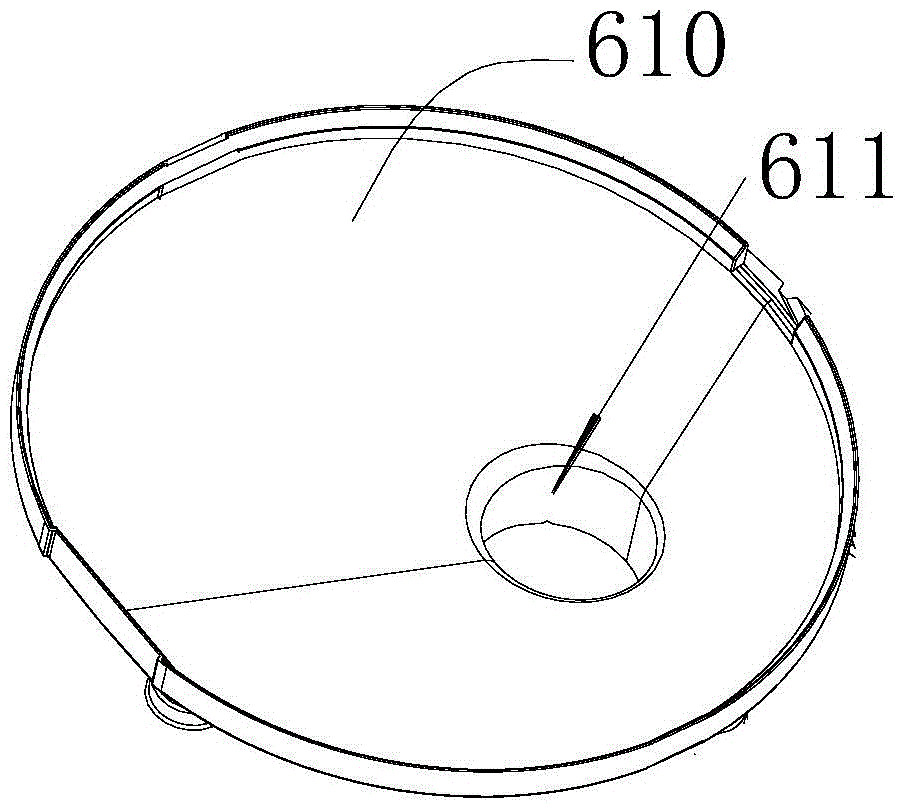

Cooking utensil

The invention provides a cooking utensil which comprises a cooker body and a cooker cover. The cooker cover is provided with a storage bin for storing raw materials, a discharge port is formed in the storage bin, and a first material conveying device is arranged in the storage bin; the cooker cover is further provided with a first driving device, and the first material conveying device is driven by the first driving device to convey the raw materials in the storage bin to the discharge port, wherein the volume of the storage bin is 0.2 L-3.6 L. The volume of the storage bin can be increased to decrease the overall size of the cooker cover, then the size of the cooking utensil is decreased, and therefore usage of a user is promoted.

Owner:JOYOUNG CO LTD

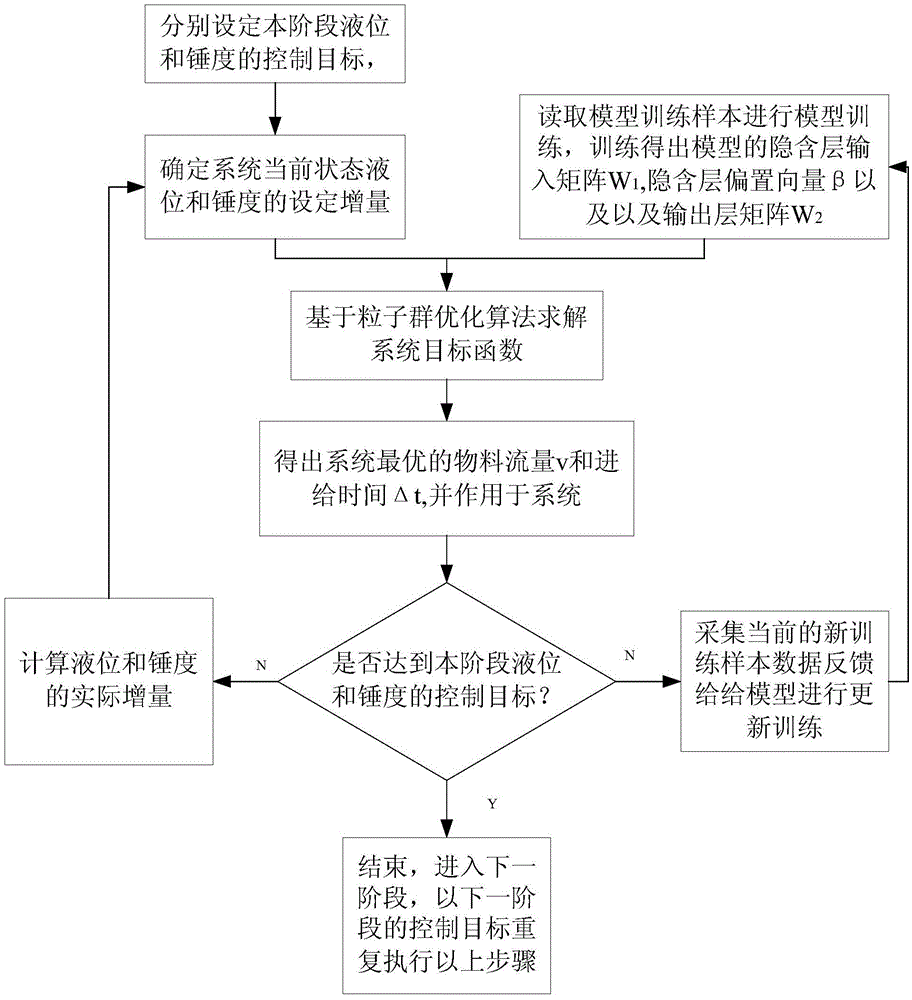

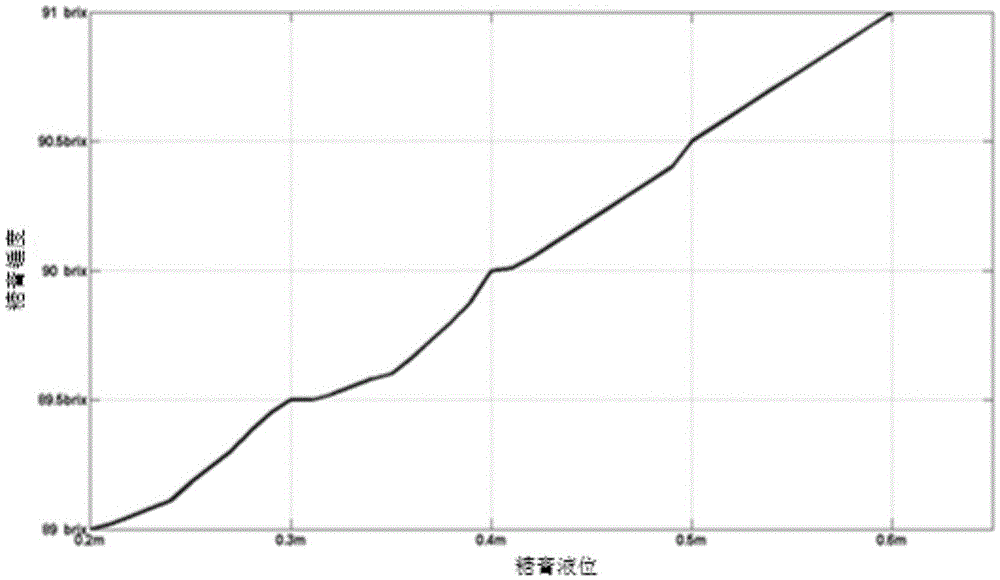

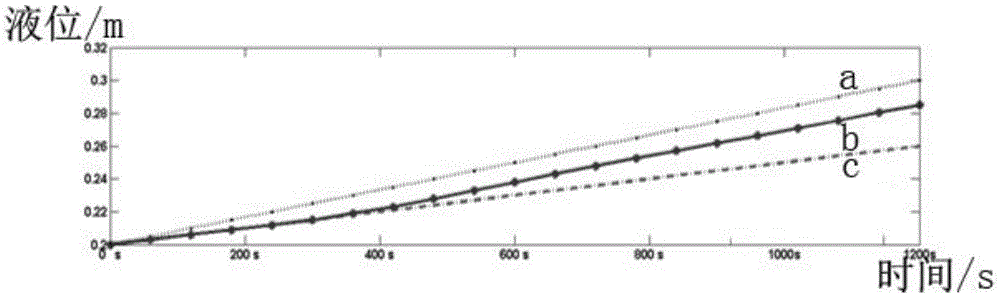

Method for controlling sugar boiling crystallization process based on sequential extreme learning machine

InactiveCN105488530ARealize automatic cookingHigh feasibilityCharacter and pattern recognitionTime errorProcess requirements

The invention discloses a method for controlling a sugar boiling crystallization process based on a sequential extreme learning machine. The method comprises: constructing a control model of sugar boiling crystallization process parameters based on the sequential extreme learning machine by using a feed flow rate and a feed time as inputs and using a liquid level variant and a brix variant as outputs; constructing a target function according to process requirements, and rapidly solving the target function in combination with a particle swarm optimization algorithm to optimize the feed flow rate and the feed time. By adopting the method, an on-line learning mechanism of the sequential extreme learning machine is constructed, a rolling optimization mechanism is formed, and follow-up adaptive control is constructed. The method can be used for detecting the liquid level and the brix change rate of the sugar boiling crystallization process online and adaptively adjusting the feed flow rate according to real-time errors, thus meeting the process requirement of synchronous rise of the liquid level and the brix, having strong feasibility and replacing a manual operation to realize automatic boiling of the sugar boiling crystallization process.

Owner:GUANGXI UNIV

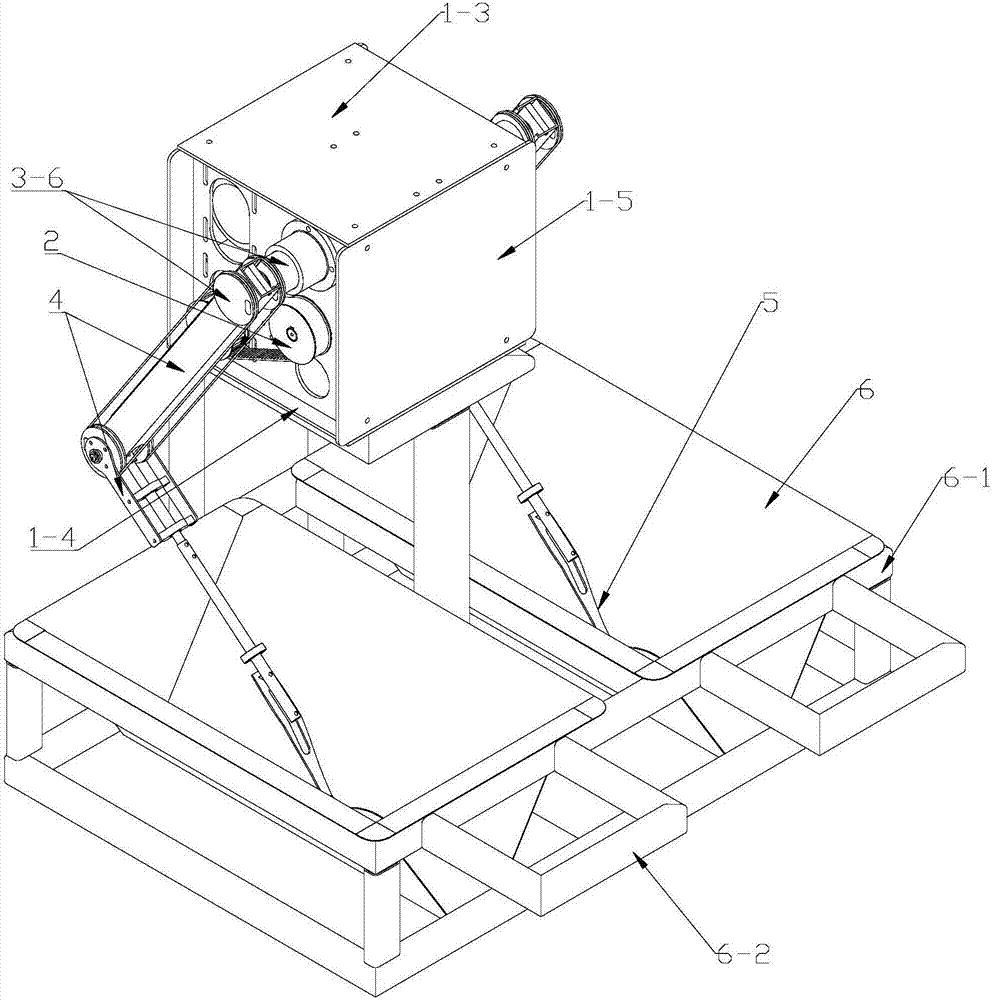

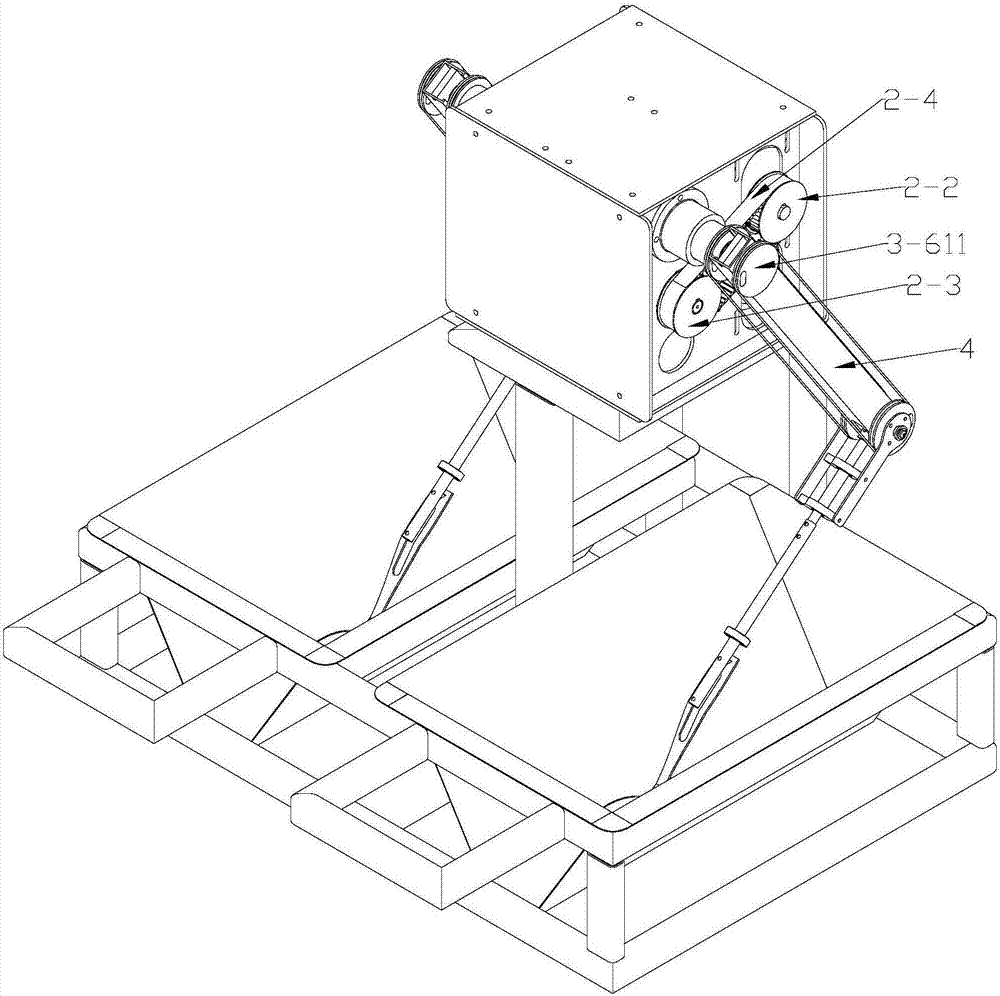

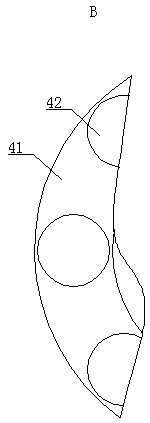

Dish taking robot

ActiveCN107336227ARealize automatic cookingProgramme-controlled manipulatorSimulationFuture of robotics

The invention relates to the technical field of robots and in particular relates to a dish taking robot. The dish distributing robot is characterize by comprising a fixed rack, a driving device, a linking device, a simulated arm, a dish shovel and a dish holding basin. The linking device comprises four cams, a cam shaft, a lower arm fixing shaft, three lower driving arms, three upper driving arm, a driving arm connecting rod and a knot sleeve. The driving device drives the linking device, so that the simulated arm moves and the dish shovel takes dishes from the dish holding basin. Compared with the prior art, the linking device is driven by the driving device to move to simulate a dish taking movement of the simulated arm so as to automatically take dishes; furthermore, the driving device can be started by swiping a card and perform deduction.

Owner:SHANGHAI JINGHONG ROBOT CO LTD

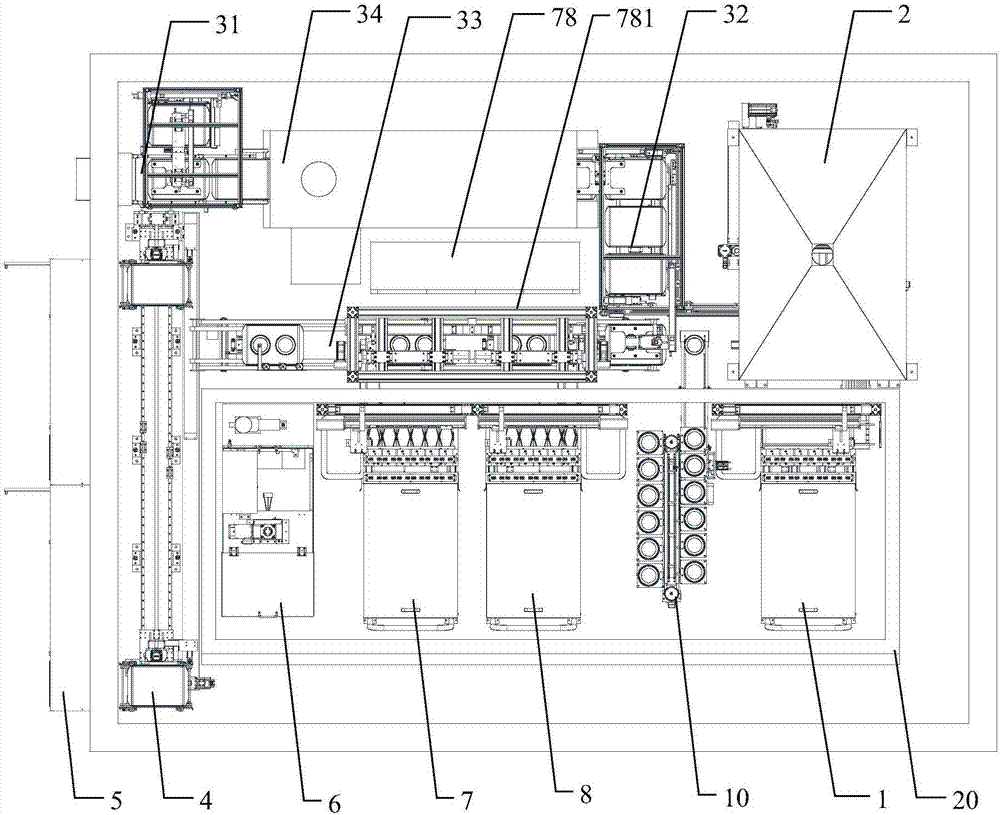

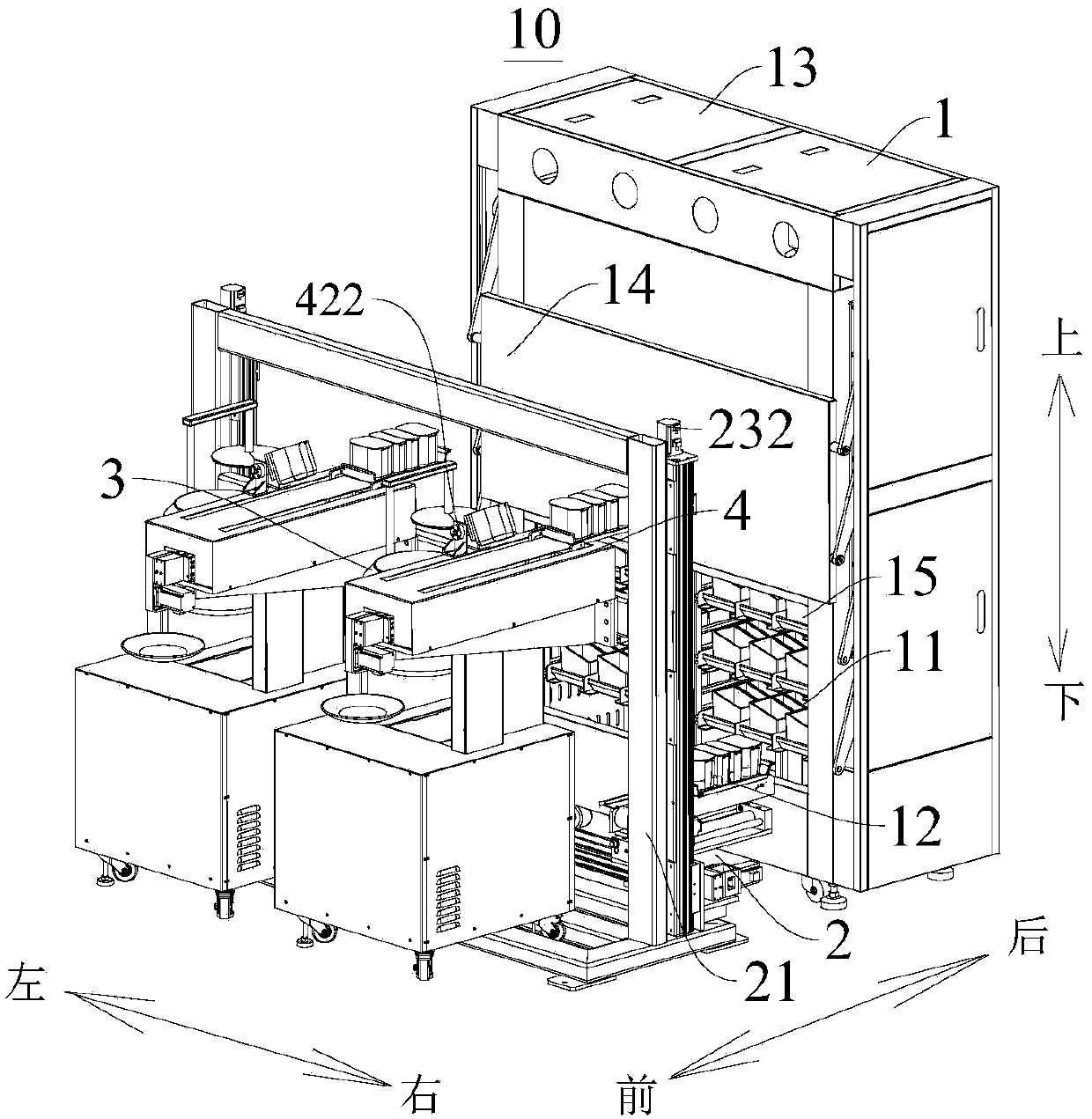

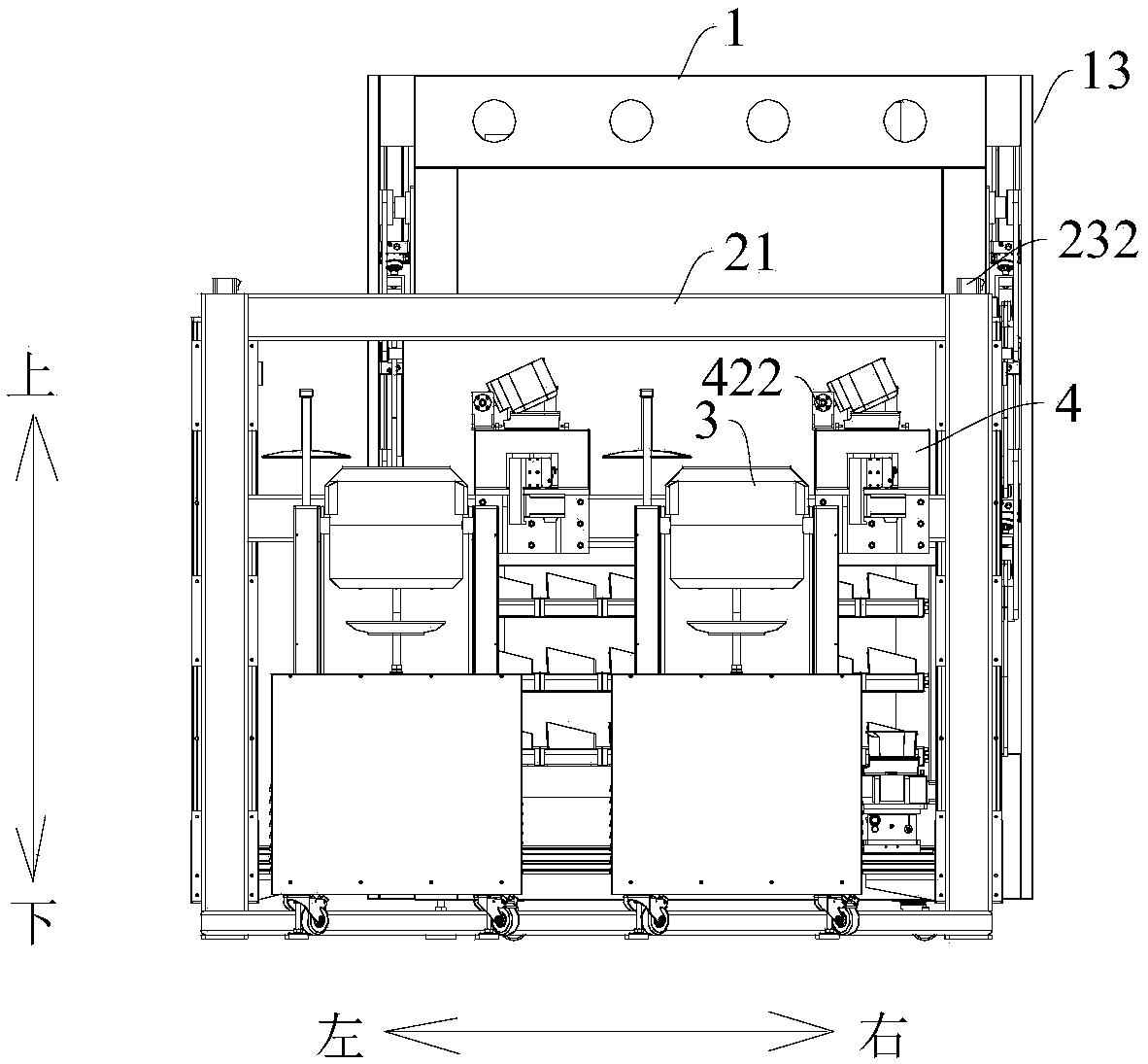

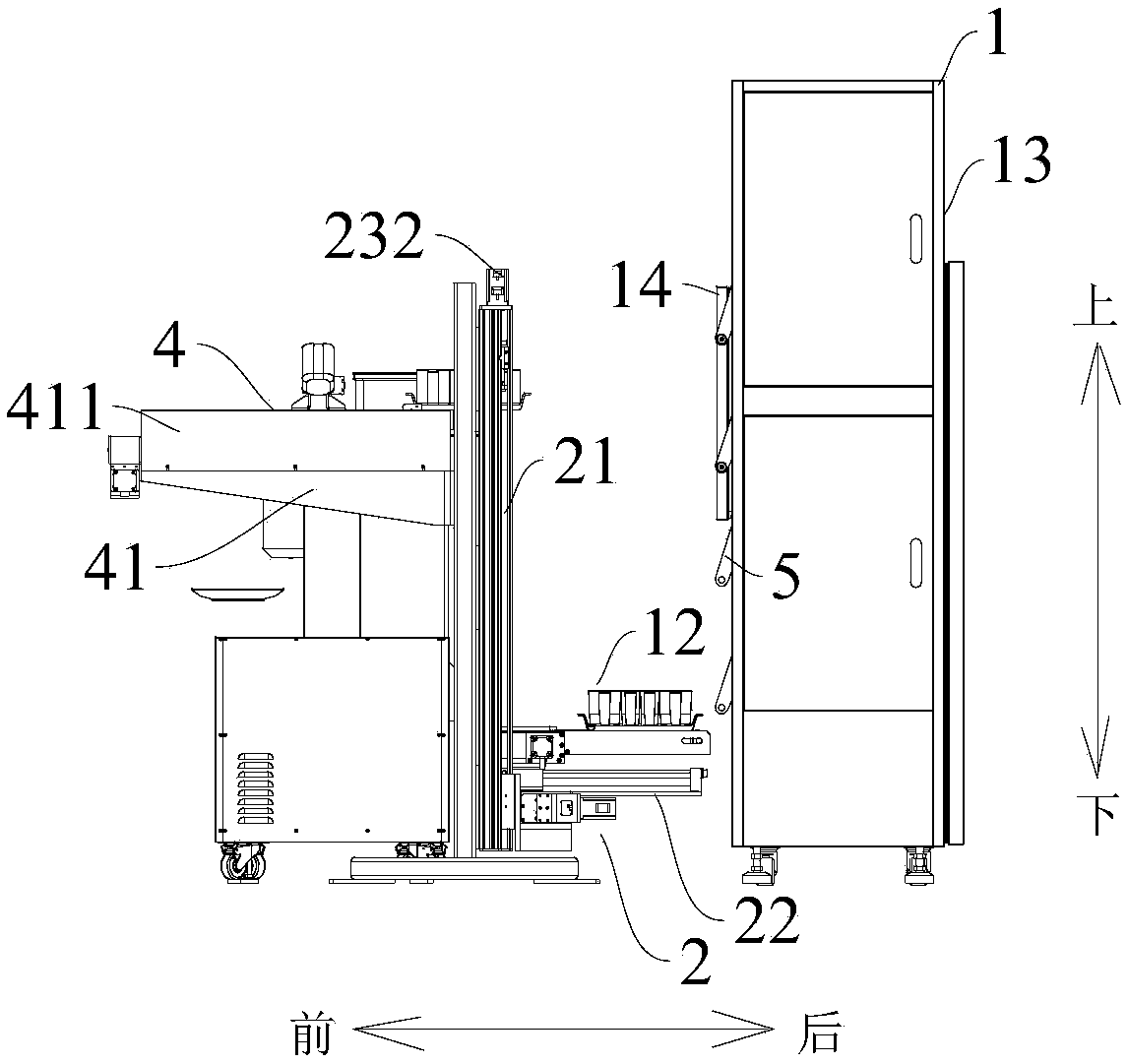

Intelligent dish-frying system

PendingCN109998358AEasy cookingRealize automatic cookingCooking vessel constructionsAdditive ingredientEngineering

The invention provides an intelligent dish-frying system. The intelligent dish-frying system comprises a rack, a food material treating assembly, an operation assembly, a distributing and conveying assembly and a controller, wherein the food material treating assembly comprises a food material storing unit, a washing unit and a processing unit; the food material storing unit comprises a pluralityof storage grids and a first pushing mechanism; cutting blades are arranged on the processing unit; the operation assembly comprises an ingredient adding mechanism, a water conveying mechanism, a finished product tray, driving mechanisms and at least three pot bodies, the pot bodies and the rack are connected through the driving mechanisms, the driving mechanisms drive the corresponding pot bodiesto perform overturning and / or rotating movements, and the ingredient adding mechanism is arranged above the pot bodies; and the distributing and conveying assembly is used for conveying food materials, and the controller is used for controlling the food material treating assembly, the operation assembly and the distributing and conveying assembly to move. For the intelligent dish-frying system provided by the invention, the process including vegetable washing, vegetable cutting, material feeding, vegetable frying, staple food cooking and the like can be automatically realized, so that dish frying and staple food cooking are enabled to be simpler, and the time consumed in dish frying and staple food cooking by an operator is saved.

Owner:SHENZHEN INST OF ADVANCED TECH

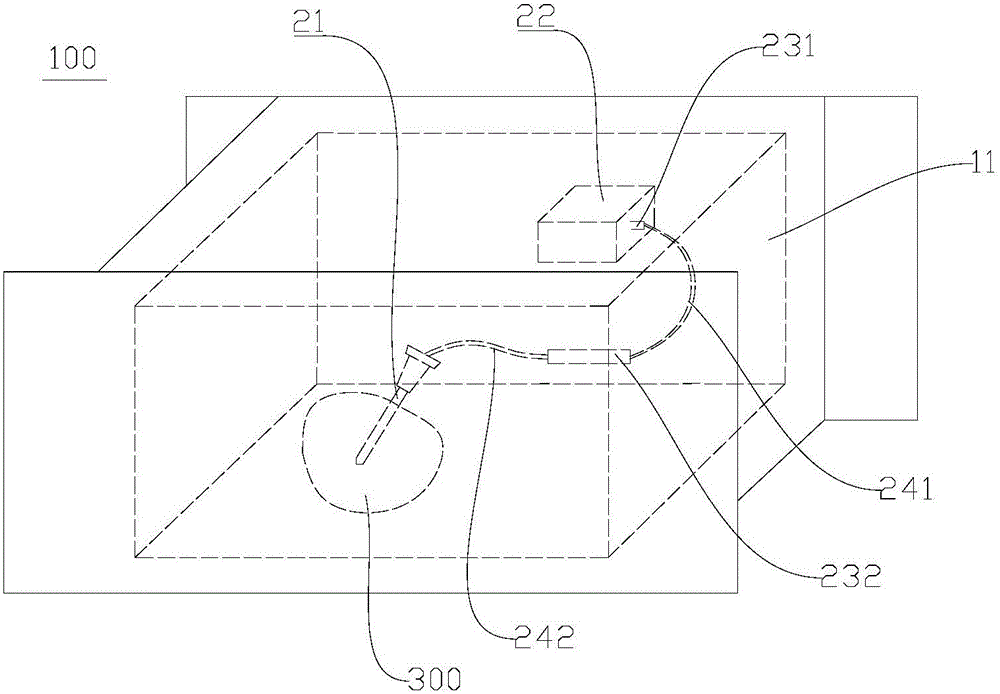

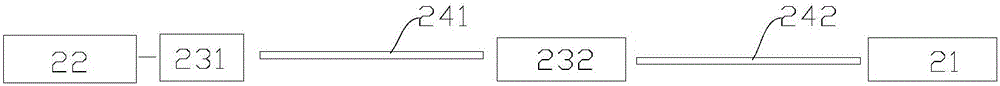

Cooking device

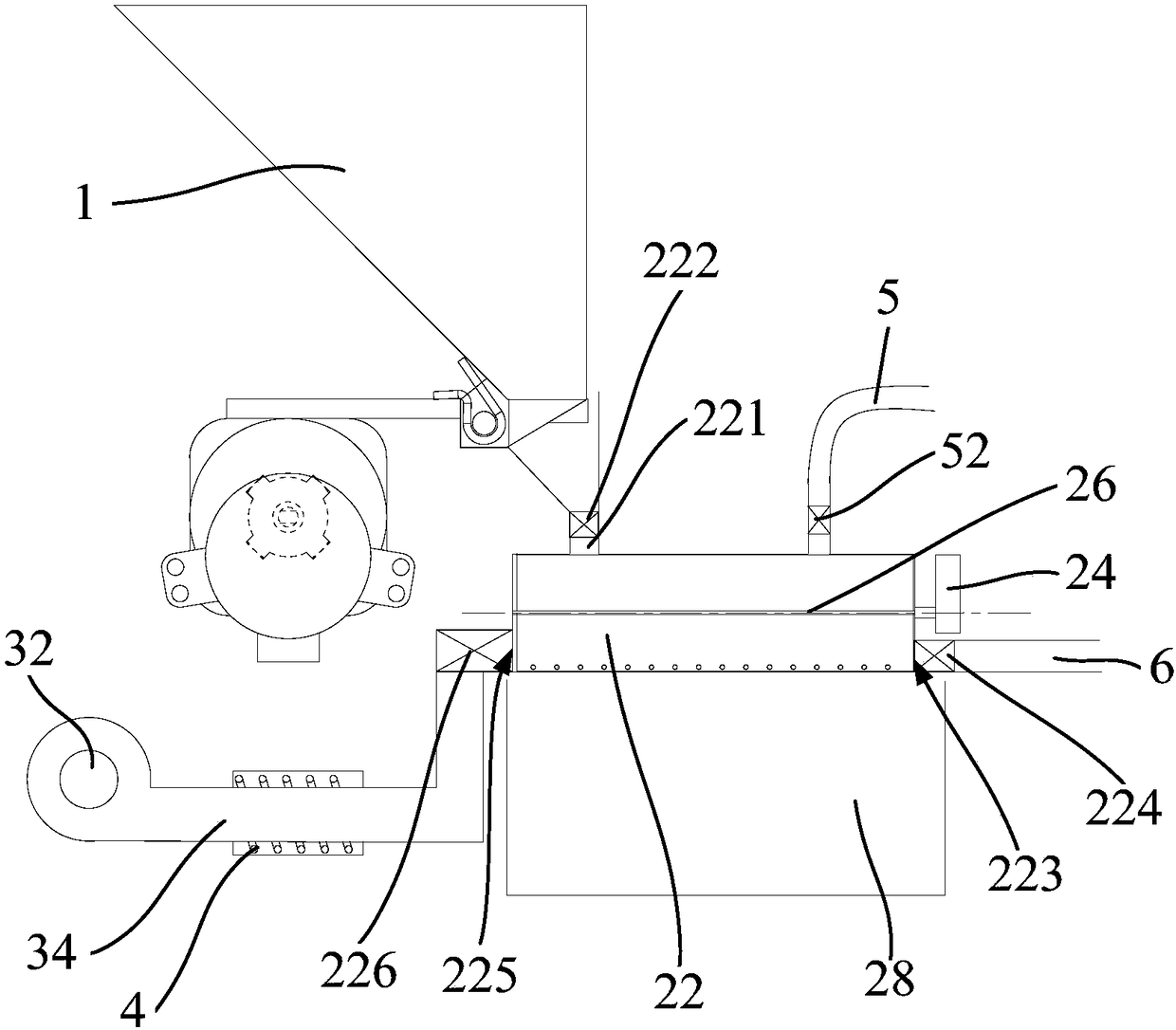

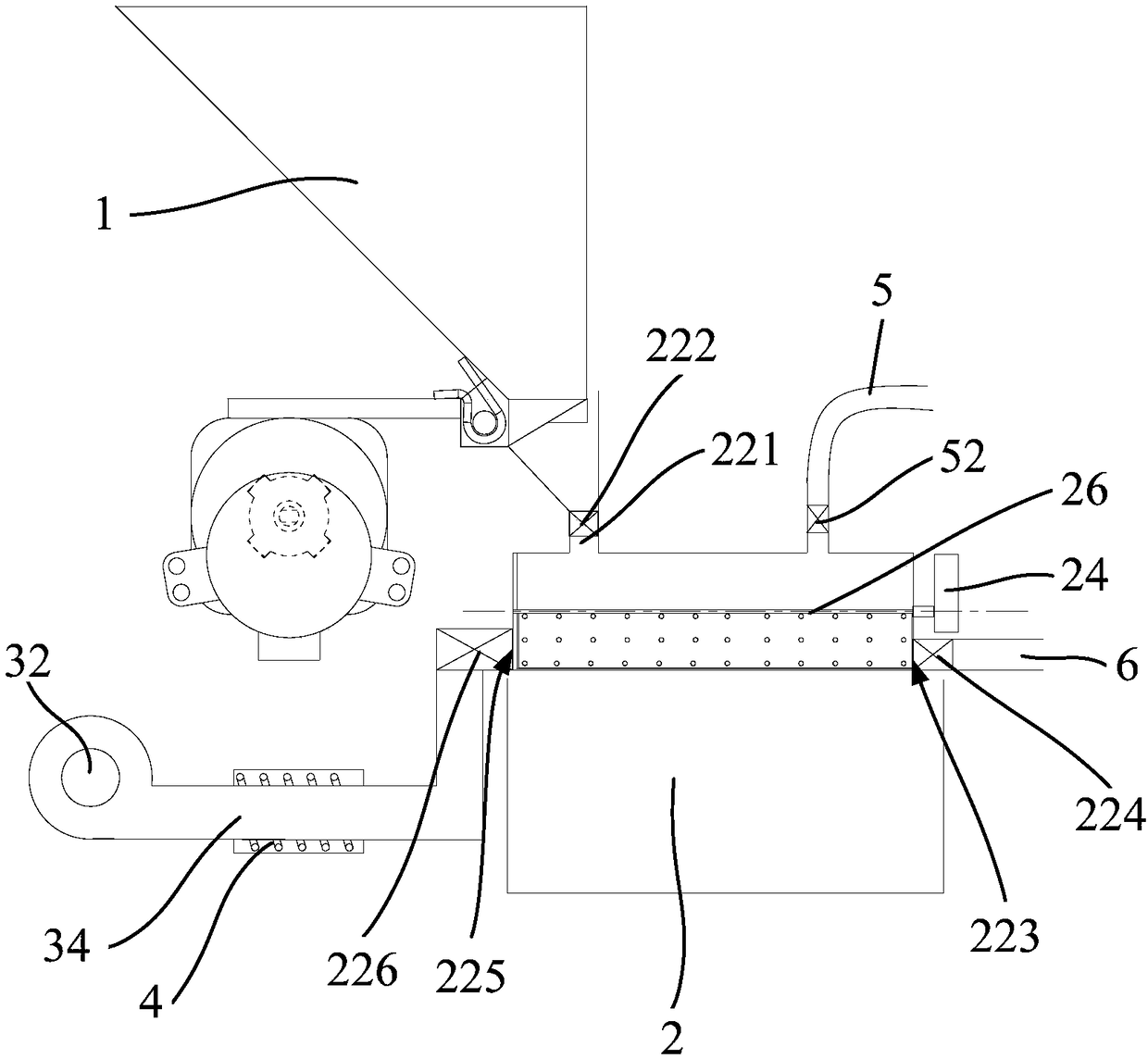

The invention discloses a cooking device. The cooking device comprises a raw material conveying device (21), a food containing device (23), a cooking area (25), a noodle pouring device (27) and a support (28), wherein the raw material conveying device (21) is arranged at an inlet end of the support (28); the food containing device (23) is arranged below the raw material conveying device (21), the cooking area (25) is arranged in the support (28), and the noodle pouring device (27) is arranged at an outlet end of the support (28). The cooking device is simple in structure and reasonable in design and facilitates automatic cooking.

Owner:JIANGSU DESHITIANXIA INTELLIGENT TECH CO LTD

Full-automatic degelatinizing machine and full-automatic degelatinizing method

PendingCN105853229AEasy to operateShorten the boil timePharmaceutical product form changeEngineeringOperability

The invention provides a full-automatic degelatinizing machine. The full-automatic degelatinizing machine comprises a shell, a heating device, a degelatinizing vessel and an upper cover. Meanwhile, the invention also provides a full-automatic degelatinizing method for the full-automatic degelatinizing machine. According to the full-automatic degelatinizing machine and the full-automatic degelatinizing method disclosed by the invention, the degelatinizing time can be shortened, automated boiling is realized, and the operability for degelatinizing operation is improved.

Owner:HIT SMART FACTORY CO LTD

Cooking device and cooking method

ActiveCN111281117AIncrease productivityRealize automatic cookingCooking vessel constructionsProcess engineeringFood material

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Full-automatic cooking processor

Disclosed is a full-automatic cooking processor. The processor comprises a barrel body. An opening in the barrel body faces upwards, a transverse plate is fixedly installed at the position, close to the upper end, inside the barrel body, a spherical through groove is formed in the middle of the transverse plate, a first sphere is cooperatively installed inside the spherical through groove, a firstthrough hole is formed in the top of the first sphere, a vertical tube is fixedly installed inside the first through hole, the upper and lower ends of the vertical tube are both closed, a rotating disc is installed at the bottom inside the barrel body, a transverse rail is fixedly installed at the upper portion of the rotating disc, a sliding block is cooperatively installed in the middle of theupper portion of the transverse rail, first hydraulic rods are symmetrically and fixedly installed at the two ends of the upper portion of the transverse rail, the first hydraulic rods are parallel tothe transverse rail, the inner ends of movable rods of the first hydraulic rods are fixedly connected with the side of the sliding block, and the lower end of the vertical tube is connected with themiddle of the top of the sliding block through a stretchable shaft. The processor is suitable for places such as a dining hall and a wedding party hotel, and the cooking efficiency can be effectivelyimproved through automatic cooking; due to automatic control, it can be ensured that the cooking process does not go wrong, the taste of dishes is ensured, the labor intensity of workers can be lowered, and the human cost can be lowered.

Owner:SICHUAN TOURISM UNIV

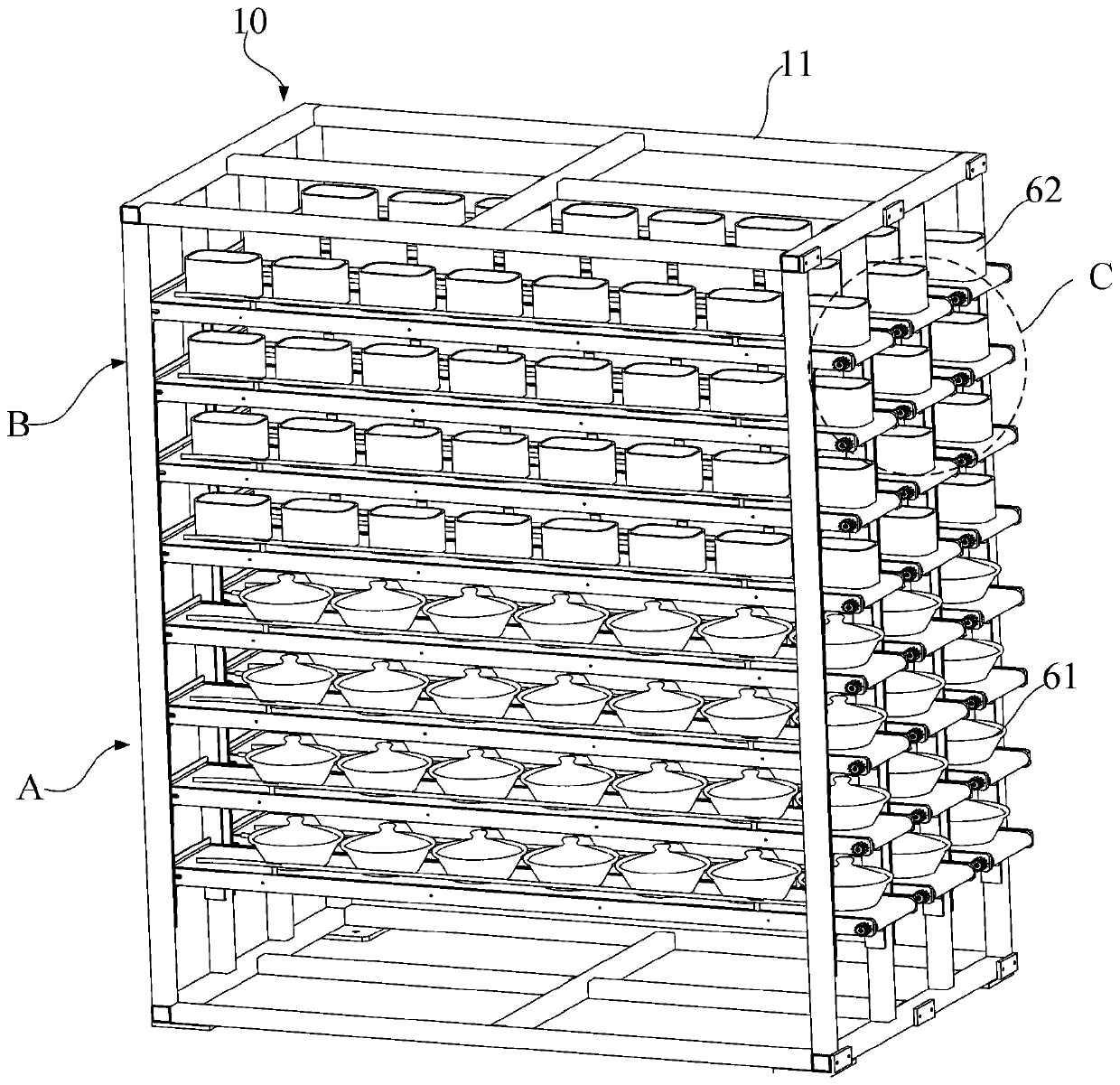

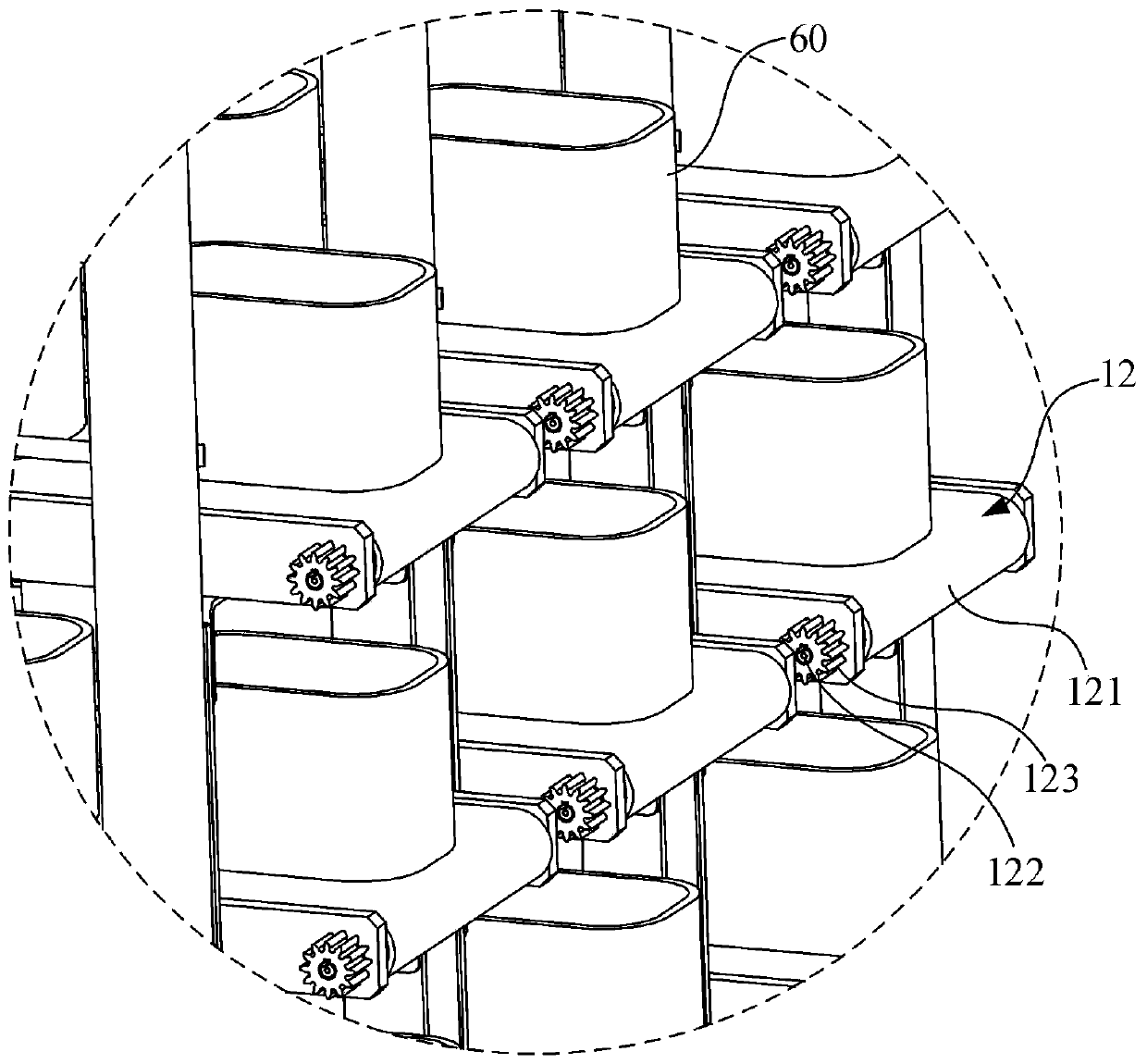

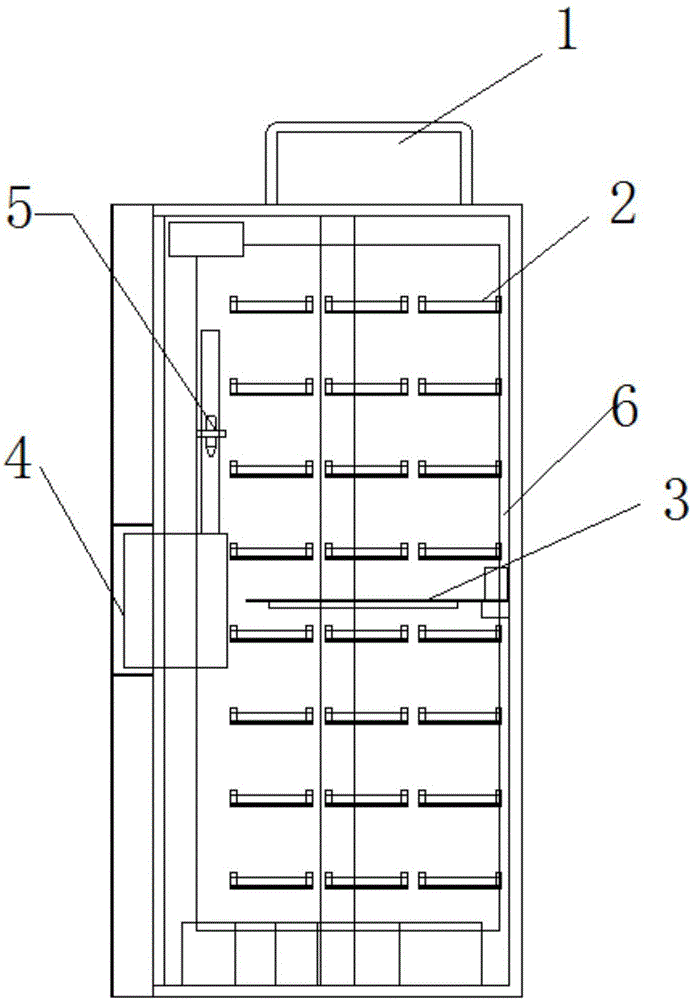

Vending machine capable of cooking noodles

InactiveCN106683284ANovel structureRealize automatic cookingApparatus for meter-controlled dispensingPreserved FoodsControl system

The invention discloses a vending machine capable of cooking noodles. The vending machine comprises a housing, wherein a water-injecting and steam-heating device is arranged at the top of the inner wall of the housing, a crawler-type meal box goods shelf driving device is arranged in the housing, a micro-wave oven corresponding to the crawler-type meal box goods shelf driving device is arranged on the housing, and a goods pushing and positioning device is arranged between the micro-wave oven and the crawler-type meal box goods shelf driving device. A steam module connected with the water-injecting and steam-heating device is arranged at the bottom of the crawler-type meal box goods shelf driving device in the housing. A control system is arranged at the bottom of the housing. The vending machine is novel in structure, achieves automatic noodle cooking, has a vending function. In addition, the vending machine is provided with a refrigeration module, preserves foods in a non-working state and has a wide market application prospect.

Owner:广州云聚鲜智能科技有限公司

Baking working method of electric oven

InactiveCN105011779AAchieve weighingRealize automatic cookingDomestic stoves or rangesLighting and heating apparatusCooking & bakingMotor drive

The invention discloses a baking working method of an electric oven. The baking working method is applied to the electric oven with a motor driving a rotating shaft of a barbecue fork to rotate to bake food. The baking working method comprises the following steps that firstly, the cycle T0 of the barbecue fork with the empty load is measured; secondly, the food is fixed to the barbecue fork, the cycle T1 of the barbecue fork with the load is measured; thirdly, the mass M1 of the food on the barbecue fork is calculated, M1=(T1 / T0)<2*>M0, and M0 is the default mass at the empty load; fourthly, the baking time and / or temperature are / is set according to the mass M1 of the food. The electric oven is provided with a grid rotary tray and an infrared transmitting and receiving device, the cycles of the barbecue fork with the empty load and the load are measured, and therefore the weight of the carried food is worked out. The food is weighed while installation is easy, the baking time and temperature are reasonably set accordingly to better adapt to food with different weights, and the automatic cooking of the food is achieved.

Owner:广东西雅斯智能科技有限公司

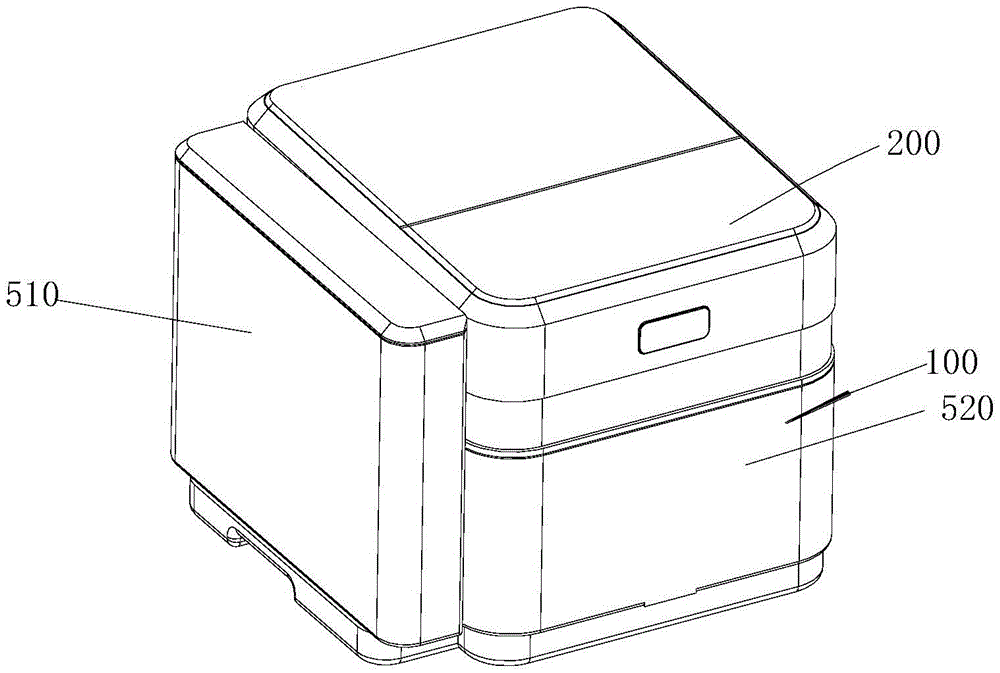

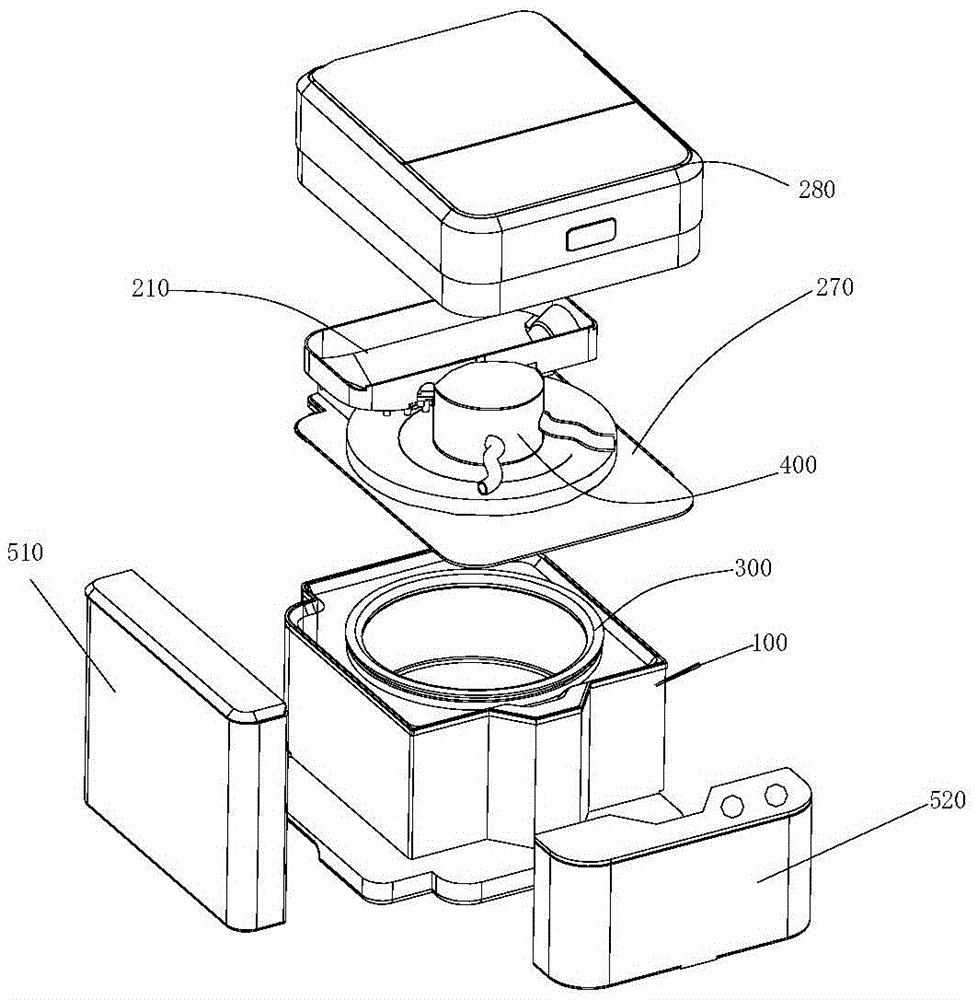

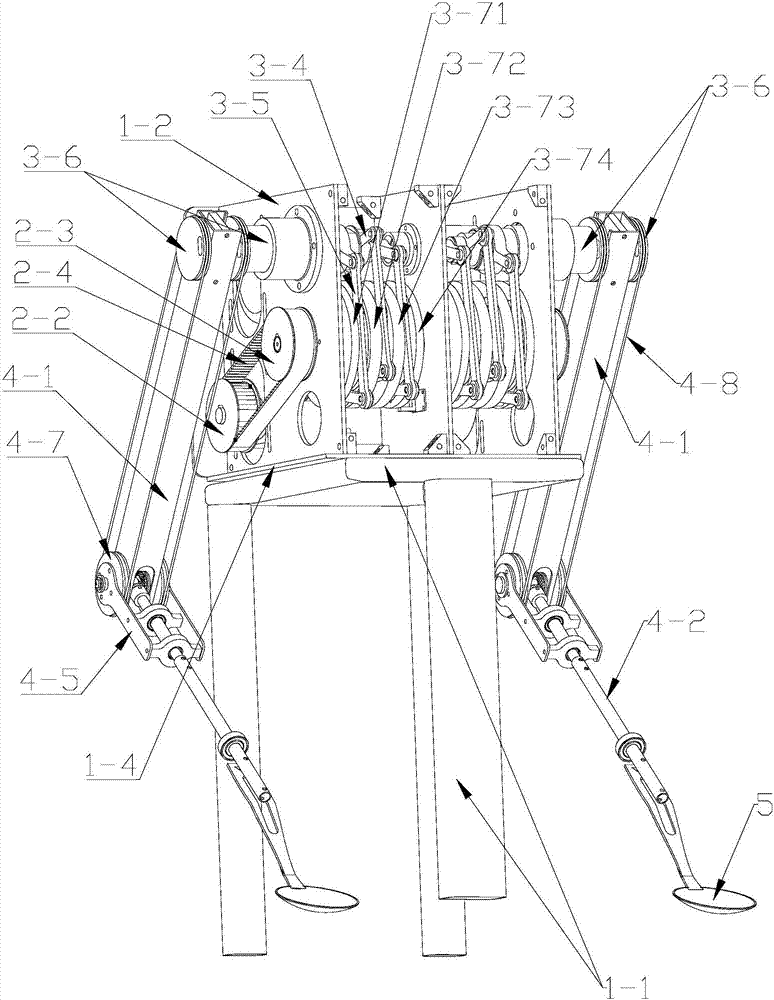

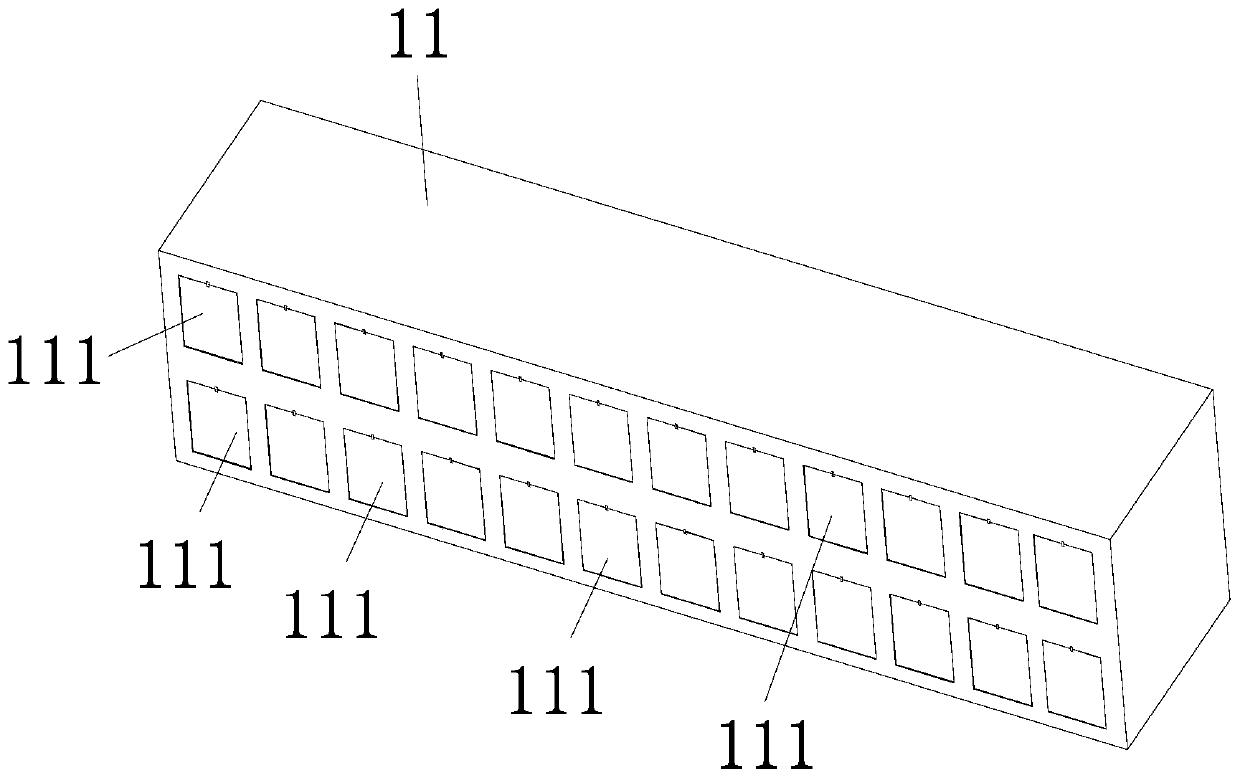

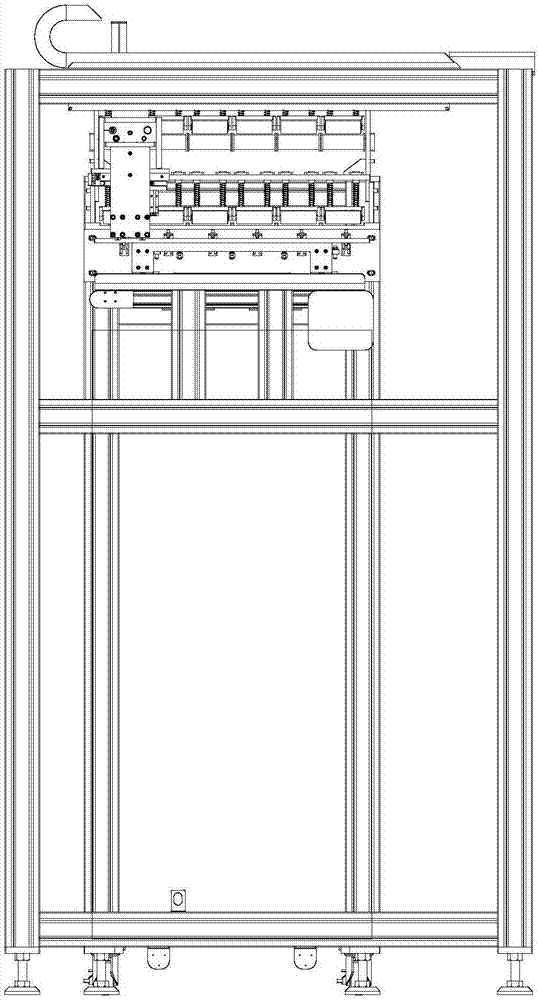

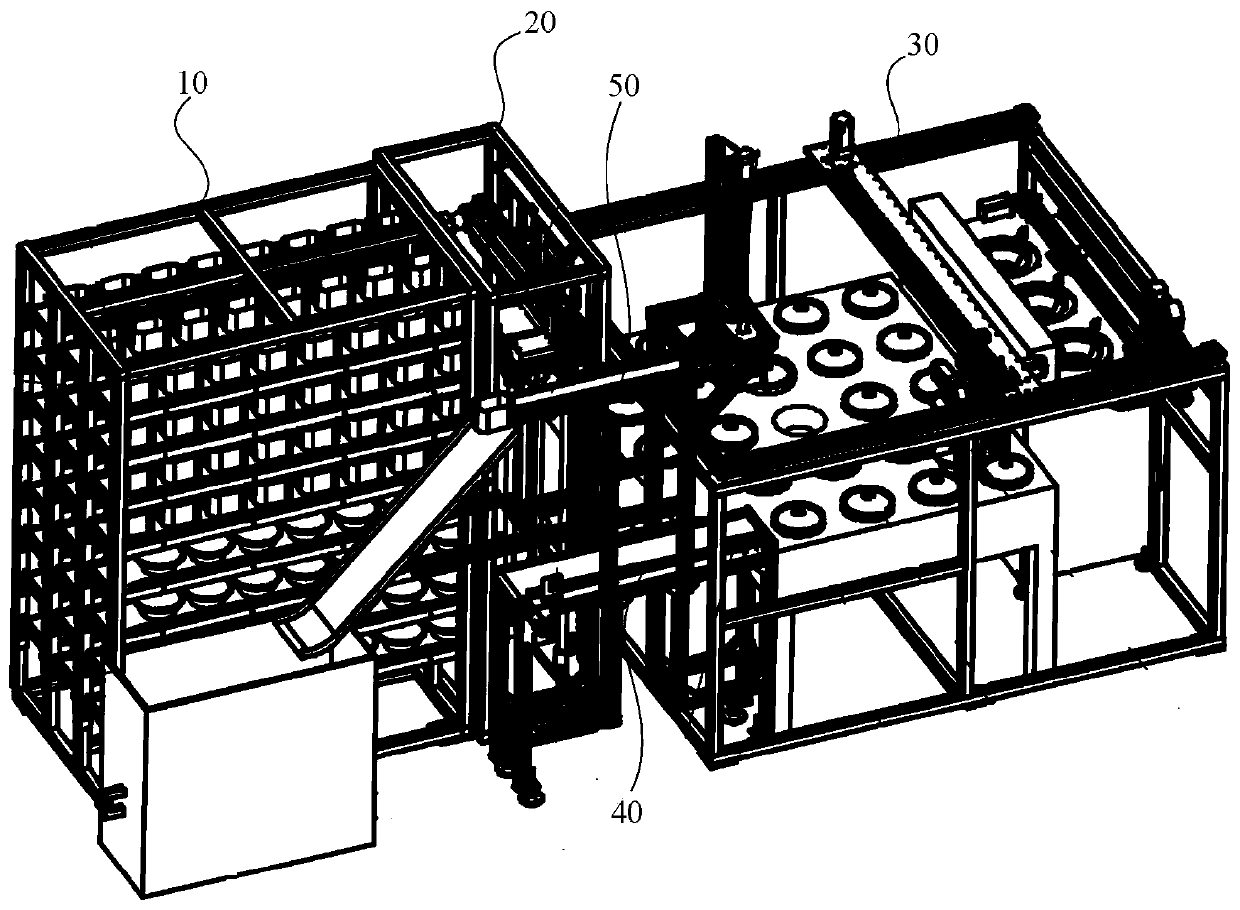

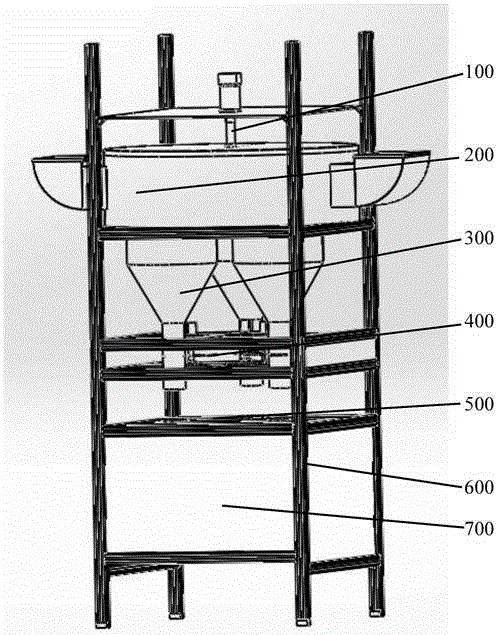

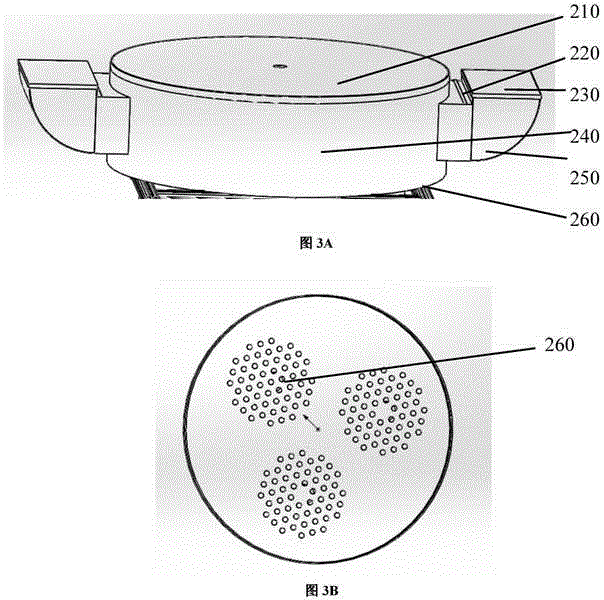

Automatic rice distribution system for student canteens

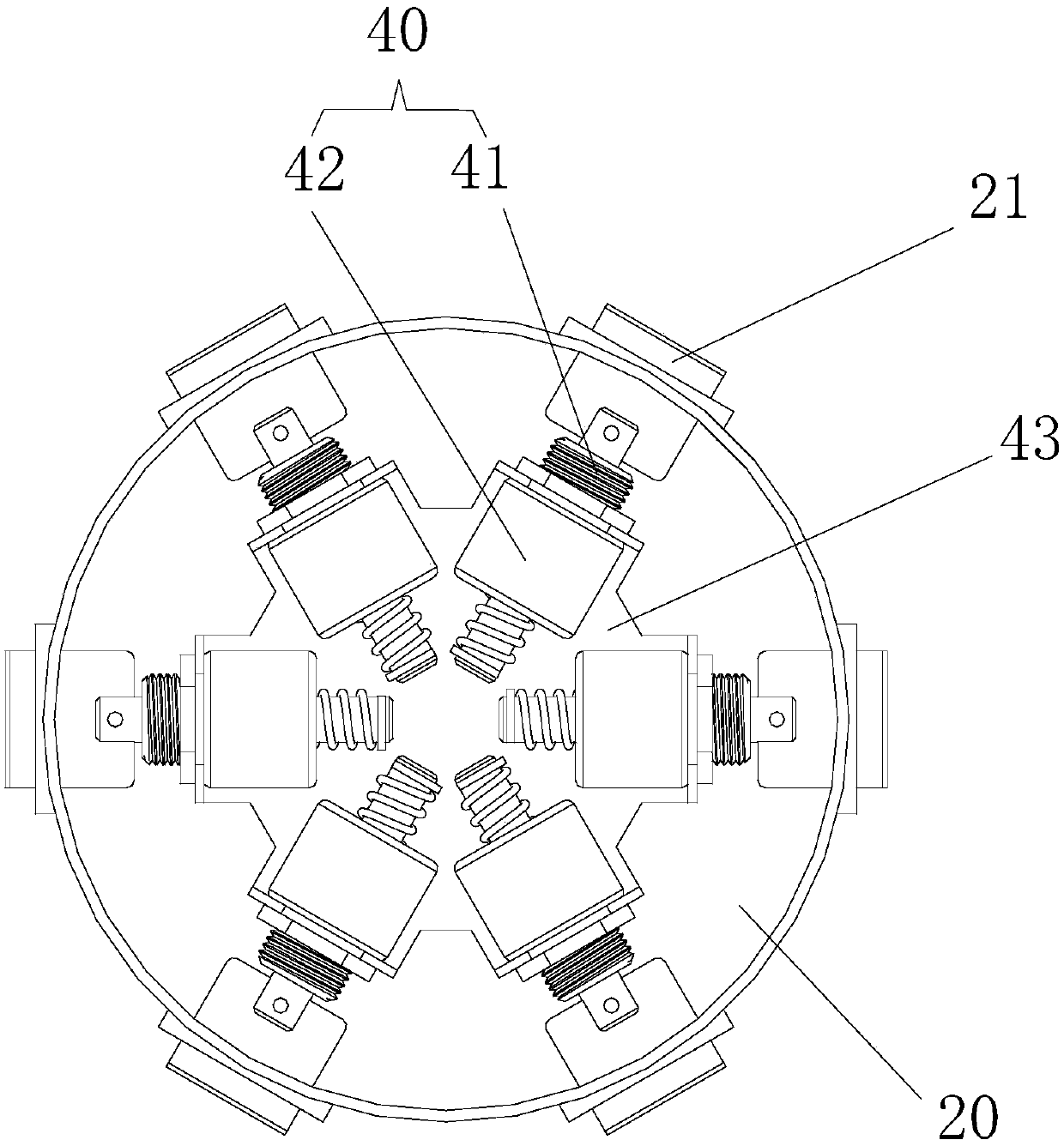

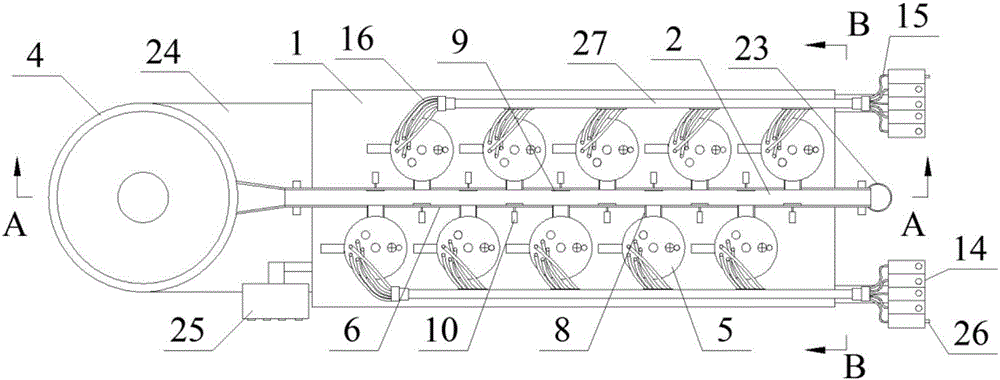

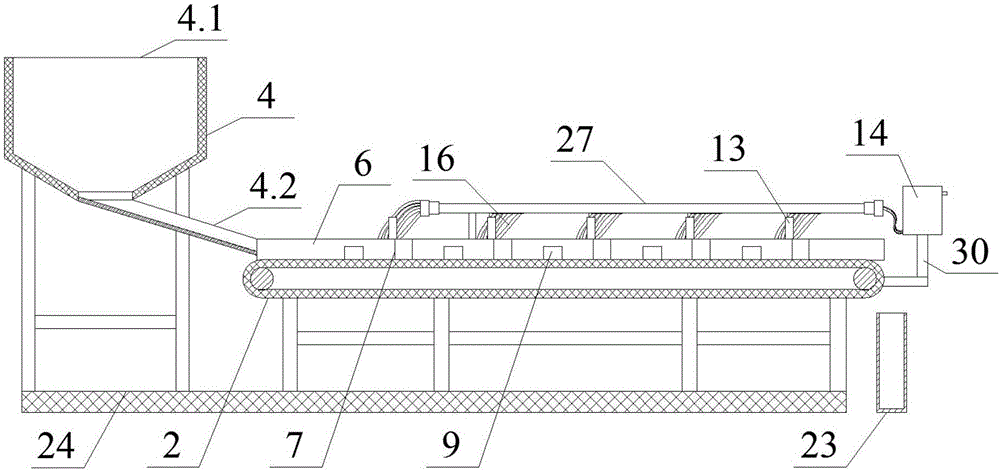

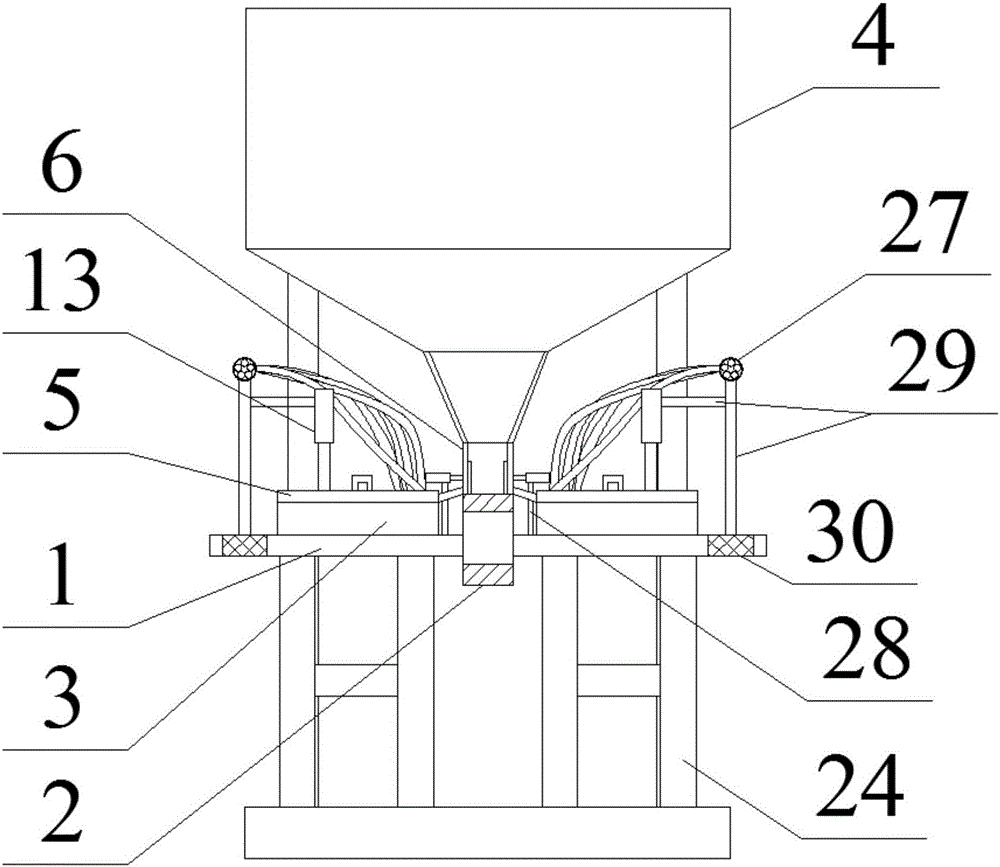

ActiveCN105447971ARealize automatic cookingImprove cooking efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesMicrocontrollerControl system

The invention belongs to the field of food machinery and especially relates to an automatic rice distribution system for student canteens. According to the automatic rice distribution system for student canteens, by measuring the rice weight with a sensor, accurate rice distribution is realized. The system is characterized in that: the inner of an integral frame 600 is provided with a stirring mechanism 100, a rice filling device 200, three sets of rice leakage devices 300, three sets of rice leakage outlet open-close devices 400, three signal detecting modules 500, and a one-chip microcomputer control system 700 , which are arranged from top to bottom; the stirring mechanism 100 is connected to a power supply, the rice leakage outlet open-close devices 400 and the signal detecting modules 500 are electrically connected to the one-chip microcomputer control system 700; the system is provided with the stirring mechanism and the sensor device; the rice filling device is provided with a rice adding funnel and so on. Automatic rice distribution is realized, the rice is kept friable and the taste is not affected. The system has following advantages: the accuracy of rice distribution is not affected by the rice cooking quality, the interference is low, the weight accuracy of each meal is guaranteed, the rice can be added at any time in the rice filling process, and the whole machine is convenient to clean.

Owner:HUAZHONG AGRI UNIV

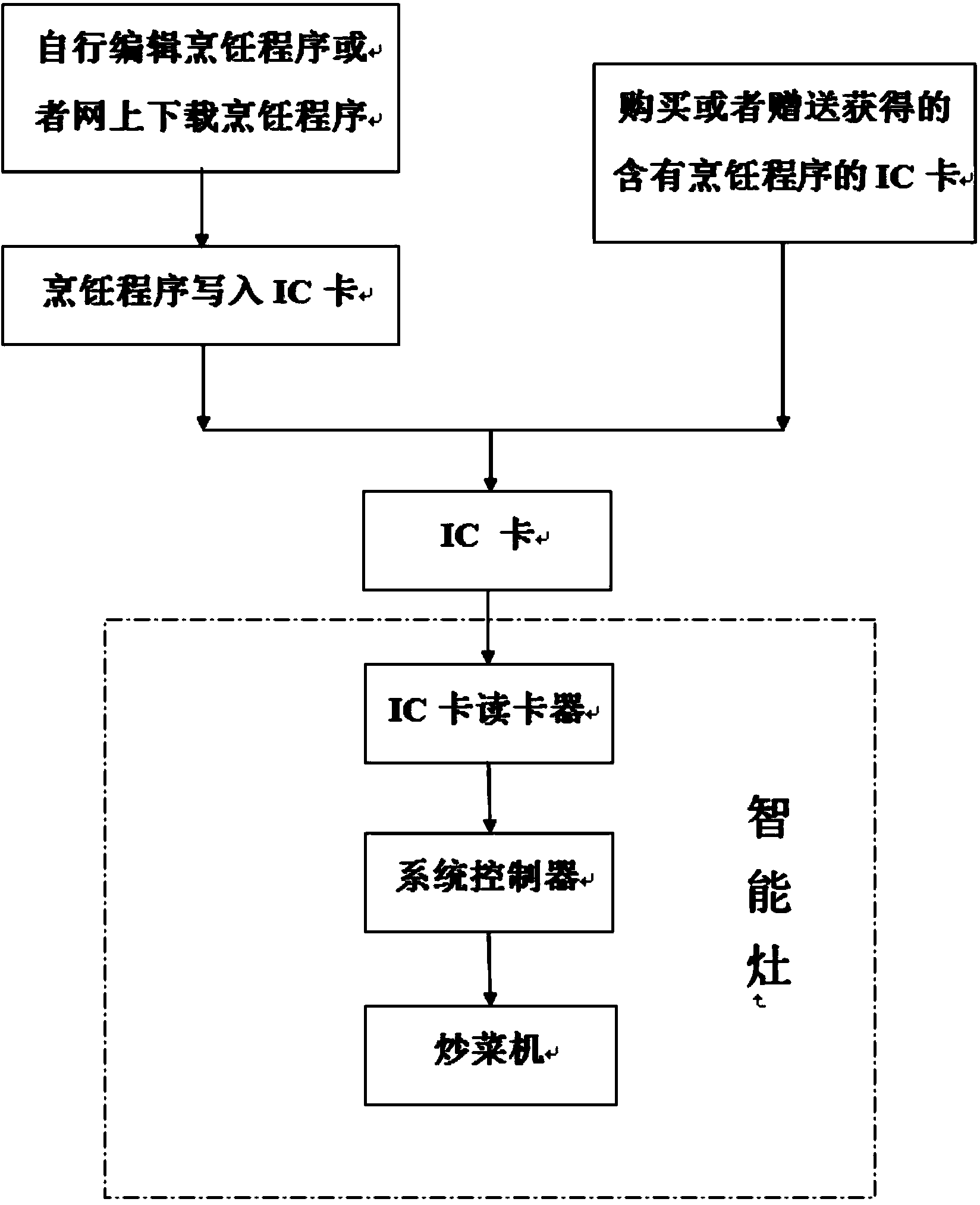

Intelligent cooking stove and IC card entering method of cooking procedures

InactiveCN103900117ARealize automatic cookingImprove convenienceDomestic stoves or rangesLighting and heating apparatusFood qualityProcess engineering

The invention relates to the field of kitchen automation. The invention provides an intelligent cooking stove and an IC card entering method of cooking procedures. No abundant cooking procedures are prestored in the intelligent cooking stove, and proper cooking procedures can be instantly entered according to the real-time cooking demands. The intelligent cooking stove can stimulate artificial work to cook according to the entered cooking procedures and the prepared materials and seasonings to obtain high-quality dishes with favorable color, taste, mouthfeel and the like. The intelligent cooking stove does not need to search for the proper cooking procedure from the system in the automatic cooking process, thereby saving the complex step of regulation and setting; the intelligent cooking stove can start automatic cooking as long as selecting the proper IC card to perform simple cooking procedure entering; the intelligent cooking stove can control the heating temperature, cooking time and material addition sequence and time points in a stimulated artificial cooking mode; and compared with the existing automatic cooking stove, the intelligent cooking stove provided by the invention can obtain dishes with higher food quality than the existing automatic cooking stove.

Owner:SUZHOU WESTON HOME AUTOMATION

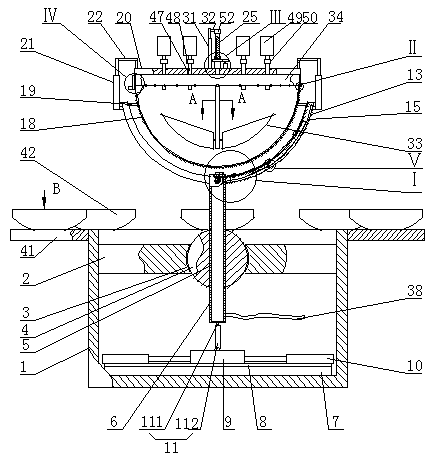

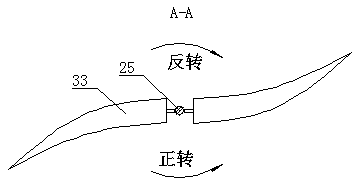

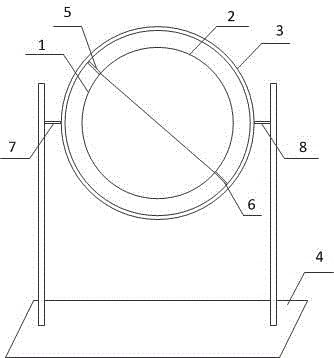

Spherical frying pan

ActiveCN105816006AAvoid affecting the flip effectFlip freelyCooking vessel supportEngineeringFood material

The invention discloses a spherical frying pan. The spherical frying pan comprises a pan body and a bracket, wherein the pan body comprises two semi-spherical shells; the two semi-spherical shells are enclosed to form a spherical shell; at least one semi-spherical shell comprises an electromagnetic heating unit; the bracket comprises support rings and a base; both sides of one semispherical shell are connected with the support rings through two revolving shafts; the support rings are connected to two support rods of the base through the revolving shafts; the circle centers of the support rings are coincided with the sphere center of the spherical shell; a connection line of the symmetrical revolving shafts passes through the sphere centers of the spherical shell. During use of the spherical frying pan, food materials and seasonings are put into the pan body firstly, and then the semi-spherical shells are enclosed to form the enclosed spherical shell. Foods in the pan body are heated through the electromagnetic heating unit. Through two pairs of revolving shafts and support rings, the pan body can be overturned to any angle, and a stir-frying effect can be achieved without any turner. The pan body is enclosed fully, so that internal oil smoke is prevented leaking, and air pollution is reduced. The spherical frying pan is suitable for the field of food cooking.

Owner:ZHEJIANG JIANLIN ELECTRONICS

Cooking system

InactiveCN109573445ARealize automatic cookingImprove work efficiencyConveyorsCooking vesselsFood storageProcess engineering

The invention discloses a cooking system. The cooking system comprises a freezer, a taking-out mechanism, cooking mechanisms and discharging mechanisms. A storage space is defined in the freezer; refrigeration equipment is arranged inside the freezer; a plurality of storage units are arranged inside the storage space; the cooking mechanisms are used for automatically cooking food; the multiple cooking mechanisms are arranged in a spaced mode in the length direction of the freezer; the discharging mechanisms are used for discharging materials to the cooking mechanisms; and the taking-out mechanism is used for sending the storage units which are taken out to the discharging mechanisms. Through cooperation of the freezer, the taking-out mechanism, the cooking mechanisms and the discharging mechanisms, the functions of low-temperature food storage, mechanical food grabbing and discharging in the cooking mechanisms are integrated on the cooking system, the function of automatic cooking of the cooking system is achieved, and accordingly a large amount of labor is saved and the working efficiency of the cooking system is improved. Meanwhile, the food are stored in the freezer and are keptfresh, and the food eating safety is ensured.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Cooking equipment and control method of cooking equipment

ActiveCN108209644ARealize automatic cookingAvoid tightnessClimate change adaptationVessels with intergral heatingFood materialProcess engineering

The invention provides cooking equipment and a control method of the cooking equipment. The cooking equipment comprises a cleaning device, a discharging device, a drying device, a conveying device, acooking body and a power supply device, wherein the cleaning device is used for cleaning food materials and comprises a cleaning cylinder, and a feed inlet, a discharging opening and a drainage hole used for drainage are formed in the wall of the cleaning cylinder; the discharging device is connected with the feed inlet and used for conveying food materials into the cleaning cylinder; the drying device is connected with the cleaning cylinder and used for drying the cleaned food materials; the conveying device is connected with the cleaning cylinder and used for conveying the dried food materials to the cooking body through the discharging opening; the cooking body is connected with the conveying device and used for cooking the food materials; the power supply device is used for supplying power to the cooking equipment. According to the technical scheme, a series of operations including feeding, discharging, cleaning, conveying, cooking and the like of the food materials like rice can be automatically achieved so that the food materials such as rice can be automatically cooked from discharging to cooking; meanwhile, due to the arrangement, the food materials such as rice are cleaned, dried and then separately conveyed to the cooking body so that the reliability of products can be ensured.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com