Heating equipment, cooking device and cooking method of heating equipment

A technology of heating equipment and cooking methods, which is applied in the direction of lighting and heating equipment, electric heating fuel, gaseous heating fuel, etc., can solve problems such as occupying user time, unfavorable user control, and affecting user experience, so as to improve user experience and save Effect of cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

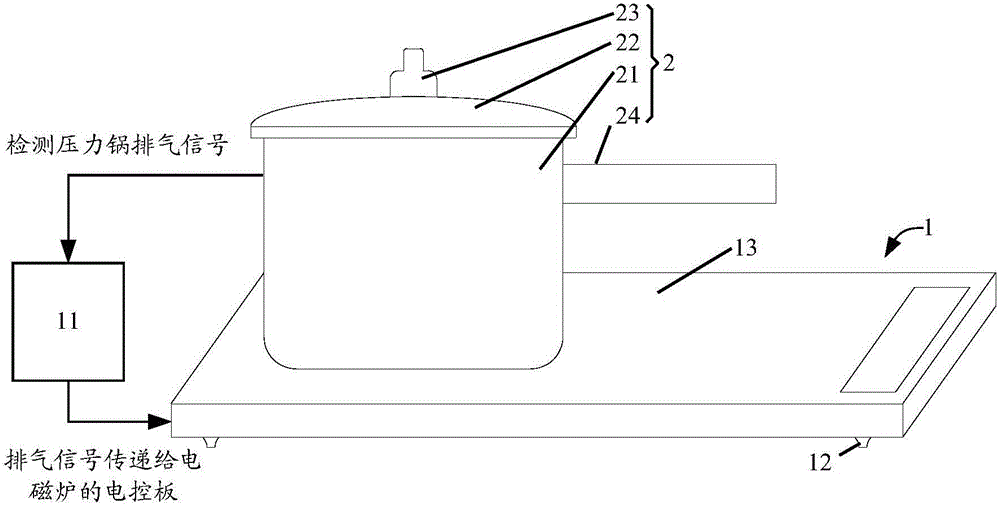

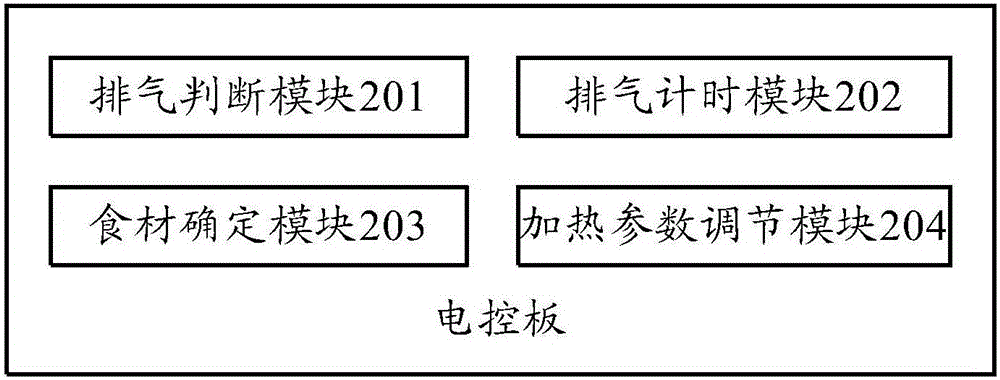

[0079] like image 3 As shown, the exhaust detection assembly 11 is a sound sensor 111, and the sound sensor 111 detects whether the ordinary pressure cooker 2 is exhausted (such as collecting sound by a microphone) by sensing the sound signal in the ordinary pressure cooker 2 exhaust process, specifically, the sound sensor 111 The detected sound signal is transmitted to the electric control board of the induction cooker 1, and the electric control board controls the firepower of the induction cooker 1. Among them, the internal structure of the electric control board is as follows: Figure 4 As shown, it includes: a primary amplification module 41 , a filtering module 42 , a secondary amplification module 43 , a detection module 44 , an AD sampling module 45 , a microprocessor 46 and a heating control module 47 . in, Figure 4 The microphone 40 shown in is a specific implementation of the sound sensor 111 in the present invention. Specifically, the working principle of the ...

Embodiment 2

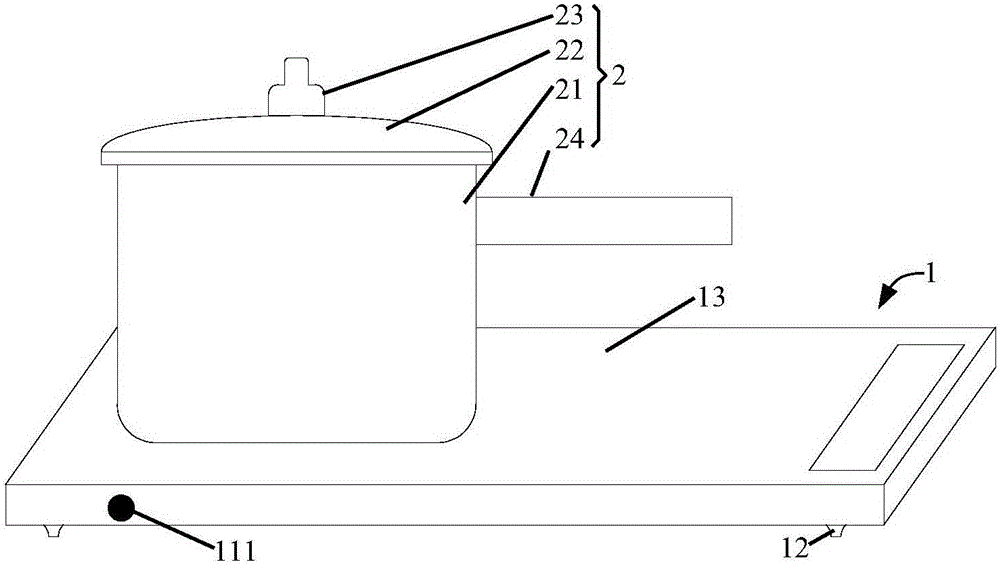

[0090] like Figure 5 As shown, the exhaust detection assembly 11 is a sound sensor 111 and a temperature sensor 112. The sound sensor 111 and the temperature sensor 112 detect the exhaust by sensing the sound (such as collecting sound by a microphone) and temperature changes in the exhaust process of the common pressure cooker 2, And the exhaust signal is transmitted to the electric control board of the induction cooker 1, and the electric control board controls the firepower of the induction cooker 1. in, Figure 5 14 shown in is the induction cooker base.

[0091] Wherein, temperature sensor 112 can be installed on the body of common pressure cooker 2, or be installed in the middle part of the coil plate of induction cooker 1 and be close to the surface of panel 13 (ie Figure 5 In addition, the infrared temperature sensor can also be used to detect the temperature signal around the exhaust valve, and the infrared temperature sensor can be installed in the bottom cover 14...

Embodiment 3

[0107] Such as Figure 7 As shown, the exhaust detection assembly 11 is a sound sensor 111 and a vibration sensor 113. The sound sensor 111 and the vibration sensor 113 detect the exhaust by sensing the sound (such as collecting sound by a microphone) and vibration changes in the common pressure cooker 2 exhaust process. And the exhaust signal is transmitted to the electric control board of the induction cooker 1, and the electric control board controls the firepower of the induction cooker 1. in, Figure 7 14 shown in is the induction cooker bottom cover.

[0108] In this embodiment, the internal structure of the electric control board is as Figure 8 As shown, it includes: an amplification module 82 , a trigger module 83 , a primary amplification module 85 , a filter module 86 , a secondary amplification module 87 , an AD sampling module 88 , a microprocessor 89 , and a heating control module 80 . in, Figure 8 The vibration detection module 81 shown is the vibration sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com