Patents

Literature

309results about How to "Strong automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

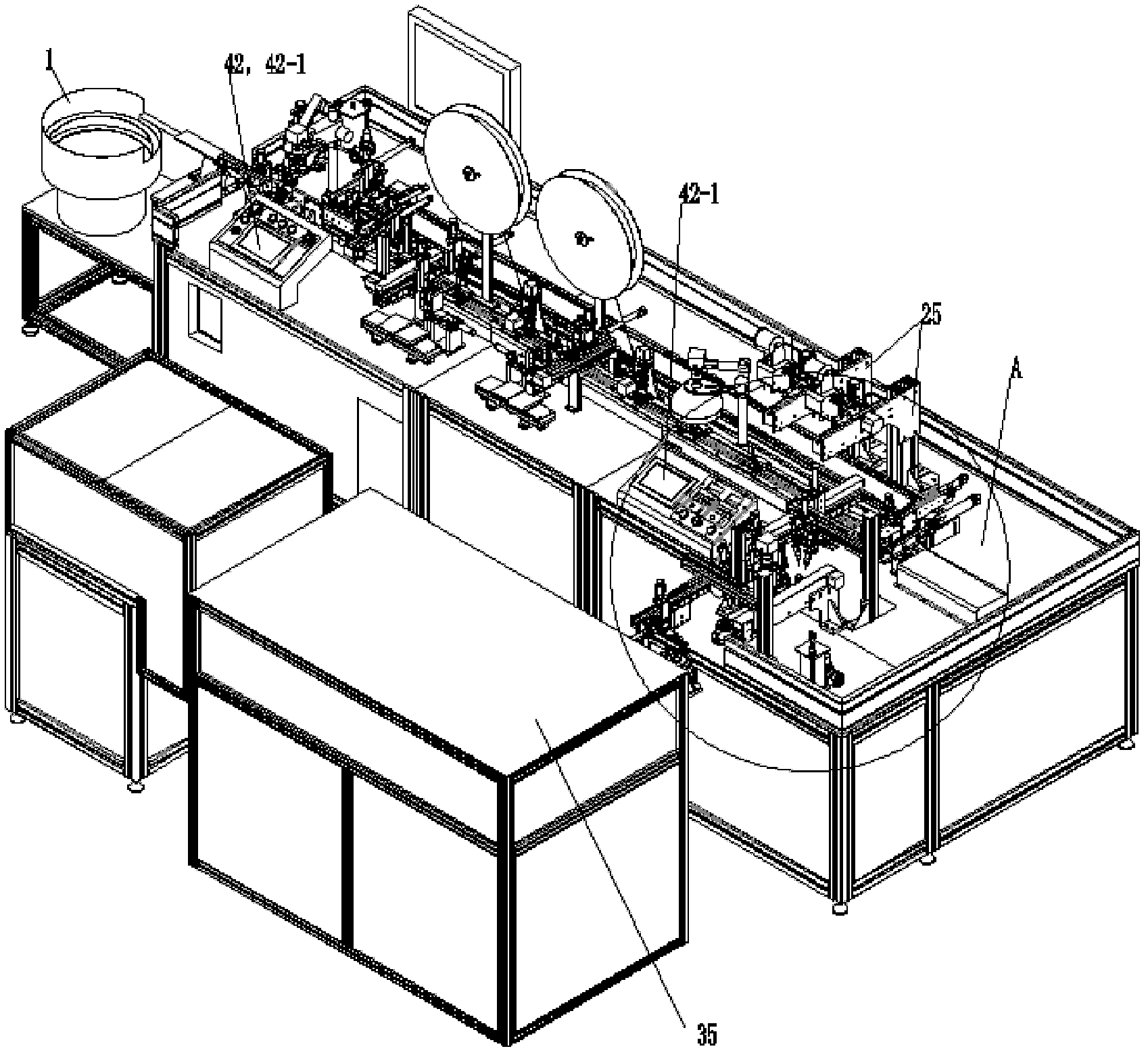

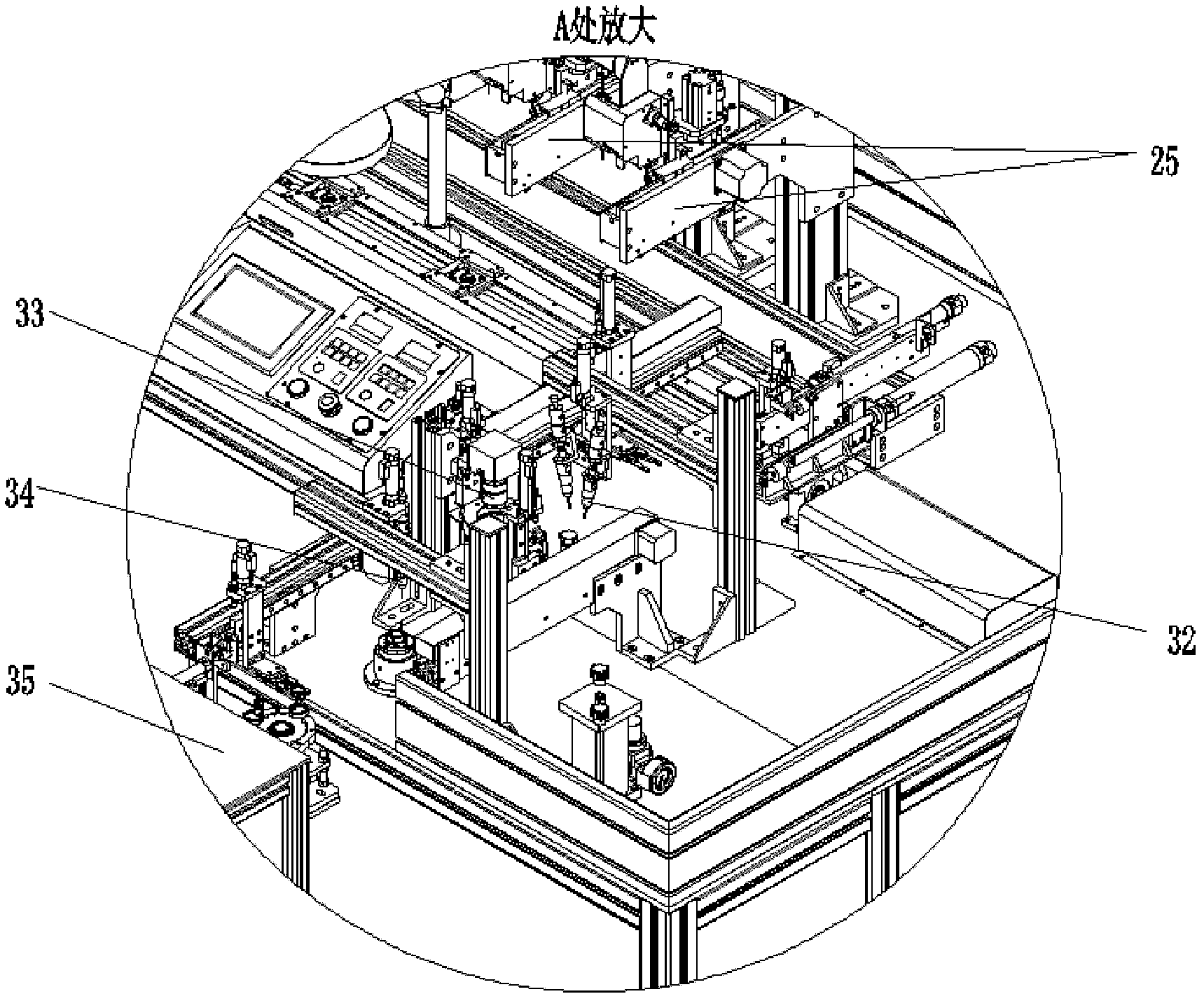

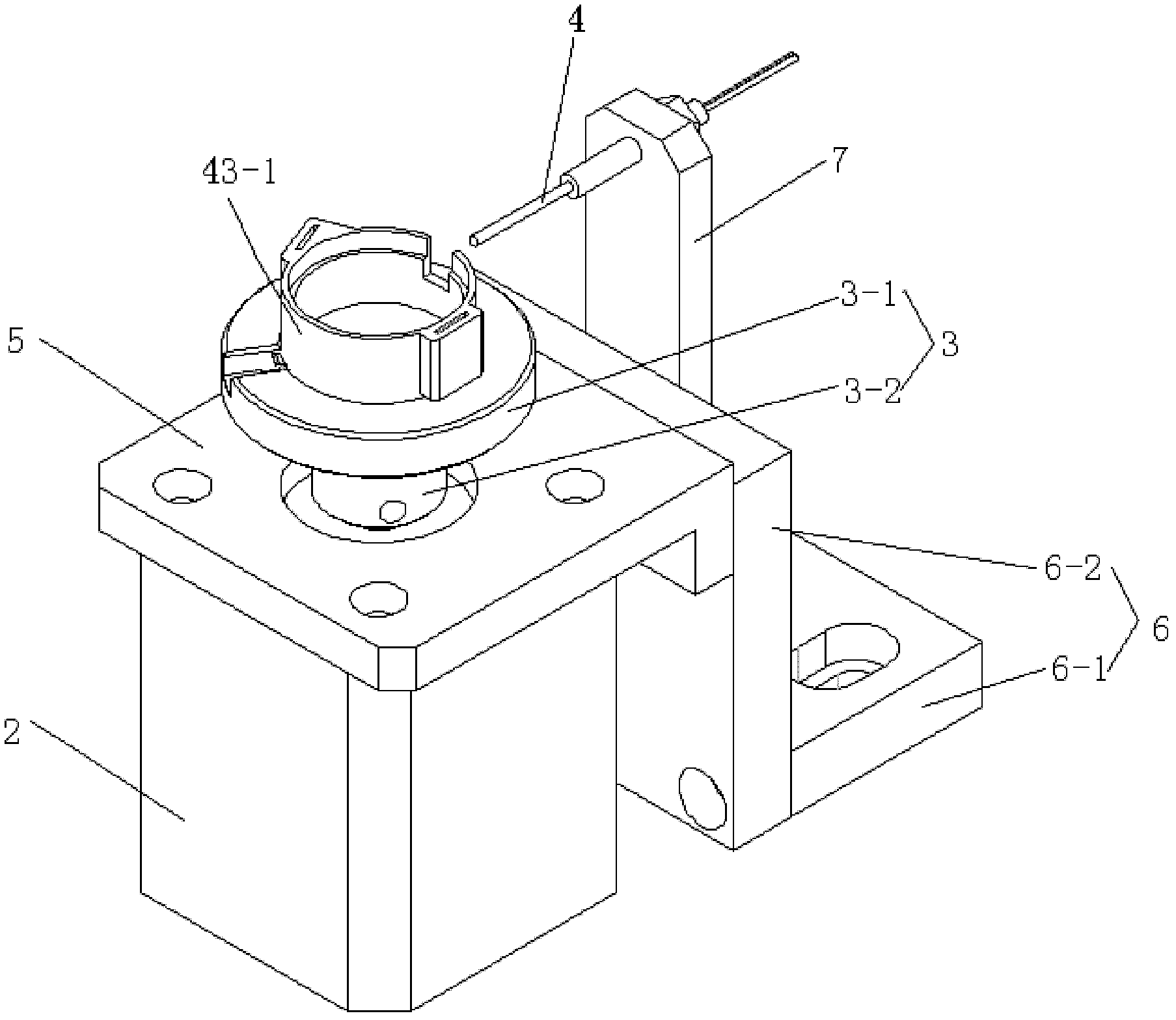

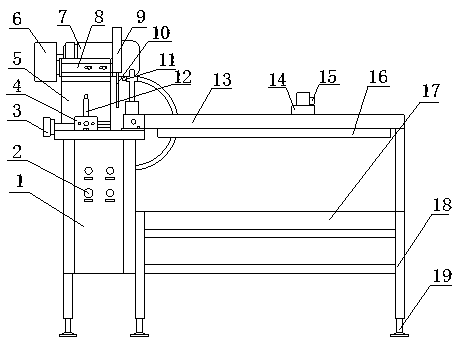

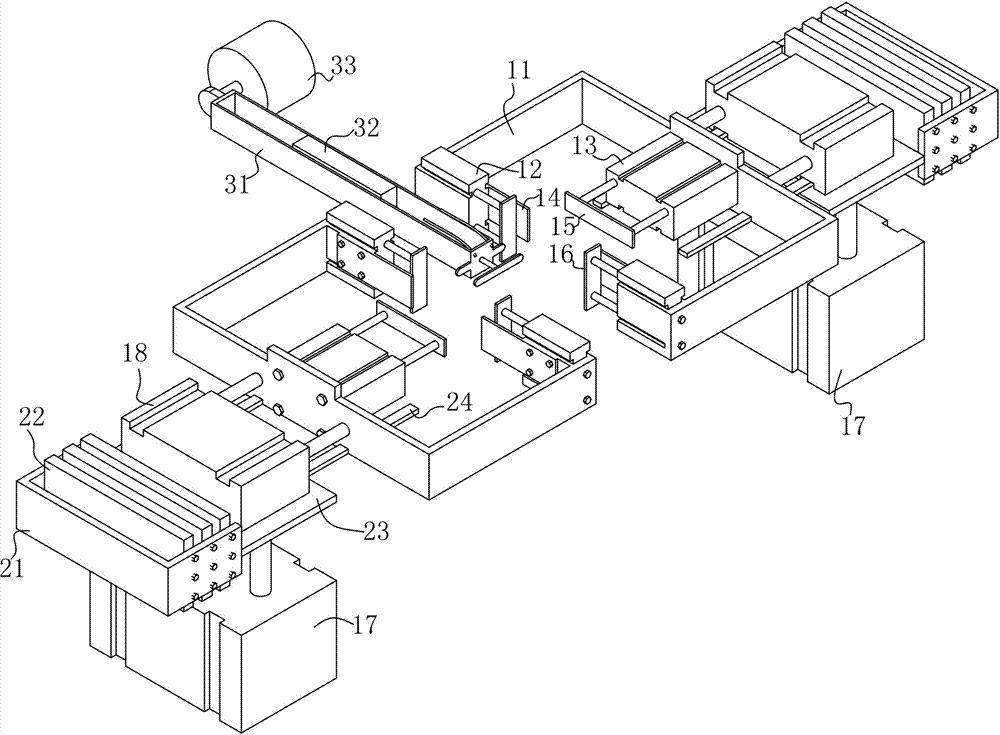

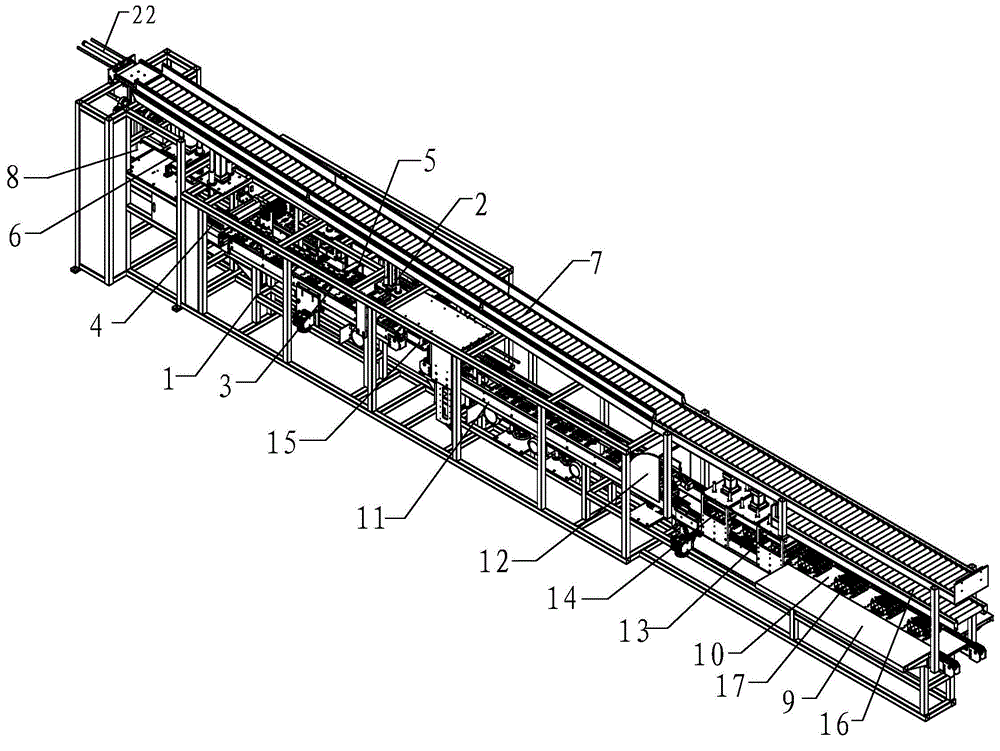

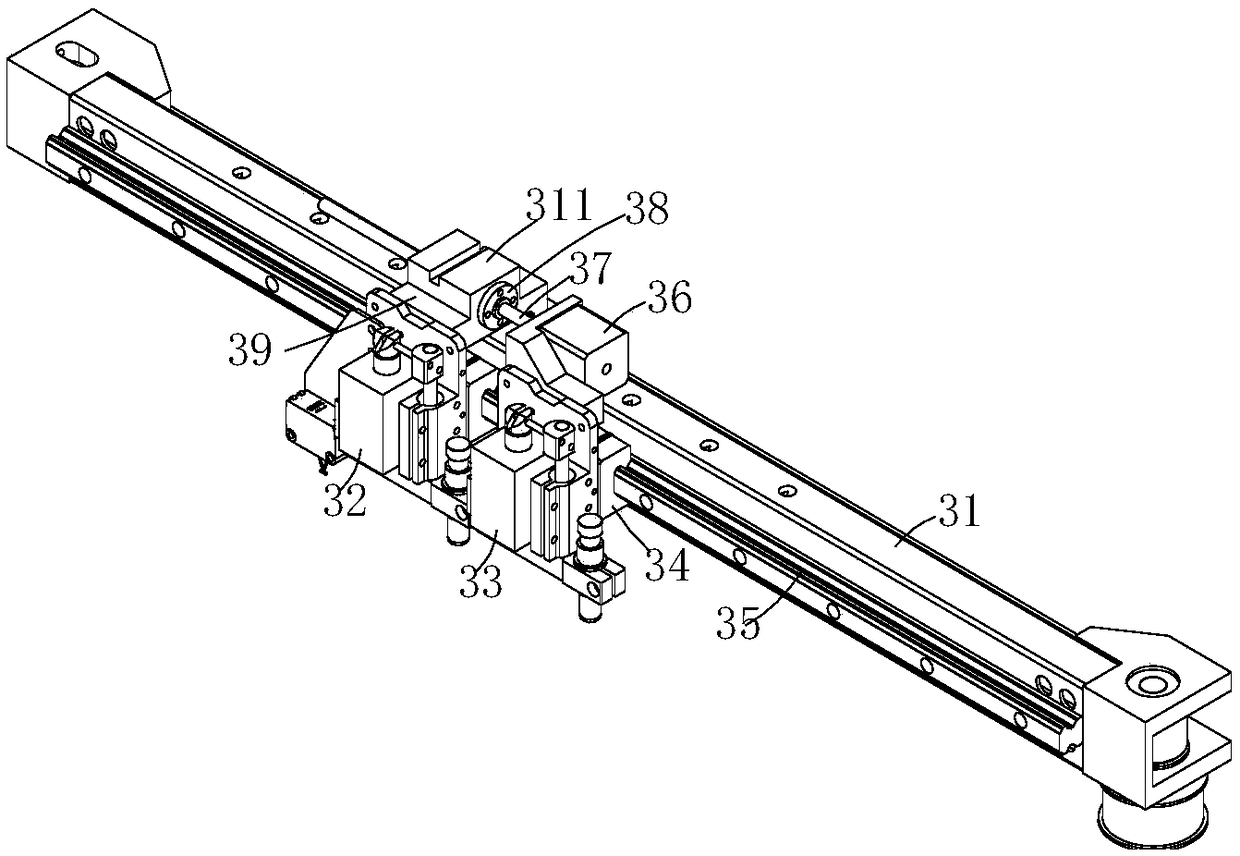

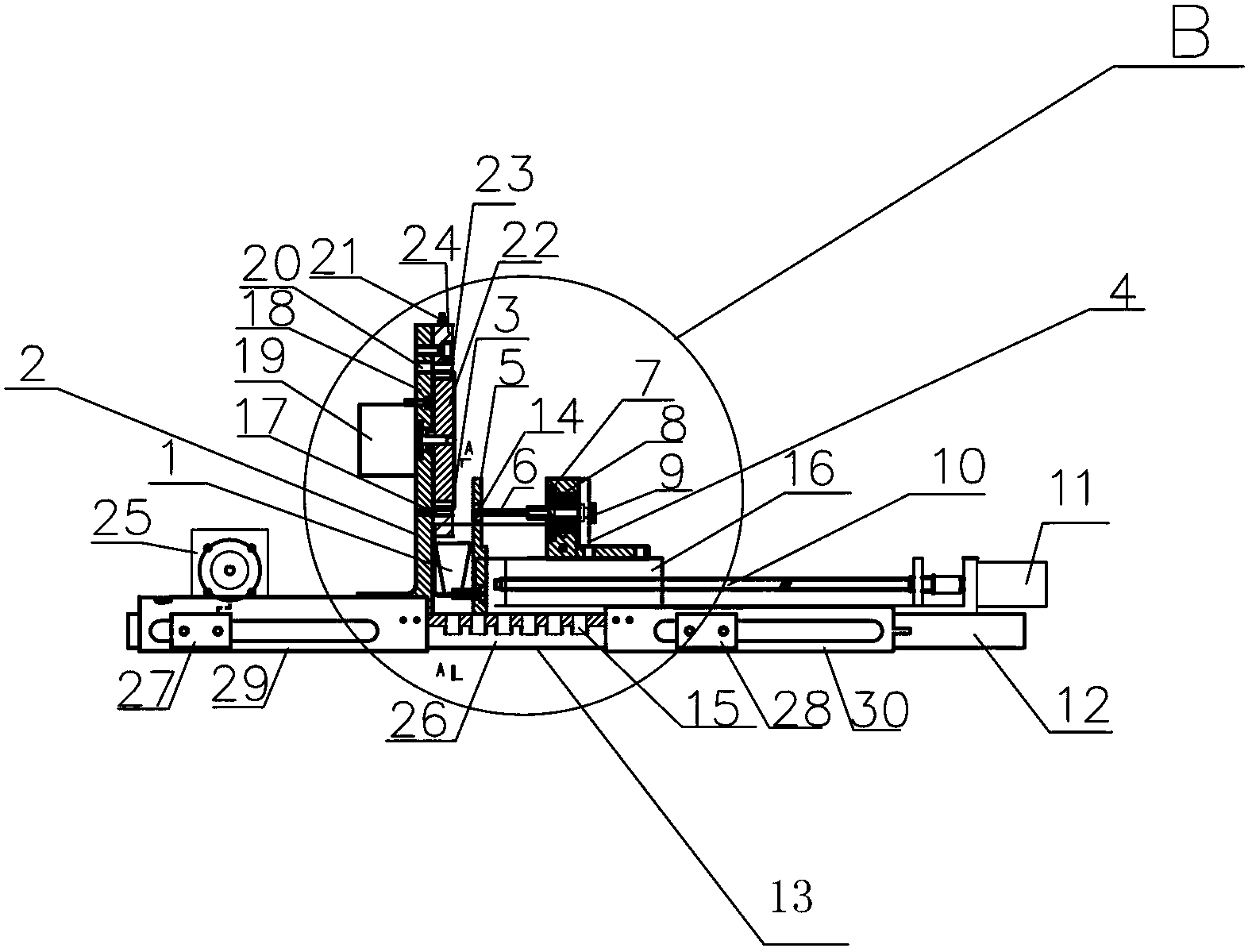

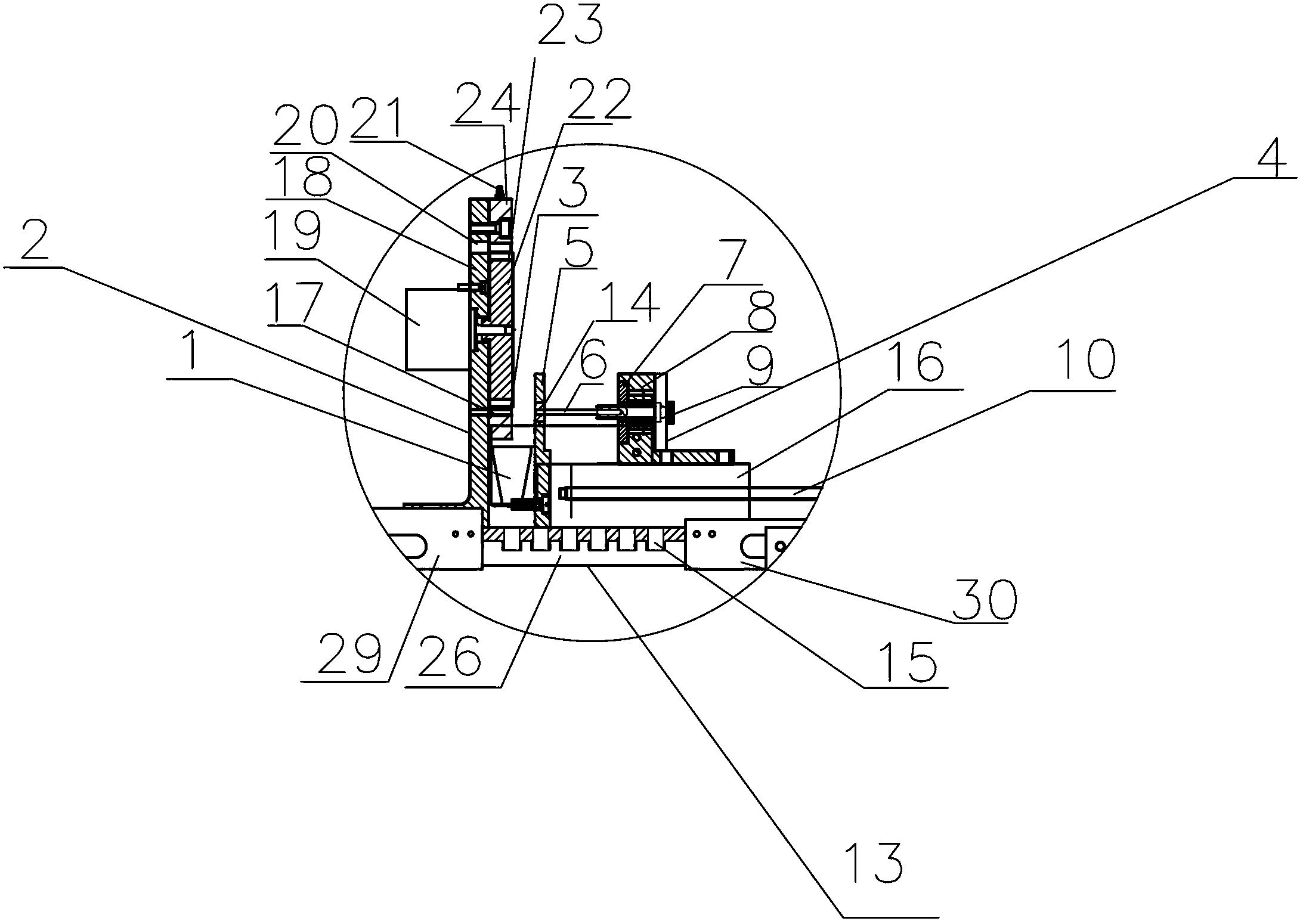

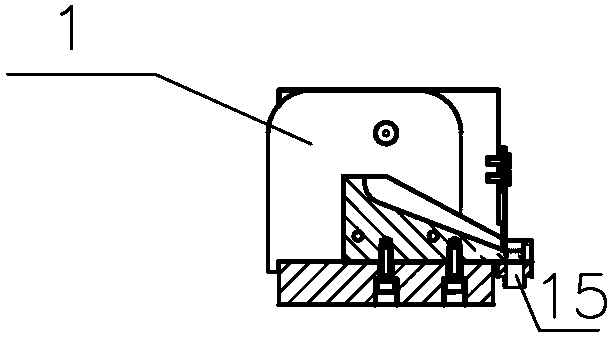

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

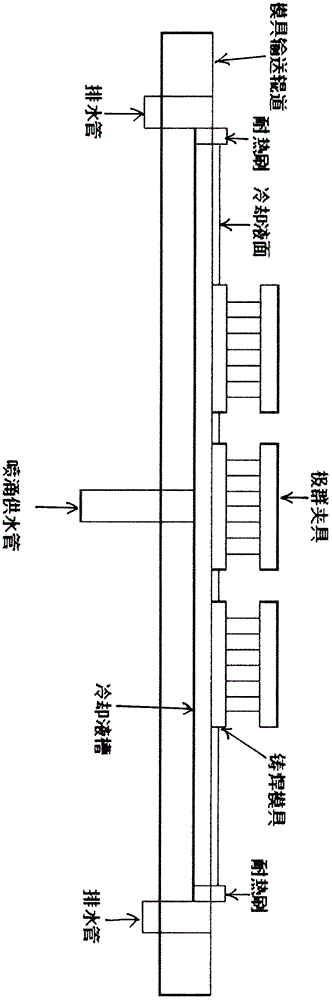

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

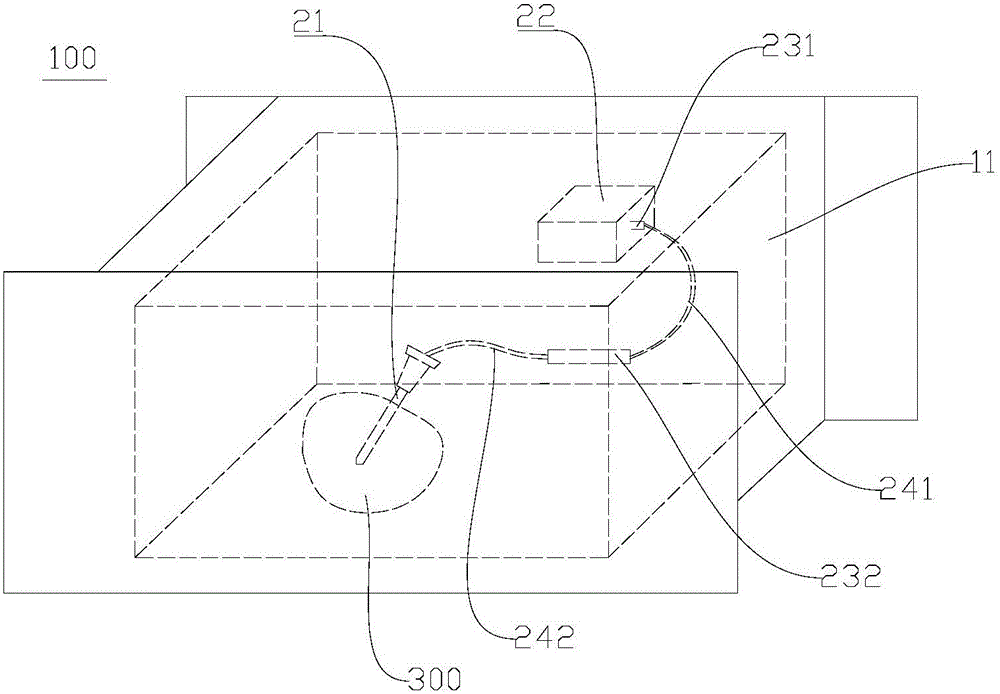

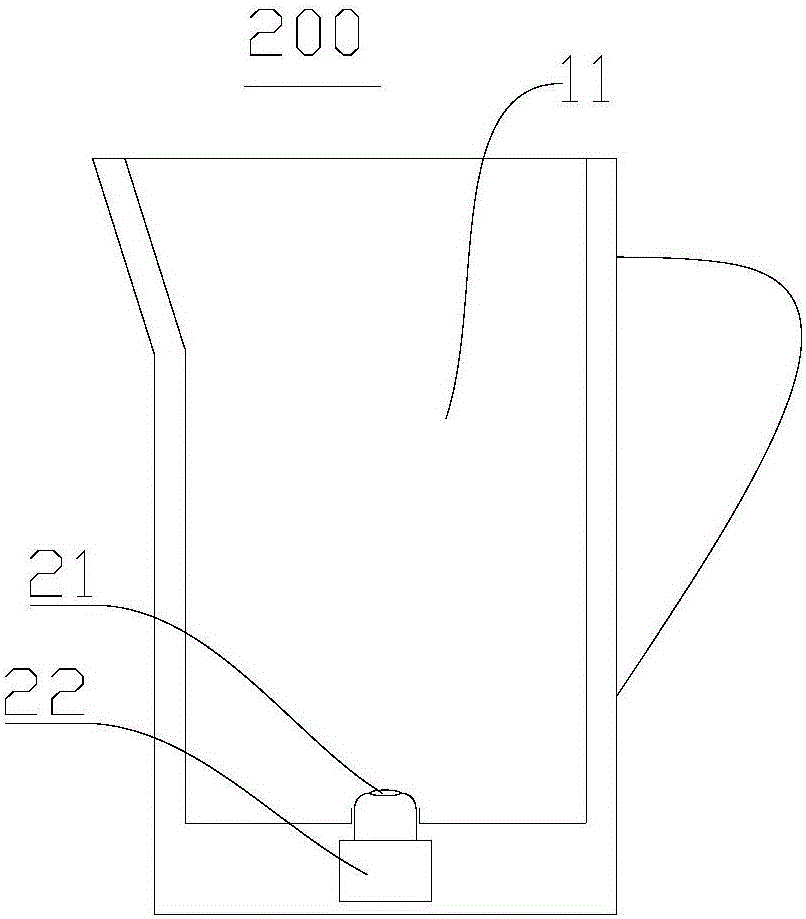

Cooking method and cookware

ActiveCN105708306AGood cooking effectRealize automatic cookingCooking vesselsRelevant informationEngineering

The invention discloses a cooking method and cookware. The cooking method comprises the following steps: irradiating food to be cooked with preset light rays to make the food to be cooked reflect emergent light rays, and detecting spectrum information of the emergent light rays; setting a corresponding cooking procedure and / or adjusting a set cooking procedure according to the spectrum information. According to the cooking method disclosed by the invention, relevant information of the food to be cooked can be analyzed by a spectrum detection method, and the food to be cooked can be cooked in a targeted manner according to an analysis result, so that an optimal cooking effect can be achieved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

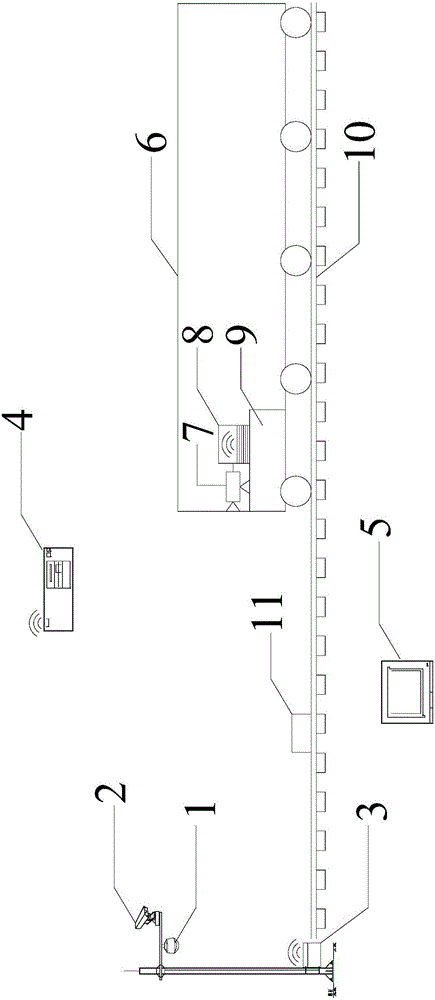

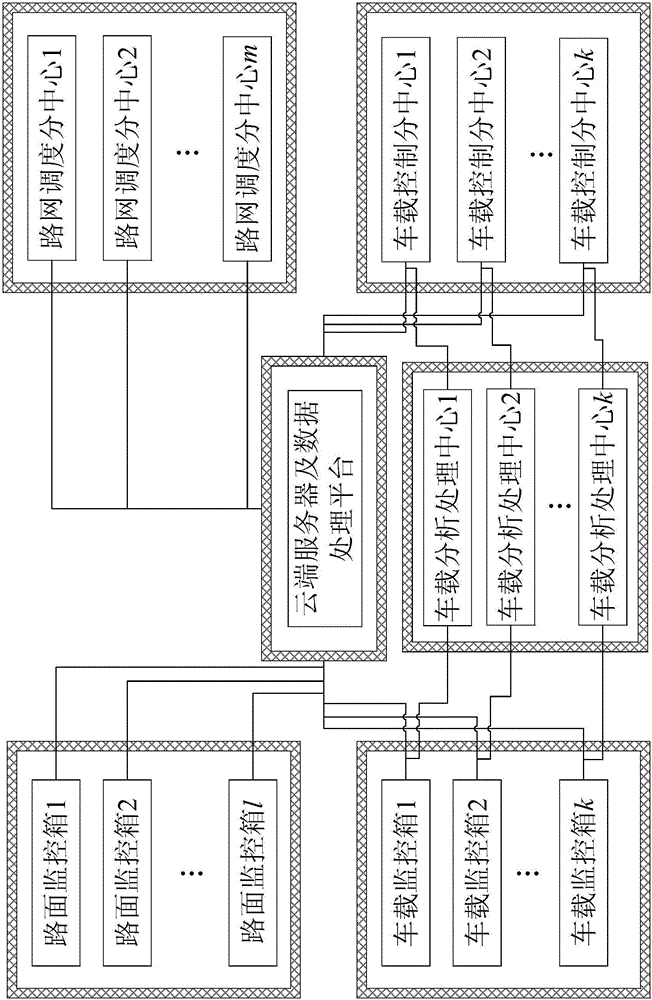

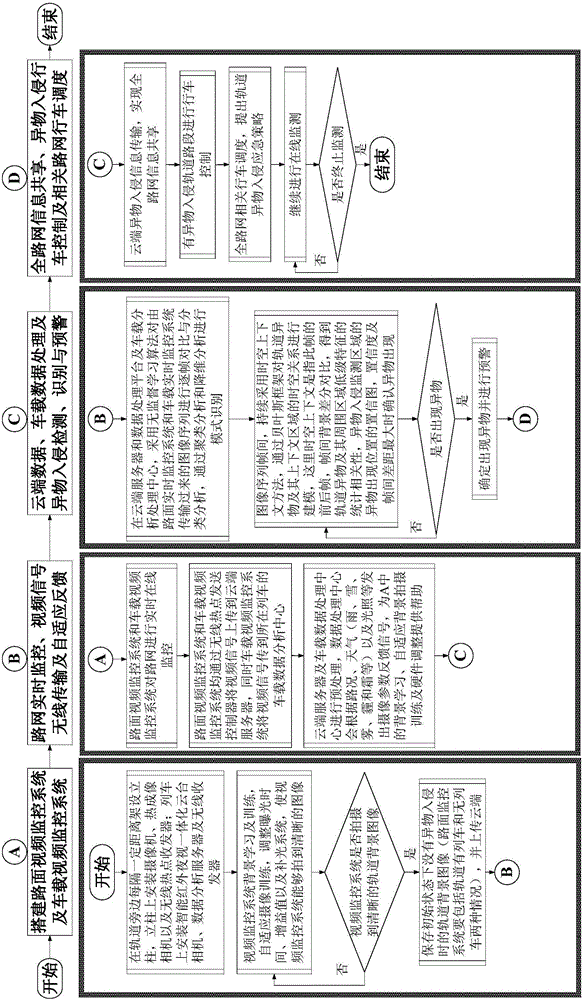

Automatic detecting and early warning method for track foreign matter invasion based on Internet of Things technology

ActiveCN105799740ALittle environmental disturbanceProcessing speedCharacter and pattern recognitionRailway signalling and safetySelf adaptiveInternet of Things

The invention provides an automatic detecting and early warning method for track foreign matter invasion based on the Internet of Things technology. The method comprises the specific implementation step A of setting up a pavement video monitoring system and a vehicle-mounted video monitoring system; the step B of monitoring a road network in real time, transmitting video signals wirelessly and carrying out self-adaptive feedback; the step C of processing cloud data and vehicle-mounted data, detecting foreign matter invasion, recognizing the foreign matter invasion and giving an alarm; the step D of sharing full road network information, controlling driving when the foreign matter invades, and dispatching driving of the related road network.

Owner:ZHEJIANG UNIV

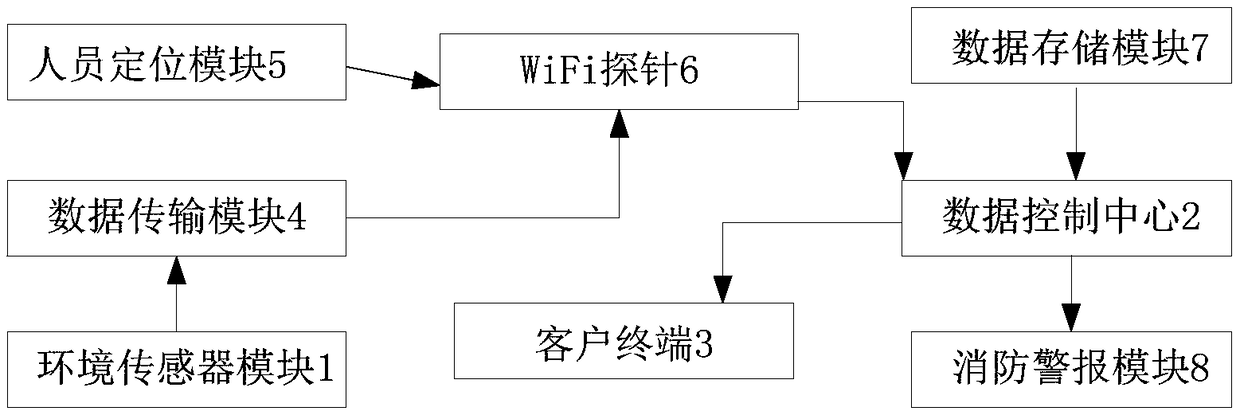

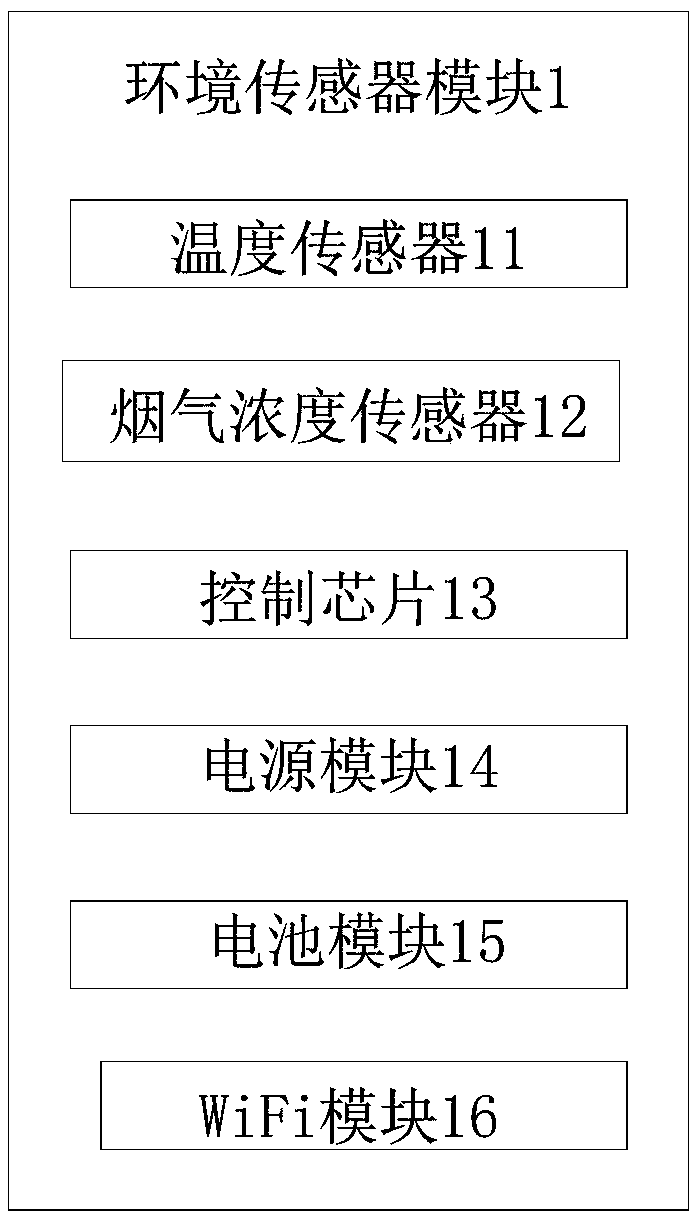

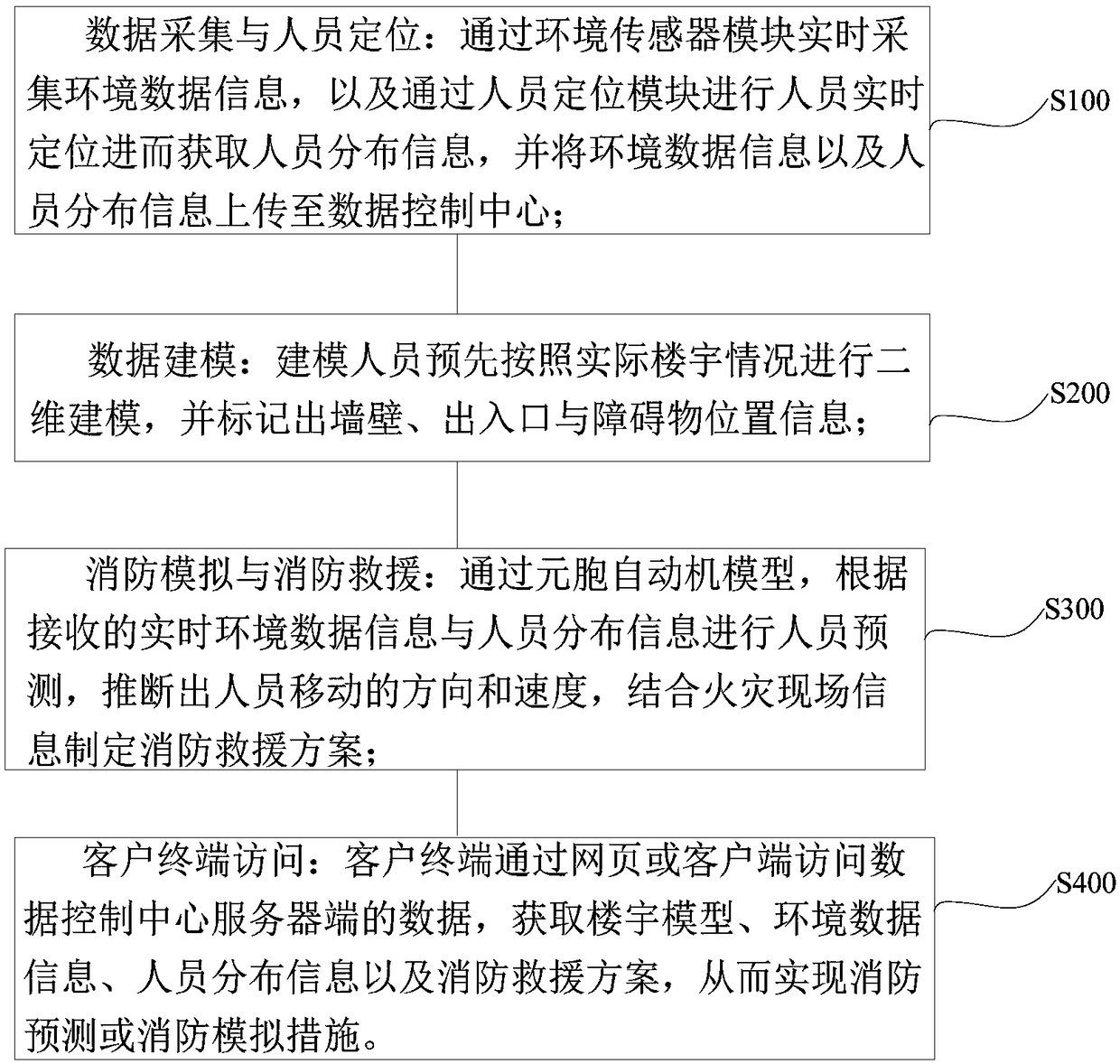

Intelligent fire-fighting system and method based on WiFi probe for fire monitoring and rescue escape

InactiveCN109215285ARealize automatic alarmForm powerfulMachine supportsMeasurement devicesData informationCrowds

The invention provides an intelligent fire-fighting system based on a WiFi probe for fire monitoring and rescue escape. The system comprises an environment sensor module, a data control center, a client terminal, a data transmission module, a personnel positioning module, and a WiFi probe. The environment sensor module is used for acquiring an environment data information in real time. The personnel positioning module is used for performing personnel positioning in real time to acquire a personnel distribution information. The data control center is used for receiving and storing the environment data information and the personnel distribution information, and making a corresponding fire-fighting rescue scheme. The data transmission module is in wireless connection with the data control center through the WiFi probe. The client terminal is used for receiving the real-time environment data information, the personnel distribution information, and the fire-fighting rescue scheme sent by the data control center. The invention further provides an intelligent fire-fighting method based on the WiFi probe for fire monitoring and rescue escape. The invention can provide an effective simulated escape rescue scheme, and effectively disperse the crowd when a fire occurs.

Owner:王悦廷

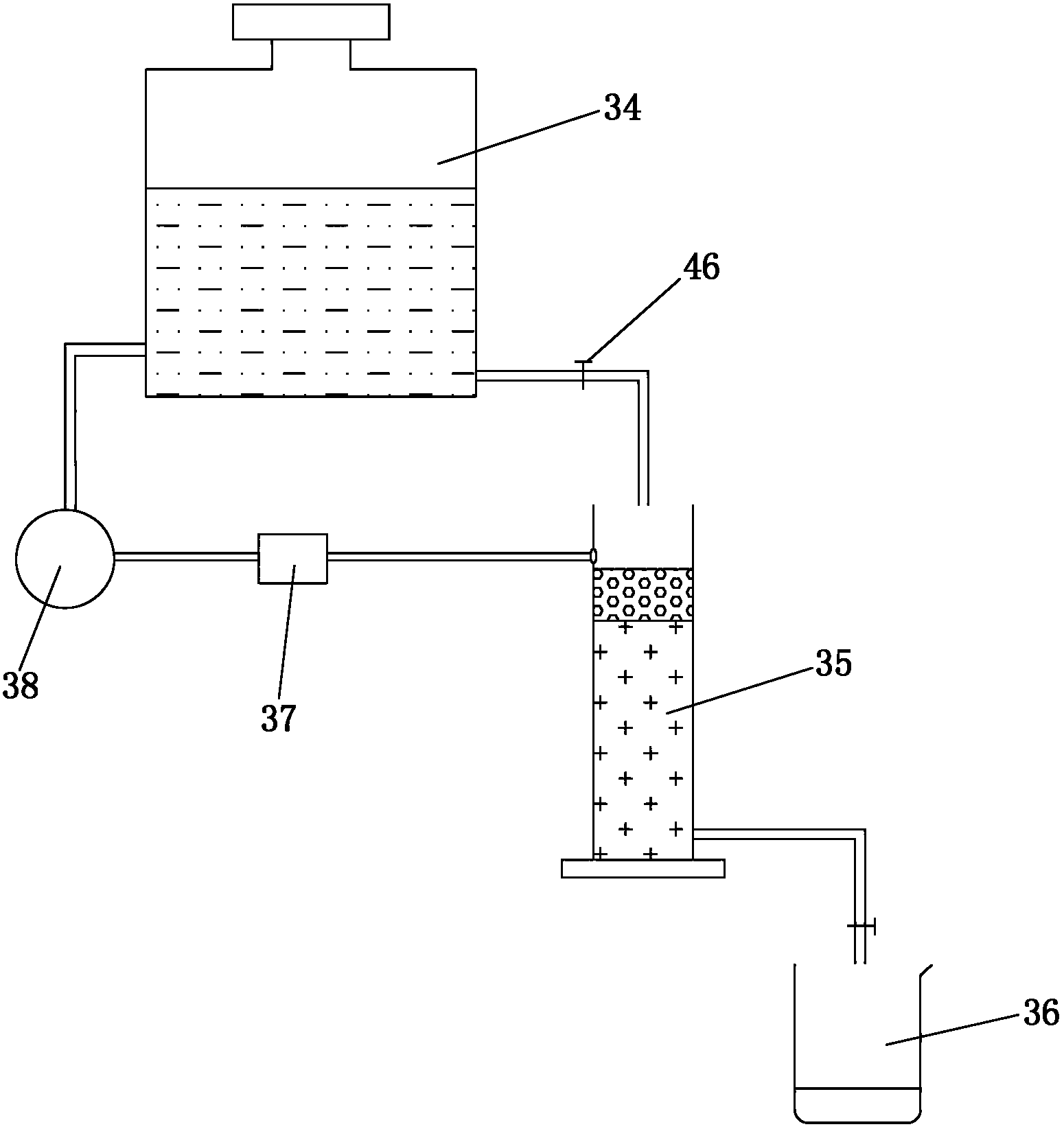

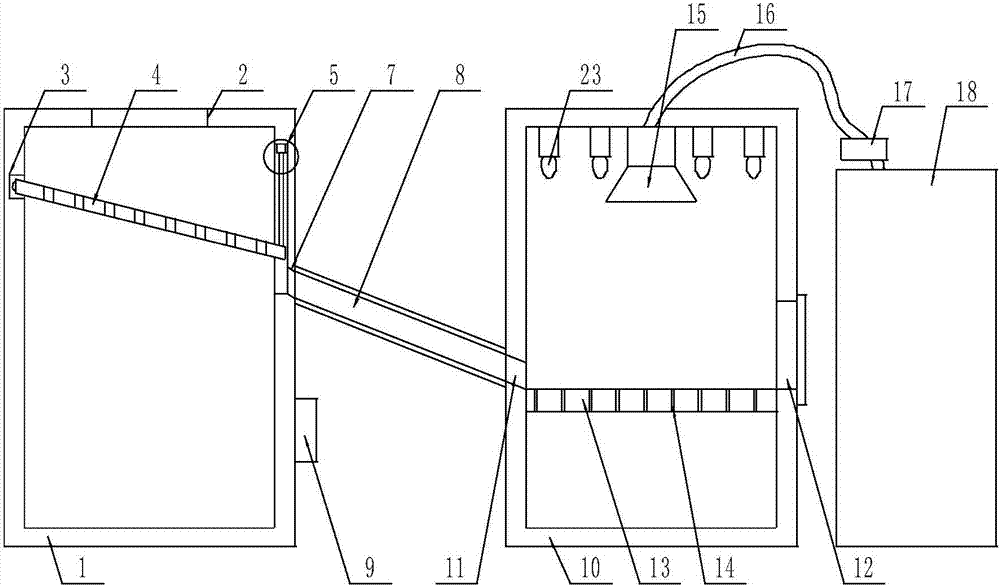

Fully-automatic earth pillar leaching experiment device

The invention discloses a fully-automatic earth pillar leaching experiment device. The fully-automatic earth pillar leaching experiment device comprises an automatic constant head height solution outflowing device, a detachable earth pillar body and an automatic continuous sampling device; the automatic constant head height solution outflowing device consists of a target pollutant solution containing bottle and an automatic constant head height mechanism, and the automatic constant head height mechanism consists of a magnet, a valve, a rotating wheel, a bracing wire and a buoyancy ball; and the automatic continuous sampling device consists of a sampling plate, a motor, a relay, a power supply and a timer, the motor is connected with the power supply by the relay, the timer is connected with the relay, a plurality of grooves are evenly formed in the circumference of the upper surface of the sampling plate, a first liquid level probe and a second liquid level probe are arranged in a test tube, the first liquid level probe is connected with the relay by a conductive wire, and the second liquid level probe is electrically connected with the relay by a hard conductive wire, a touch type chute and a conductive metal ball. The fully-automatic earth pillar leaching experiment device has a simple structure, is reasonable in design, convenient to use and strong in automation, saves labor force, and is applicable to popularization.

Owner:CHANGAN UNIV

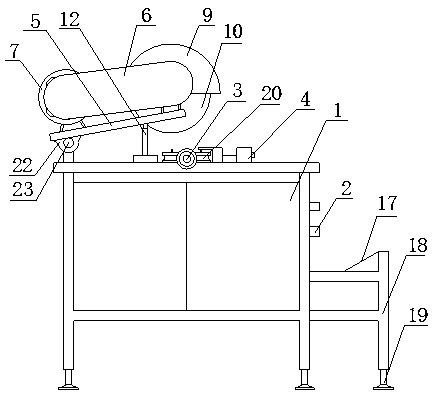

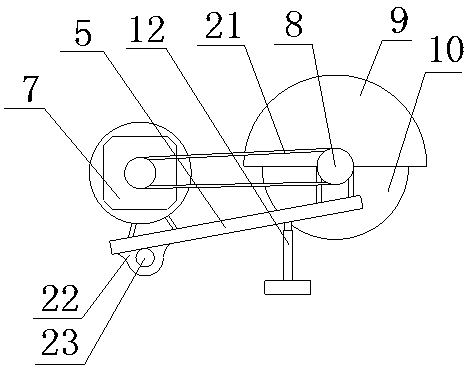

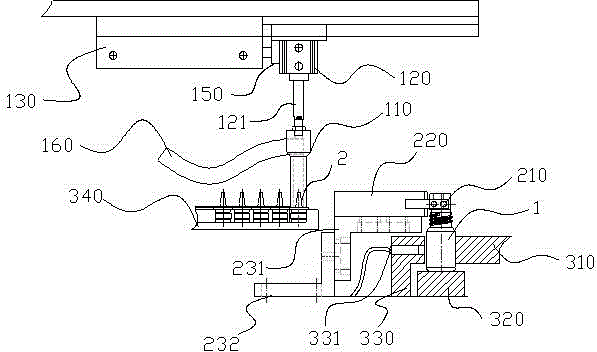

Automatic pipeline cutting machine

InactiveCN103878434AAvoid accidental injuryHigh precisionTube shearing machinesShearing machine accessoriesEngineeringInductor

The invention discloses an automatic pipeline cutting machine comprising a case, an intake pipe joint, a motor and a cutter body. A frame with a receiving groove is welded on the right side of the case and a fixed block is arranged on the top of the case. The left side of the fixed block is connected with the intake pipe joint and two wheels with conterminous outside diameter are arranged on one side of the fixed block. A rotating rod is arranged on the case. A seesaw with a bump on one side is set into the rotating rod and connected with the rod. The other side of the seesaw is fixed on the case via a lift rod. The motor and a rotating shaft are respectively arranged on both ends of the seesaw, the motor is connected with the rotating shaft via a belt pulley and another end of the rotating shaft is connected with the cutter body. A slide way is arranged on the case and the frame, above the receiving groove. A stopper with an inductor is arranged on the slide way and an opening and closing plate is arranged on the bottom of the slide way. The automatic pipeline cutting machine has automatic transport and high precision, is saving in time and labor, strong in automation, good in safety, efficient in process, less in noise, and can reduce labor intensity and improve economic efficiency.

Owner:山耐斯气动液压(磐安)有限公司

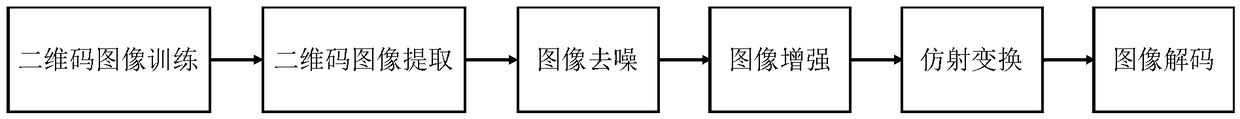

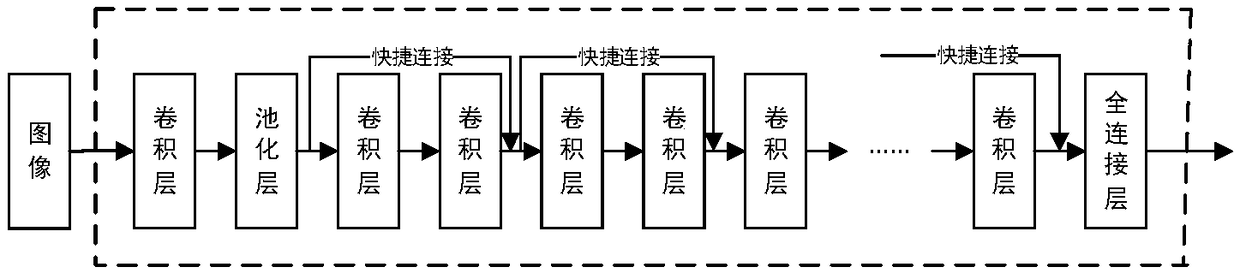

A method for automatically screening two-dimensional codes in fashion image

InactiveCN109241808ARobustHigh precisionNeural architecturesNeural learning methodsTheoretical computer scienceAlgorithm

The invention relates to a method for automatically screening two-dimensional codes in fashion images. The method comprises the following steps: step S1, constructing a depth learning two-dimensionalcode detection frame; 2, designing that loss function of the target detection; 3, performing extraction preprocessing of the two-dimensional code target area; 4, decoding the two-dimensional code candidate region. The invention has the advantages of solving the problem that a large number of two-dimensional code pictures doped in a fashion database seriously affect the visual experience of customers and the performance of the algorithm, and a two-dimensional code recognition and screening solution with stronger robustness, higher accuracy and better automation is established.

Owner:上海宝尊电子商务有限公司

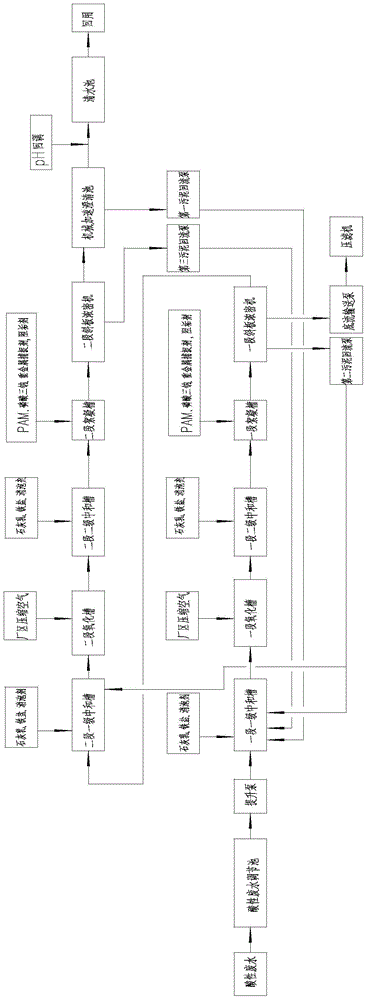

Acid wastewater treatment system and method

ActiveCN104058515AReduce processing costsIncrease flexibilityWaste water treatment from metallurgical processMultistage water/sewage treatmentWater treatment systemSludge

The invention belongs to the technical field of water treatment and in particular relates to an acid wastewater treatment system and a method. The system comprises an acid wastewater regulating tank, a lifting pump, a one-section primary neutralizing tank, a one-section oxidization tank, a one-section secondary neutralizing tank, a flocculation tank, a one-section inclined plate thickener, a two-section primary neutralizing tank, a two-section oxidization tank, a flocculation tank, a two-section inclined plate thickener, a mechanical acceleration clearing tank and a clear water tank, wherein the one-section inclined plate thickener is respectively connected with the one-section primary neutralizing tank and the two-section primary neutralizing tank by a second sludge reflux pump; the one-section inclined plate thickener is further connected with a filter press by a bottom-flow conveying pump; the two-section inclined plate thickener is connected with the one-section primary neutralizing slot by a third sludge reflux pump; and the mechanical acceleration clearing tank is connected with the one-section primary neutralizing slot by the first sludge reflux pump. On the condition of increasing investment, the system disclosed by the invention lowers acid wastewater treatment cost, comprehensively utilizes wastes, and realizes optimal automation and cyclic utilization of water resources.

Owner:KUNMING ENG & RES INST OF NONFERROUS METALLURGY

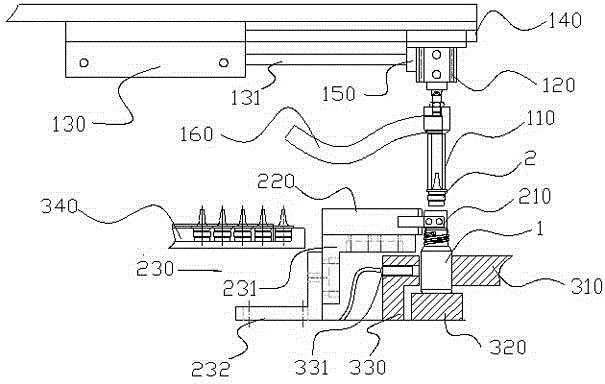

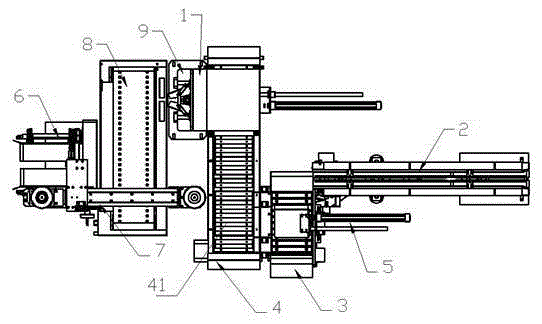

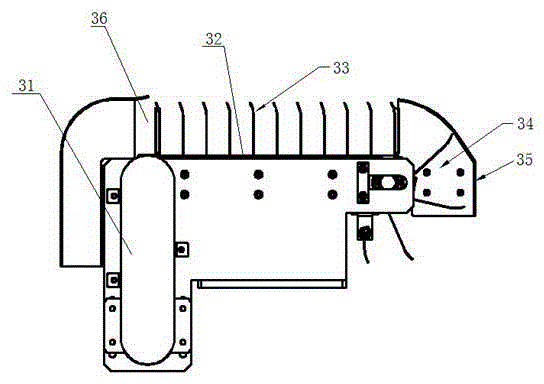

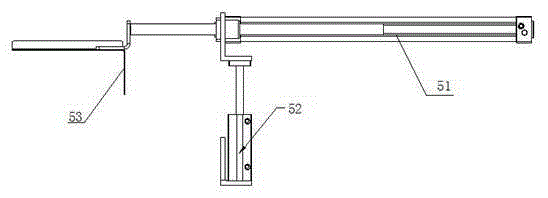

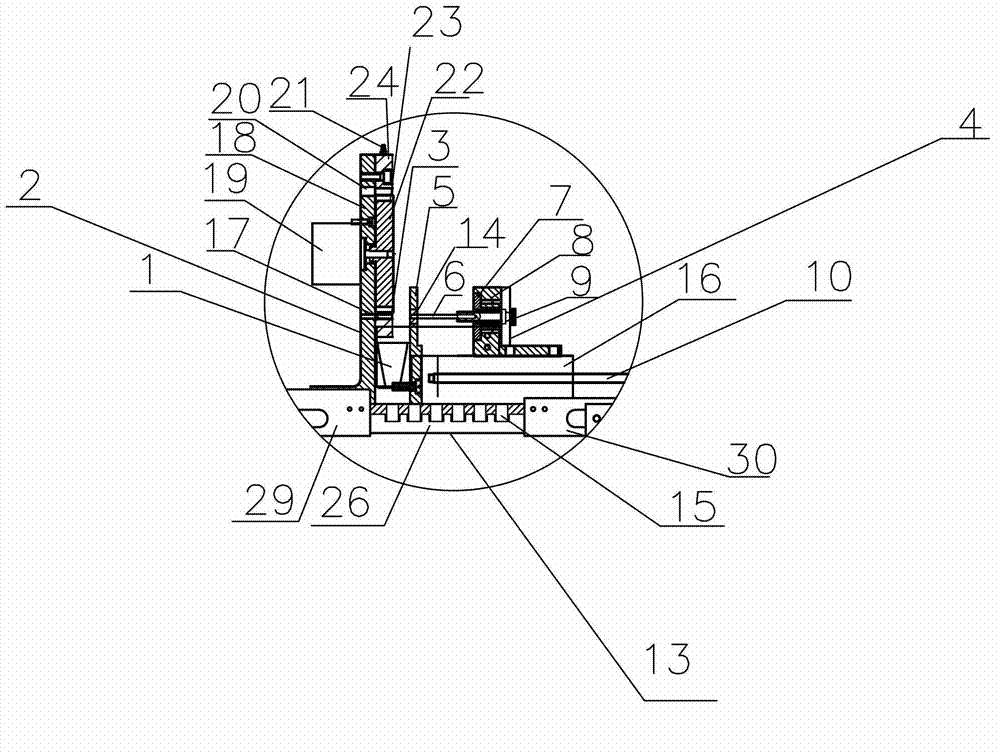

Automatic inner plug locating and installing mechanism

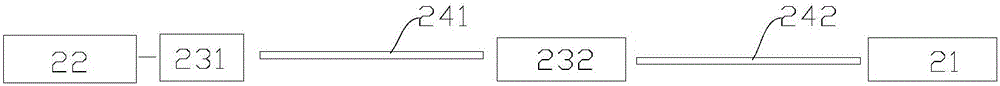

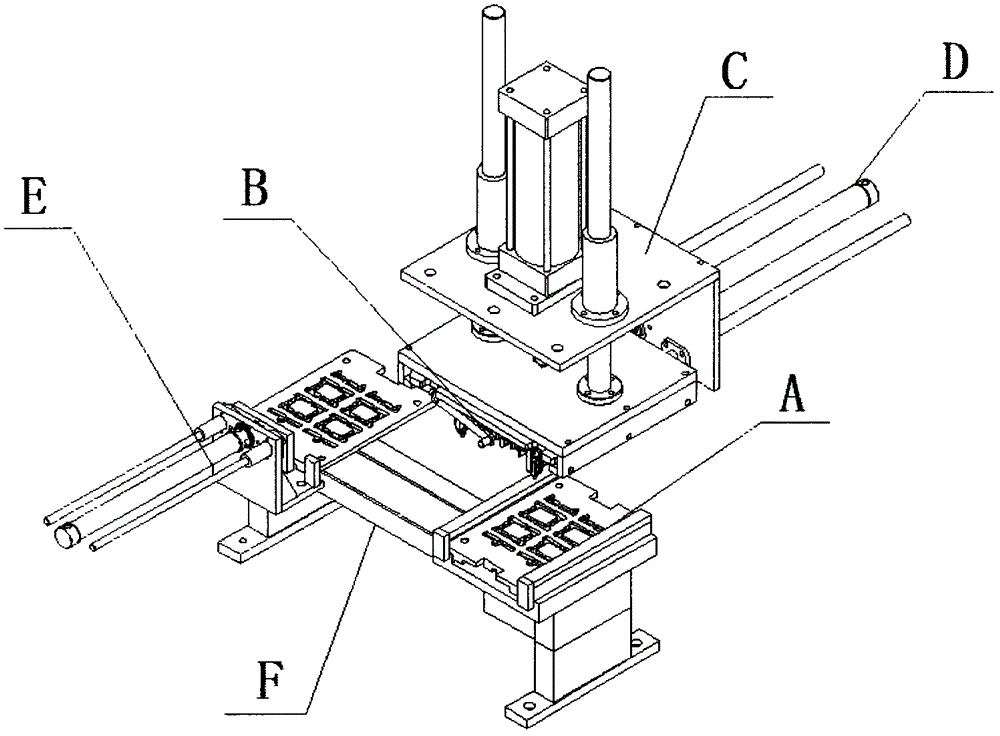

ActiveCN104058249AGuaranteed stabilityGuaranteed reliabilityClosure using stoppersConveyor partsControl systemEngineering

The invention discloses an automatic inner plug locating and installing mechanism. The automatic inner plug locating and installing mechanism comprises a mechanical hand system, a bottle opening locating system, a transporting system and a control system, wherein the mechanical hand system comprises an inner plug sucking hand, a lifting air cylinder, a transverse moving air cylinder, a guide rail which is arranged on a rack and a sliding block, and the middle upper part of the inner plug sucking hand is provided with a vacuum pipe which is communicated with a vacuum generator; the bottle opening locating system comprises a locating clamping block, a locating air cylinder and a locating and supporting seat which is used for fixing the locating air cylinder; the transporting system comprises a rotating disc which is used for transferring a bottle from a bottle installing station to a plug installing station, a supporting block, a guardrail and an inner plug transporting guide rail; the control system is electrically connected with the mechanical hand system, the bottle opening locating system and the transporting system. According to the automatic inner plug locating and installing mechanism disclosed by the invention, the problem of low working efficiency caused as an inner plug is manually installed by a person is overcome, the automation degree is strong, and the working efficiency can be greatly increased; each system sequentially works, strictness and coordination are realized, the inner plug can be conveniently installed, the stability of the automatic inner plug locating and installing mechanism is ensured from the structure design, and the reliability is strong.

Owner:GUANGZHOU BEAUTY STAR CO LTD

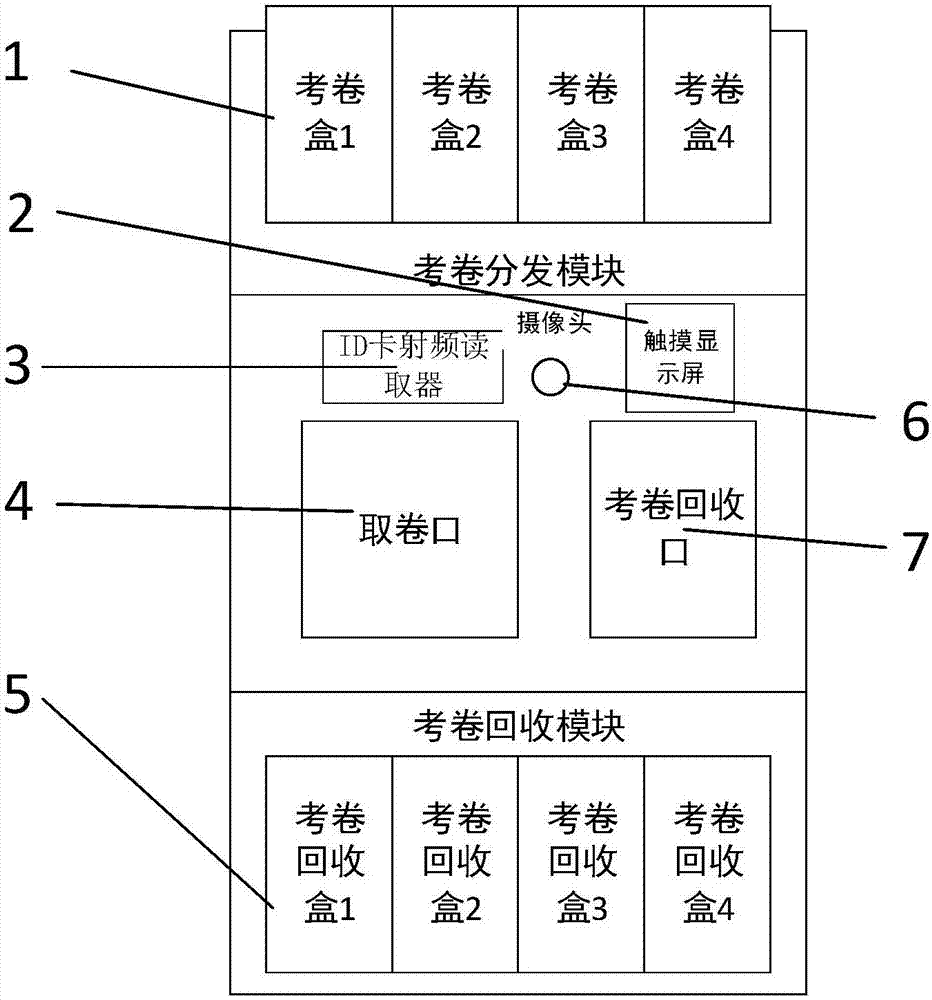

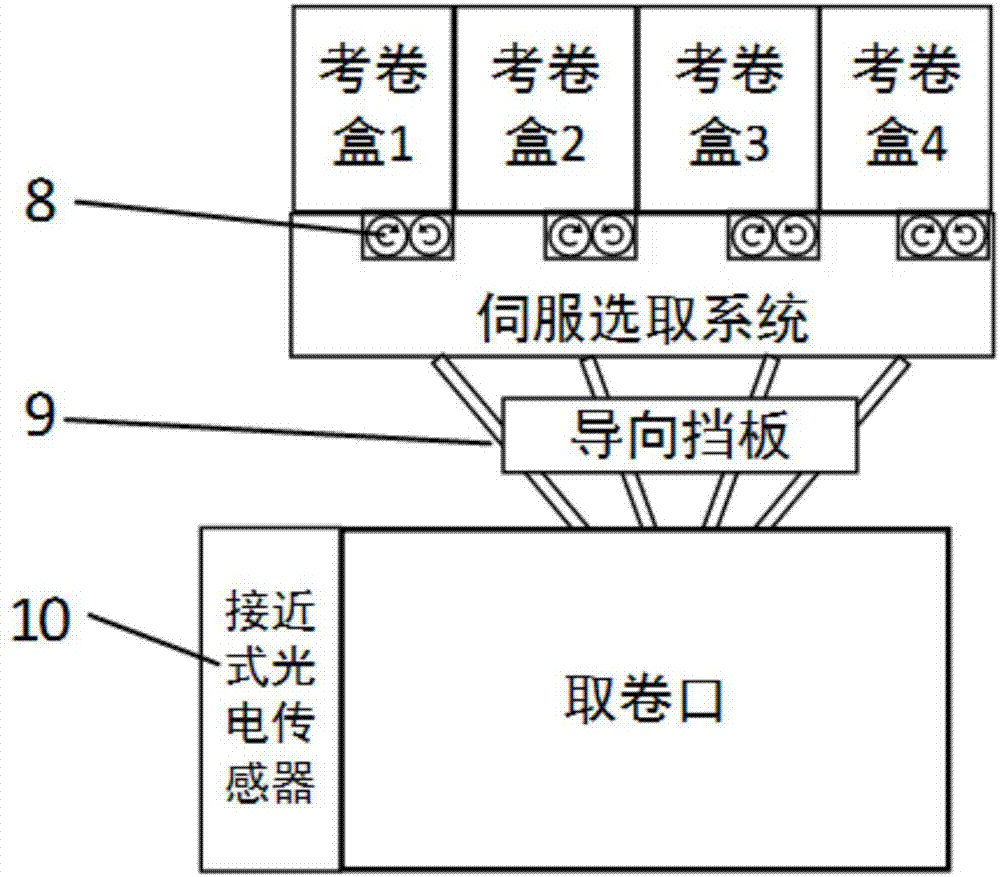

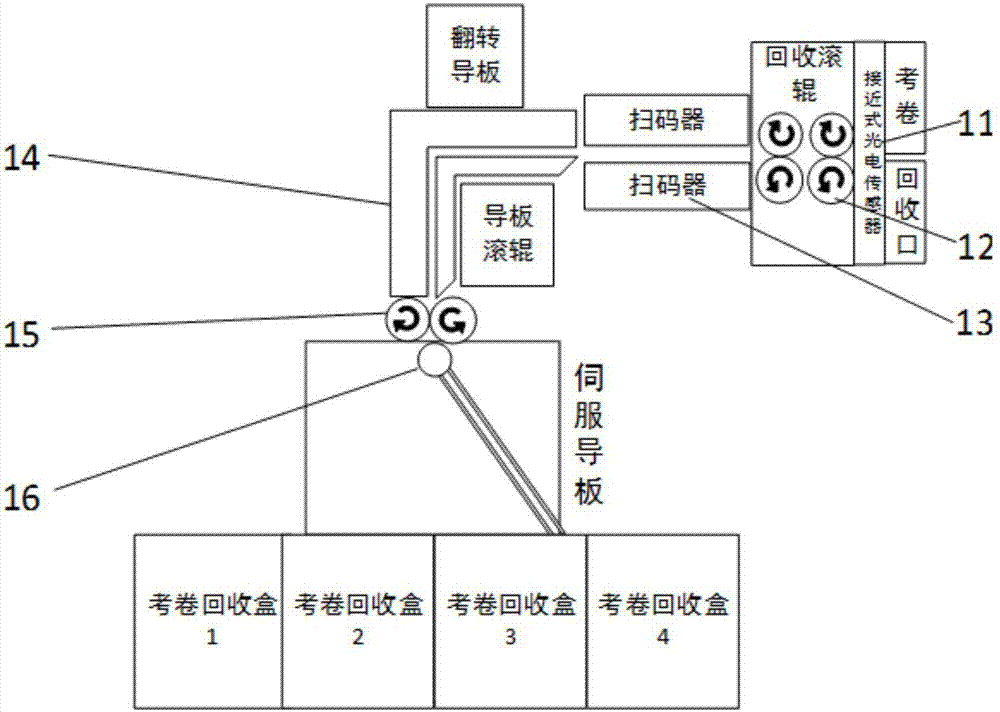

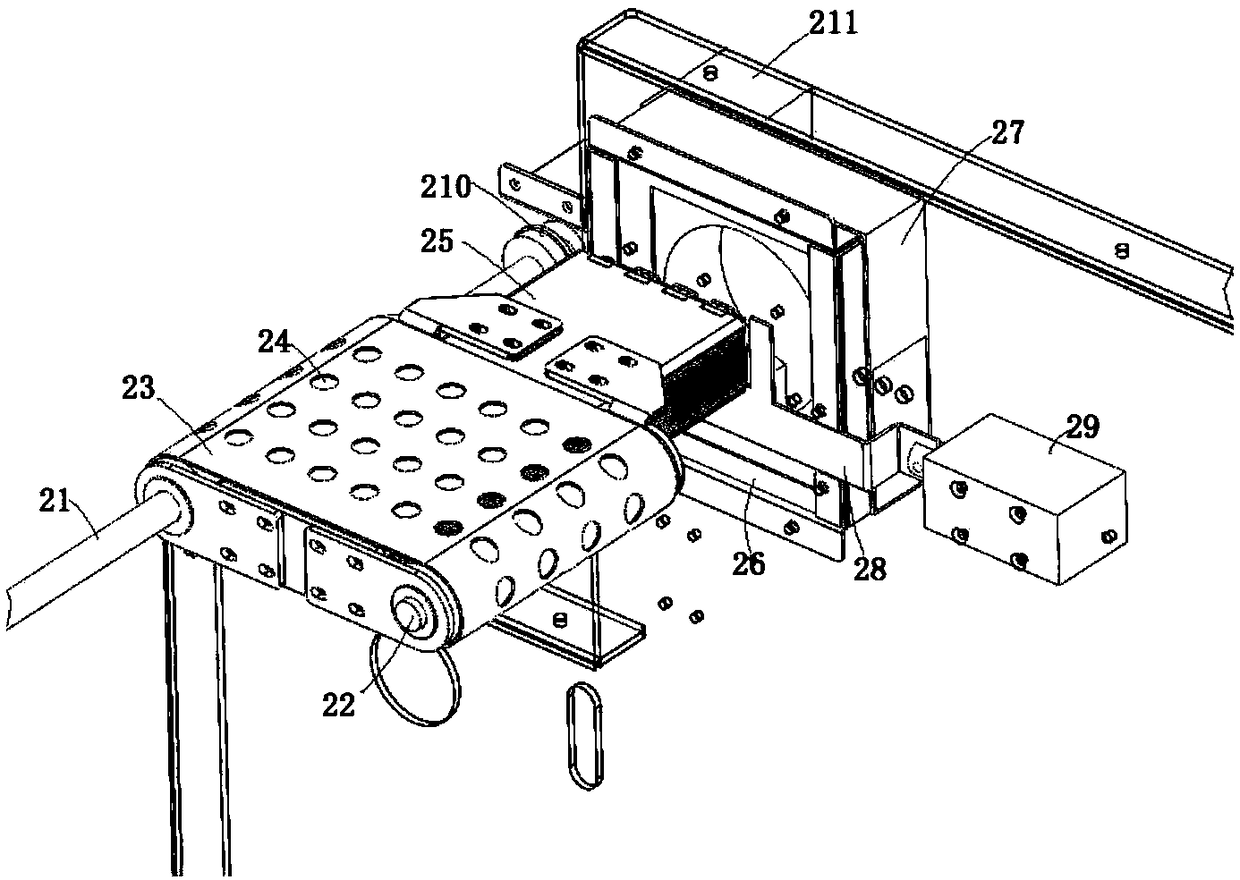

Examination paper automatic delivery and recovery machine

ActiveCN106952419AReduce workloadReduce work stressApparatus for meter-controlled dispensingIdentity recognitionEXAMINATION ROOM

The invention provides an examination paper automatic delivery and recovery machine, which comprises an identity recognition and examination paper matching module, an examination paper storage module, an examination paper delivery module and an examination paper recovery module, wherein the identity recognition and examination paper matching module is used for recognizing the identity of examinees and recognizing and matching on the examination paper of the examinees; the examination paper storage module is used for storing examination papers in different examination types in one examination room; the examination paper delivery module is used for automatically delivering examination papers of the examination of different subjects and performing recording according to the identity information of different examinees; the examination paper recovery module is used for automatically classifying and sorting the subjects of the examination papers according to the identity information of the examinees.

Owner:SHANGHAI UNIV OF ENG SCI

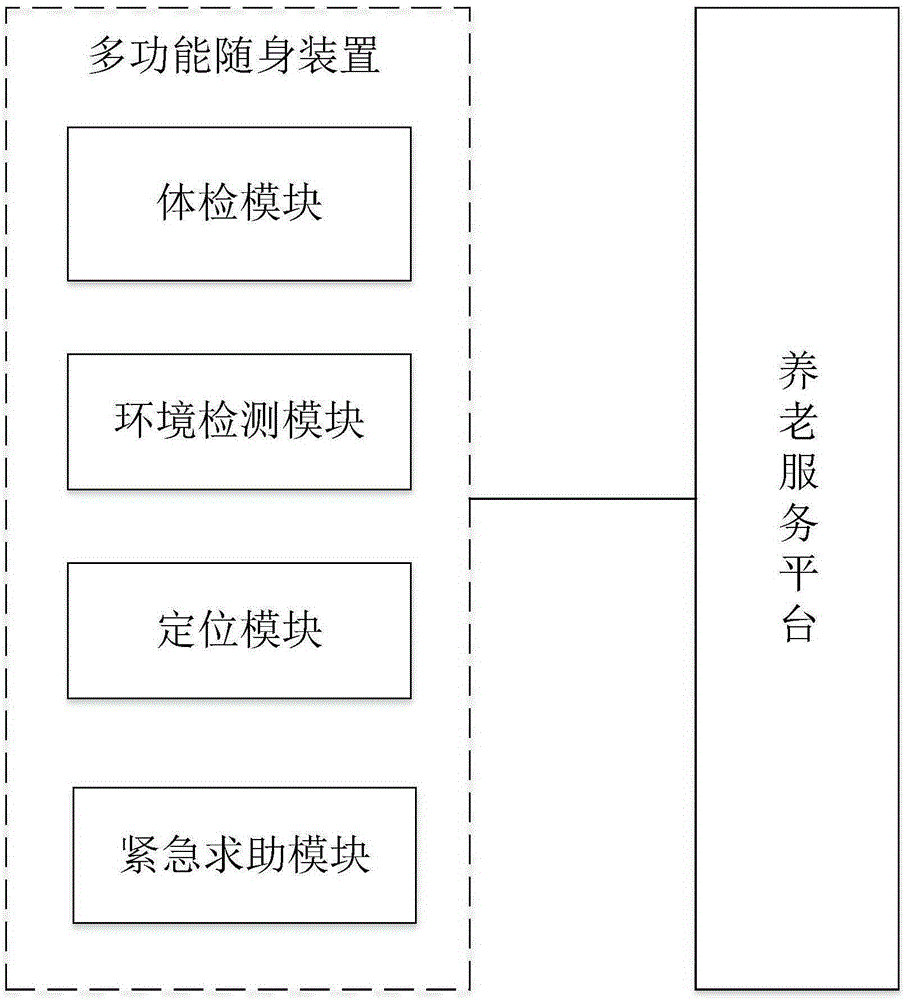

Multi-functional smart home care system

InactiveCN105404777ATimely treatmentPrevent health deteriorationDiagnostic recording/measuringSensorsPhysical well beingEngineering

The present invention discloses a multi-functional smart home care system. The system comprises a multi-functional portable apparatus and an aged service platform. The multi-functional portable apparatus is worn by the aged and comprises a physical examination module, an environment detection module,a positioning module and an emergency calling module. According to the multi-functional smart home care system provided by the present invention, the aged service platform can learn a current health condition of the aged by comparing acquired body health data of the aged with a threshold in a health mode, so as to determine a health level of the aged, and can directly inform medical institutions such as a community health service center or a hospital to make a home diagnosis, so as to treat the aged in time and avoid deterioration of the health condition of the aged. According to the system provided by the present invention, the aged are cared remotely by means of the physical examination module,the positioning module and the emergency calling module, so that the system is high in intelligence, high in automation and is beneficial for relieving the pressure brought by the problem of caring for the aged after population aging.

Owner:合肥愿与网络技术有限公司

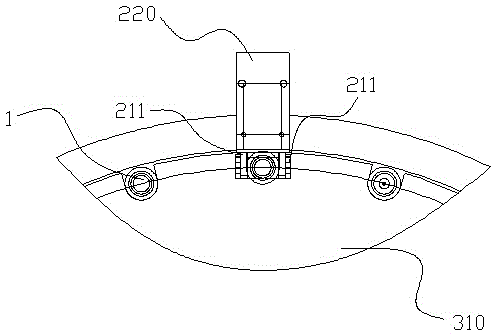

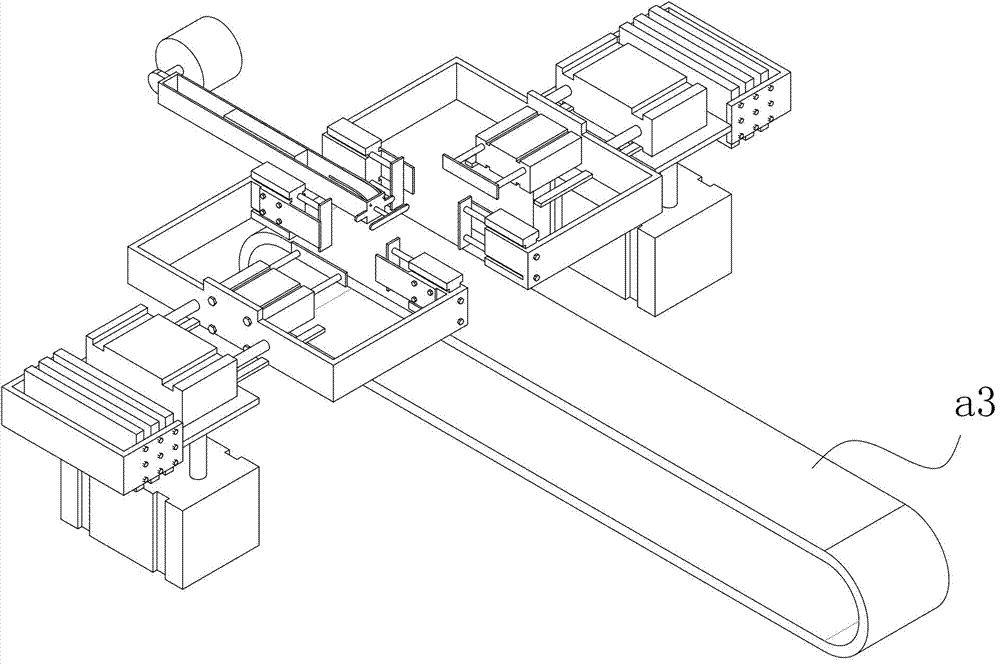

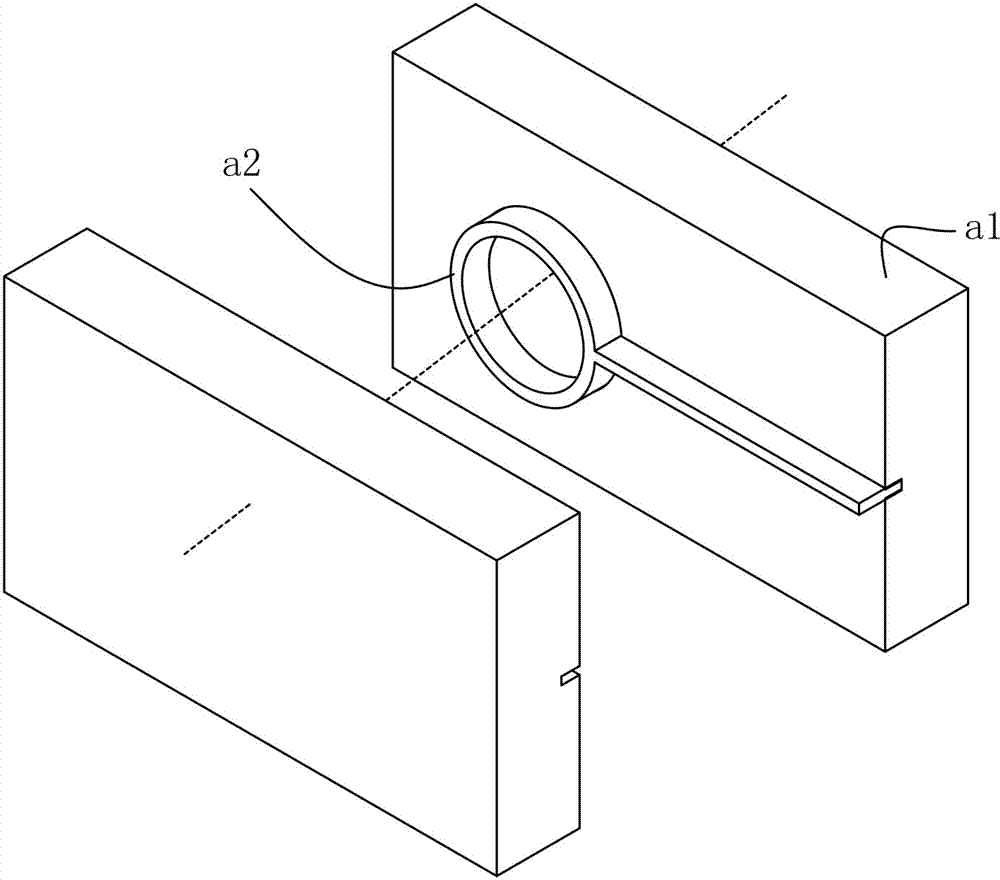

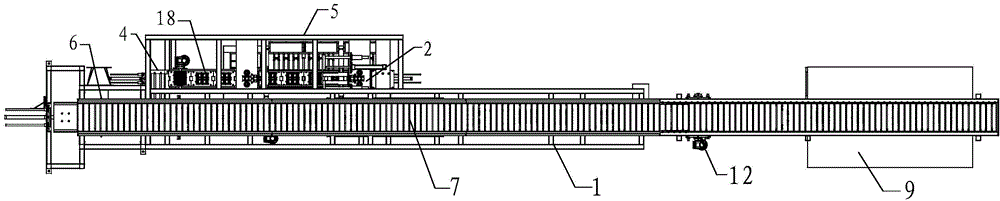

Ring wax fetching complete machine with conveyor belt

The invention discloses a ring wax fetching complete machine with a conveyor belt. The ring wax fetching complete machine comprises the conveyor belt, and a ring wax fetching structure which is arranged above the conveyor belt, wherein the ring wax fetching structure is used for fetching a ring wax out of the inner part of a wax mould. By utilizing combined type mechanical hands, a manual wax fetching operation is skillfully replaced by a mechanical wax fetching operation, and therefore, the efficiency is quick, the cost is low, and the highly automation is achieved.

Owner:太仓市简汇信息技术有限公司

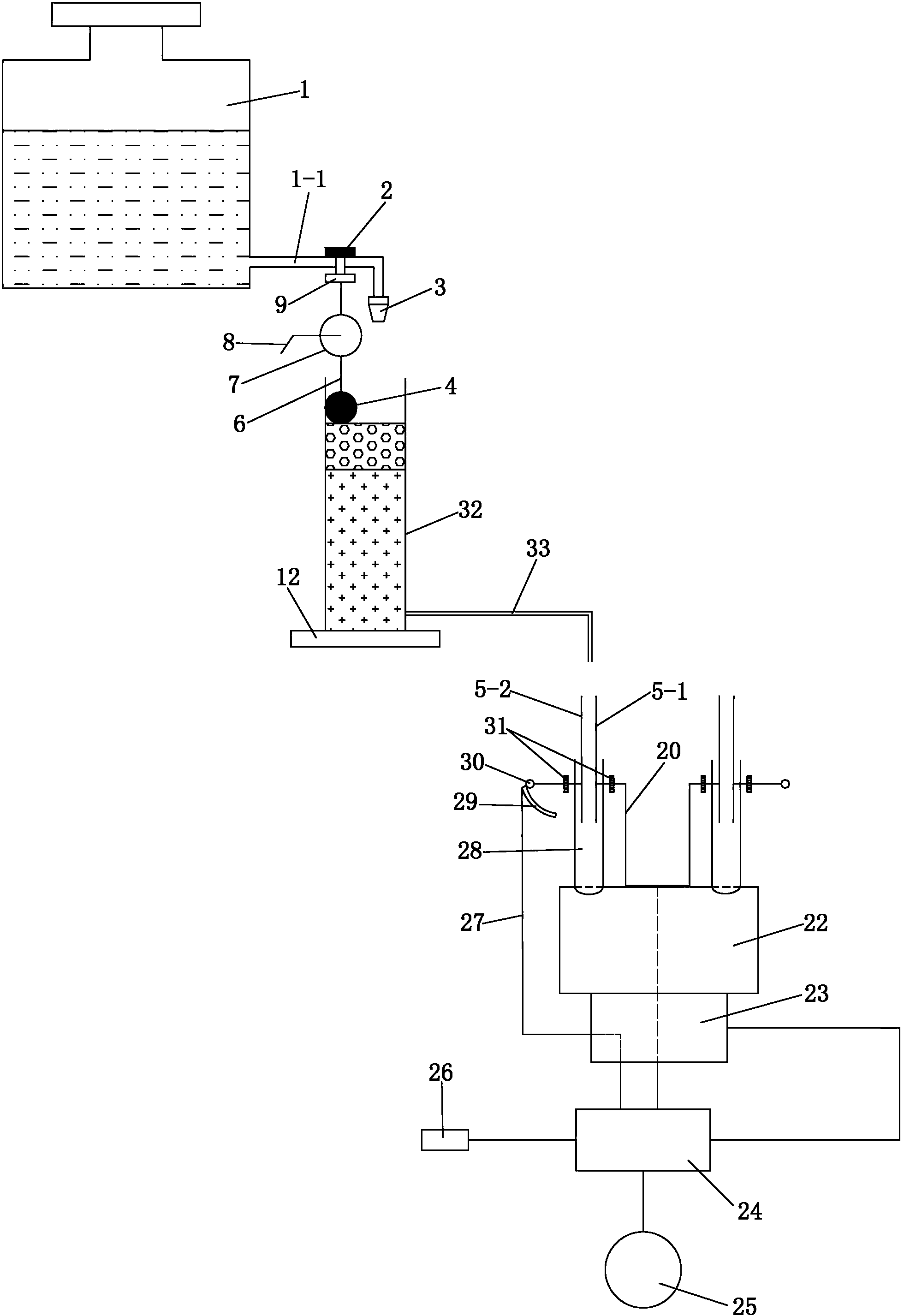

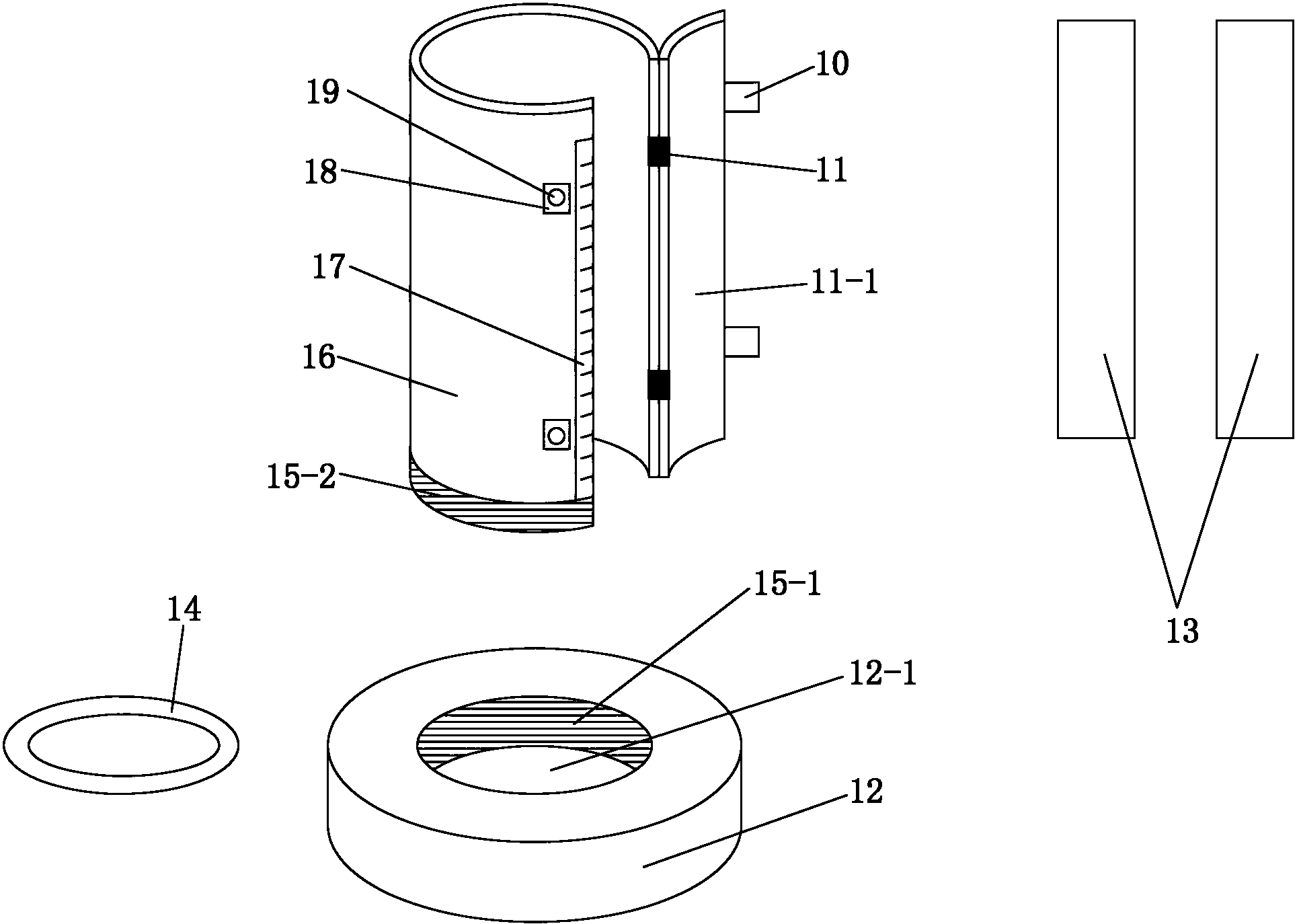

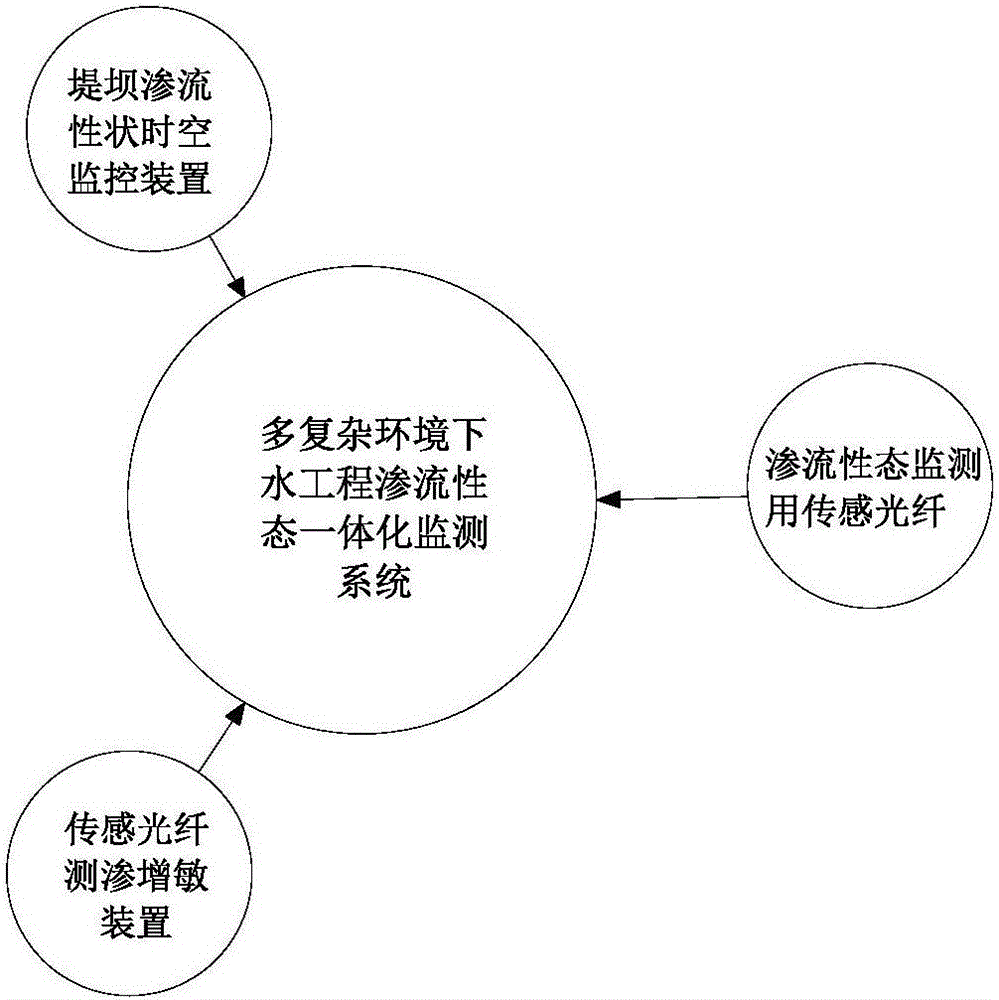

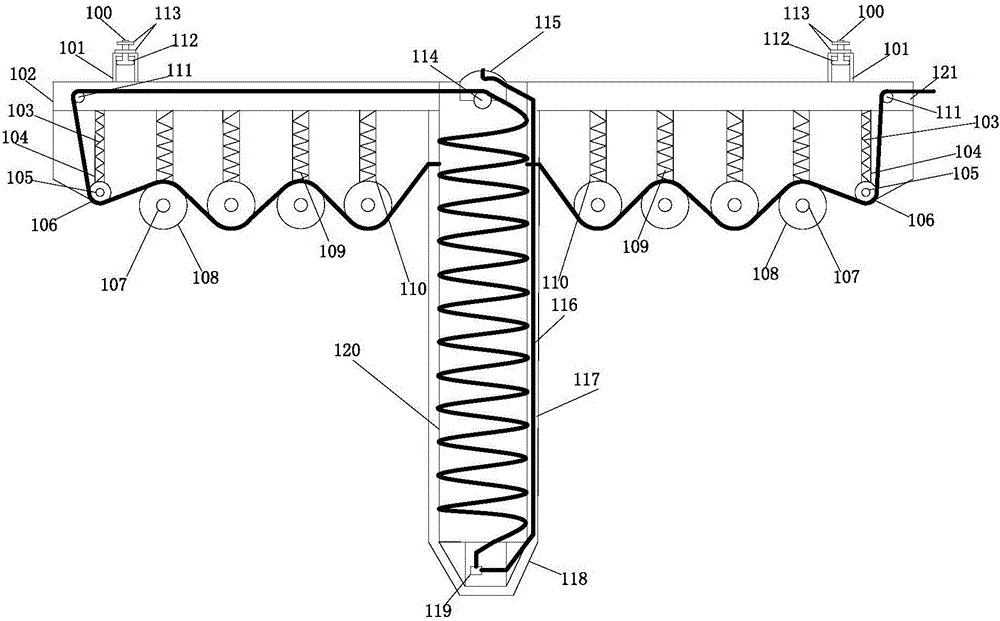

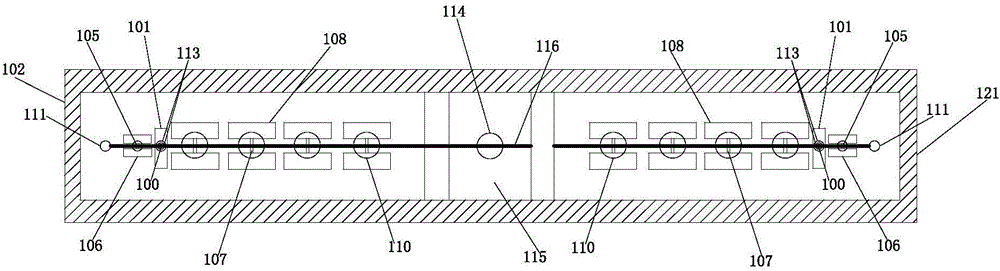

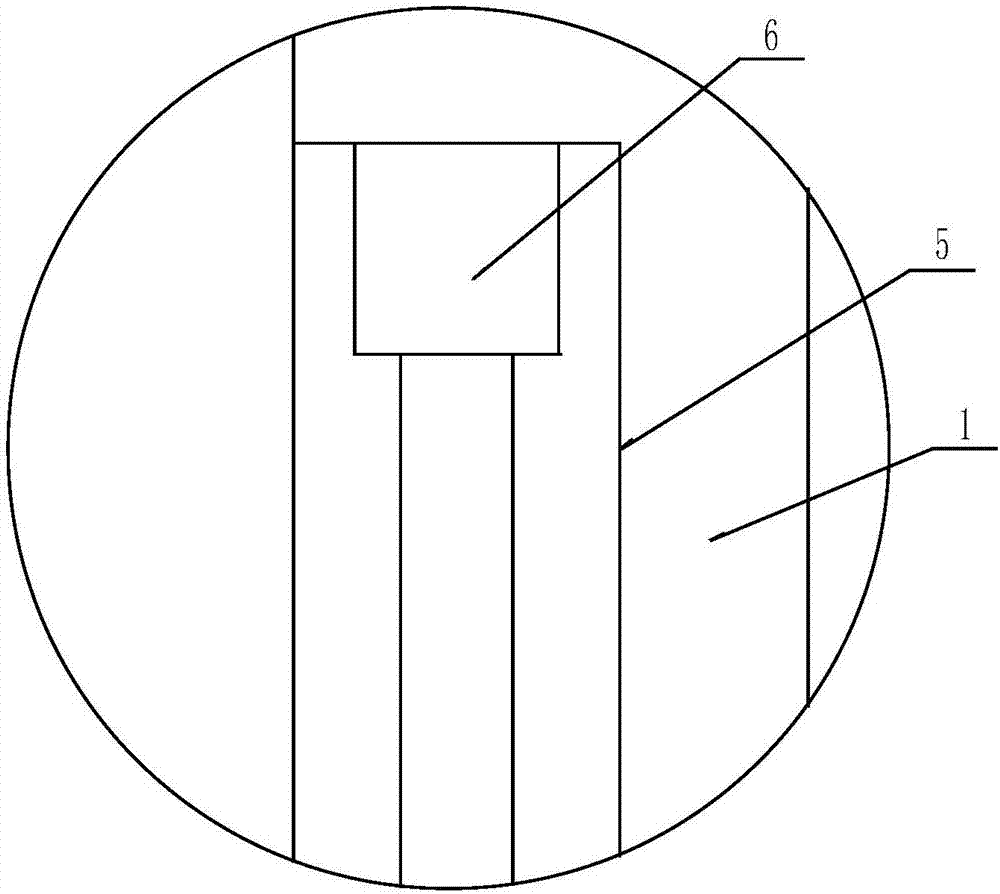

Integrated monitoring system and integrated monitoring method for seepage behavior of water engineering under complex environments

ActiveCN105738268AComplete structureStrong automationCladded optical fibreEarth material testingFiberIntegrated monitoring

The invention discloses an integrated monitoring system and an integrated monitoring method for the seepage behavior of water engineering under complex environments. The integrated monitoring system comprises a seepage behavior space-time monitoring device and a sensor fiber seepage-detecting sensibilizing device, wherein the seepage behavior space-time monitoring device comprises a vertical force bearing fiber pillar, an outer edge through pipe and a sensor fiber; a left force-bearing beam and a right force-bearing beam are respectively arranged at the two sides of the vertical force-bearing fiber pillar; the outer edge through pipe is arranged on the vertical force-bearing fiber pillar in a sleeving manner; a fiber collecting box is arranged above a second transition round end; the sensor fiber in the fiber collecting box passes through the outer edge through pipe and is connected with an element bearing carrier containing a temperature measuring device, and then passes by the second transition round end and a first transition round end in turn, penetrates through an elastic device and is led from a third transition round end. According to the integrated monitoring system for the seepage behavior of the water engineering under complex environments provided by the invention, the research and development for basic sensor fiber and serial products and techniques, such as secondary processing for common sensor fiber, etc., are put forward, and the space-time horizontal and longitudinal quantitative and qualitative evaluation can be realized.

Owner:HOHAI UNIV

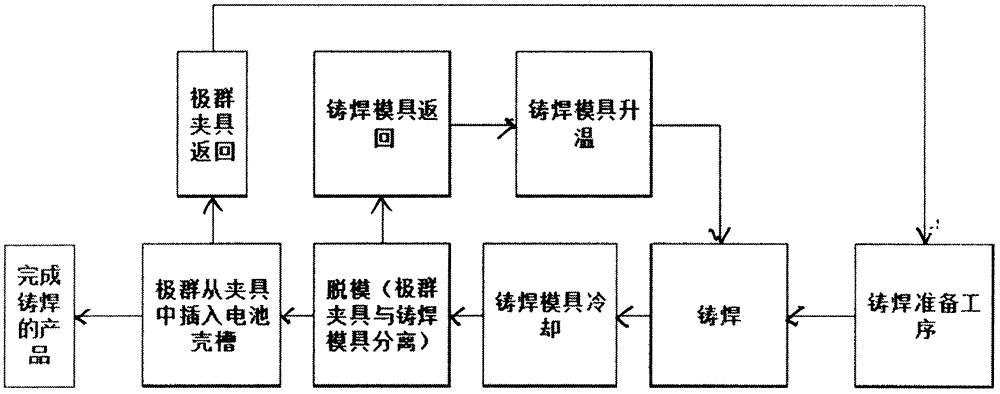

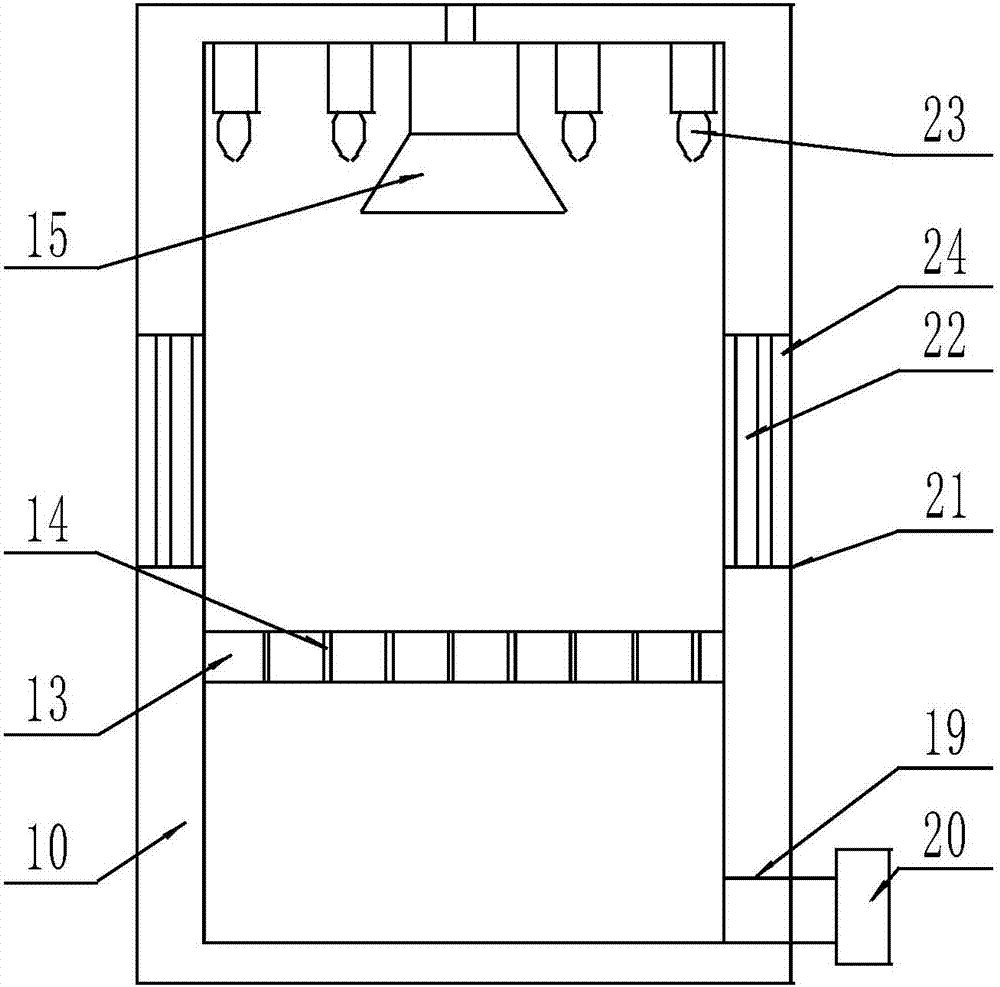

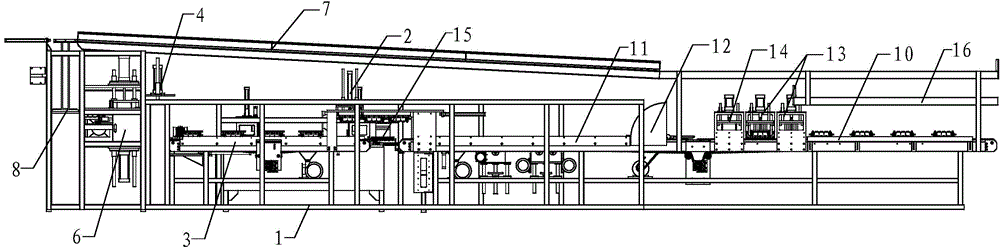

Continuous cast-welding device for busbar and polar column of lead-acid battery

InactiveCN106141145AShorten cycle timeReduce labor intensityCell component detailsLead smeltingDevice form

The invention discloses a continuous cast-welding device formed by units, independent from one another and automatically connected, for heating a cast-welding mould, cast-welding a plurality of polar plates and polar lugs, cooling the mould and a busbar after cast-welding, demoulding the busbar from the cast-welding mould, accommodating demoulded polar groups in a groove, returning the mould and a clamp and the like. The production cycle formed by adding centralized operation of a plurality of working procedures is decomposed and compressed into the production cycle time of operation of one work procedure so that the production efficiency can be improved greatly. A device used for increasing the temperature of lead alloy liquid is adopted for the cast-welding mould. A heating mechanism is arranged below the liquid level of a lead smelting furnace and used for sequentially feeding a plurality of cast-welding moulds into the mechanism by use of an automatic machine, maintaining the moulds below the lead alloy liquid level to heat the moulds, and providing cast-welding for the moulds sequentially. After the temperatures of the cast-welding moulds meet cast-welding requirements, the cast-welding moulds are then sequentially taken out of the heating mechanism according to the first in first out principle so that cast-welding of polar group busbars and polar columns of batteries can be conducted.

Owner:刘凡

Cloths hanger exposed to sun

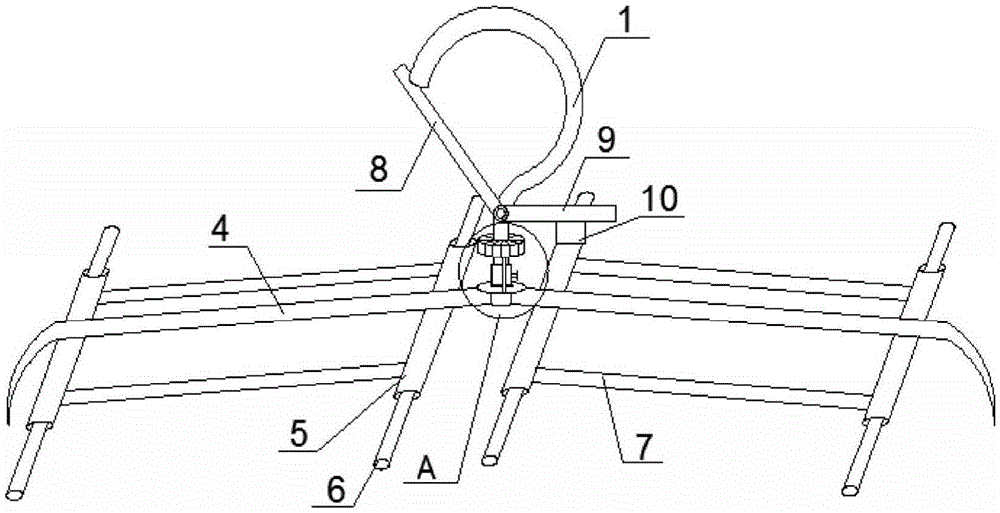

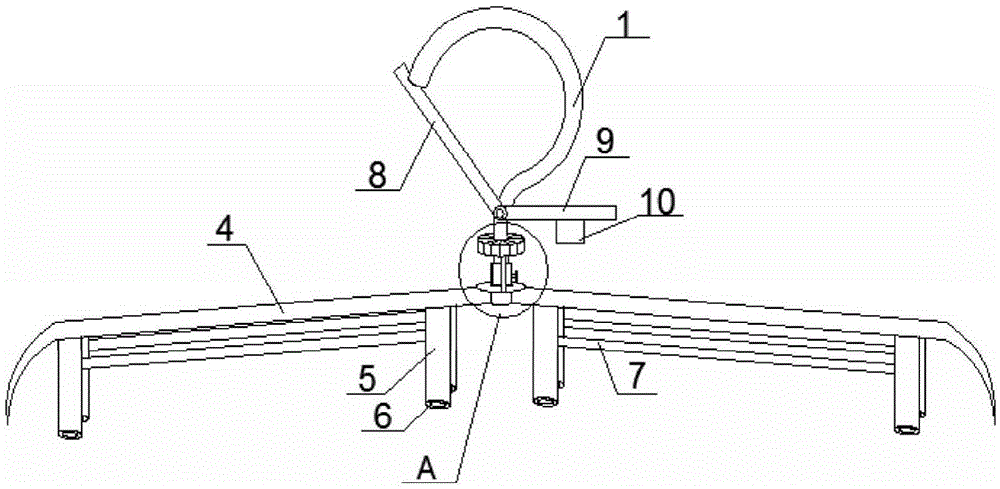

ActiveCN105395013AGuaranteed to be sunnyPrevent convex deformationApparel holdersCircular discGear wheel

The invention discloses a cloths hanger exposed to the sun. The cloths hanger exposed to the sun comprises a hook, a rotating device, a supporting body, four pairs of fixing clamps and a gear position device. The hook comprises a hook body, a rod body and a self-locking part. The rotating device comprises a spiral spring box, a bevel gear and a hollow barrel body, wherein a spiral spring gear of the spiral spring box is meshed with the bevel gear. The supporting body comprises two clothes hanger arms, wherein one end of each clothes hanger arm is fixedly connected with the barrel body, and two telescopic rods are arranged on the clothes hanger arms. The fixing clamps are arranged on the joints of the clothes hanger arms and the telescopic rods. The gear position device comprises a photosensitive element, a horizontal disk and a controller. According to the cloths hanger exposed to the sun, the clothes hanger arms are driven to rotate through a spiral spring driving device, and therefore rotation of clothes can be achieved; the sun-curing direction of the clothes is adjusted in time according to the light intensity value detected by the photosensitive unit; meanwhile, due to the fact that the telescopic rods and connecting rods are designed on the clothes hanger arms and the width of the supporting body is adjusted according to the width of the shoulders of the clothes, the shoulders of the clothes can be prevented from protruding and deforming. The cloths hanger exposed to the sun has the advantages of being low in cost, high in automation degree and wide in application range.

Owner:王境伟

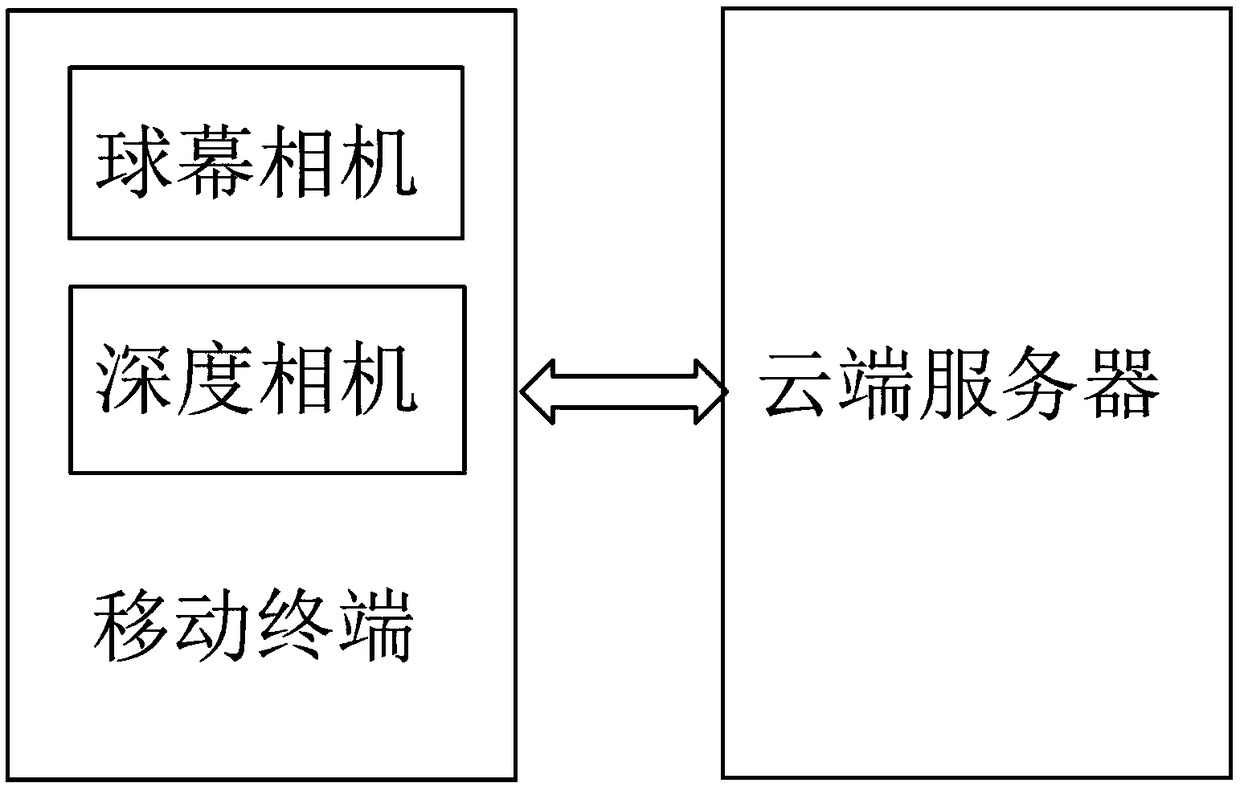

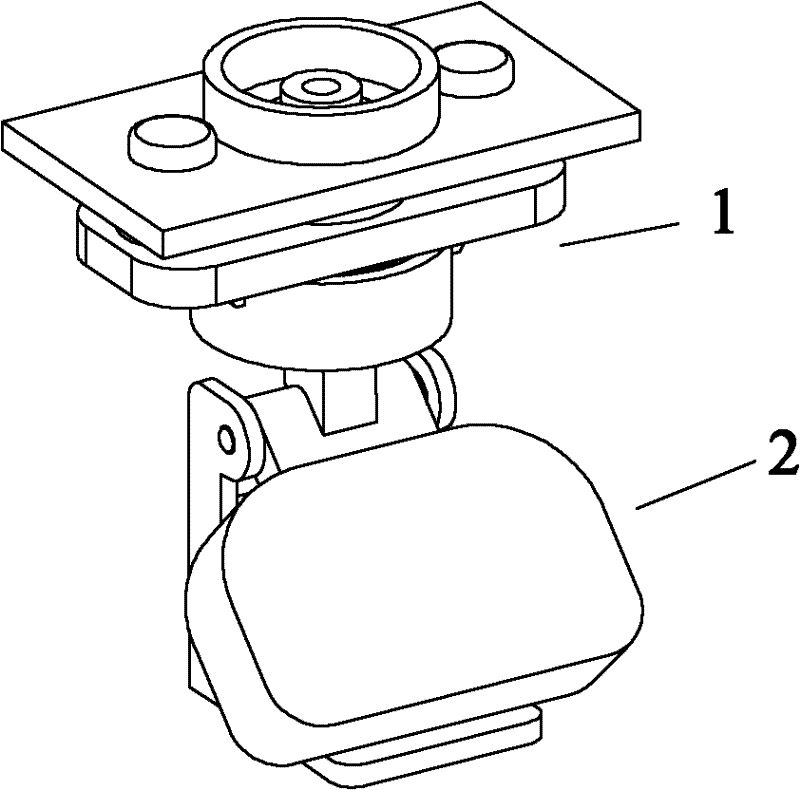

Three-dimensional modeling method and system combining dome-screen camera and depth camera

ActiveCN108629829AAccurately establishedRich in detailsImage enhancementImage analysisCamera lensPoint cloud

The invention provides a three-dimensional modeling method nuclear system combining a dome-screen camera and a depth camera, which relates to the technical field of three-dimensional imaging modeling.The system at least comprises the depth camera and a dome-screen camera. The method comprises eight steps that S1, a dome-screen camera lens and a depth camera lens are fixed at the same position inthe space; S2, photographing is carried out by using the dome-screen camera; S3, preliminary positioning is carried out through a VSSLAM algorithm; S4, the three-dimensional information and space information in the three-dimensional picture are adopted for calibration; S5, further accurate positioning is carried out; S6, a dense point cloud is formed; S7, the accurate dense point cloud is furtherobtained; S8 digital modeling is carried out to generate a three-dimensional model; S9 mapping of the three-dimensional model is automatically carried out according to the color information in the two-dimensional panoramic photo. The invention is advantageous in that the three-dimensional model has the advantages of the dome-screen camera and the depth camera at the same time, and the three-dimensional model is more accurate; the defects that the angle of the depth camera is single, the vision field is limited, and the dome-screen camera is prone to generating errors are solved.

Owner:CHINA GERMANYZHUHAIARTIFICIAL INTELLIGENCE INST CO LTD +1

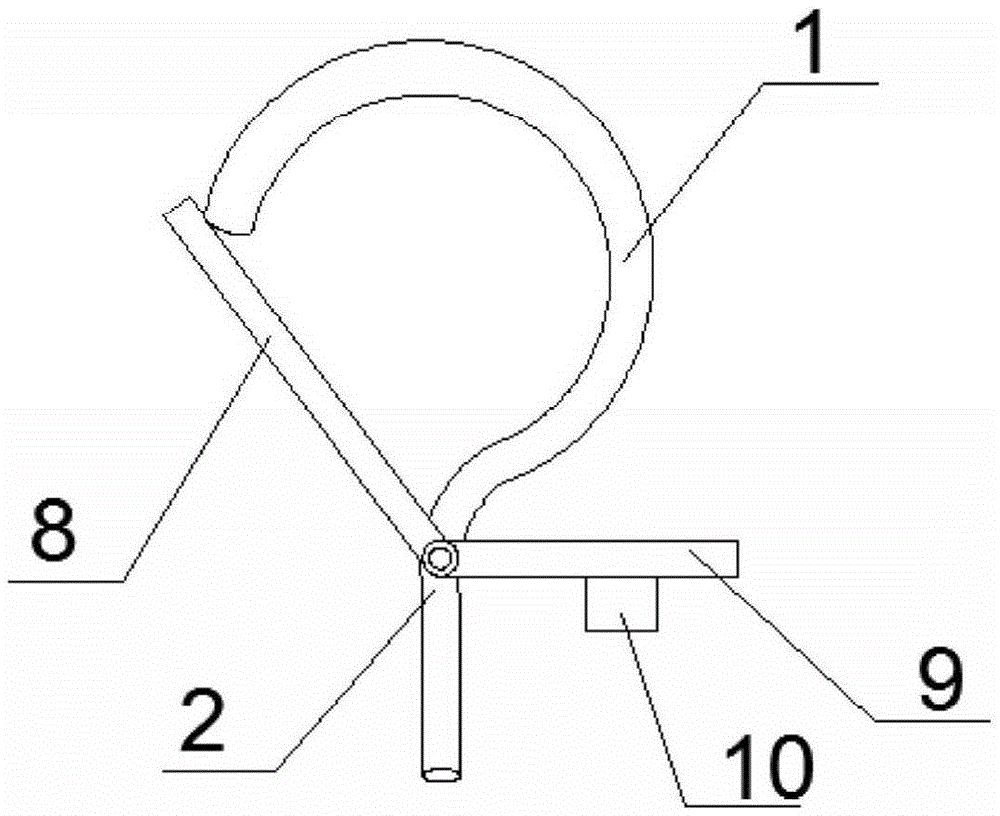

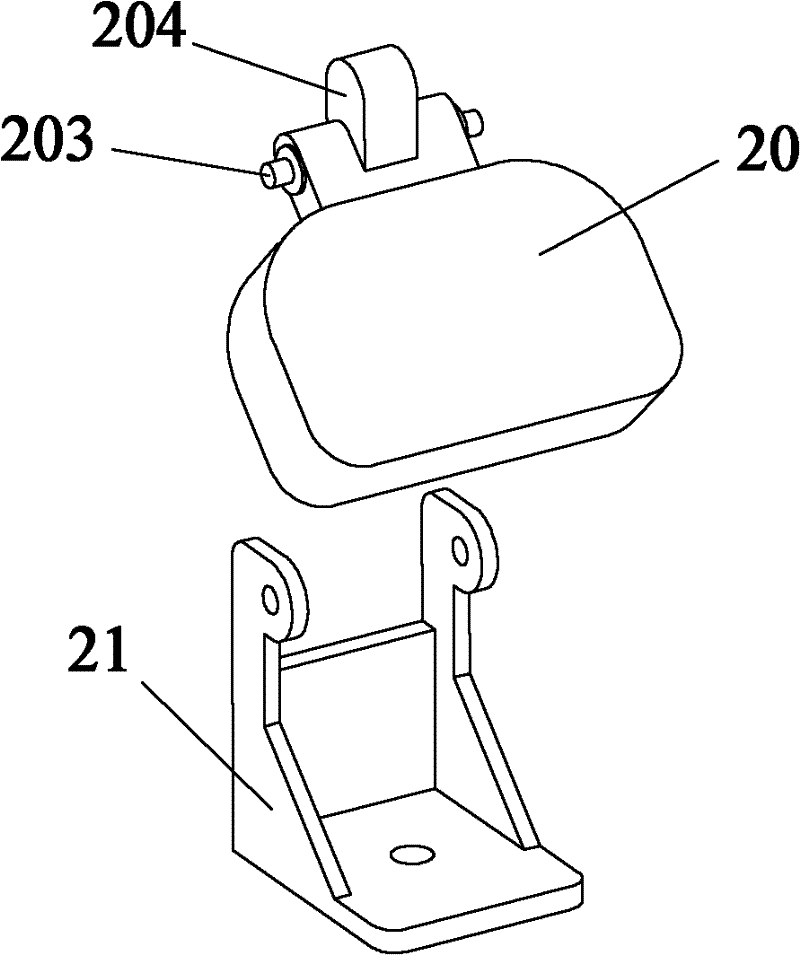

Detachable floater type water valve device and humidifier

InactiveCN102410386AEffective controlNo need to increase drive powerOperating means/releasing devices for valvesSpace heating and ventilation safety systemsWater levelCheck valve

The invention discloses a detachable floater type water valve device. The floater type water valve device comprises a valve part and a floater part, and the valve part is separated from the floater part; the valve part is a check valve, and comprises a valve seat and a spool structure running through the center of the valve seat, and the lower end of the spool structure is provided with a cambered surface; the floater part comprises a pivotally arranged lever type floater structure, which comprises a floater at one side of a pivot and an abutting part at the other side of the pivot, and the end part of the abutting part is provided with a cambered surface, which correspondingly abuts against the cambered surface of the spool structure; and the floater can be rotated with the pivot as the axis according to the change of water level to drive the abutting part to slide to push the cambered surface of the spool structure, so that the valve part can be opened and closed. The detachable floater type water valve device utilizes the floater and the leverage to open and close the valve.

Owner:BEIJING YADU INDOOR ENVIRONMENT PROTECTION TECH

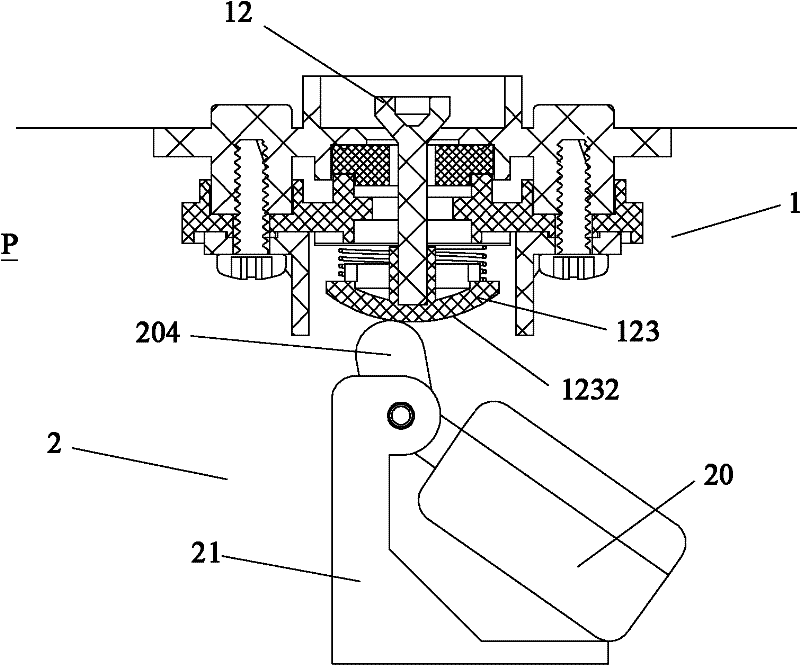

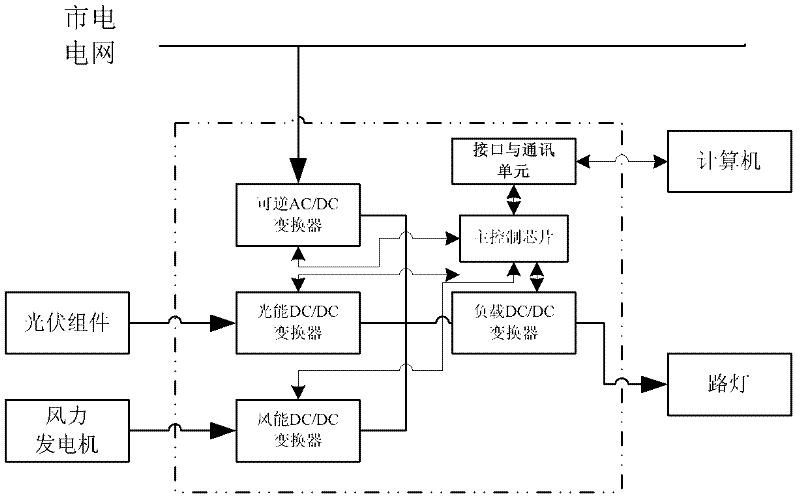

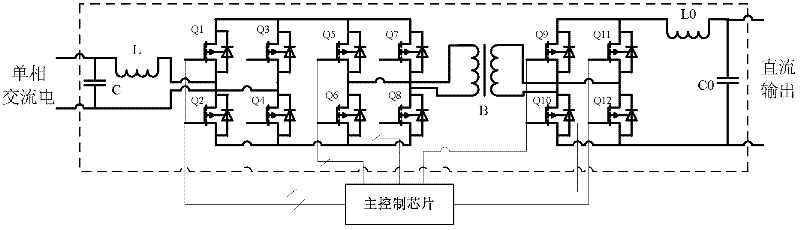

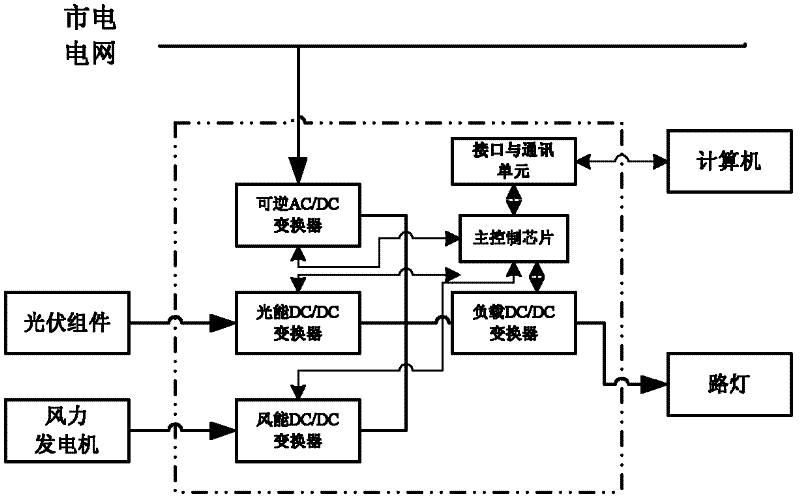

Controller for grid-connected generating wind solar complementary street lamp system

The invention provides a controller for a grid-connected generating wind solar complementary street lamp system, which can combine a wind solar complementary generating system and a mains supply power grid. First, the wind solar complementary generating system supplies power to a street lamp and feeds redundant electrical energy to the mains supply power grid. When wind solar electric energy production can not meet requirements of normal work of the street lamp, the mains supply power grid supplies power to the street lamp so that mains supply is saved, and normal work of the street lamp is guaranteed. A special storage battery is not required to be configured in the wind solar complementary generating system, and cost is reduced. The controller comprises a main control chip, a wind energy direct current (DC) / DC converter connected with a wind driven generator connected with the main control chip in bi-directional mode, a luminous energy DC / DC converter connected with a photovoltaic assembly, a load DC / DC converter connected with the street lamp and a reversible alternating current (AC) / DC converter connected with the mains supply power grid. The street lamp is respectively connected with the luminous energy DC / DC converter, the wind energy DC / DC converter and the reversible AC / DC converter respectively through the load DC / DC converter.

Owner:湖南终南山科技发展有限公司

Soybean processing equipment

The invention discloses a soybean processing equipment, which comprises a screening mechanism, a washing mechanism, a drying mechanism and a sterilizing mechanism. The horizontal groove on one side surface, the screen mesh hinged in the horizontal groove, the vertical groove opened on the other side surface of the screening box, the multiple screens arranged on the inner upper surface of the vertical groove and the telescopic end connected to the other end of the screen mesh The telescopic motor, the outlet one opened on one side of the screening box and located in the vertical groove, and the connecting pipe connected to the outlet one are jointly formed. The side surface of the screening box is provided with a PLC control system, and the PLC control system is respectively It is electrically connected with the screening mechanism, the washing mechanism, the drying mechanism and the sterilizing mechanism. The beneficial effects of the invention are that the structure is simple, the use is convenient, the automation is strong, the soybeans can be automatically screened, and the cleaning, drying and disinfection treatment is carried out, the work efficiency is improved, and time is saved.

Owner:湖南天爱农业科技有限公司

Continuous cast welding device for busbar and pole columns of lead-acid battery

The invention provides a continuous cast welding device for a busbar and pole columns of a lead-acid battery. The continuous cast welding device comprises a rack. The rack is provided with a cast welding device, a cooling device of a cast welding die, a demolding device of the cast welding die and a pole group clamp, a cast welding die temperature rising device, a pole group slotting device and a clamp return roller table. An outlet of the cast welding device is connected with an inlet of the cooling device. An outlet of the cooling device is connected with an inlet of the demolding device. The outlet of the cast welding die of the demolding device is connected with an inlet of the cast welding die temperature rising device. A pole group clamp outlet of the demolding device is connected with a pole group inlet of the pole group slotting device. A clamp outlet of the pole group slotting device is connected with an inlet of the clamp return roller table through a clamp overturning and lifting device. The continuous cast welding device can meet the requirements of cast welding of lead-acid batteries of various types such as the automobile starting type, the valve control sealing type and the tubular positive plate type and used for traction vehicles, the high-degree automation of cast welding production can be achieved, and the time of the cast welding process is shortened greatly.

Owner:刘凡

Food packaging technology

ActiveCN105235946AEasy to storeEasy to transportWrapper twisting/gatheringMaterial resourcesEngineering

The invention discloses a food packaging technology and relates to the technical field of the food packaging technology. The food packaging technology includes a material conveying step, a material overturning and arranging step, a material sorting step, a bag taking step, a bag opening step and a packaging step. According to the packaging technology, after food is packaged in small bags through an outer packaging machine, the small bagged food is overturned, arranged, sorted and laminated; and finally, the small bagged food is packaged into food packaged in large bags. The whole technologic process is full automatic and mechanical, manual packaging is not needed, and a large amount of manpower and material resources are saved. The packaging technology is high in automatic and mechanical degree, packaging efficiency can be improved easily, and storage and transportation of the food packaged in bags are facilitated.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

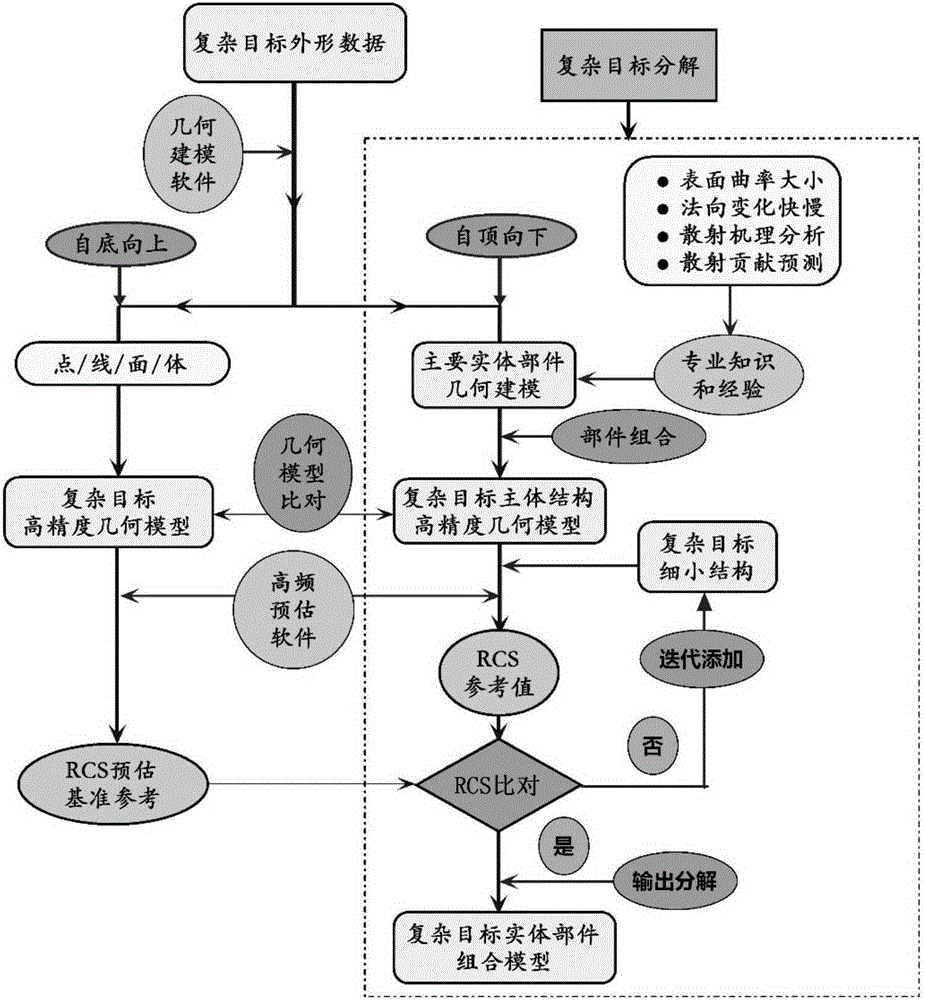

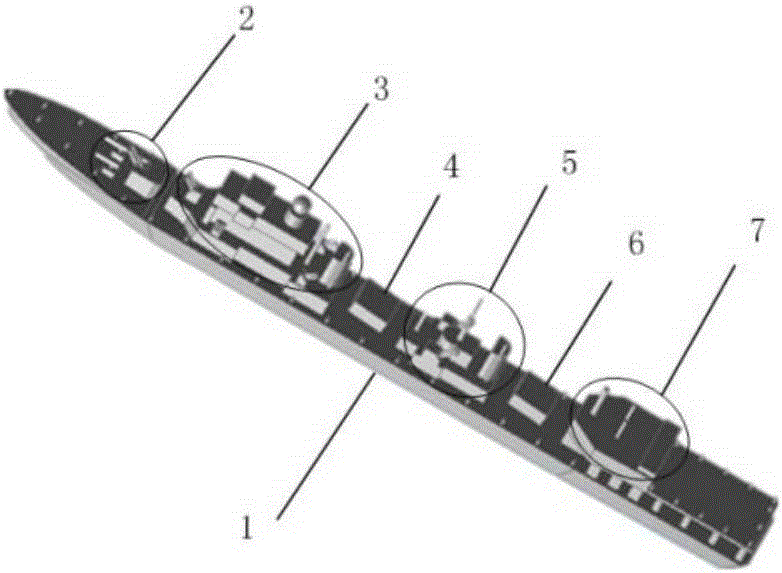

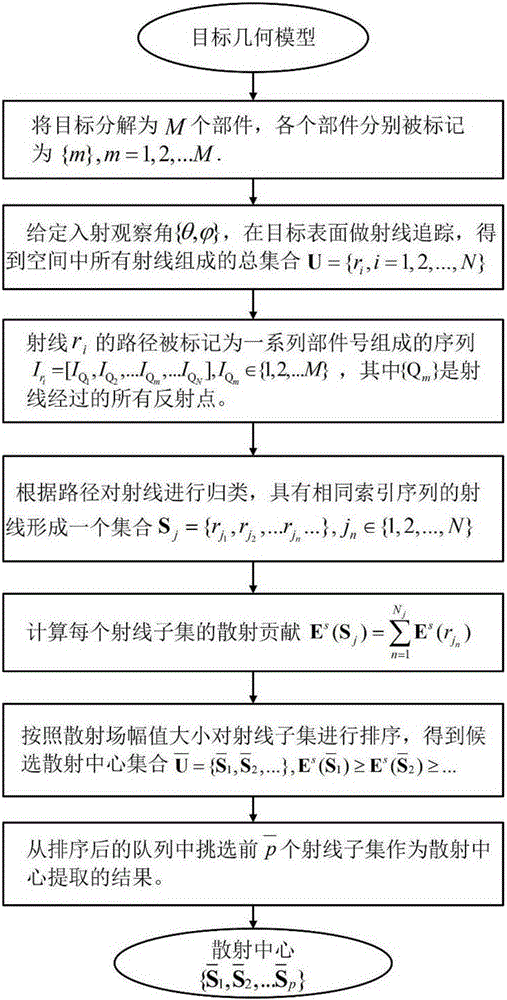

Analysis method for stable scattering structure of ship

InactiveCN105259547AQuick extractionStrong automationWave based measurement systemsStructure analysisParticle physics

The invention relates to an analysis method for a stable scattering structure of a ship. An entity part of the ship is decomposed, an entity model of a geometrical structure of the ship is divided into 6 areas, the paths of all rays in the space are marked by tracking the rays, the rays are classified and clustered according to the paths, echo response of different parts is separated to obtain a scattering source of a complex fine ship model, and the strong scattering source is ordered and screened according to a determination result of the scattering source. RCS contribution change of the assigned scattering source within the wide angle range is checked to extract the stable scattering source, mapping relation between the entity part and the target scattering feature is established, and an effective auxiliary approach is provided for feature analysis of the highly-fine complex geometrical model of the ship. The method can be used to extract the scattering source in all angles of the complex target rapidly, the stable scattering source is obtained from analysis, and the method is suitable for different types of targets.

Owner:WUHAN UNIV

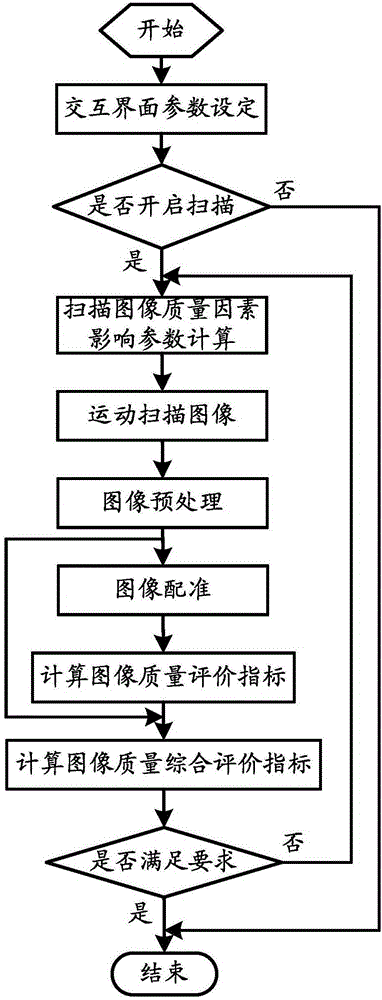

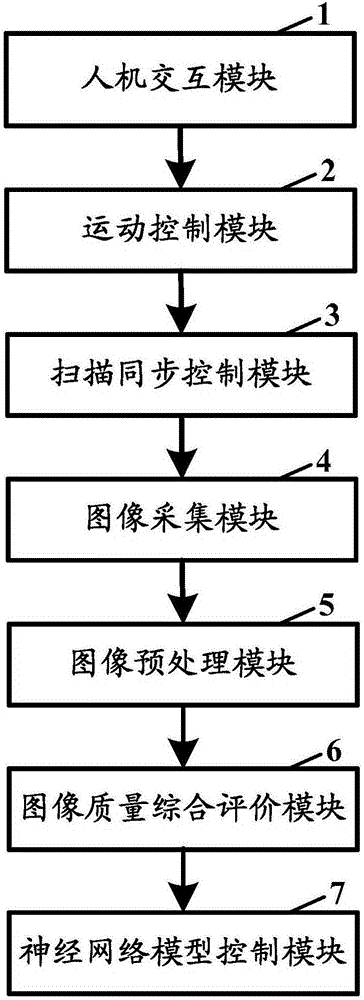

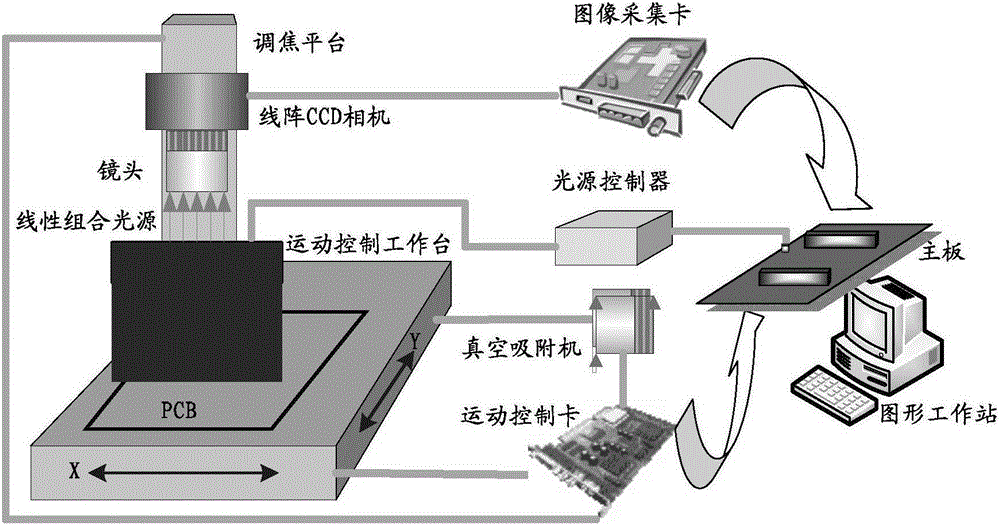

Self-adaptive control method and system oriented to fast scan of image with optimal quality

ActiveCN105227802AStrong automationIntelligentPictoral communicationImaging processingImaging quality

The invention is applicable to the field of image processing and provides a self-adaptive control method. The self-adaptive control method comprises the steps: A, setting interactive interface parameters, and configuring an expected image quality comprehensive evaluation index and a threshold condition; B, calculating image scanning quality affecting factor parameters according to the expected image quality comprehensive evaluation index; C, according to the factor parameters, scanning an image to obtain a scanned image and pre-processing the scanned image to obtain a post-scanning image; D, calculating the post-scanning image and a corresponding standard image to obtain an image quality comprehensive evaluation index; E, comparing the image quality comprehensive evaluation index with the expected image quality comprehensive evaluation index to obtain an optimal scanning factor parameter; F, scanning the image according to the optimal scanning factor parameter. According to the self-adaptive control method, a complex nonlinear system can be controlled to scan the image, to calculate the image quality comprehensive evaluation index, and to control the image scanning quality affecting factor parameters, thereby obtaining an optimal scanned image which is applied to the following image processing.

Owner:SHENZHEN UNIV

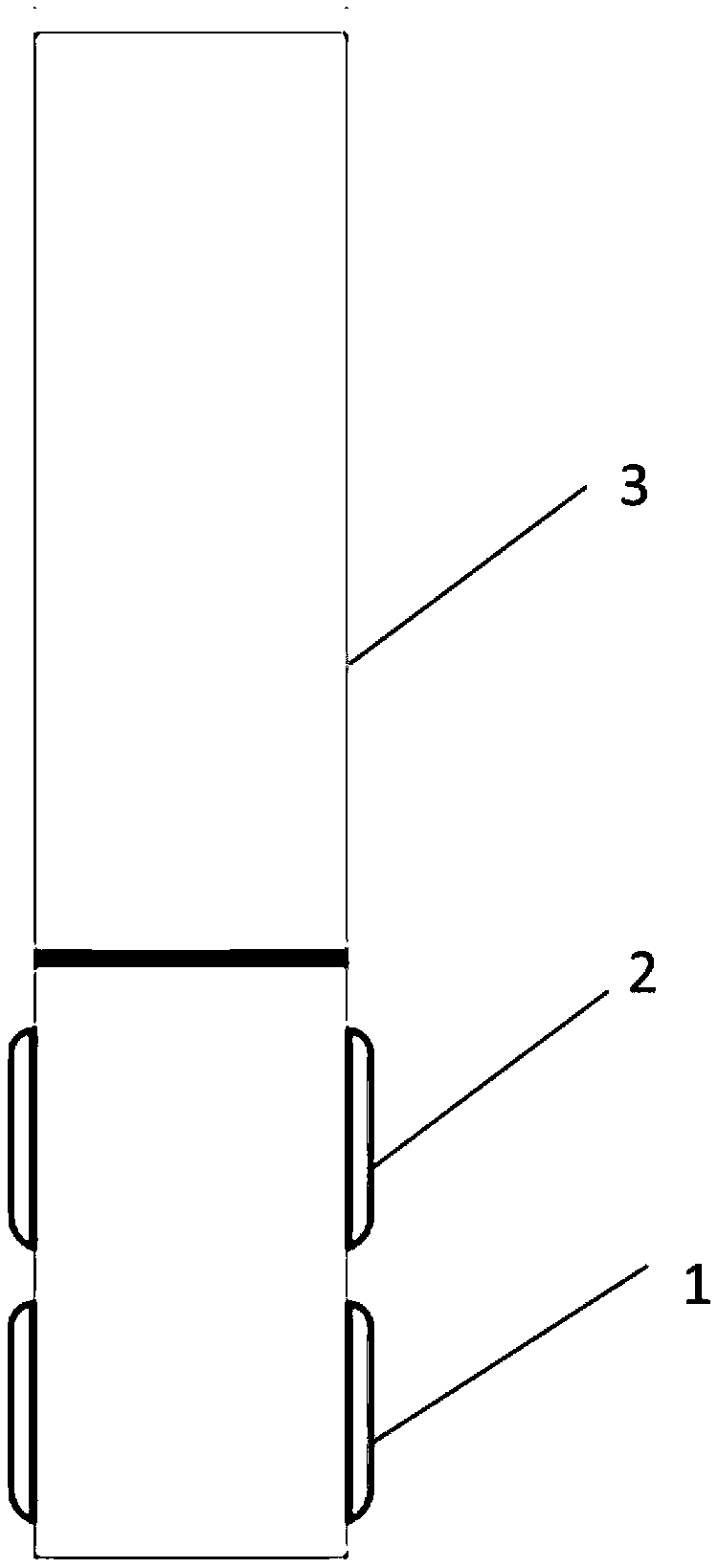

Self-plugging audio test jig, and self-plugging audio test method

The present invention discloses a self-plugging audio test jig, and a self-plugging audio test method. The jig comprises an audio plug fixed in a whistle box and a container going in and out the whistle box. When the container goes in or out the whistle box, the audio plug can be plugged in or out. The method comprises the steps of placing a to-be-tested terminal in the container, enabling the container to enter the whistle box to plug an audio interface automatically, carrying out the audio test, plugging out the audio interface automatically when the container quits, etc. According to the present invention, the thrust generated by that the container goes in or out the whistle box drives the to-be-tested terminal to plug in or out the plug, so that the test automation and usability are guaranteed, the cost is reduced, and the test efficiency is improved.

Owner:南京声准科技有限公司

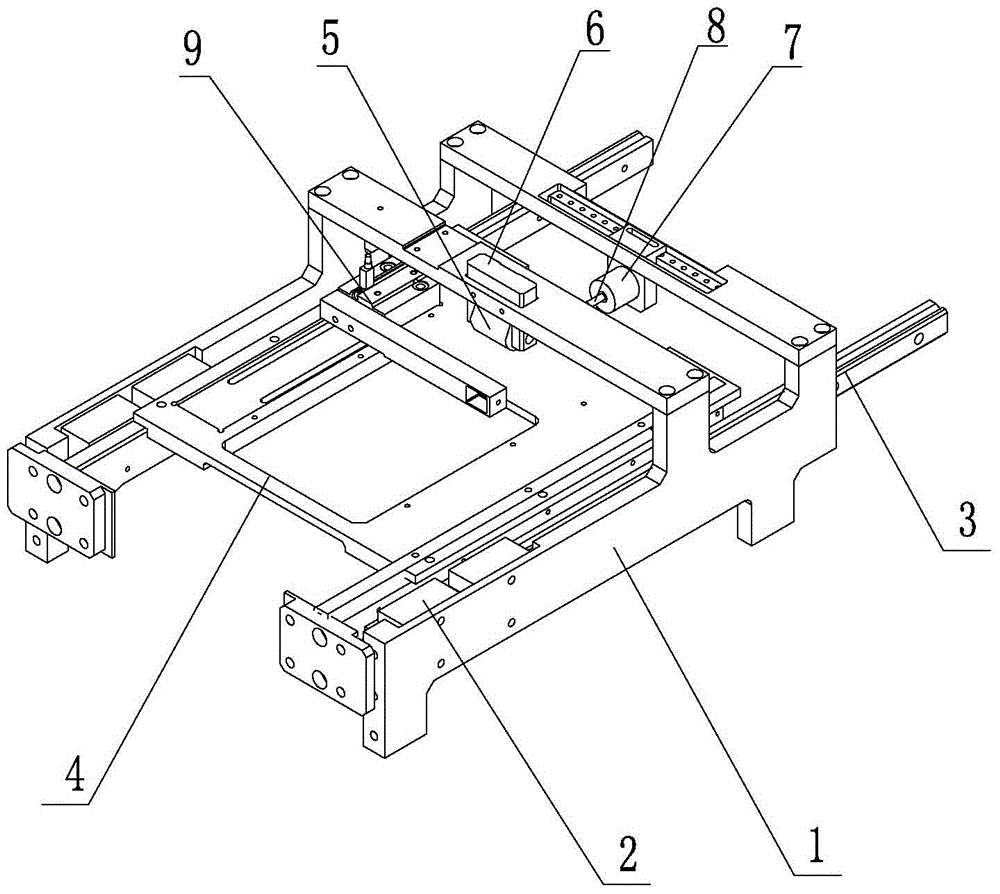

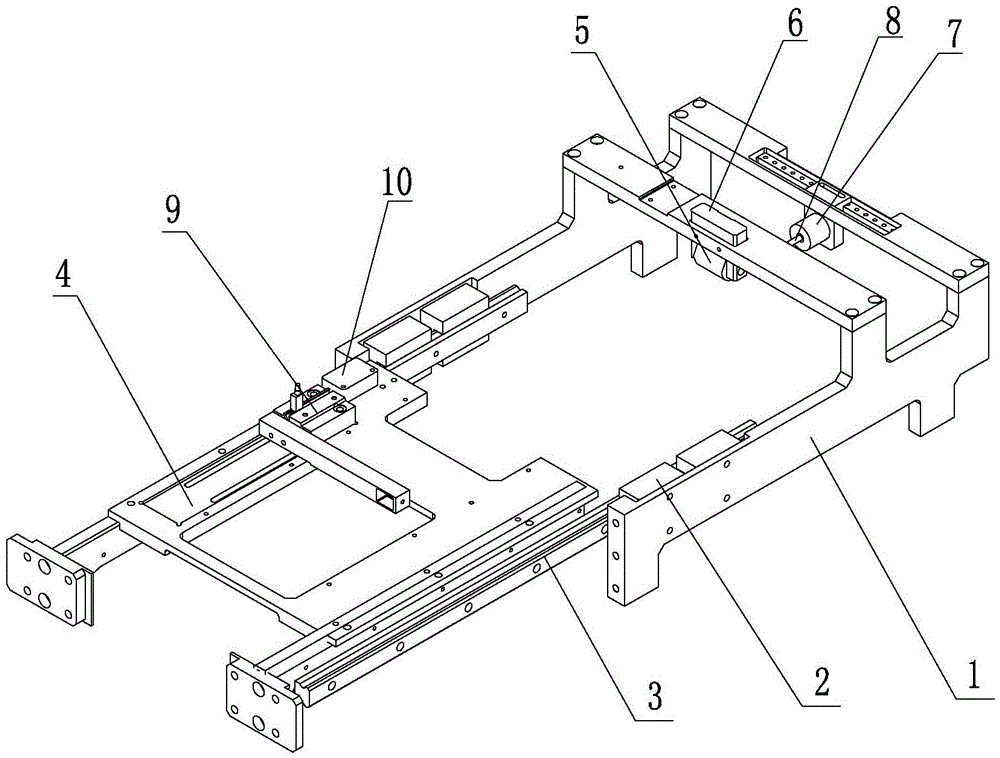

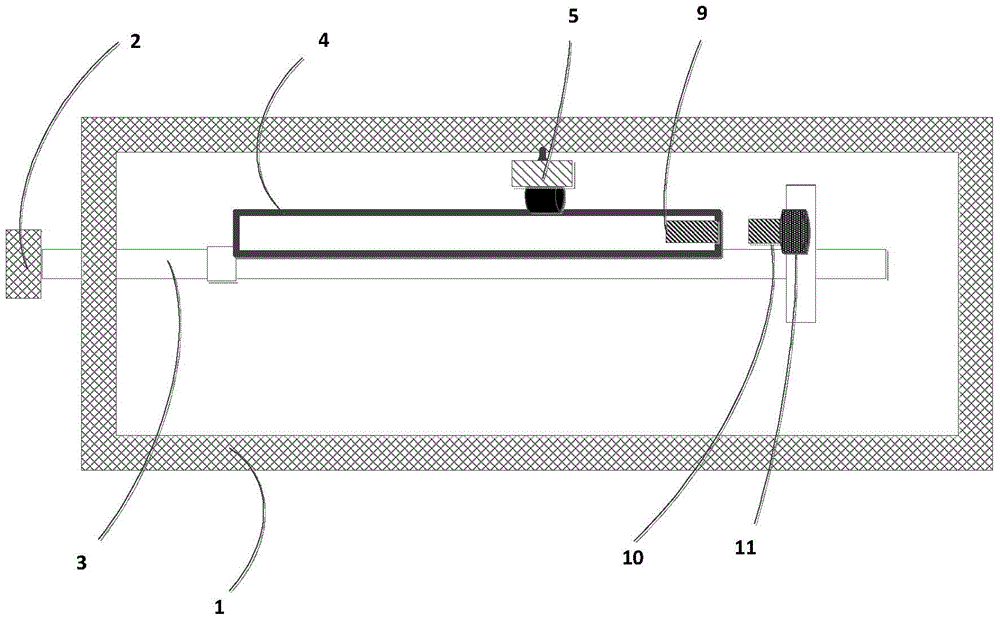

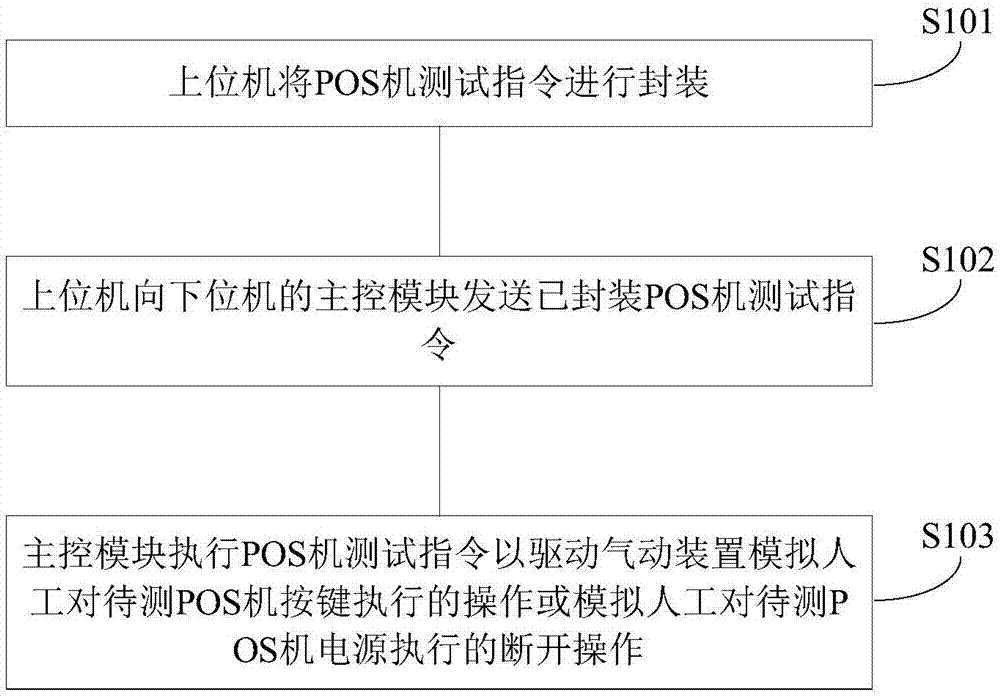

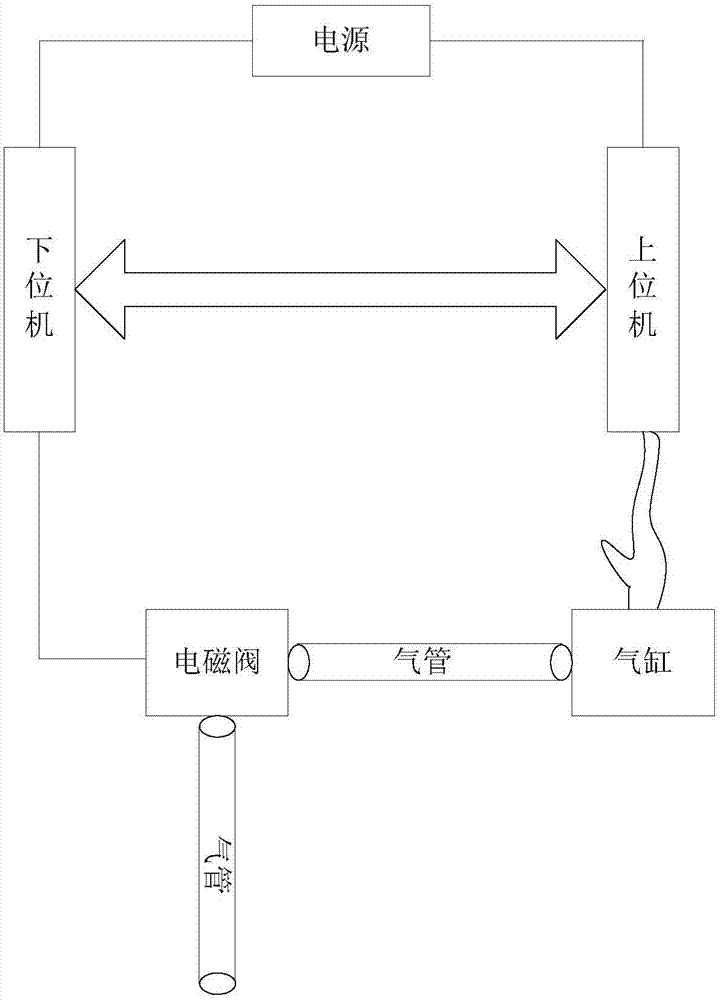

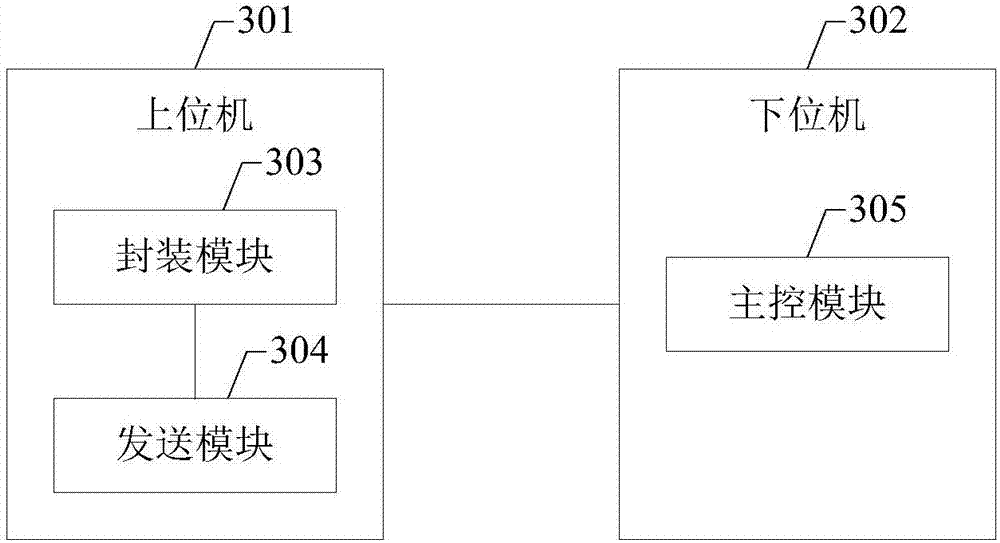

Method and device for testing POS machine, computer readable storage medium and terminal device

The invention relates to the field of financial equipment manufacturing and providing a method and device for testing a POS machine, a computer readable storage medium and a terminal device so as to reduce the cost of a POS machine test and improve the efficiency and correctness of the POS machine test. The method comprises the steps that: a host machine packages a POS machine test instruction; the host machine sends the packaged POS machine test instruction to a master control module of a lower machine; and the master control module executes the POS machine test instruction to drive a pneumatic device to simulate an artificial operation executed for POS machine keys to be tested or simulate an artificial disconnection operation executed for the POS machine power supply. The invention provides a technical scheme, on one hand, an operation that a computer executes an instruction is much than a manual operation in the aspect of automation, on the other hand, since a machine can tirelessly work tirelessly and continuously, the efficiency is higher than that of a manual test, the accuracy is better than that of the manual test, and thus the cost of the POS machine test is greatly reduced.

Owner:PAX COMP TECH SHENZHEN

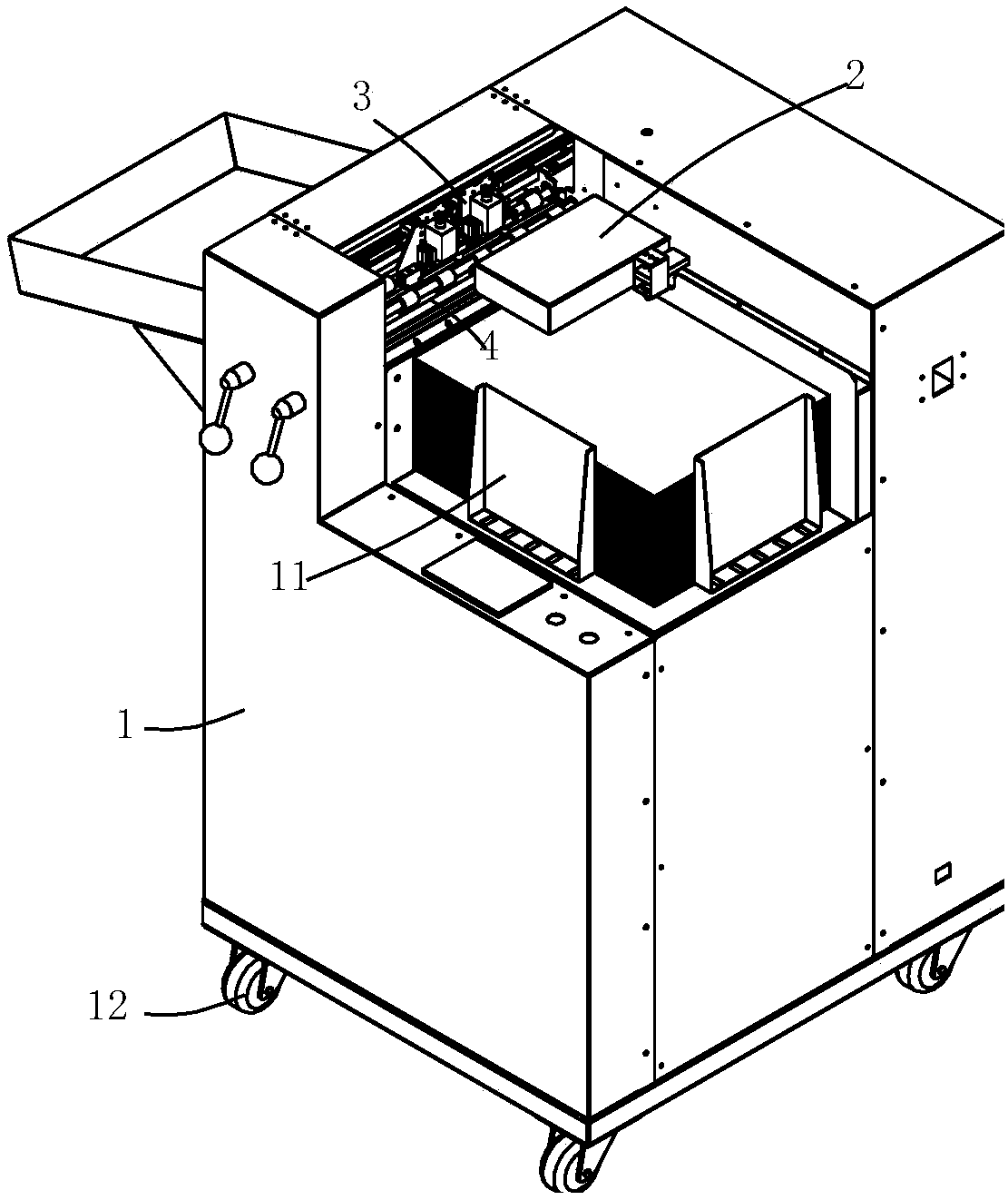

Digital page type label die cutting machine

PendingCN108098920ANot easy to fall offNo mechanical damageMetal working apparatusArticle feedersPaper sheetLarge capacity

The invention relates to a digital page type label die cutting machine. The digital page type label die cutting machine comprises a machine body. A large-capacity fed paper storage area is arranged atthe bottom of the machine body. An updraft paper feeding mechanism is arranged above the large-capacity fed paper storage area. A double-cutter die cutting structure is arranged on one side of the updraft paper feeding mechanism. A double-roller paper conveying structure is arranged below the double-cutter die cutting structure, the number of paper sheets can be as big as 1000, and the cutting size is 340*800 mm. The digital page type label die cutting machine has the function of double machine head interval automatic adjustment, and is a novel application of the digital die cutting technology and the updraft paper feeding technology in the label die cutting industry.

Owner:NINGBO VOREY TECH CO LTD

Automatic detecting and sorting device for insertion and extraction force of special ceramic sleeves

The invention provides an automatic detecting and sorting device for insertion and extraction force of special ceramic sleeves. The automatic detecting and sorting device comprises a frame, wherein a base is arranged on the frame; a feeding mechanism, a sorting mechanism and a detecting mechanism are arranged on the base; the detecting mechanism comprises a baffle plate, a detecting plug gauge, a linear bearing, a detecting base, an insertion and extraction force detecting sensor, a ball screw module and a drive step motor, wherein a sleeve with an opening on the center is arranged on the baffle plate; the baffle plate is fixedly connected with the ball screw module by a bolt; the detecting base is arranged on a movable block of the ball screw module; the linear bearing is arranged on the detecting base; the insertion and extraction force detecting sensor is further fixedly arranged on the detecting base; the detecting plug gauge is sleeved on the linear bearing; the tail end of the plug gauge is connected with the insertion and extraction force sensor in a contacting manner; and the drive step motor is fixedly arranged at one side of the ball screw module on the base. The automatic detecting and sorting device provided by the invention fully-automatically and intelligently realizes the insertion and extraction force detection of the special ceramic sleeves, and improves the sorting precision and efficiency.

Owner:ZHEJIANG SCI-TECH UNIV

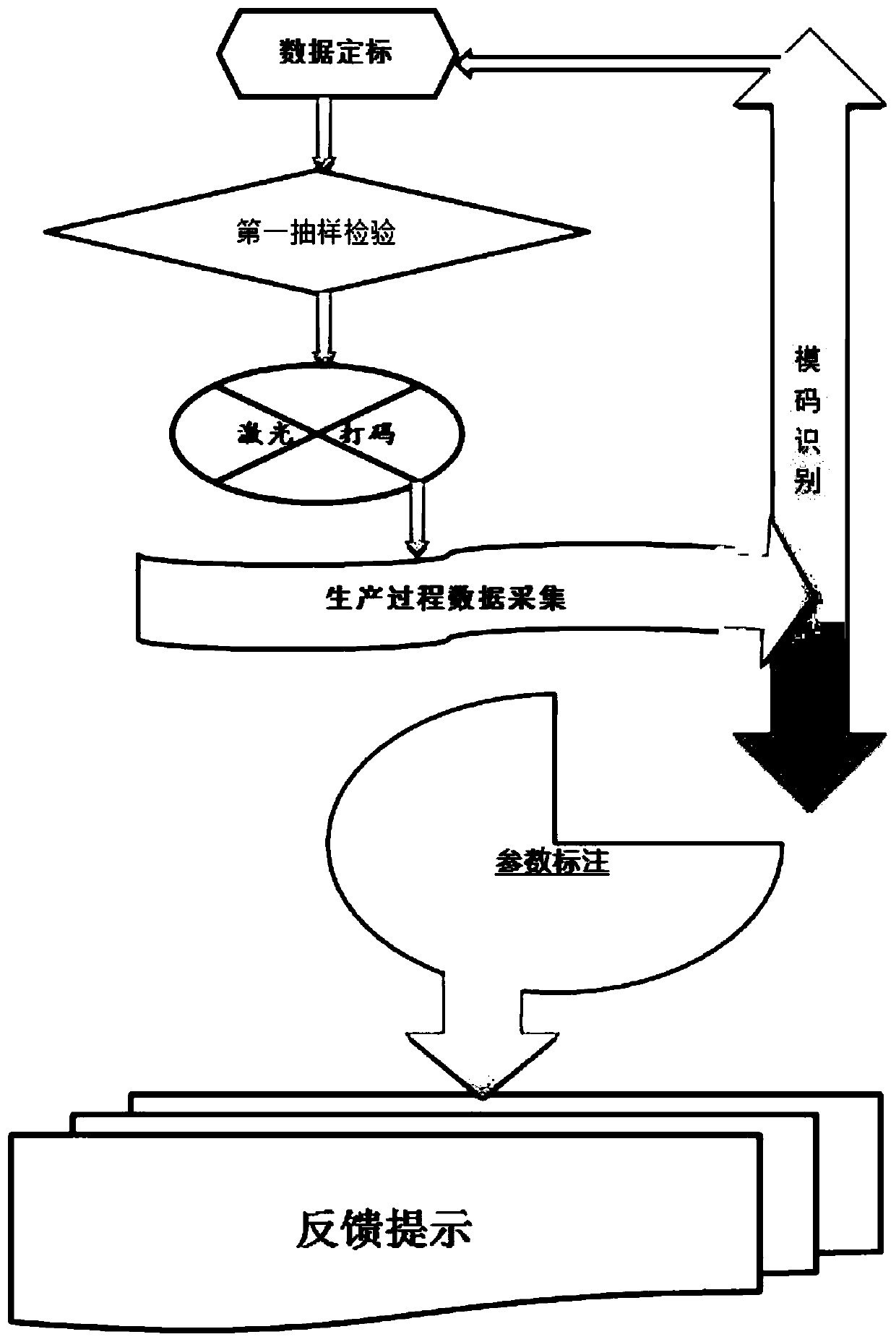

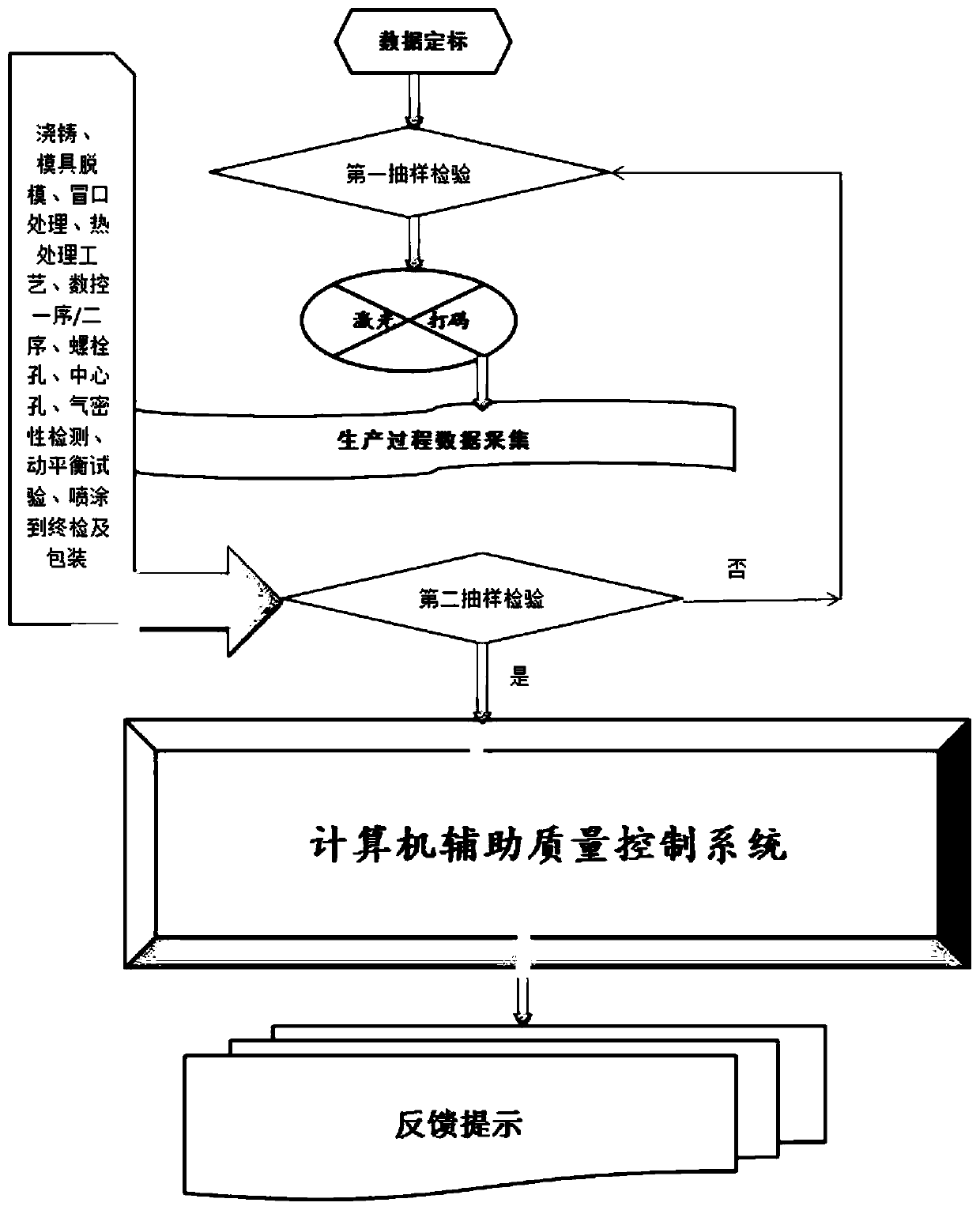

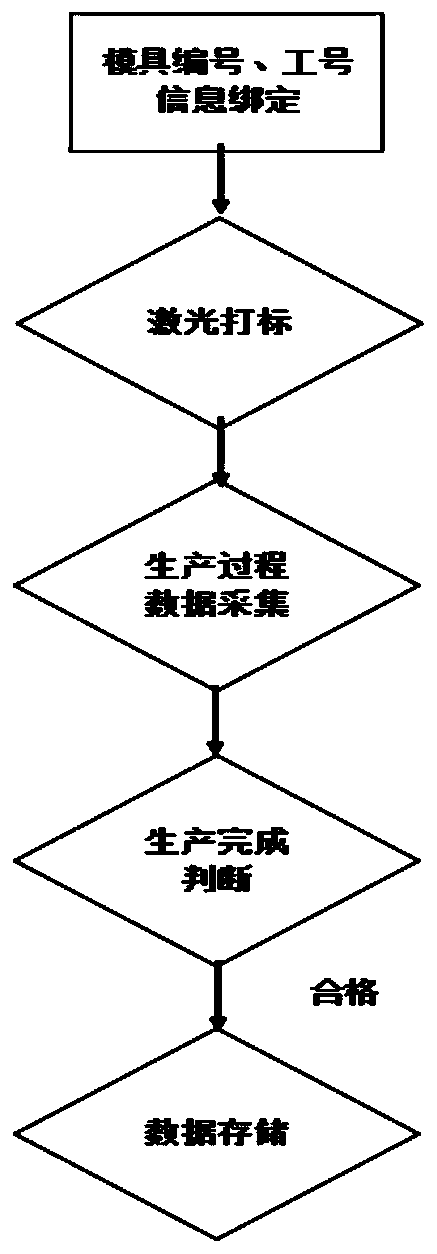

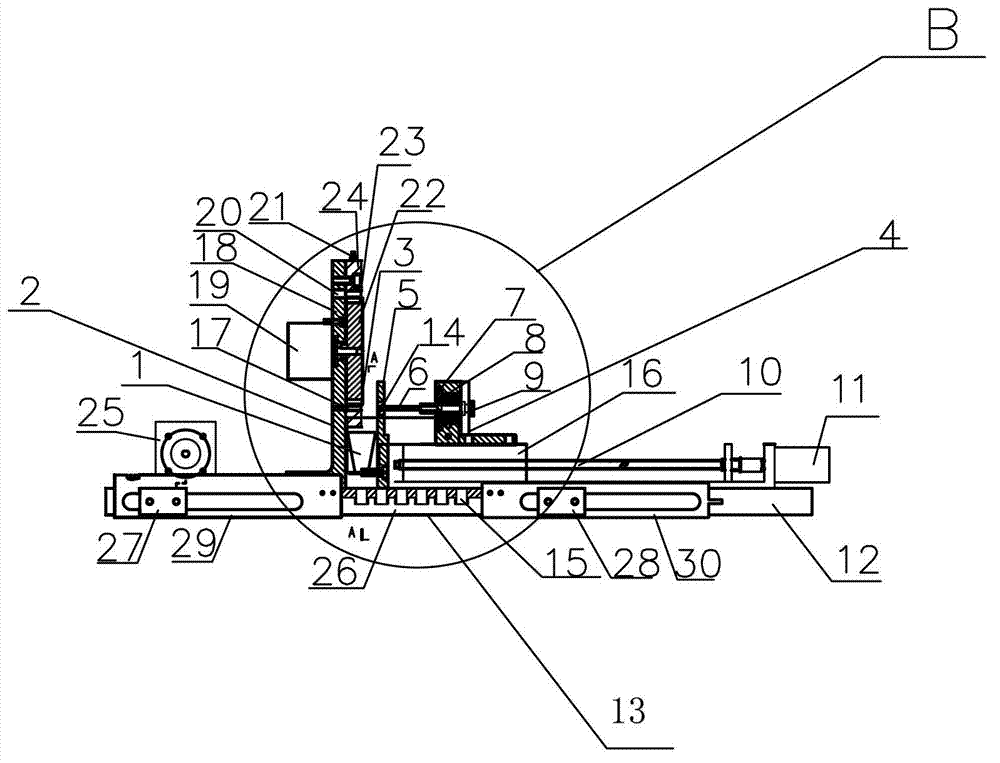

Computer-aided quality control method for hub production data

ActiveCN110852558AIncrease productivityRealize traceabilityMeasurement devicesCasting safety devicesComputer-aidedQuality control

The invention provides a computer-aided quality control (CAQC) method of wheel hub production data and a corresponding computer-aided quality control system. By the adoption of the method, the mode that in the traditional hub manufacturing process, quality inspection can only pass after-treatment inspection is changed, and process improvement and online quality control are conducted in the manufacturing process; meanwhile, a computer-aided control system is introduced, and problems are found and solved in the process of process improvement and online quality control; by means of the computer-aided control system, production data corresponding to multiple complex processes of hub production design can be recorded in detail, and when the production data is abnormal, feedback suggestions canbe found and given in time through production data encoding and parameter labeling processes, so that data inspection and tracing can be achieved in the production process.

Owner:连云港耀科铝业有限公司

Special ceramic bushing insertion/extraction force automatic detection sorter and using method thereof

Owner:ZHEJIANG SCI-TECH UNIV

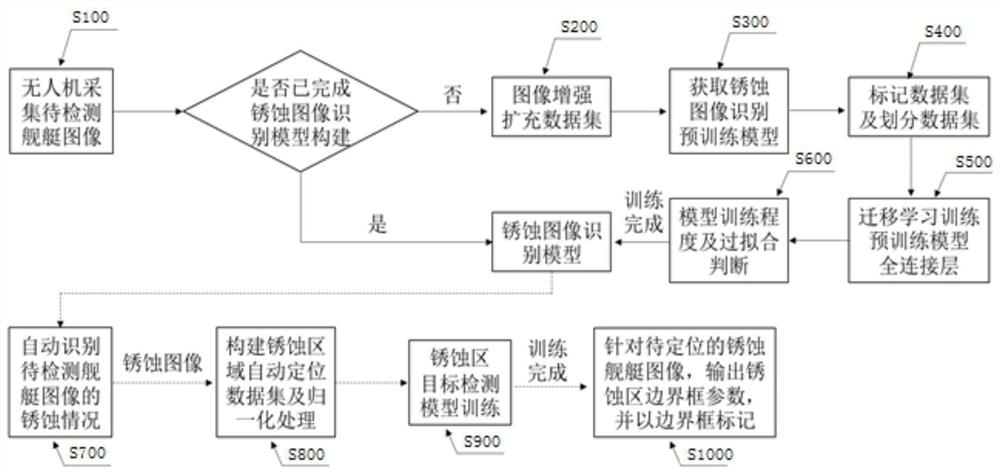

Deep inspection method for automatic identification of ship corrosion area

ActiveCN113065446AIncrease costStrong automationCharacter and pattern recognitionNeural architecturesData setAlgorithm

The invention relates to a deep inspection method for automatic identification of a ship corrosion area, wherein the method comprises the steps: building a pre-training image identification model and a corrosion image automatic identification model, then labeling a large number of ship images, and training the corrosion image automatic identification model through a part of images with labels; inputting a plurality of to-be-detected ship images into the trained model, reserving the images marked with corrosion labels, and marking a corrosion area bounding box, wherein the marked images form a corrosion area positioning data set; establishing a corrosion area target detection model, and training the model by using part of the images in the corrosion area positioning data set; and finally, inputting a to-be-positioned rusted ship image into the trained corrosion area target detection model, outputting bounding box parameters of a corrosion area, and marking the position of the corrosion area by using a bounding box. According to the method, an integrated process from ship image acquisition to corrosion area automatic positioning is realized, a deep learning image recognition algorithm and a target detection algorithm are fused, and the method is very intelligent.

Owner:青岛东坤蔚华科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com