Automatic detecting and sorting device for insertion and extraction force of special ceramic sleeves

A technology of automatic detection and special ceramics, which is applied in sorting and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

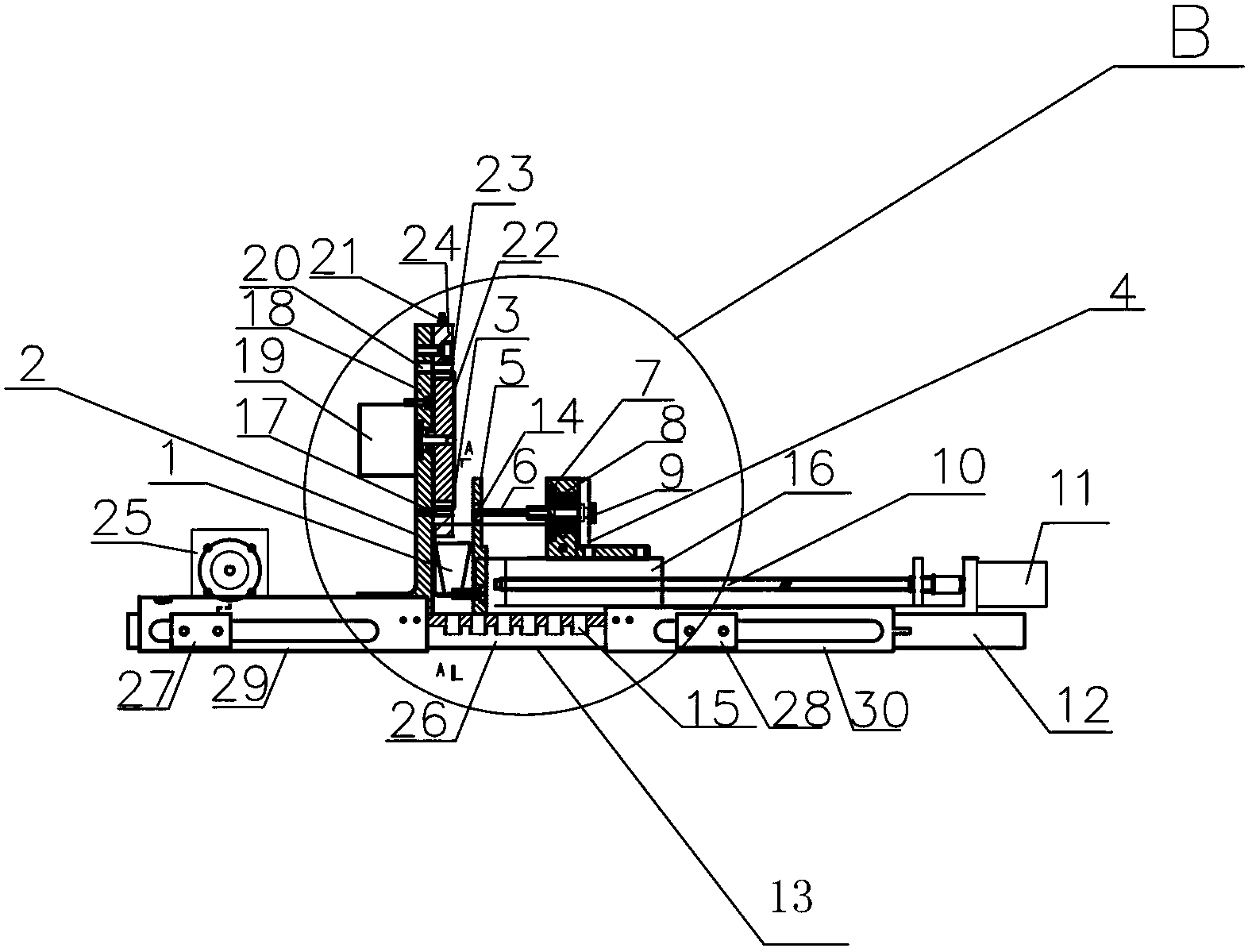

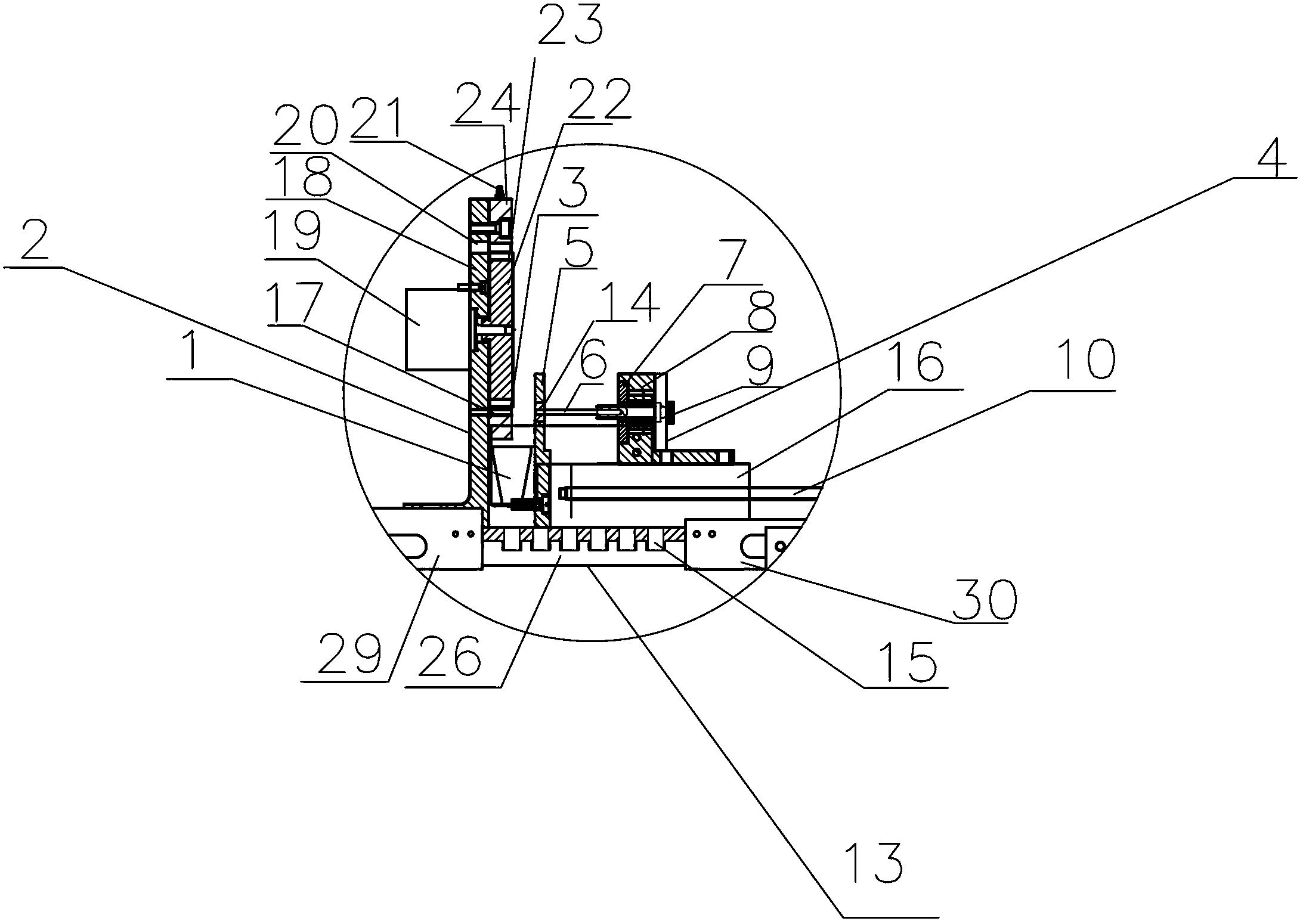

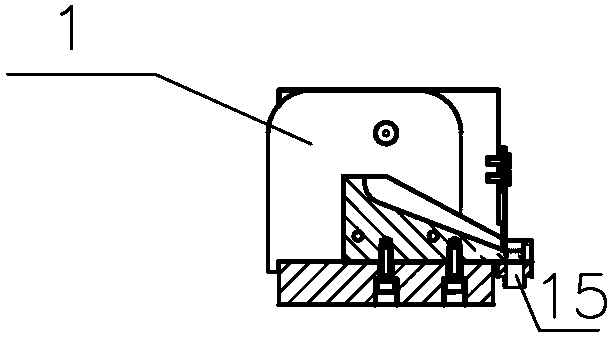

[0022] Such as figure 1 , 2 As shown, a special ceramic bushing insertion and extraction force automatic detection and classification device of this embodiment includes a frame, a base 12 is installed on the frame, and a feeding mechanism 2 and a classification mechanism are installed on the base 12. 13 and a detection mechanism 4; the feeding mechanism 2 is provided with a detection port 3; the classification mechanism 13 is provided with a distribution port 15; the detection mechanism includes a baffle plate 5, a detection plug gauge 6, a linear bearing 7. Detection base 8, insertion force detection sensor 9, ball screw module 10) and driving stepping motor 11; wherein said base 12 is equipped with baffle plate 5, ball screw module 10; said A sleeve 14 with a central opening is installed on the baffle 5; the baffle 5 is fixedly connected with the ball screw module 10 through bolts; the movable block 16 on the ball screw module 10 is installed with A detection base 8, a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com