Automatic inner plug locating and installing mechanism

An automatic positioning and inner plug technology, which is applied in the directions of closing plugs, conveyor objects, and sealing with plugs, etc., can solve problems such as low work efficiency, and achieve the effect of improving work efficiency, ensuring stability, and convenient for inner plugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] To make the present invention easier to understand, specific embodiments of the present invention will be further described below.

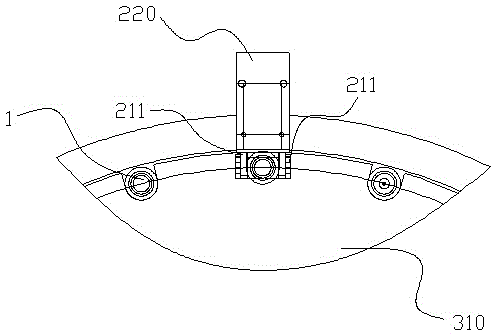

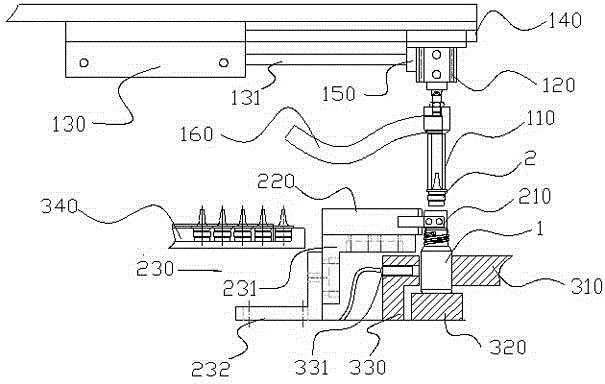

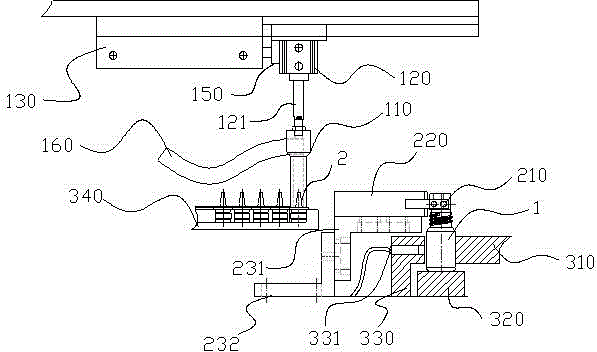

[0020] Such as figure 1 As shown in 2, 3, the automatic positioning upper plug mechanism of the present invention is mainly an automatic mechanism for plugging bottle products, including a manipulator system 100, a bottle mouth positioning system 200, a conveying system 300 and a control system ( Not marked in the picture).

[0021] Among them, the manipulator system 100 mainly moves the inner stopper 2 of the bottle 1 from the stopper removal station to the upper stopper station, and installs the inner stopper 2 into the bottle mouth of the bottle 1. The manipulator system 100 mainly uses the inner stopper suction hand 110 to grasp Take the inner stopper 2, pick up the inner stopper 2, and then move it to the top of the bottle 1, put the inner stopper 2 into the bottle mouth, and then loosen the inner stopper 2 to complete the inner stopper 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com