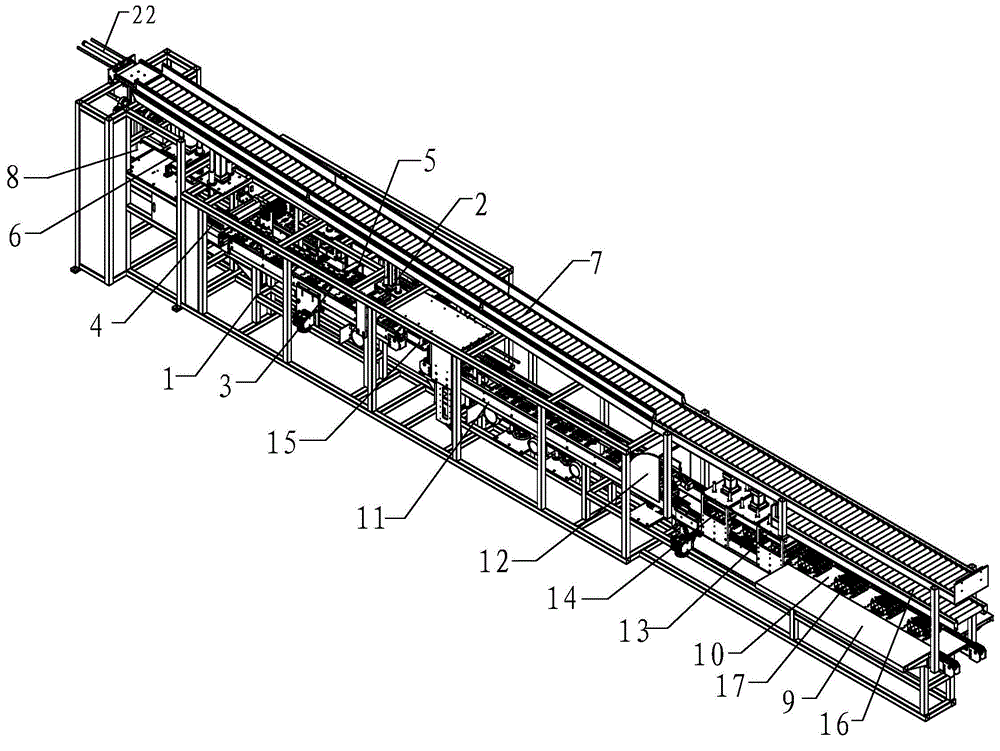

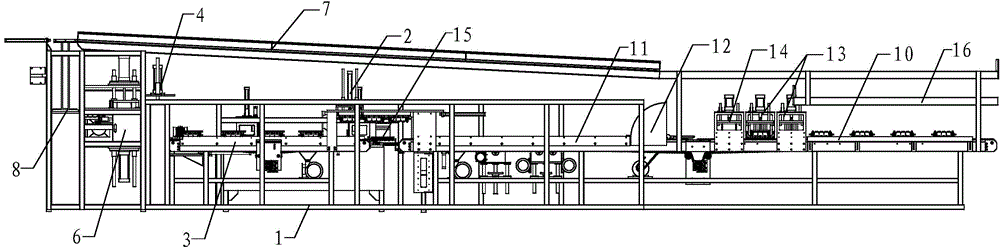

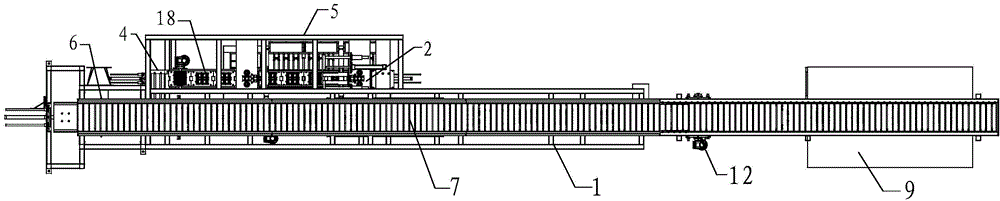

Continuous cast welding device for busbar and pole columns of lead-acid battery

A lead-acid battery and busbar technology, which is applied in the field of lead-acid battery casting and welding, can solve problems such as shortening casting time, and achieve the effects of achieving high automation, shortening cycle time, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Example: The applicant designed the battery as 6 single-cell 12V electric bicycle battery pole groups of the type 6DZM10, put them into a special pole group fixture, aligned the tabs of each pole group and pressed the pole group tightly , put the fixture into the casting welding equipment of the present invention, the equipment first automatically performs tab shaping, side tab bending, flat tab, brushing off the oxide attached to the surface of the tab and automatically brushing the casting flux to complete Preparation for casting and welding. At the same time, multiple casting and welding molds enter the heating slideway of the lead melting furnace to preheat and heat up.

[0042] The completion time of each process in the first production cycle after the equipment is started is as follows:

[0043] Casting and welding mold heating: 30 seconds;

[0044] Cast welding: 7 seconds;

[0045] Mold and busbar cooling after casting: 24 seconds;

[0046] Demoulding between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com