Digital page type label die cutting machine

A die-cutting machine and page-type technology, which is applied in object supply, metal processing, pile separation, etc., can solve the problems of time-consuming adjustment, large waste of materials, etc., and achieve the effect of not easy to fall off mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

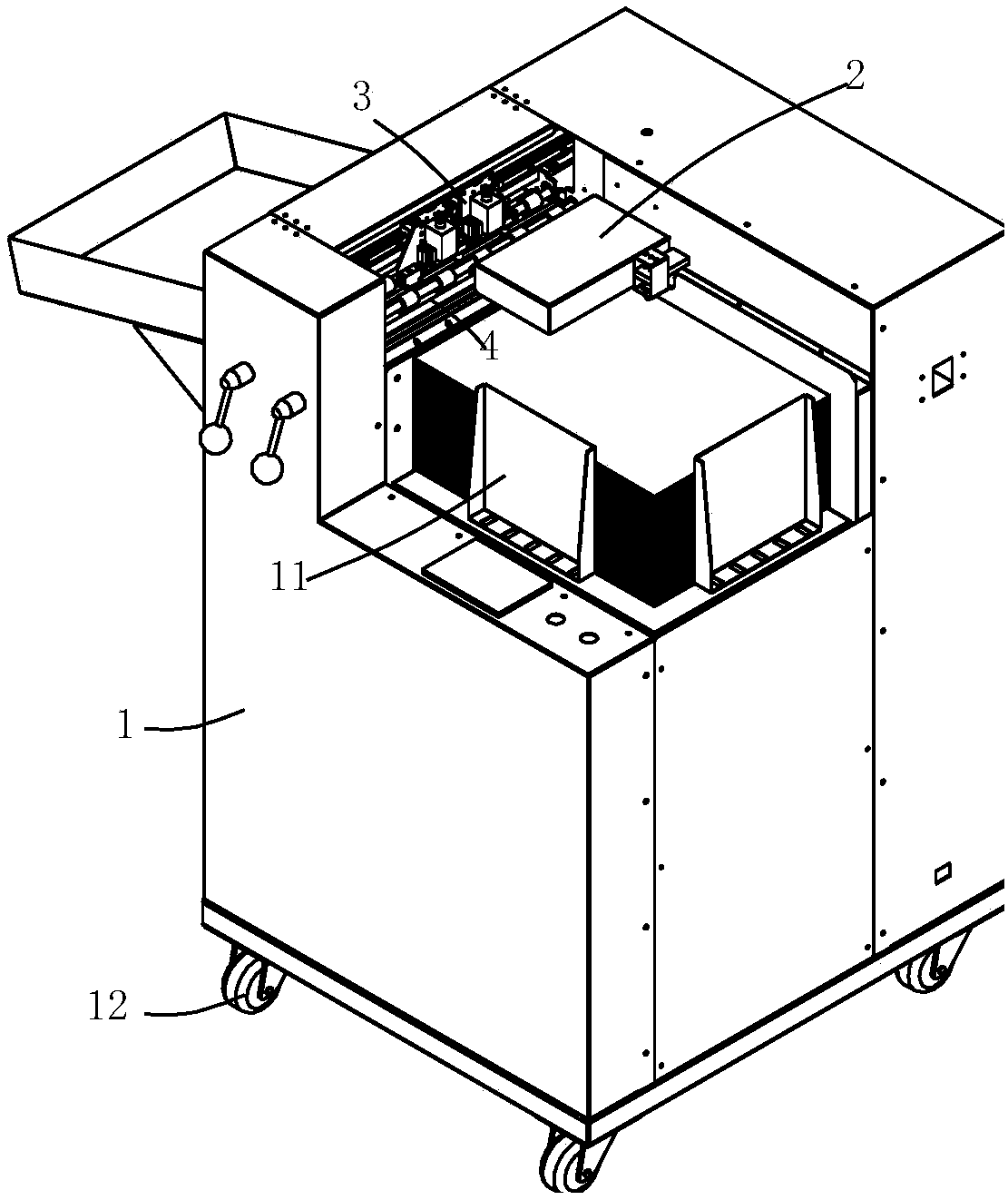

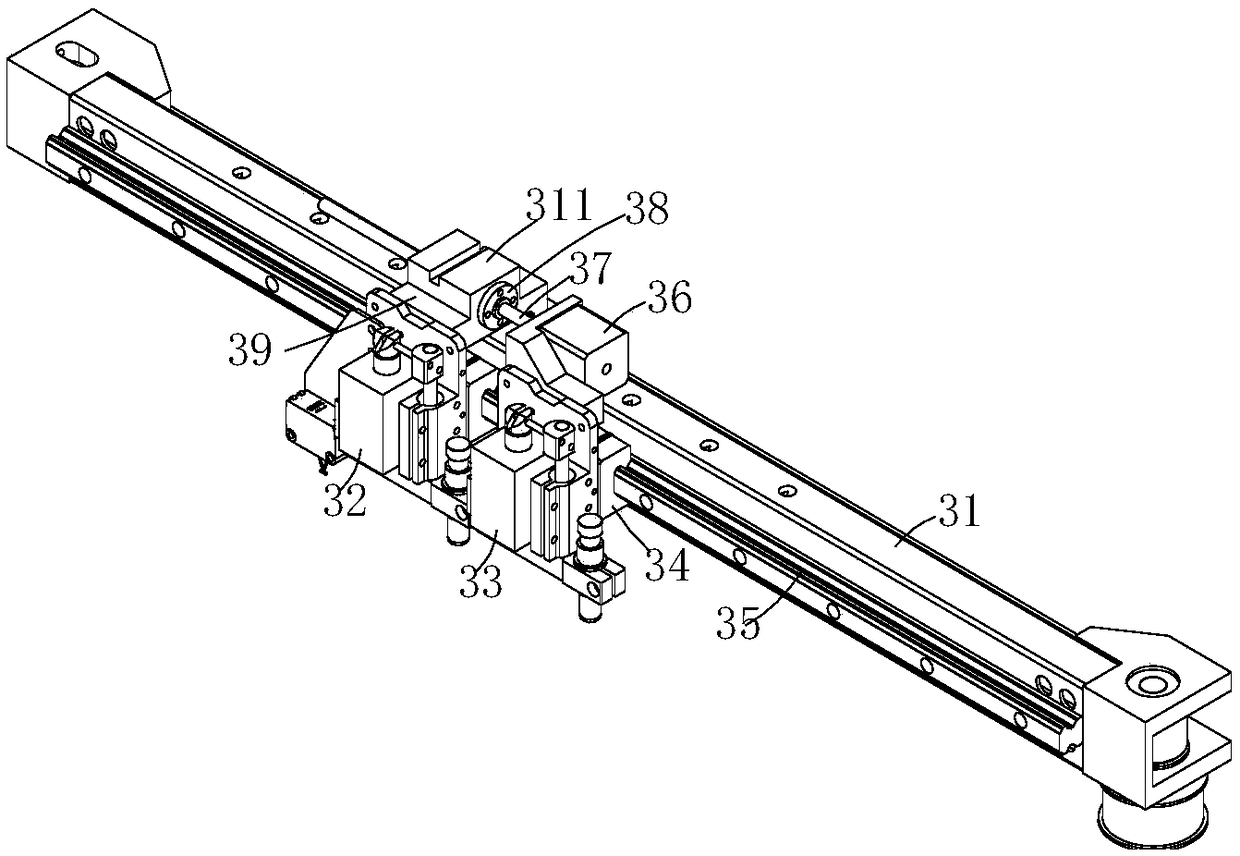

[0022] Such as Figure 1 to Figure 6 As shown, a digital page label die-cutting machine includes a body 1, host computer software, a main controller, a fully automatic positioning sensor is provided in the body, and a large-capacity paper feeding storage area 11 is provided at the bottom of the body 1 , the bottom of the fuselage is provided with rollers 12, the top of the large-capacity paper feeding storage area 11 is provided with an upper suction air feeding mechanism 2, and one side of the upper suction air feeding mechanism 2 is provided with a double-knife die-cutting structure 3, and a double-knife mold The lower part of the cutting structure 3 is provided with a double-roller paper feeding structure 4;

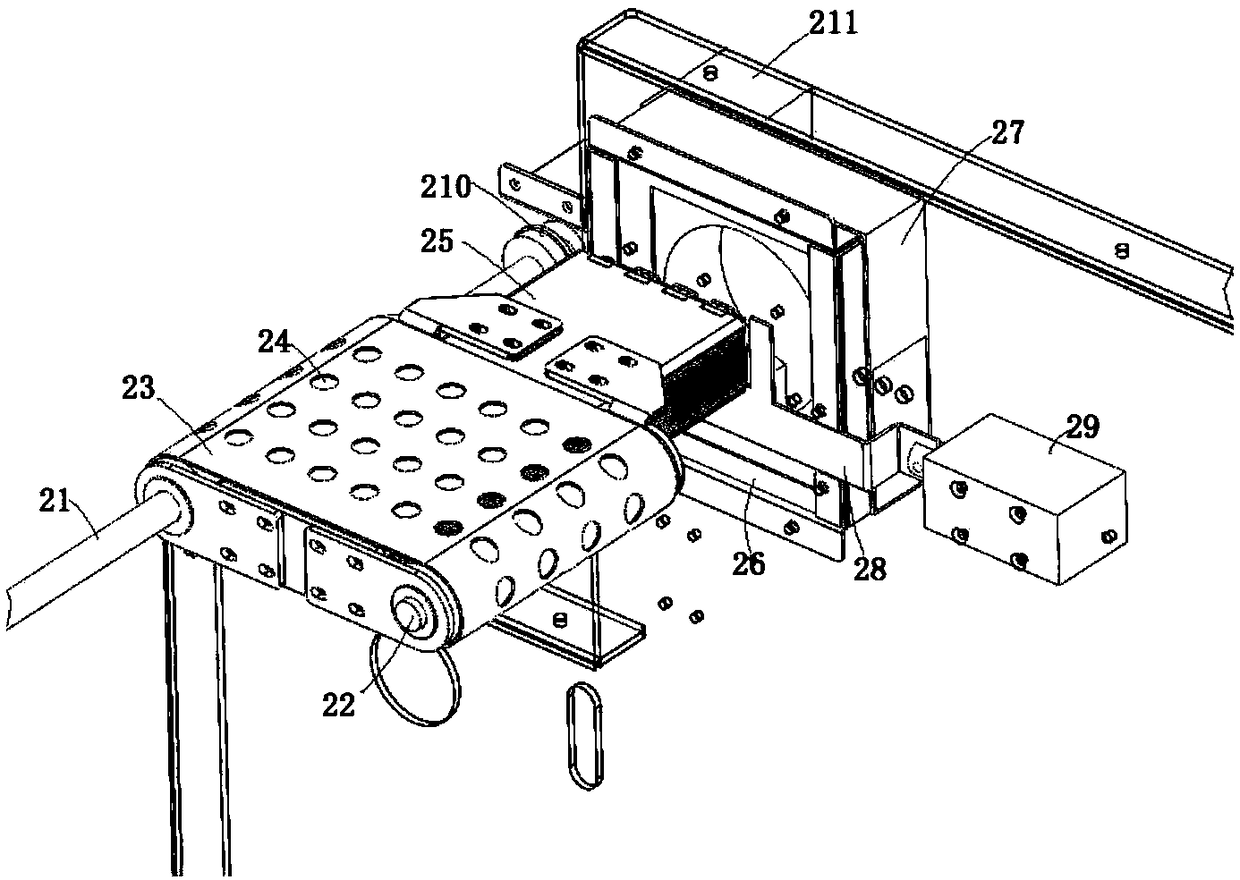

[0023] The upper suction paper feeding mechanism 2 includes a turning roller 21, one side of the turning roller 21 is provided with a driven roller 22, the turning roller 21 and the driven roller 22 are sleeved with a conveyor belt 23, and the conveyor belt 23 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com