Automatic pipeline cutting machine

A cutting machine and pipeline technology, which is applied in the field of automatic pipeline cutting machines, can solve the problems of low production efficiency, high cutting dust, and low automation, and achieve the effects of preventing accidental injury to workers, high processing efficiency, and strong automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

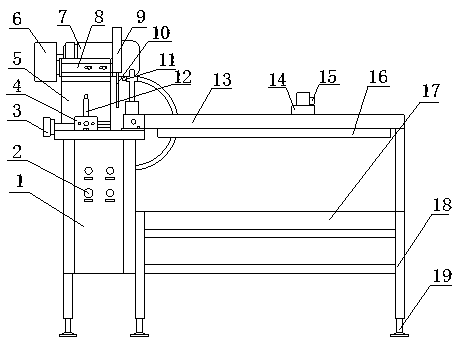

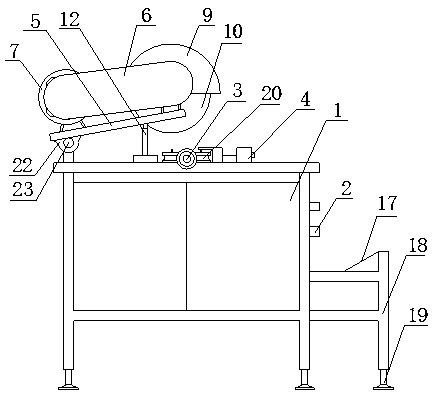

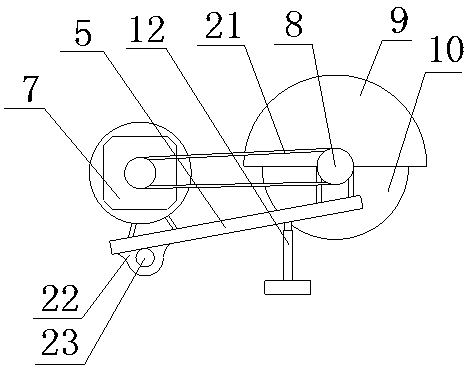

[0016] Such as figure 1 , 2 , 3, and 4, an automatic pipeline cutting machine includes a chassis 1, a pipe inlet port 3, a motor 7, and a cutting knife body 10. The right side of the chassis 1 is welded with a frame 18 with a receiving groove 17, and the chassis 1 There is a fixed block 4 on the top, the left end of the fixed block 4 is connected to the inlet pipe interface 3, and two runners 20 whose outer diameters are connected are installed on one side of the fixed block 4; The rocker 5 is inserted into the rotating rod 23 and fixedly connected with it. The other end of the rocker 5 is fixed on the chassis 1 through the lifting rod 12. The two ends of the rocker 5 are respectively installed with a motor 7 and a rotating shaft 8. The motor 7 is connected to the rotating shaft 8 through the pulley 21, and the rotating shaft 8 The other end is connected to the cutter body 10; the guide rail 13 is mounted on the chassis 1 and the frame 18, placed above the receiving groove 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com