Self-plugging audio test jig, and self-plugging audio test method

An audio test and fixture technology, applied in electrical components and other directions, can solve the problems of heavy workload, equipment complexity, high operation and maintenance costs, low test efficiency, etc., to achieve the effect of improving convenience and efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

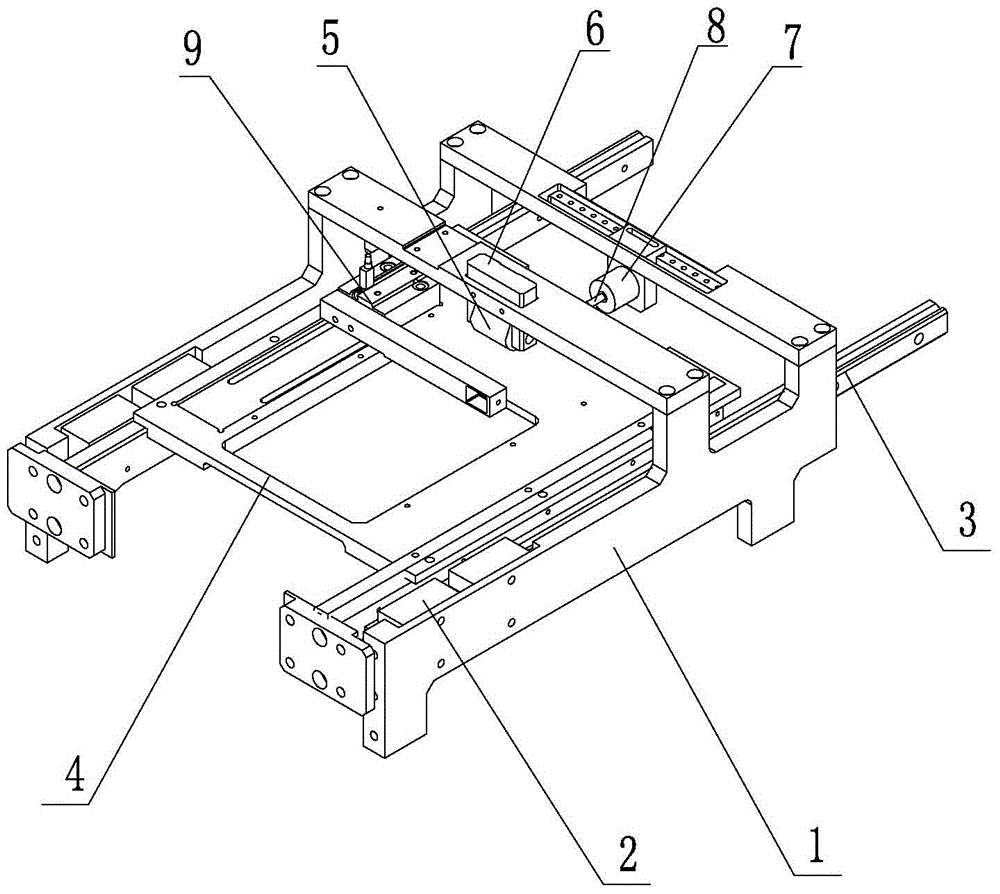

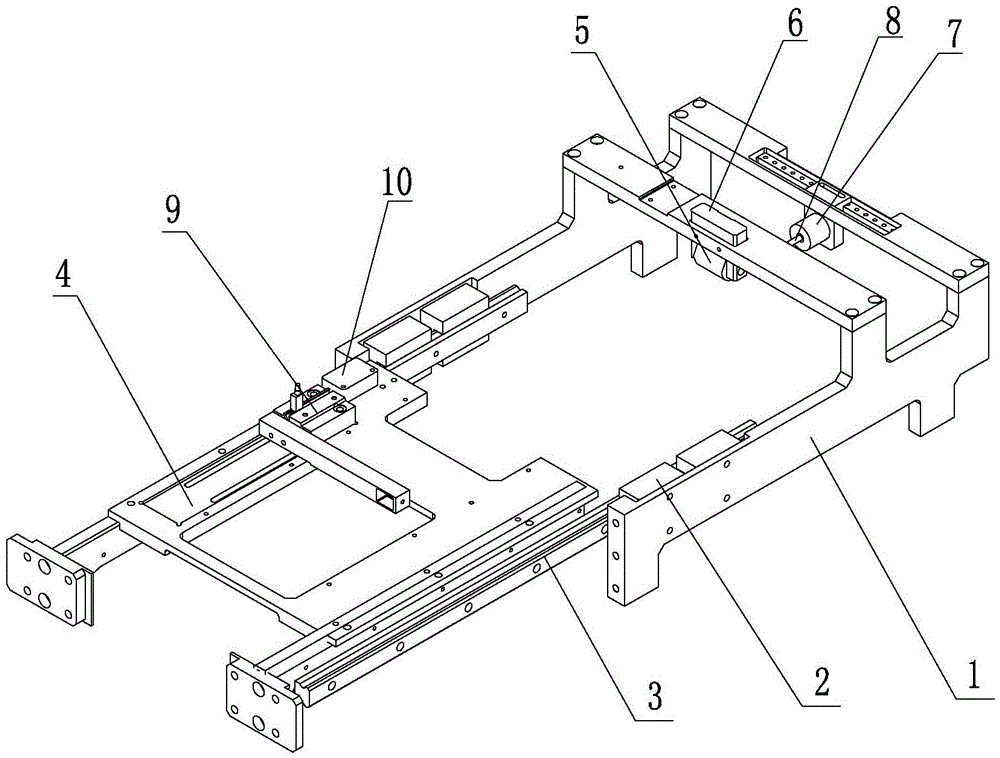

[0029] The self-plugging audio test fixture of the present embodiment is as figure 1 and figure 2 As shown, it is used for the mobile phone audio online test at the factory side, and the corresponding terminal to be tested is a mobile phone with a USB interface and an audio interface at both ends, and can complete the automatic plugging and unplugging operation of each interface in the audio test.

[0030] The whole set of devices is installed in the muffler box, so the whole muffler box is omitted in the figure. The guide rail bracket 1 fixedly installed in the muffler box, the guide rail bracket 1 slides and cooperates with the drawer 4 through the slider 2 and the guide rail 3 .

[0031] Roller 5 and audio plug 7 are installed on the guide rail bracket 1, and wherein roller 5 is fixed on mobile phone top by roller bracket 6, presses down mobile phone when drawer 4 enters muffler box, does not allow it to be upturned when inserting, has guaranteed smooth insertion.

[003...

Embodiment 2

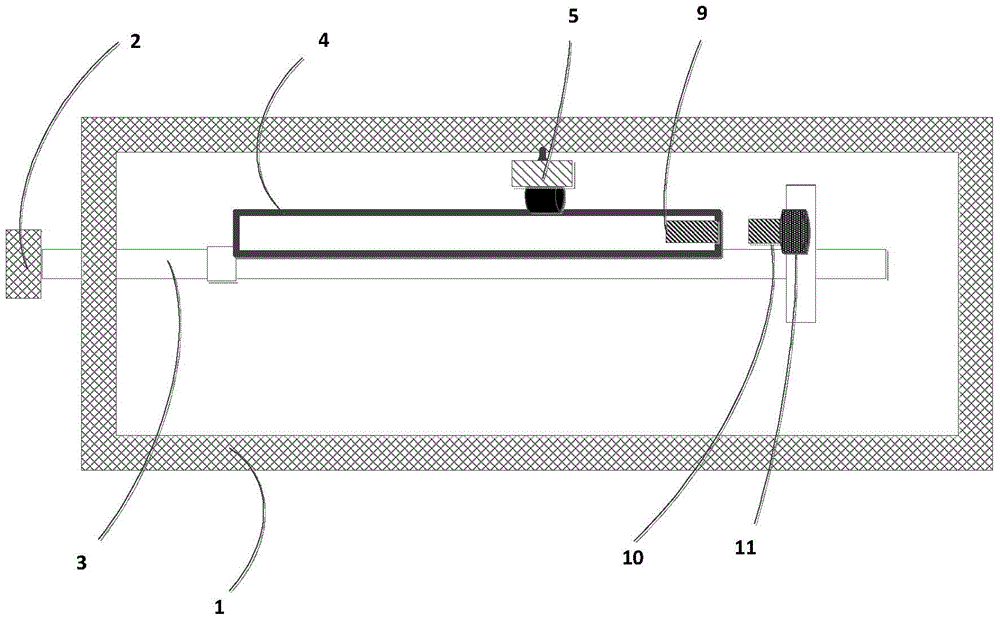

[0044] The self-plugging audio test fixture of this embodiment is used to test the terminal under test whose audio jack and USB are on the same side. Its structure diagram is as follows image 3 and Figure 4 As shown, it includes a mute box 1, a suitable container 2 (such as a drawer) for carrying the terminal to be tested, an entry and exit slide rail 3 of the container 2, a terminal to be tested 4, an adjustable roller 5 installed at a suitable position, and a terminal to be tested 4. earphone port 6 installed in a suitable position, a USB port on the terminal 4 to be tested, and a USB plug 10 installed in a suitable position; the earphone plug 7 is installed on the test box 1 through a flexible device 8; the USB The plug 10 is mounted on the test box 1 by some flexible means 11 .

[0045] The terminal 4 to be tested is placed in the container 2, and the roller 5 presses the terminal 4 to be tested when the terminal 4 to be tested enters the test box 1, and then the earphon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com