Method for controlling sugar boiling crystallization process based on sequential extreme learning machine

A technology of extreme learning machine and process control, which is applied to computer parts, instruments, character and pattern recognition, etc., and can solve problems such as unsatisfactory results, difficulty in establishing mathematical models, and complex massecuite environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

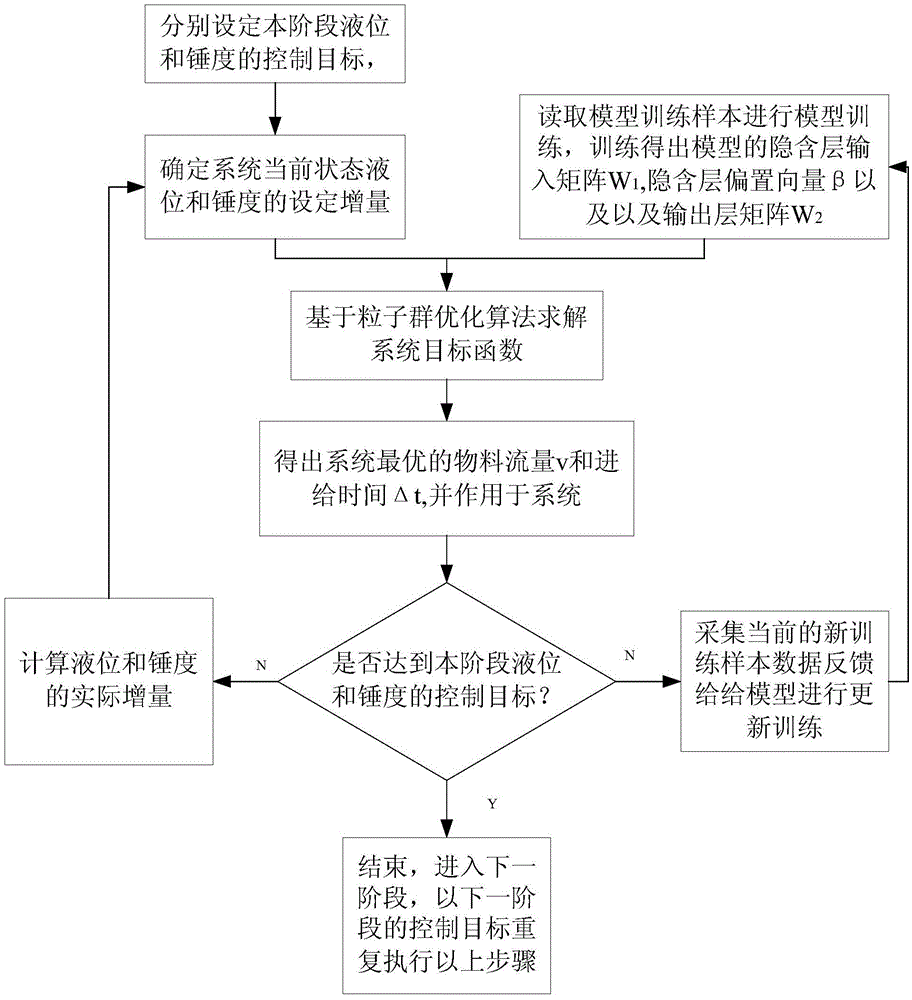

[0064] like figure 1 and figure 2 As shown, the sugar crystallization process control method based on sequential extreme learning machine includes the following steps:

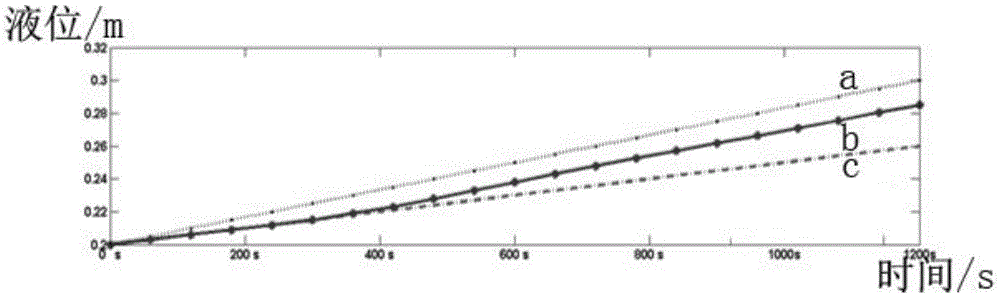

[0065] (1), divide the process curve of the sugar boiling and crystallization process into multiple stages, and set the control targets for the Brix and liquid level of each stage;

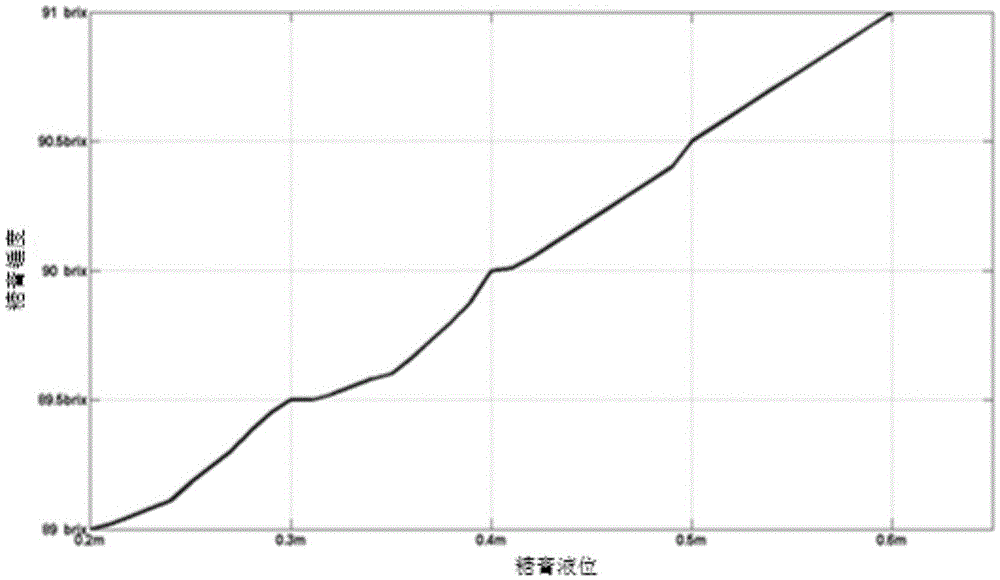

[0066] (2), with feed flow rate and feed time as input, liquid level variation and brix variation of massecuite as output, build the control model of the process parameter of boiling sugar crystallization process based on sequential extreme learning machine;

[0067] (3), adopt the least squares method to construct the objective function between the output of step (1) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com