Automatic cooker for kitchen

A cooking machine and automatic technology, which is applied in the direction of kitchen utensils, cooking utensil lids, plug-ins, etc., can solve the problems of increasing kitchen staff, requiring manual participation, and unfavorable work for chefs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

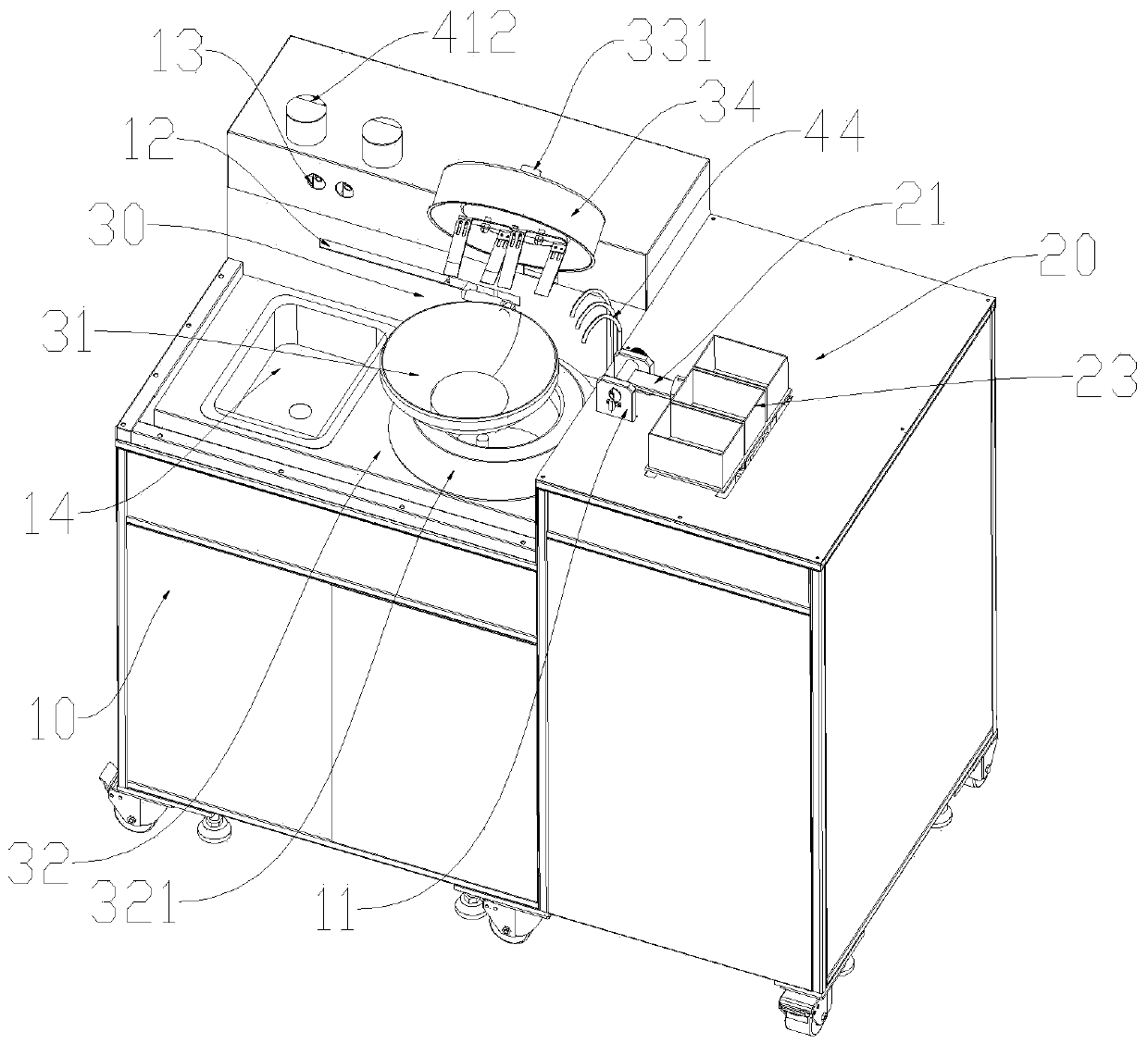

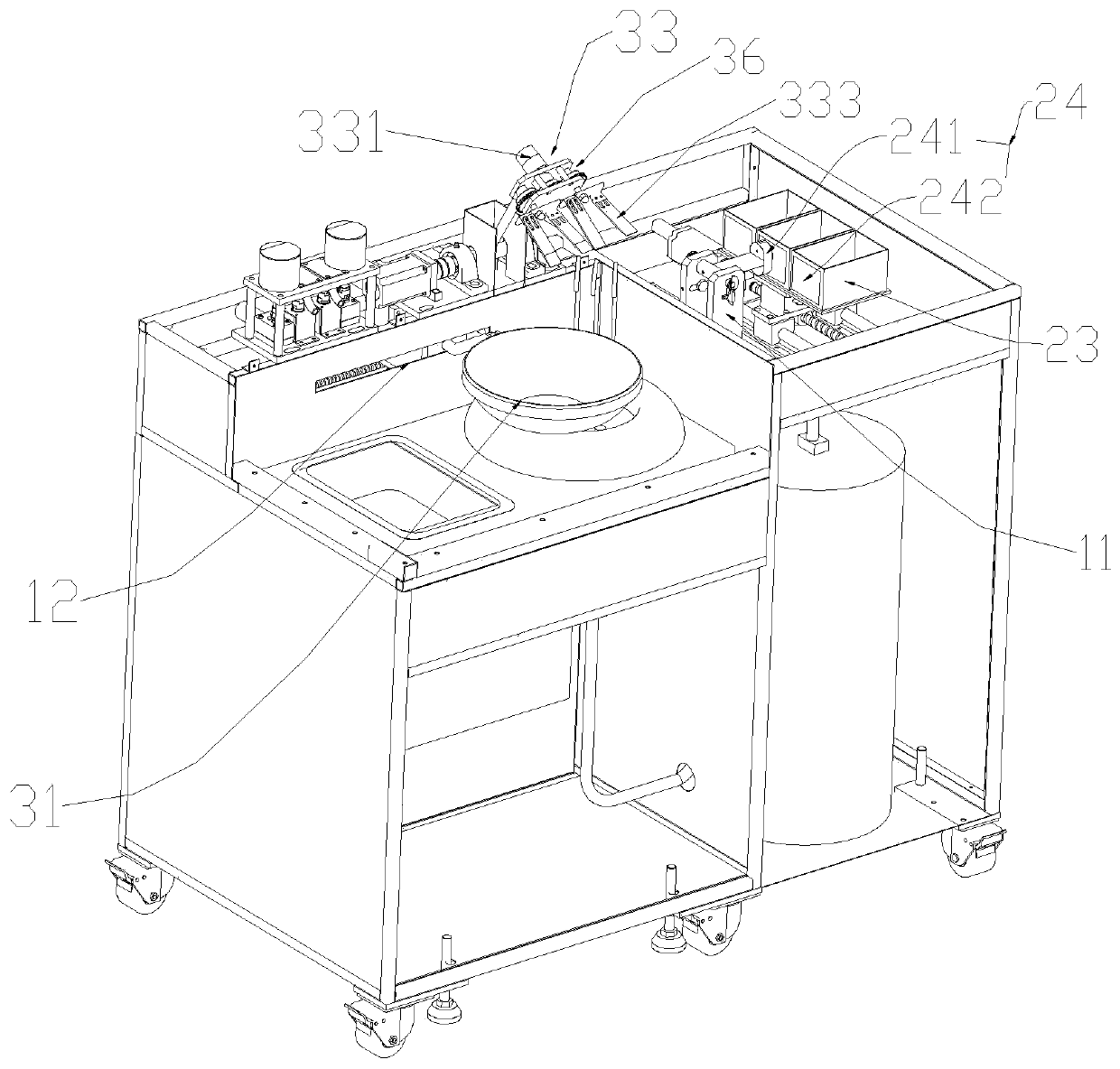

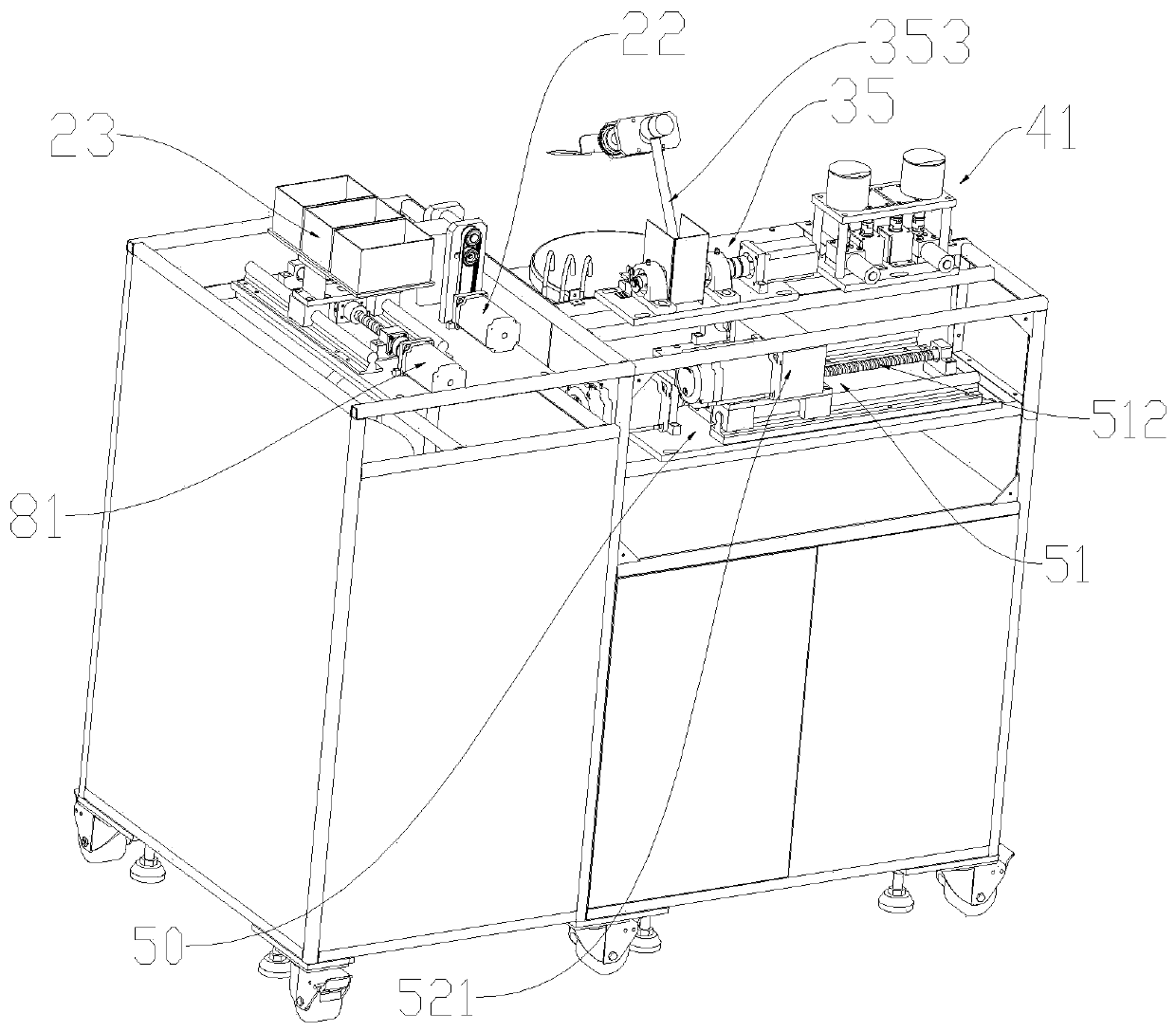

[0048] attached Figure 1-15 A kitchen automatic cooking machine is shown, see Figure 1 to Figure 4 , comprising a machine platform 10, the machine platform 10 is provided with a dish delivery unit 20, a dish processing unit 30, a seasoning delivery unit 40 and a cooked dish delivery unit 50, wherein:

[0049] see figure 1 with Figure 5, the dish delivery unit 20 comprises a rotating rod 21, a motor A22 and several vegetable boxes 23, the vegetable box 23 is arranged on the machine platform 10, the rotating rod 21 is arranged between the vegetable box 23 and the dish processing unit 30, and one end of the rotating rod 21 is arranged There is an adsorption device 24 for absorbing the vegetable box 23, the other end of the rotating rod 23 is provided with a rotating shaft 25, the machine table 10 is provided with a mounting plate 11, and the rotating shaft 25 is rotatably located on the mounting plate 11 to realize the rotation of the rotating shaft 25. The purpose of being...

Embodiment 2

[0069] This embodiment is the same as embodiment one except the following content:

[0070] see Figure 16 to Figure 18 , Stir-fry mechanism 33 comprises motor B331, rotating bar 37 and stirring bar 38, the output shaft of motor B331 connects the middle part of rotating bar 37, and rotating bar 37 is threadedly connected with stirring bar 38, and stirring bar 38 is located at the top of wok 31, When stir-frying dishes, the stir-frying mechanism 33 is lowered to the inside of the frying pan 31, driven by the motor B331, the rotating bar 37 drives the stirrer 38 to rotate, and the rotating stirrer 38 can realize the stirring of the stirrer 31. The dishes in the interior are stirred and stir-fried, and the stirring rod 38 is threadedly connected with the rotating bar 37, which is convenient for changing and overhauling the stirring rod 38. The output shaft of the motor B331 is connected to the middle part of the rotating bar 37, which is conducive to fully stirring the dishes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com