Simple flow control switch

A flow control and switching technology, applied in the direction of diaphragm valves, engine components, diaphragms, etc., can solve the problems of high price of solenoid valves, large volume and low reliability of floating ball valves, and achieve the effects of low cost, small size and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

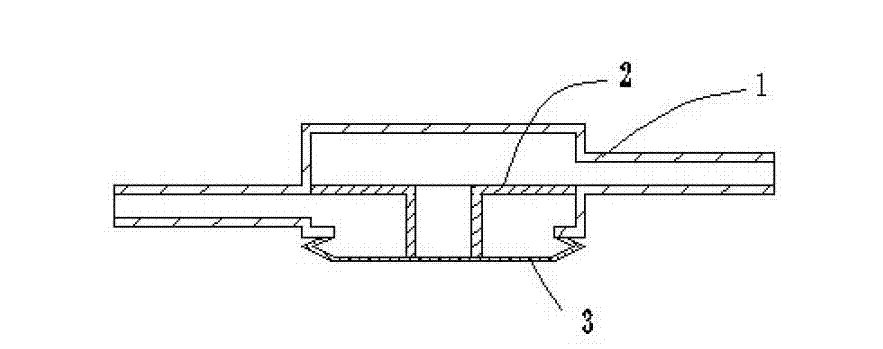

Embodiment 1

[0018] Such as figure 1 As shown, the flow control switch of this embodiment has a diaphragm 3, a valve body 1 and a valve seat 2, and the valve body also has two interfaces for connecting fluid pipelines. When there is high-pressure fluid in the flow channel, the diaphragm 3 bounces off the valve seat 2, and the valve opens; when the pressure drops, the diaphragm 3 presses the valve seat 2, and the valve closes. The elastic body is a diaphragm, and the diaphragm is directly pressed on the valve seat; when there is high-pressure fluid in the flow channel, the diaphragm bounces off the valve seat, and the valve opens; when there is no pressure in the flow channel, the diaphragm presses the valve seat , to stop the leak.

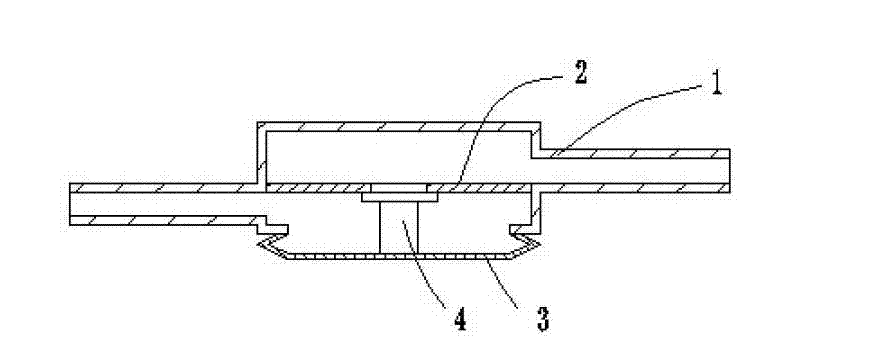

Embodiment 2

[0020] Such as figure 2 As shown, the flow control switch of this embodiment has a diaphragm 3, a valve body 1, a valve stem 4 and a valve seat 2, and the valve body 1 also has two interfaces for connecting fluid pipelines. When there is high-pressure fluid in the flow channel, the diaphragm 3 bounces up, the valve stem 4 falls away from the valve seat, and the valve opens; when the pressure drops, the diaphragm 3 pushes the valve stem 4 to press the valve seat, and the valve closes. The elastic body is a diaphragm, the diaphragm is pressed on the valve stem, and the valve stem is pressed on the valve seat; when there is high-pressure fluid in the flow channel, the diaphragm bounces up, the valve stem falls, and the valve opens; when there is no pressure in the flow channel , the diaphragm pushes the valve stem to compress the valve seat to prevent leakage.

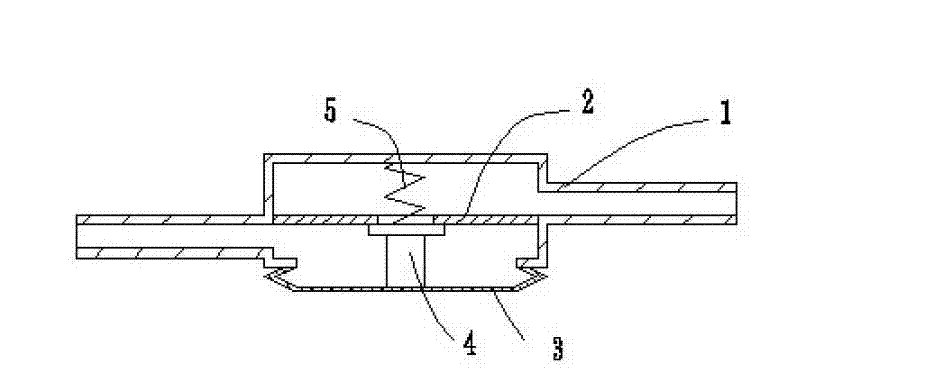

Embodiment 3

[0022] Such as image 3 As shown, the flow control switch of this embodiment has a diaphragm 3, a valve body 1, a valve stem 4, a spring 5 and a valve seat 2, and the valve body 1 also has two interfaces for connecting fluid pipelines. When there is high-pressure fluid in the flow channel, the diaphragm 3 bounces up, and the valve stem 4 breaks away from the valve seat 2 under the action of the spring 5, and the valve opens; when the pressure drops, the diaphragm 3 pushes the valve stem 4 to press the valve seat, and the valve closes . The elastic body is a diaphragm, the diaphragm is pressed on the valve stem, the valve stem is pressed on the valve seat, and the spring presses the valve stem on the diaphragm when the diaphragm bounces up; when there is high-pressure fluid in the flow channel, the diaphragm When the diaphragm bounces up, the spring presses the valve stem against the diaphragm, and the valve opens; when there is no pressure in the flow channel, the diaphragm p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com