Settling machine for multiple bar-shaped materials

A stick-shaped object and feeding machine technology, which is applied in the direction of packaging food and biscuits, can solve the problems of unrealized production and packaging, and achieve the effects of reasonable structure, automation, and simple transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

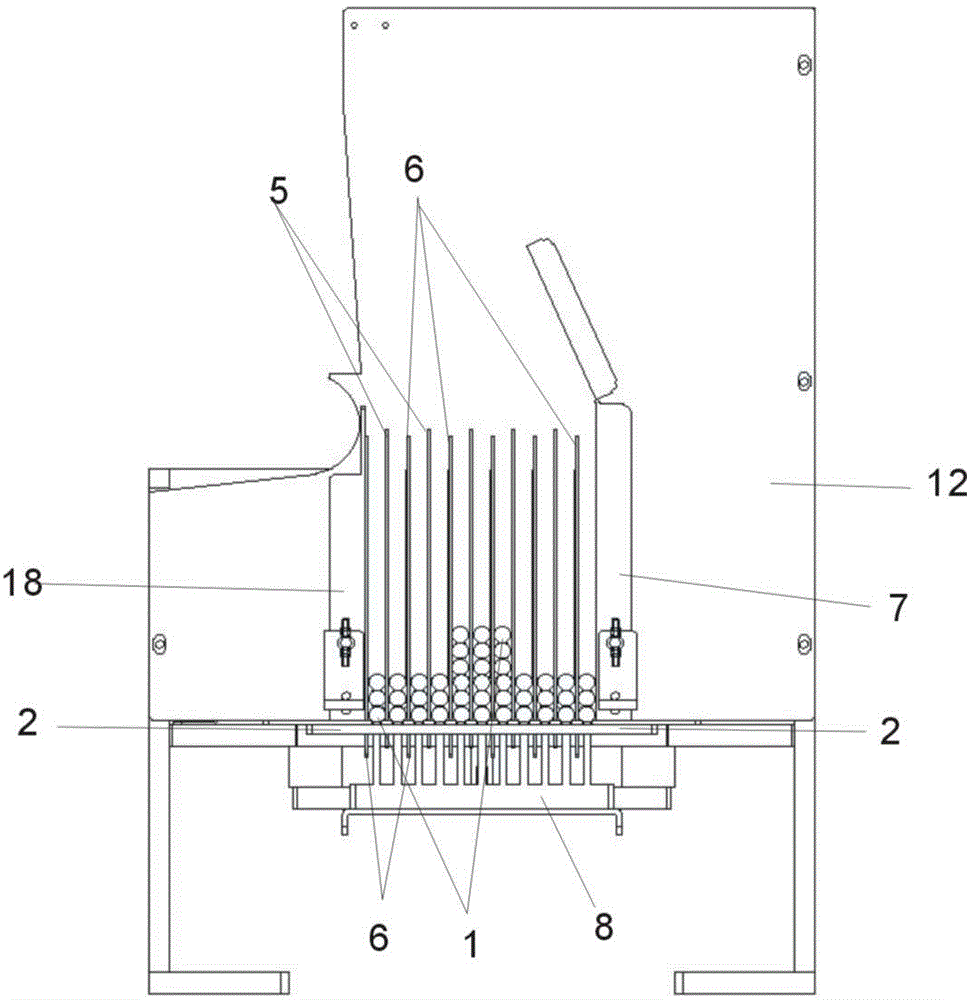

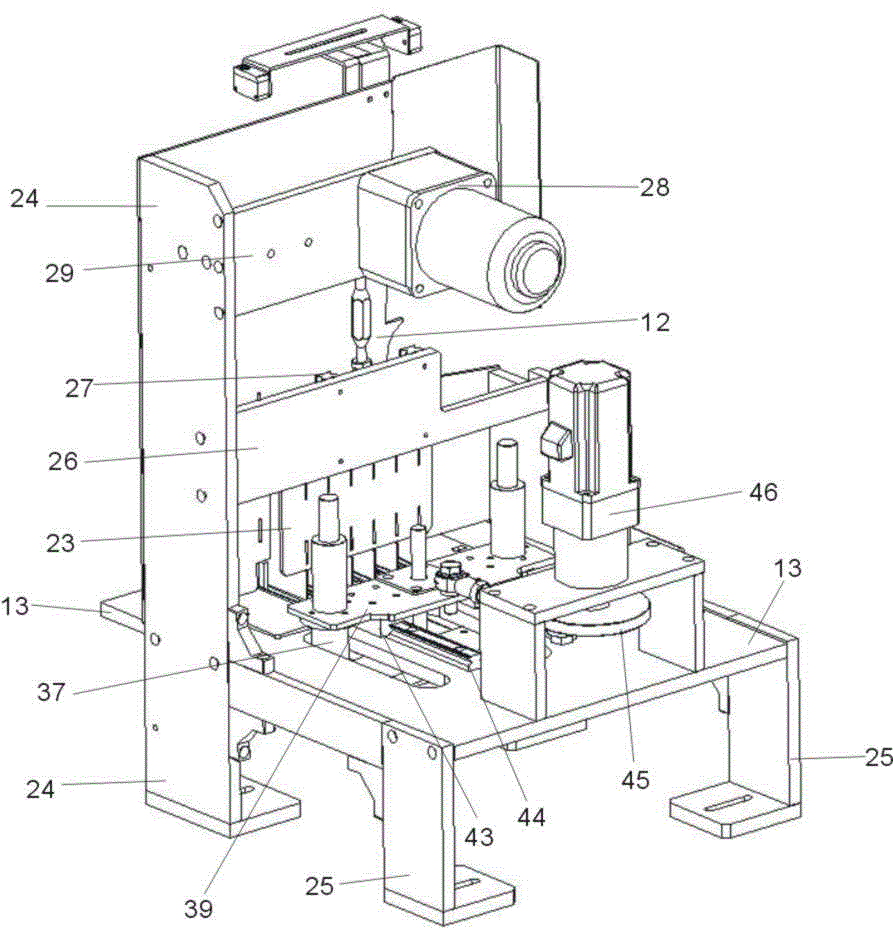

[0035] Such as figure 1 Figure 12 Shown, with eleven stick-shaped biscuits 1 as a layer, the present invention is illustrated by a stacking bin structure of one layer after another, the bin base plate 2, the rear baffle 12, Front baffle 30, silo left baffle 18, hopper right baffle 7, silo fixed partition 5, silo vibrating plate 6 and silo pusher 8.

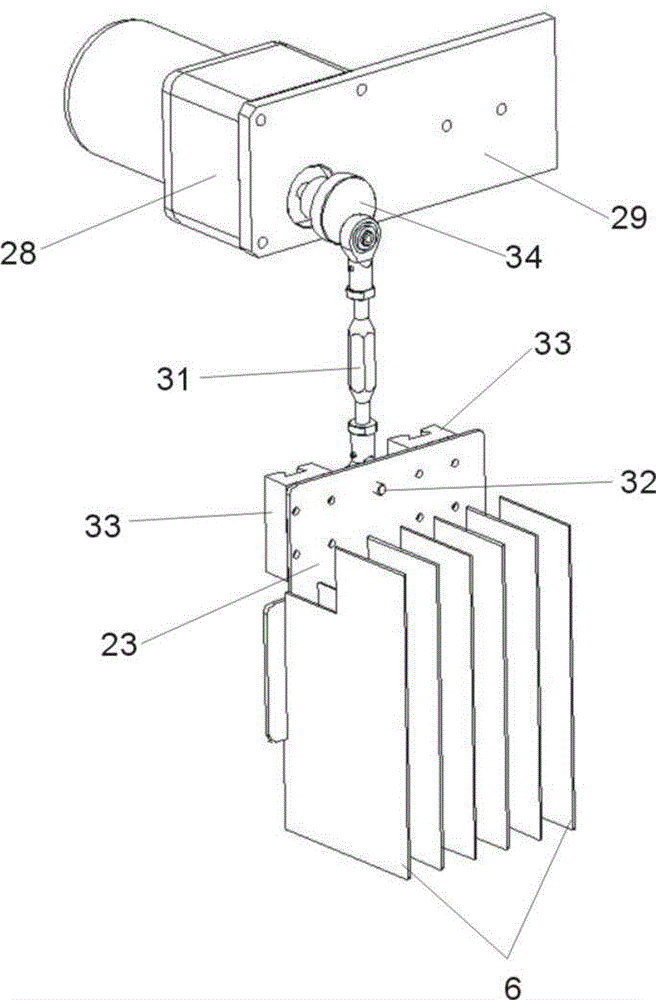

[0036] Such as figure 2 image 3 As shown, the length, width and thickness of the bin bottom plate 2 are determined according to the length and diameter of the stick biscuit 1 . The silo bottom plate 2 has a row of ten support strips 3, the length of the support strips 3 is longer than twice the length of the stick biscuit 1, and the distance between the support strip 3 and the silo bottom plate 2 on the left and right sides is smaller than the diameter of the stick biscuit 1, The distance between the adjacent support strips 3 is smaller than the diameter of the rod-shaped biscuit 1; the support strips 3 are provided with sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com