Patents

Literature

49results about How to "Shorten the boil time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

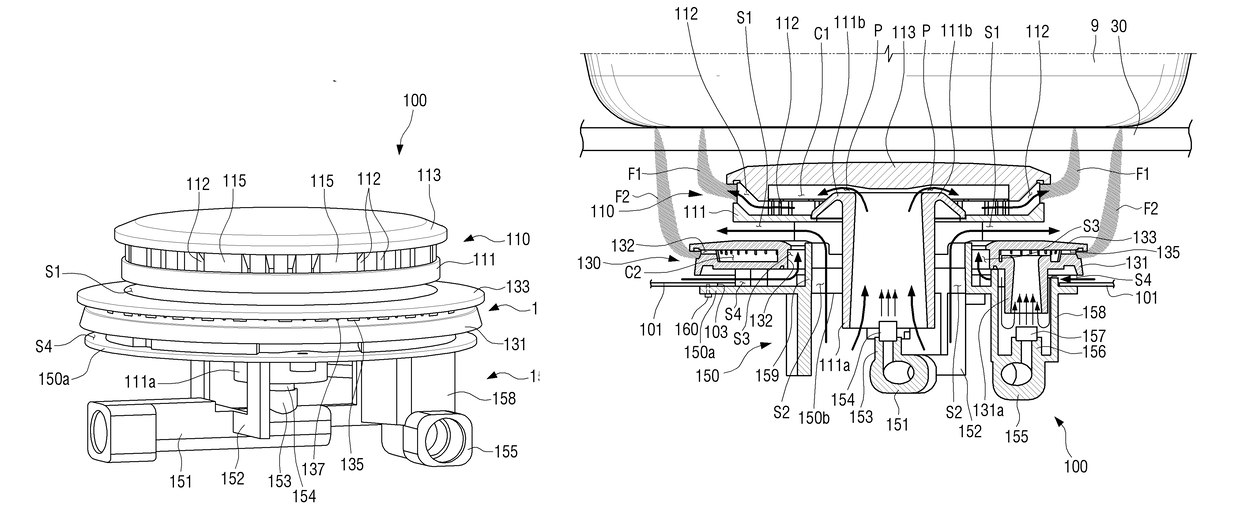

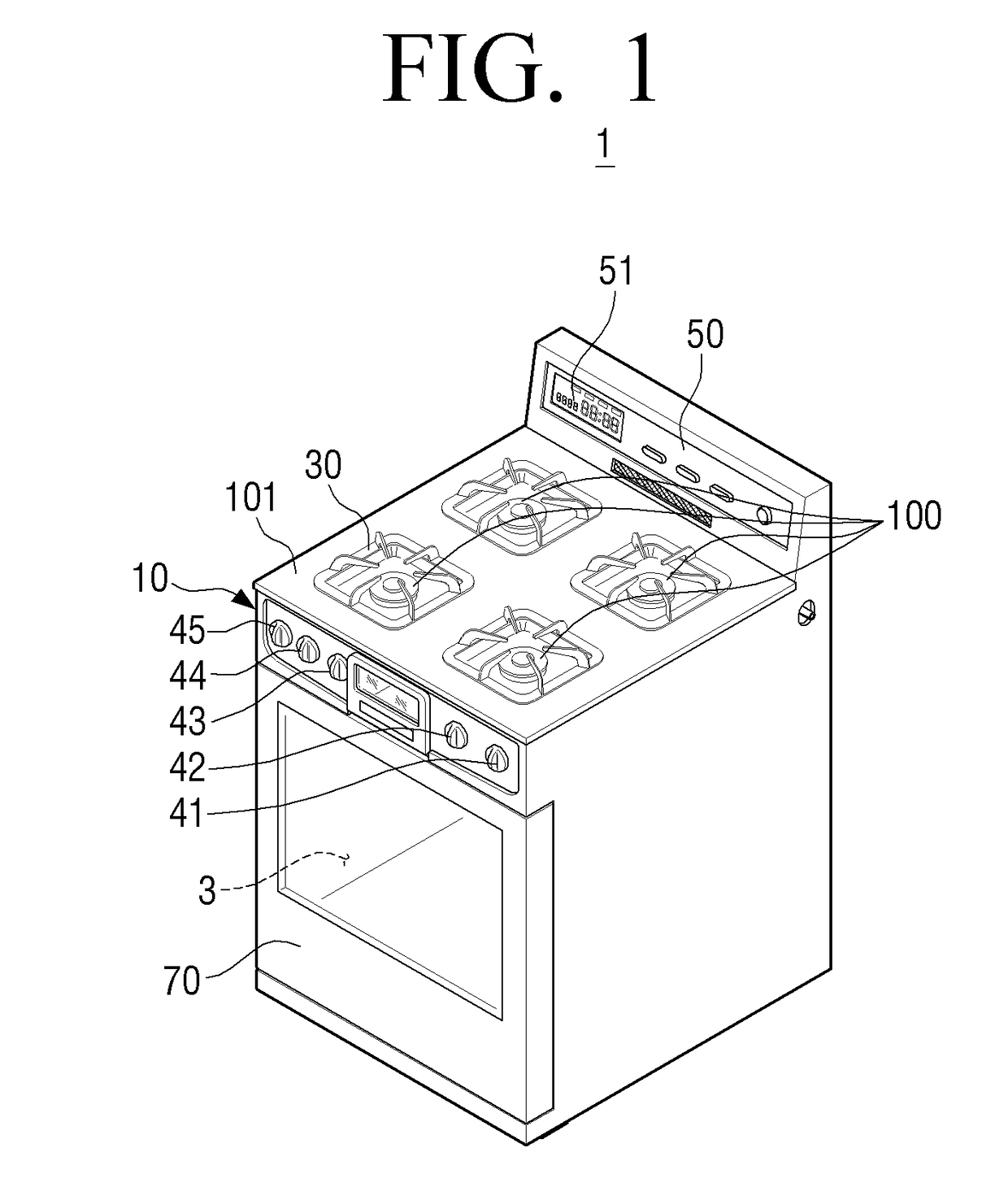

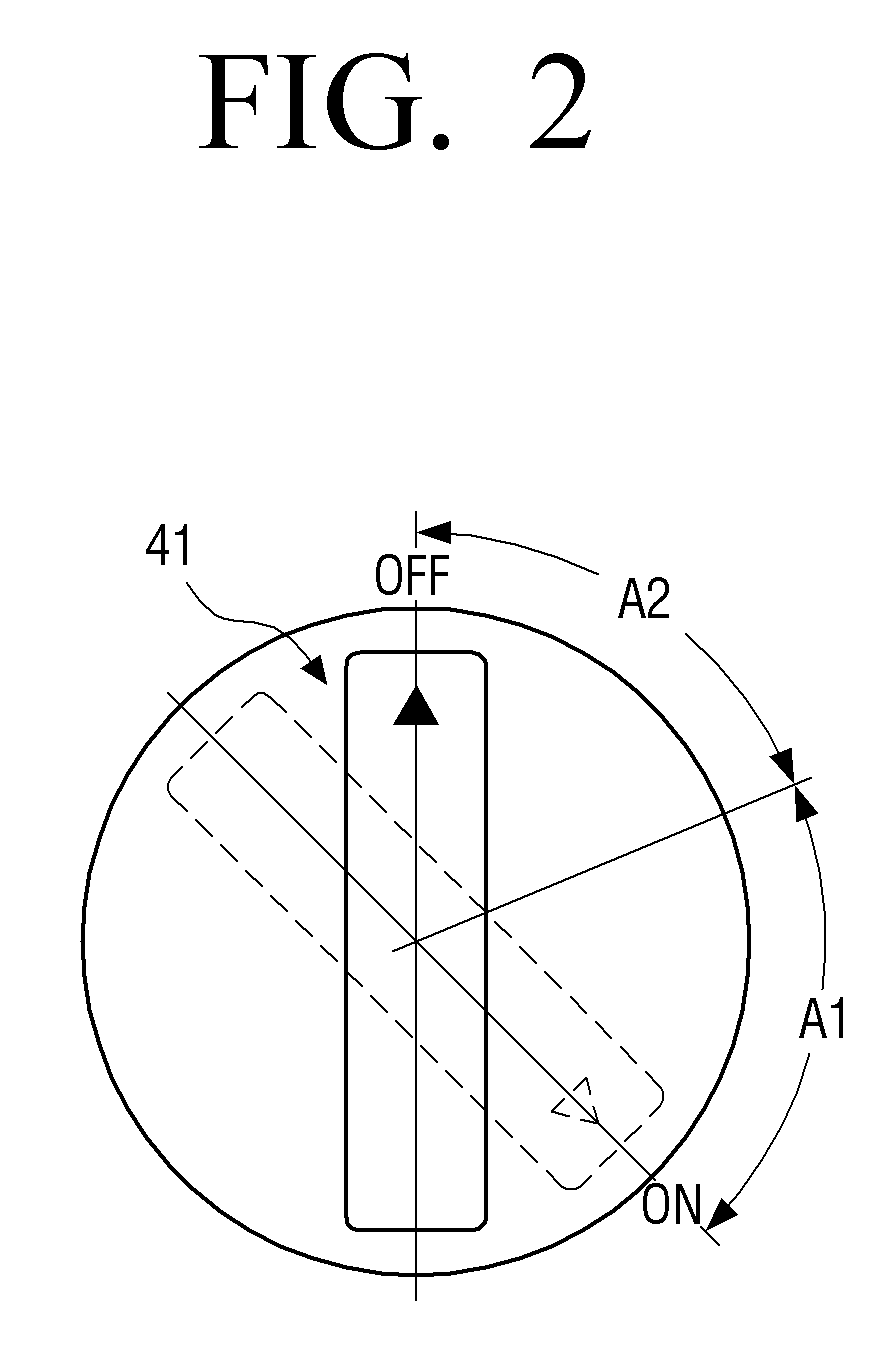

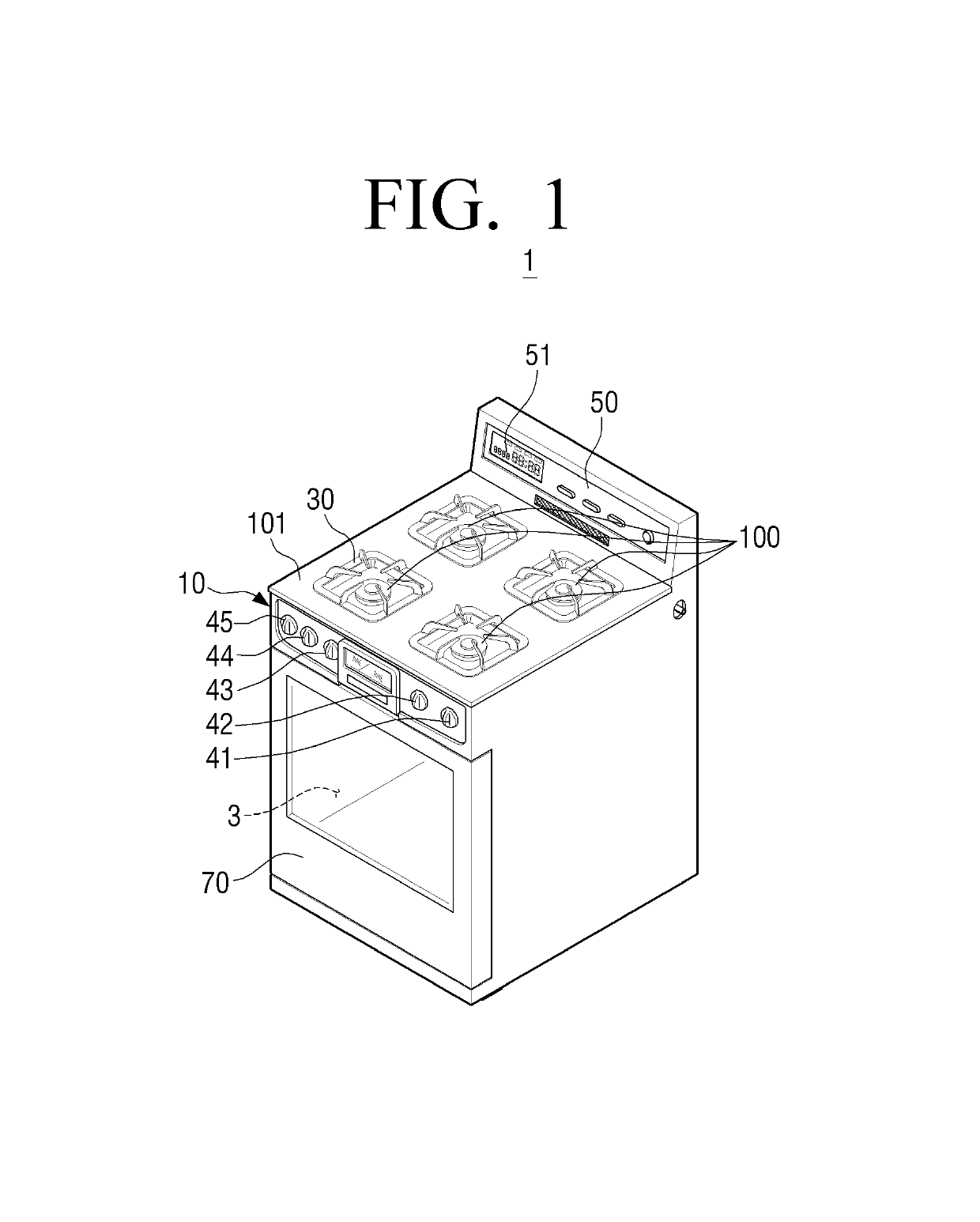

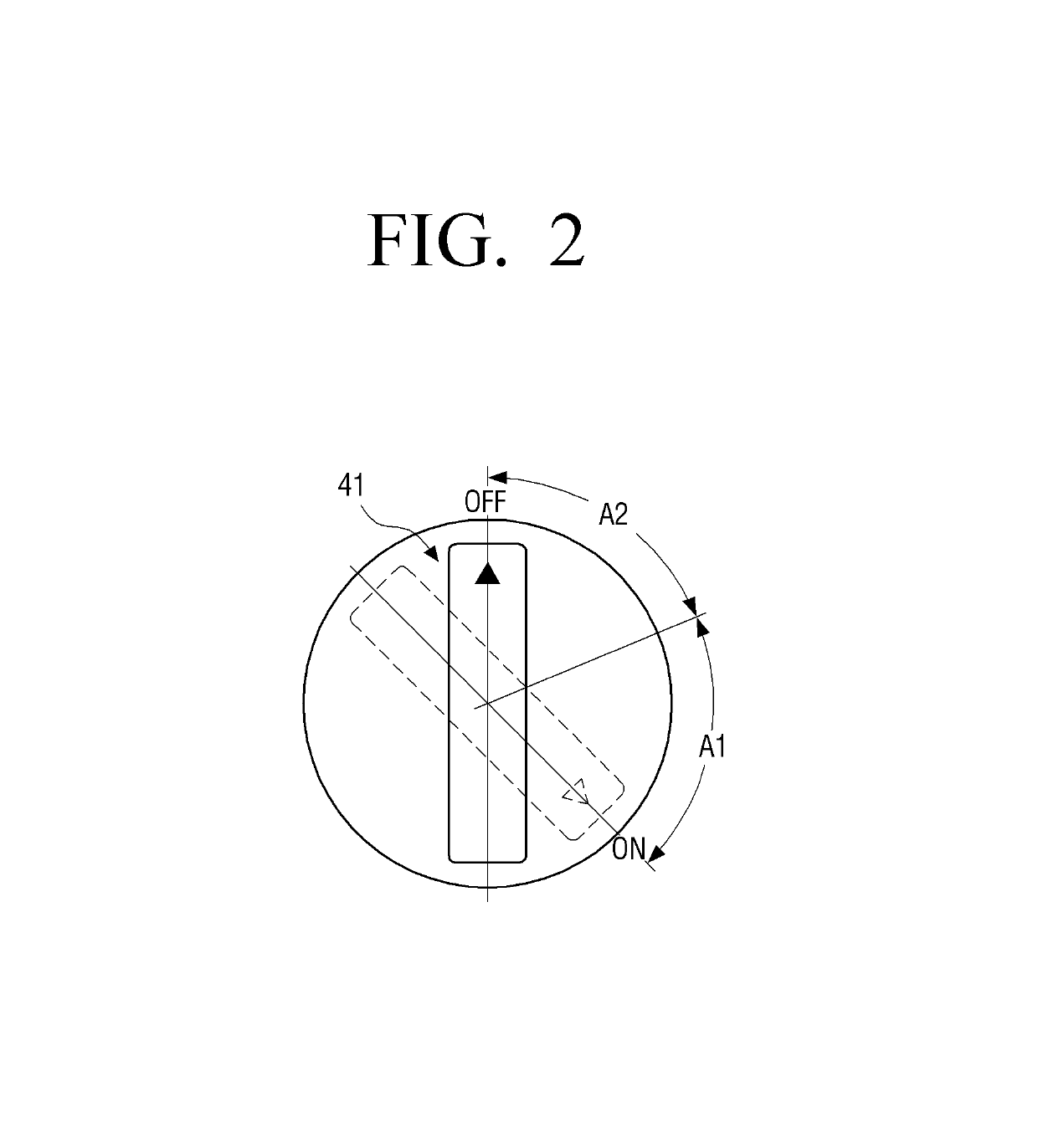

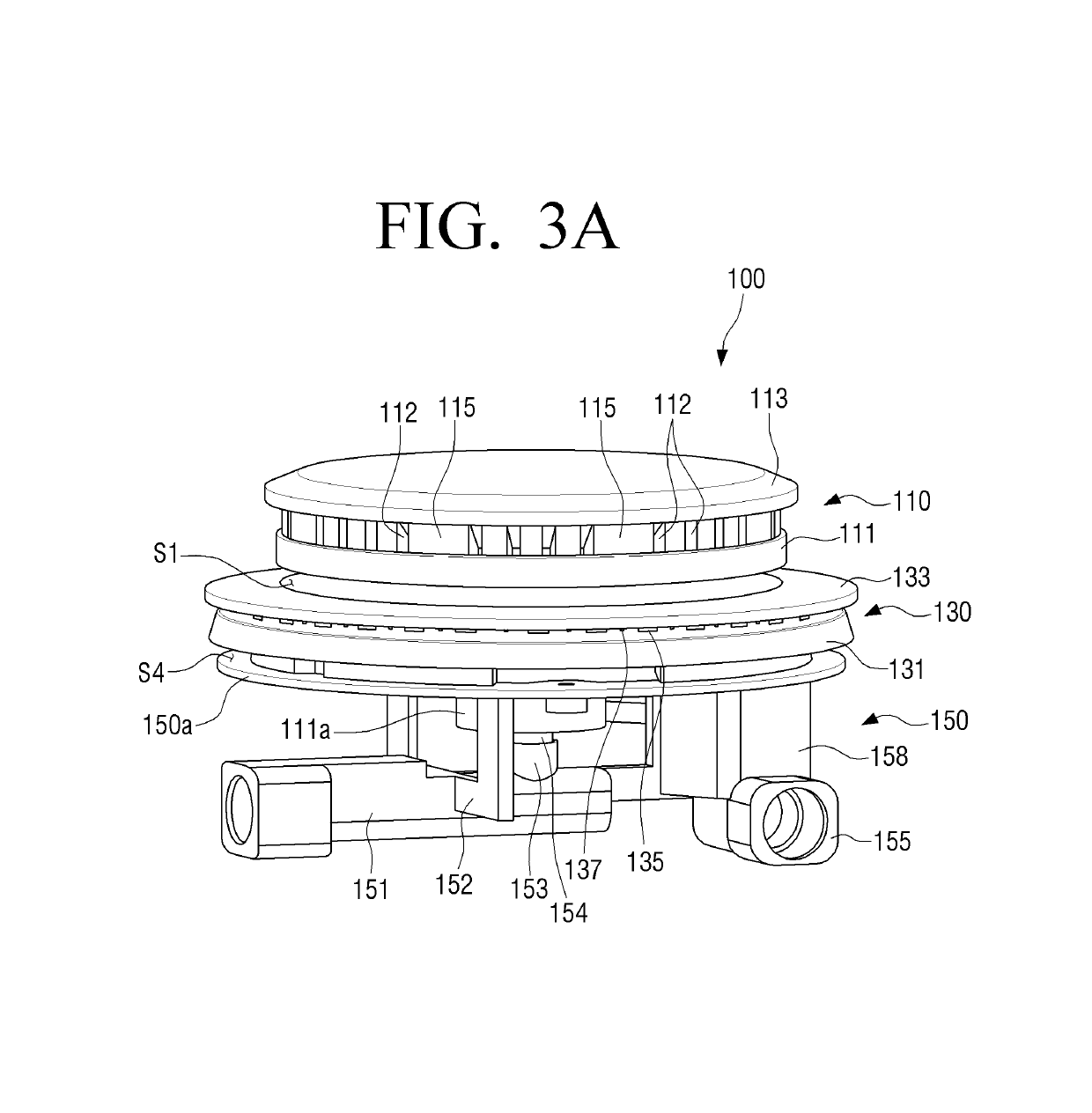

Gas burner apparatus and cooking apparatus including the same

ActiveUS20170108226A1High outputReduce boiling timeDomestic stoves or rangesNon-combustible gases/liquids supplyGas burnerElectrical and Electronics engineering

A gas burner apparatus and a cooking apparatus including the same are provided. The gas burner apparatus a first burner, a second burner spaced apart from a lower side of the first burner, a support plate on which the second burner is disposed, and a secondary air supply flow channel to supply secondary air to the first burner, the secondary air supply flow channel including a first secondary air supply flow path formed between the first and second burners and a second secondary air supply flow path starting from an area lower than the support plate, the first and second paths being connected to each other.

Owner:SAMSUNG ELECTRONICS CO LTD

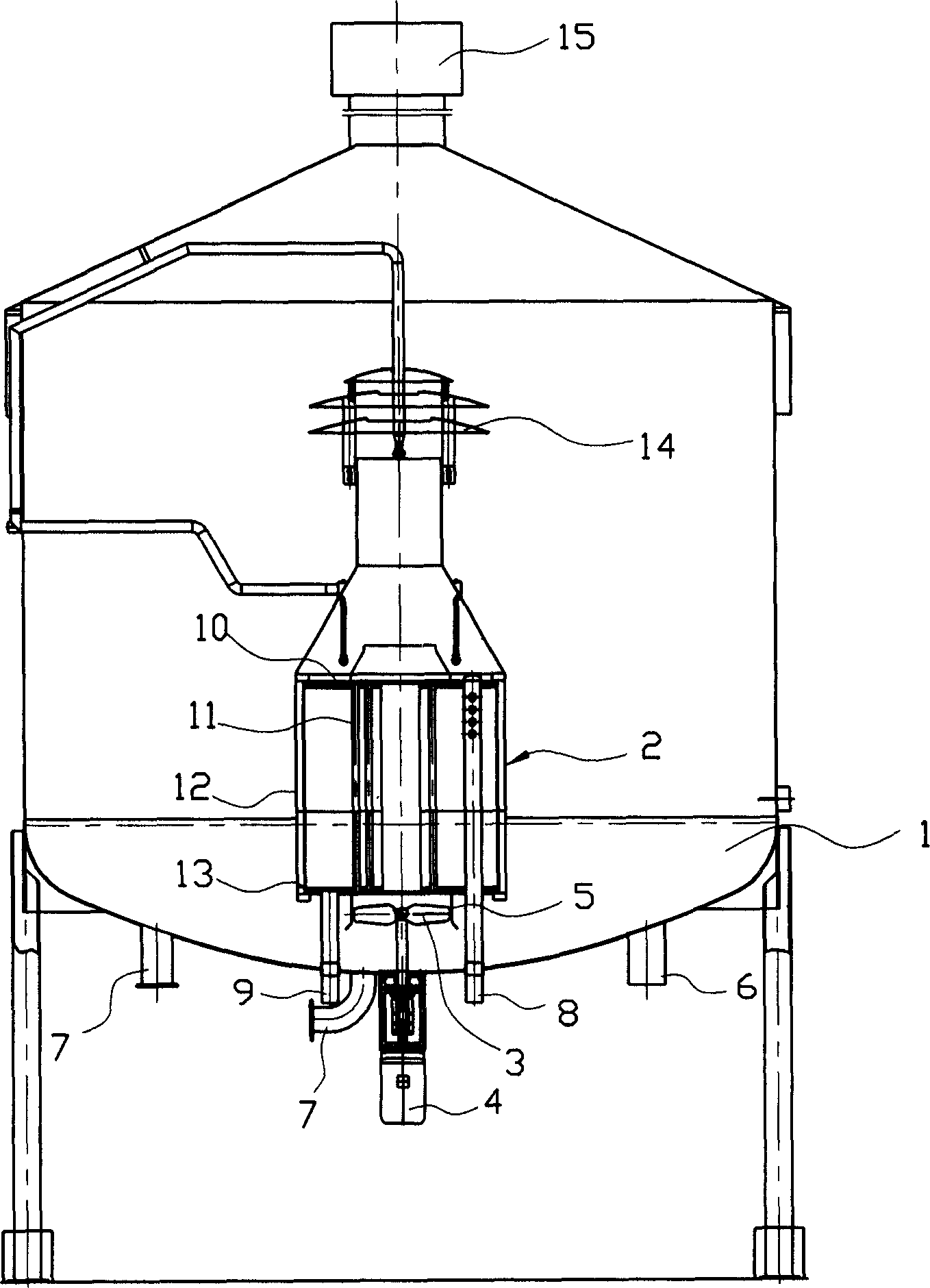

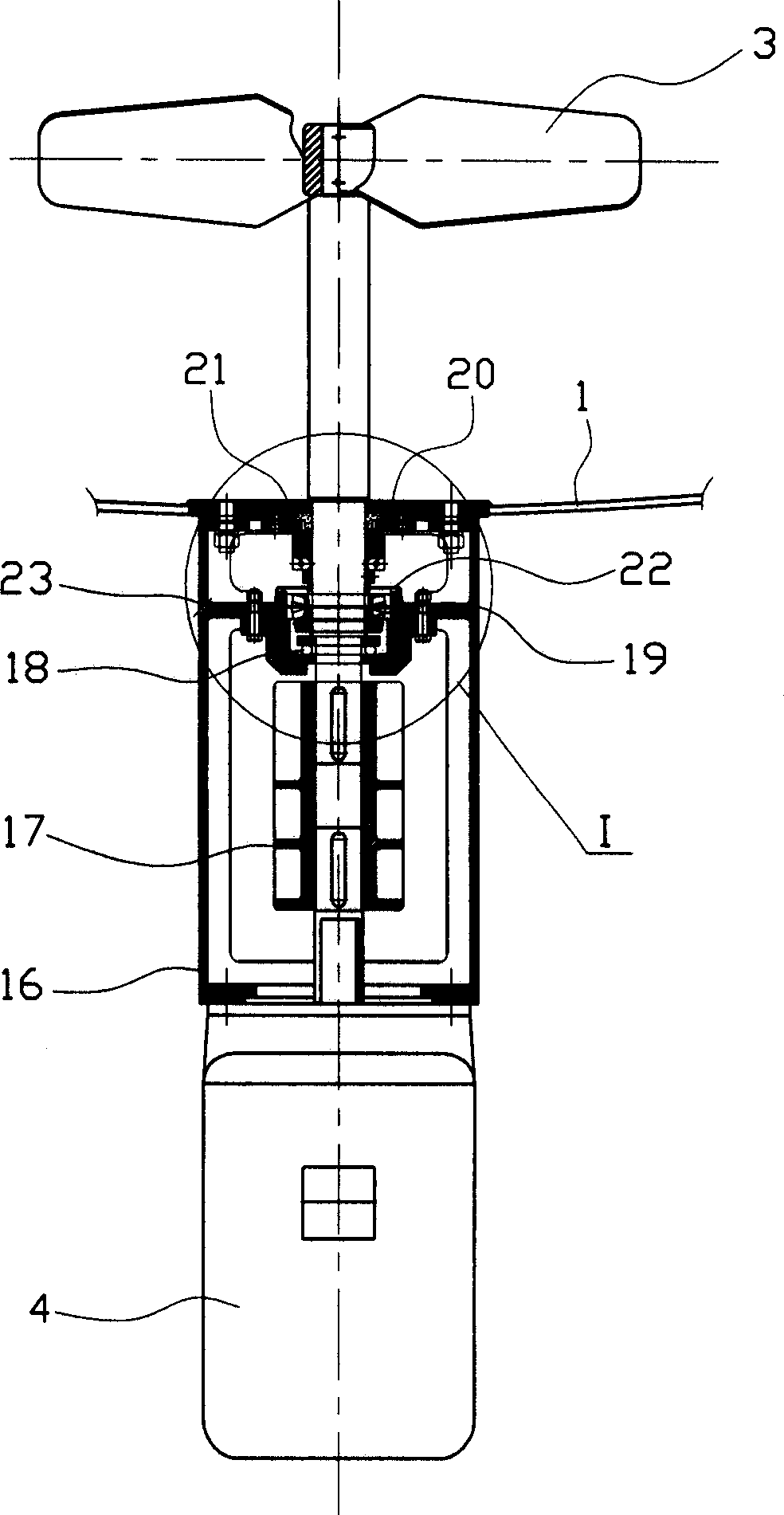

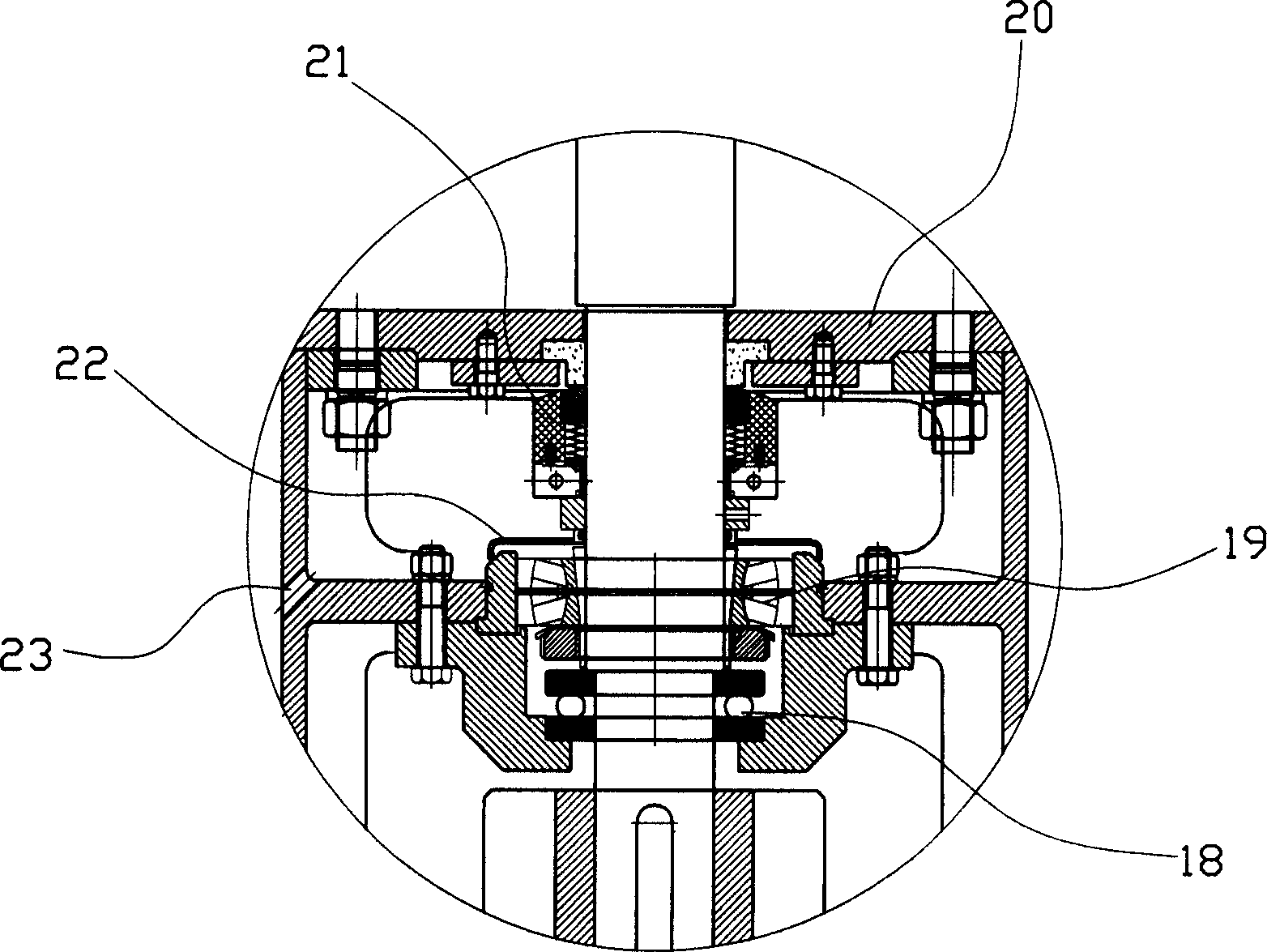

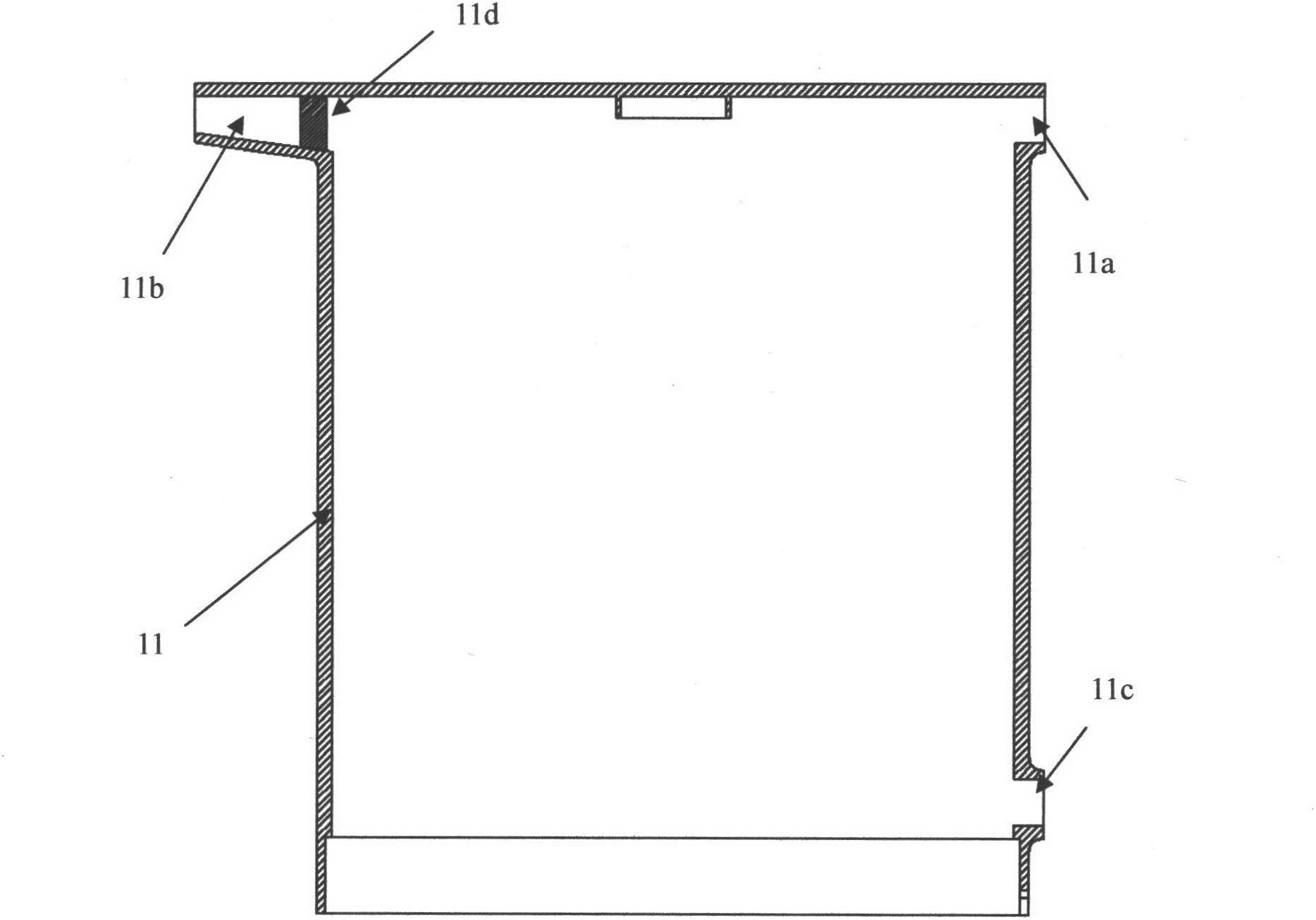

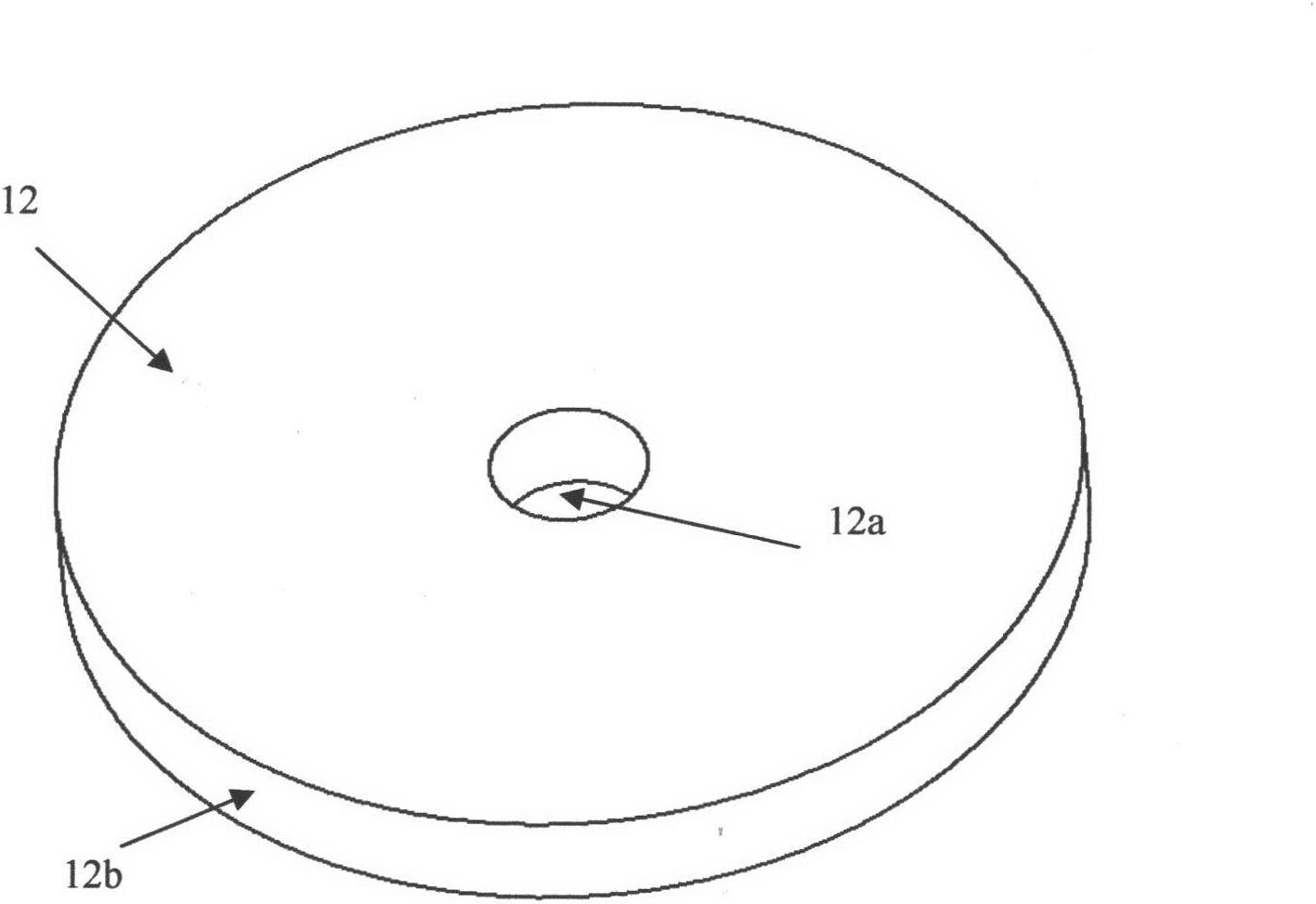

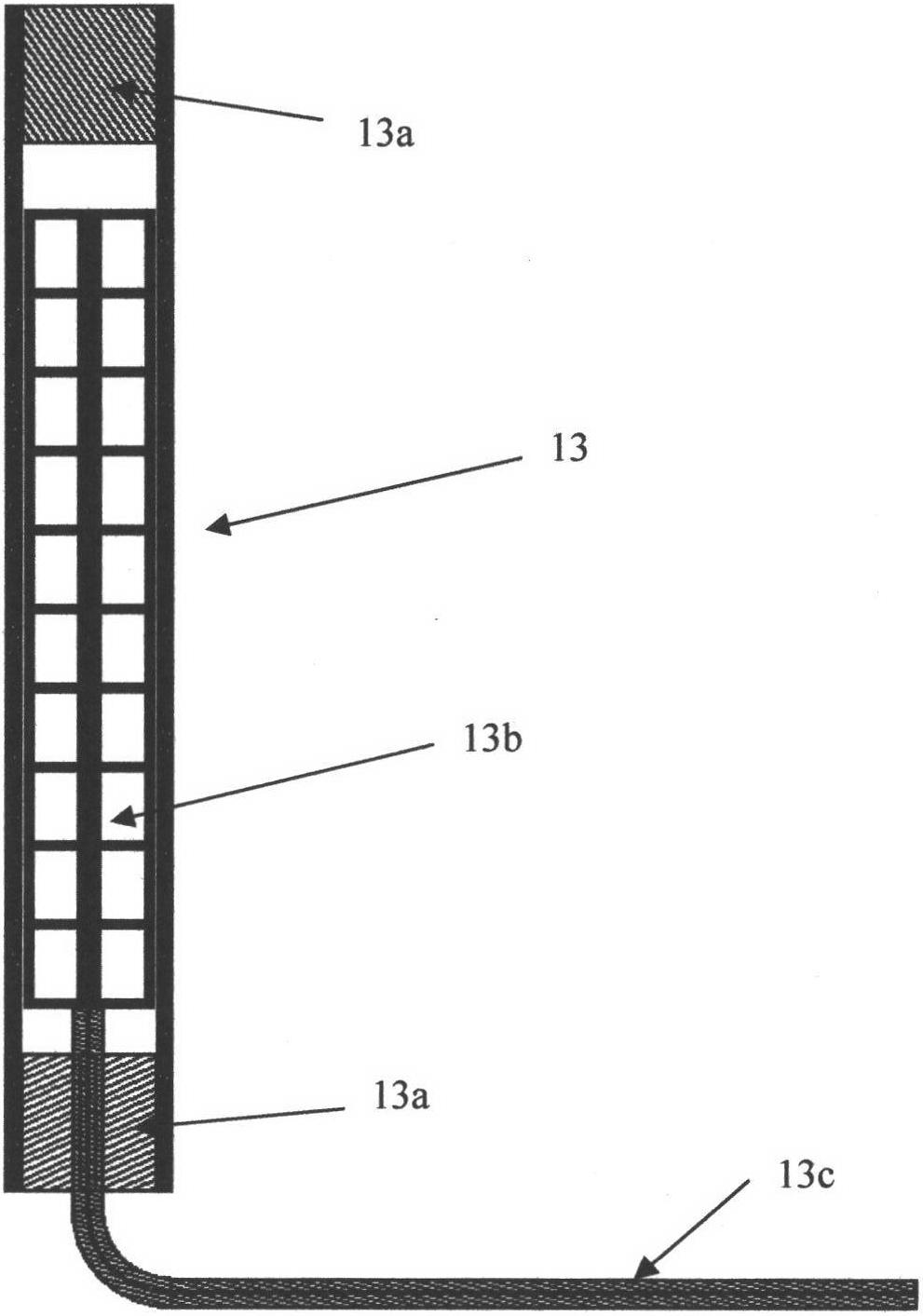

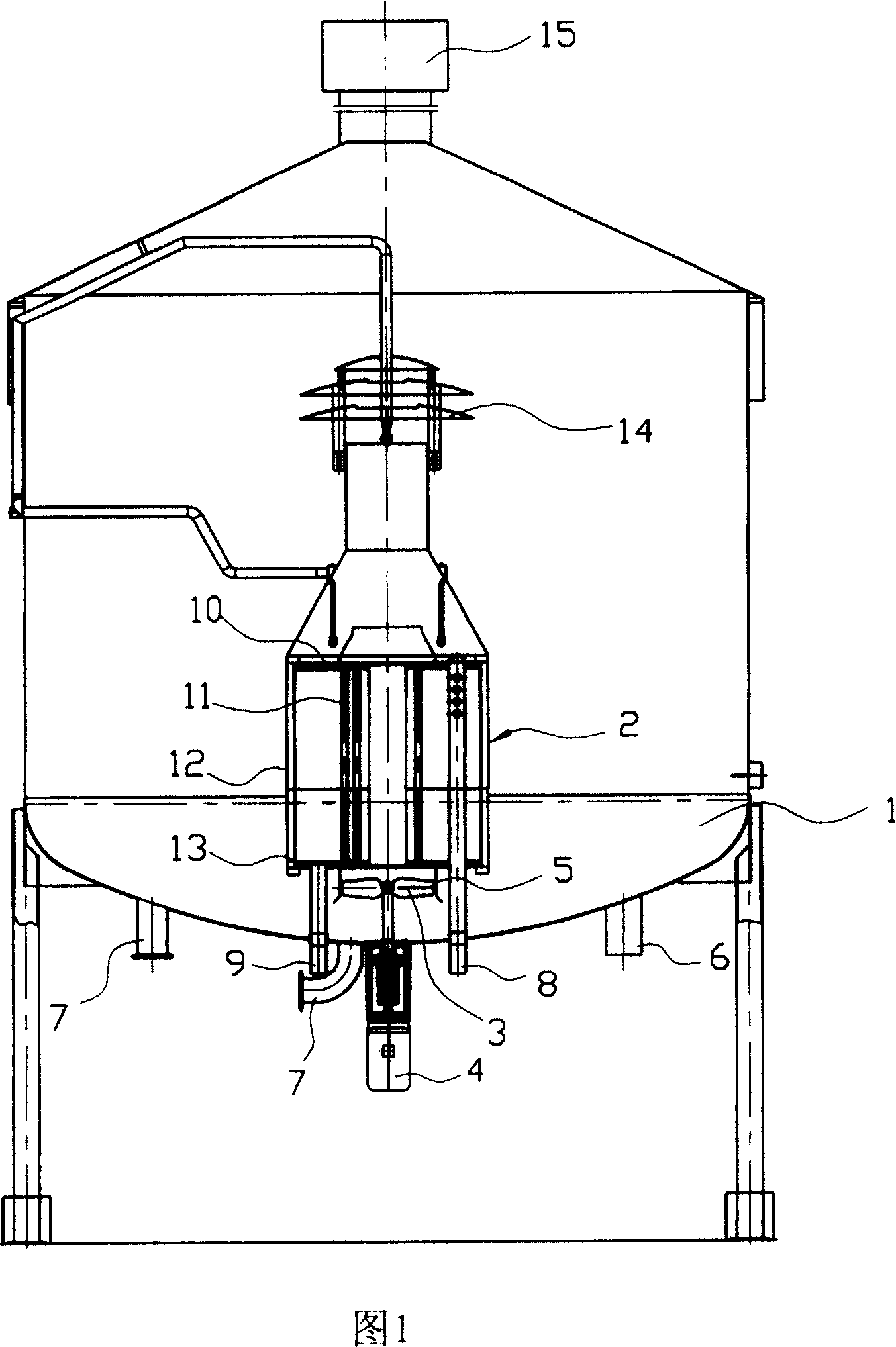

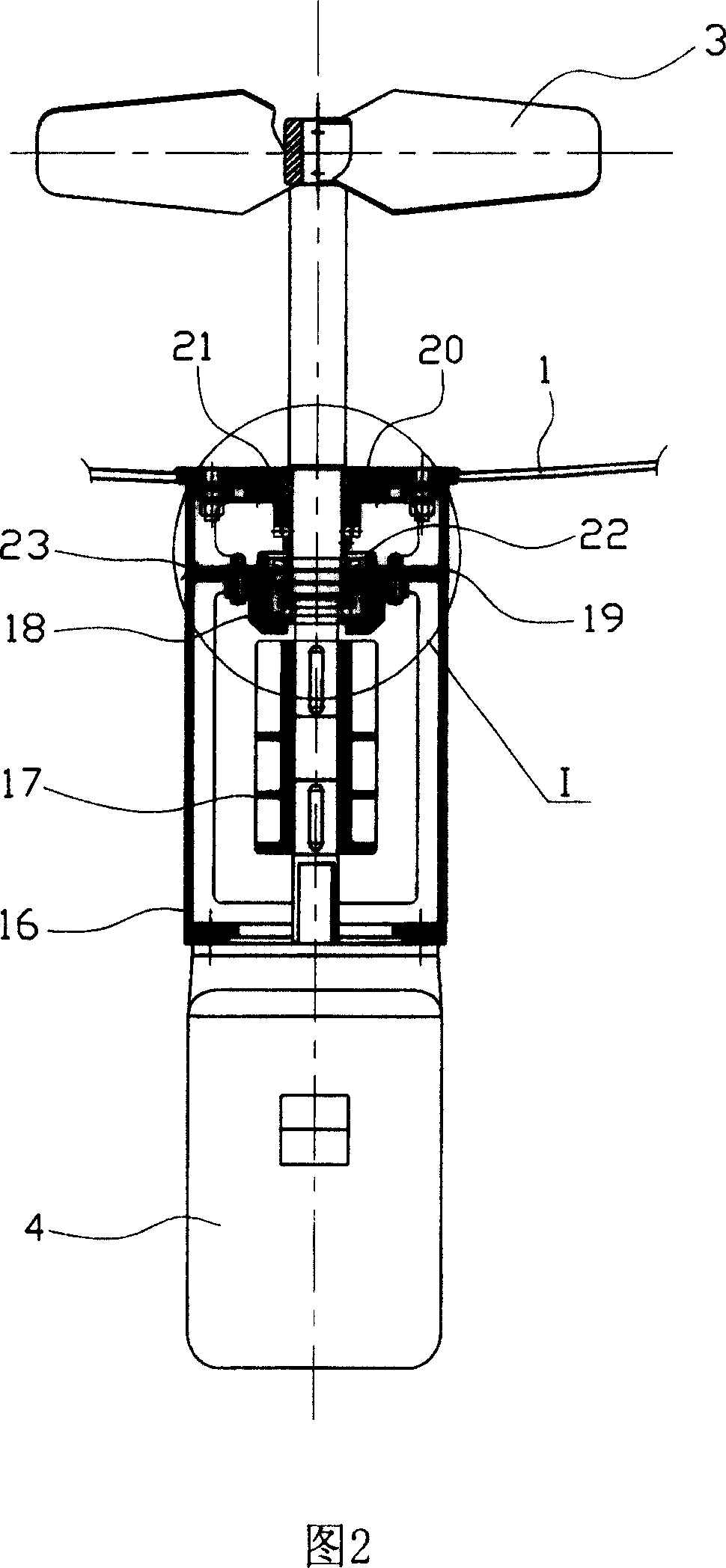

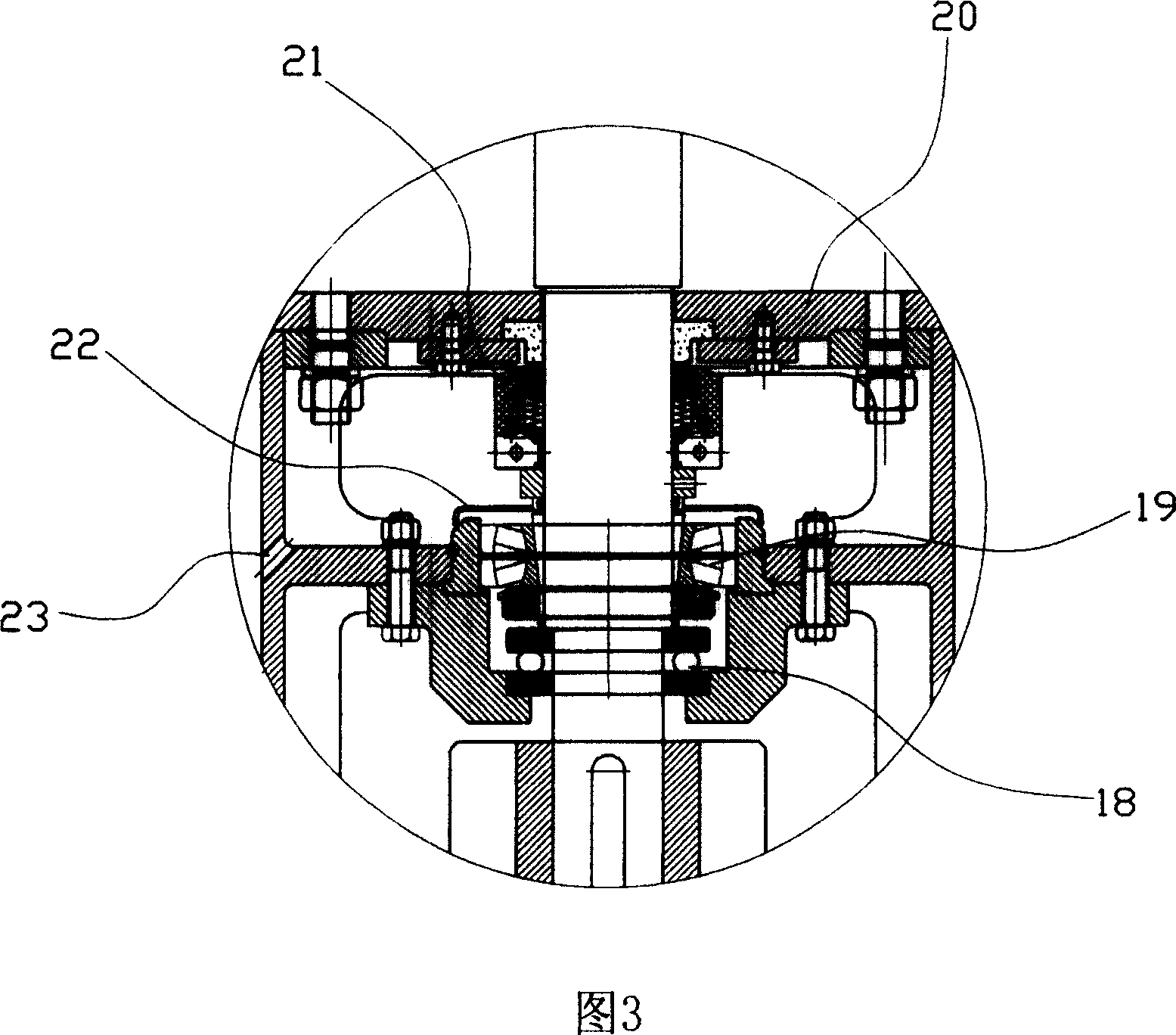

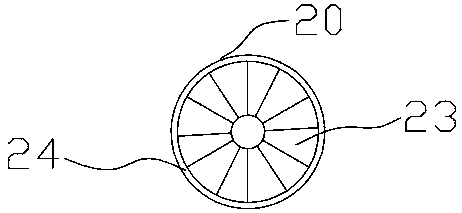

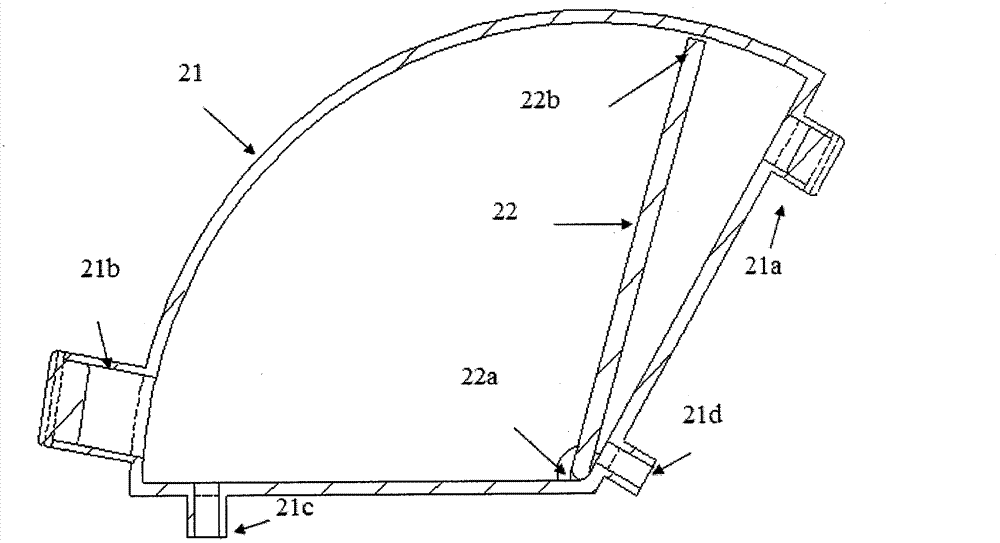

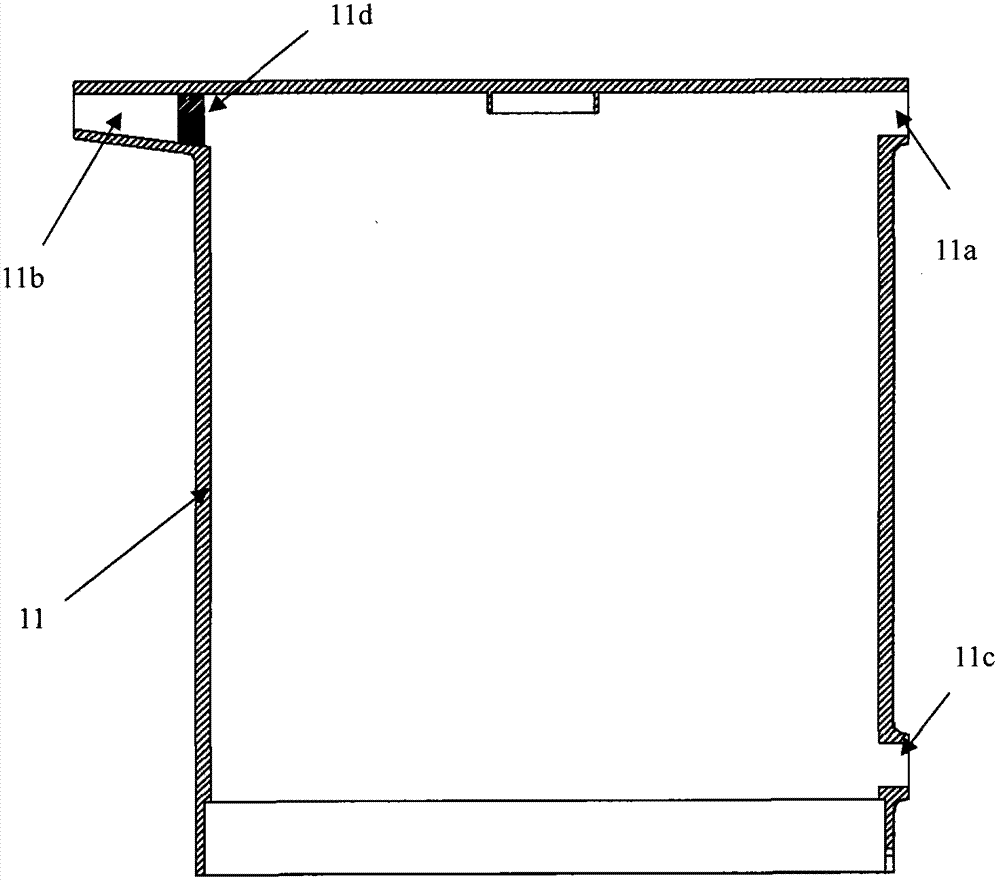

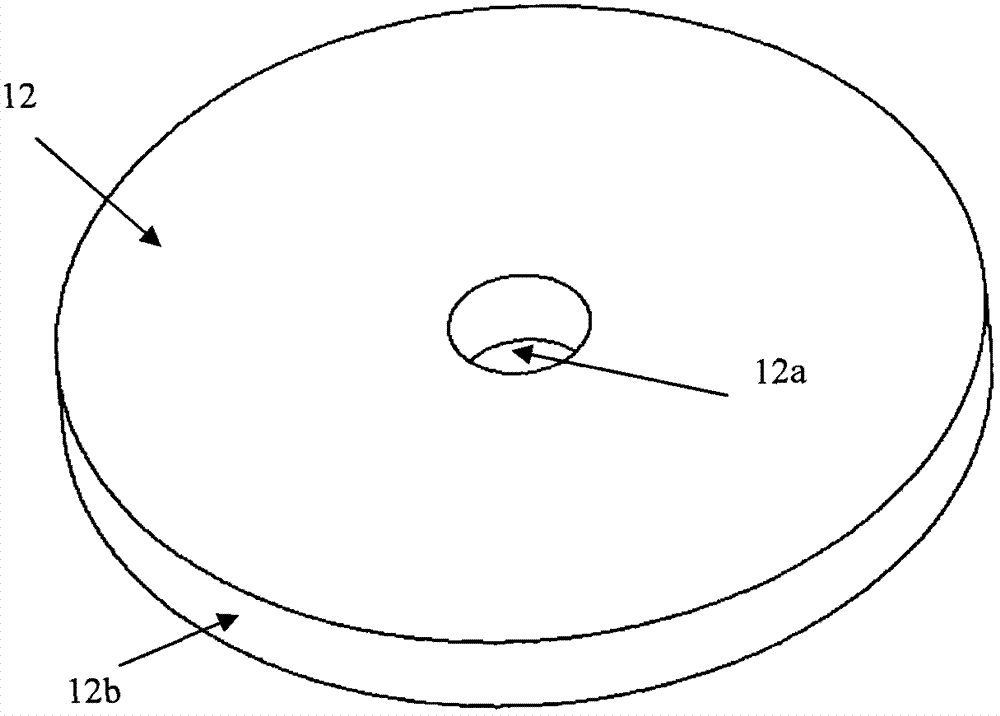

Internal circulation boiling pot

The invention relates to an internal circulation-boiling kettle. It includes kettle body, tube and shell heat exchanger, and allocation cover. The tube and shell heat exchanger includes shell body and many exchange tubes. Its feature is that kettle body is set helical runner linked to electric machinery. After adopting the upper structure, wheat juice is forced to flow to the upper around the center tube of the heat exchanger by the helical runner. This can prevent fouling and blinding, and increase í‹thermosiphoníŒ action; and at the same time the wheat juice is only need to keep boiling to realize its circulation. So this can increase boiling efficiency, economize energy sources, and reduce consumption.

Owner:NINGBO LEHUI INT ENG EQUIP CO LTD

Method for improving production efficiency of vacuum crystallization for titaniferous solution

ActiveCN102757100ARaise feed temperatureShorten the boil timeSolution crystallizationIron sulfatesPhysical chemistryCrystallization

The invention discloses a method for improving the production efficiency of vacuum crystallization for titaniferous solution, wherein the method comprises a titaniferous solution vacuum crystallization process and a titaniferous solution hot concentration process; the hot concentration discharging temperature is higher than the feeding titaniferous solution temperature for the titaniferous solution vacuum crystallization; heat exchange is carried out between feeding titaniferous solution for the titaniferous solution vacuum crystallization and discharging material for the titaniferous solution hot concentration; and then the feeding titaniferous solution that is processed through heat exchange is conveyed to a titaniferous solution vacuum crystallization container for crystallization. The method adopts the technical scheme that the conventional production temperatures and negative pressure conditions are utilized to perform the heat exchange between the feeding material for the titaniferous solution vacuum crystallization and the discharging material for the hot concentration, and the feeding temperature for the titaniferous solution vacuum crystallization is raised, so that the time for titaniferous solution boiling is shortened without changing the negative pressure conditions, the crystallization time of titaniferous solution in the vacuum crystallization container is shortened, and the production efficiency of vacuum crystallization for titaniferous solution can be improved further.

Owner:LOMON BILLIONS GRP CO LTD

Water tank device capable of changing water quality in same container

InactiveCN102631135ASolve the problem of purification and conversion of water qualitySave electricityWater-boiling vesselsWater volumeWater quality

The invention provides a water tank device capable of changing water quality in the same container, which comprises a water tank shell, a purification handle and a separation board, wherein the separation board is positioned in the water tank shell, separates the water tank shell into two cavity bodies, and can move in the water tank shell, a water purification device is arranged in the purification handle, the separation board moves along with the variation of the water volumes in the two cavity bodies, and accordingly, the water tank which is used by the same container realizes the water quality changing in the same container. According to the water tank device provided in the invention, not only is the problem of using the same smaller water tank to purify and change the water quality solved, and more electric energy saved when water is heated, but also the water heating time is shortened, and the use is very convenient.

Owner:刘小清

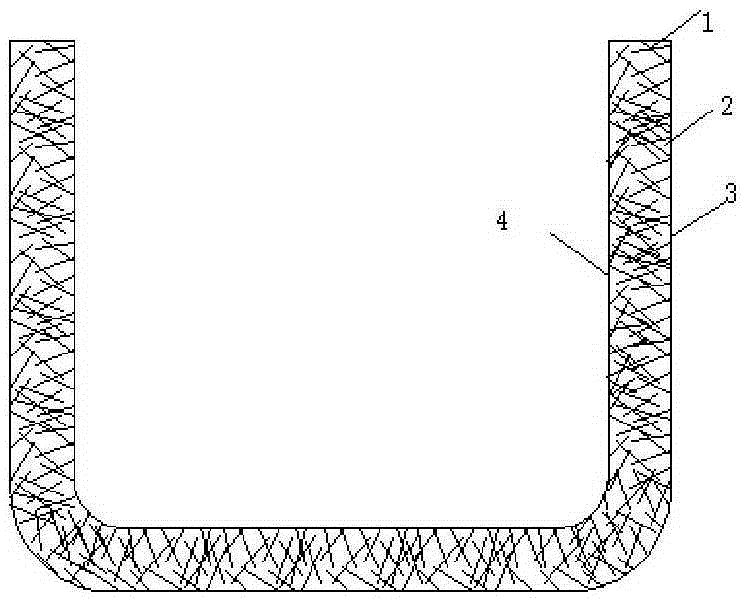

A high-thermal-conductivity ceramic inner container used for an electric cooker

ActiveCN106800404AShorten the boil timeImprove thermal shock resistanceClaywaresThermal energyCarbon fibers

The title of the invention is a high-thermal-conductivity ceramic inner container used for an electric cooker. The invention discloses a high-thermal-conductivity ceramic inner container and relates to the field of electric cookers. The ceramic inner container is characterized in that a high-thermal-conductivity carbon fiber material is added into a ceramic matrix, the carbon fiber material is arranged in the ceramic matrix in a disordered manner and is overlapped to form a heat conducting network, heat transferred from a heating disc reaches the inner wall of the inner container through the ceramic matrix and the carbon fiber network, the carbon fiber network is adopted as a high-speed passage for heat transfer, and the heating speed of the electric cooker is higher. Compared with common ceramic inner containers, the heating and temperature rising speed of the ceramic inner container is higher, low-temperature soaking time for cooking rice and other foods is short and rice taste is good.

Owner:FOSHAN BAIRUI NEW MATERIAL TECH CO LTD

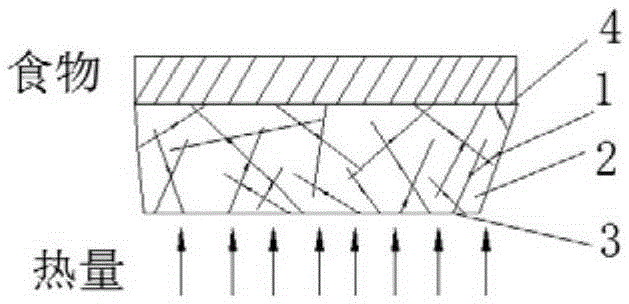

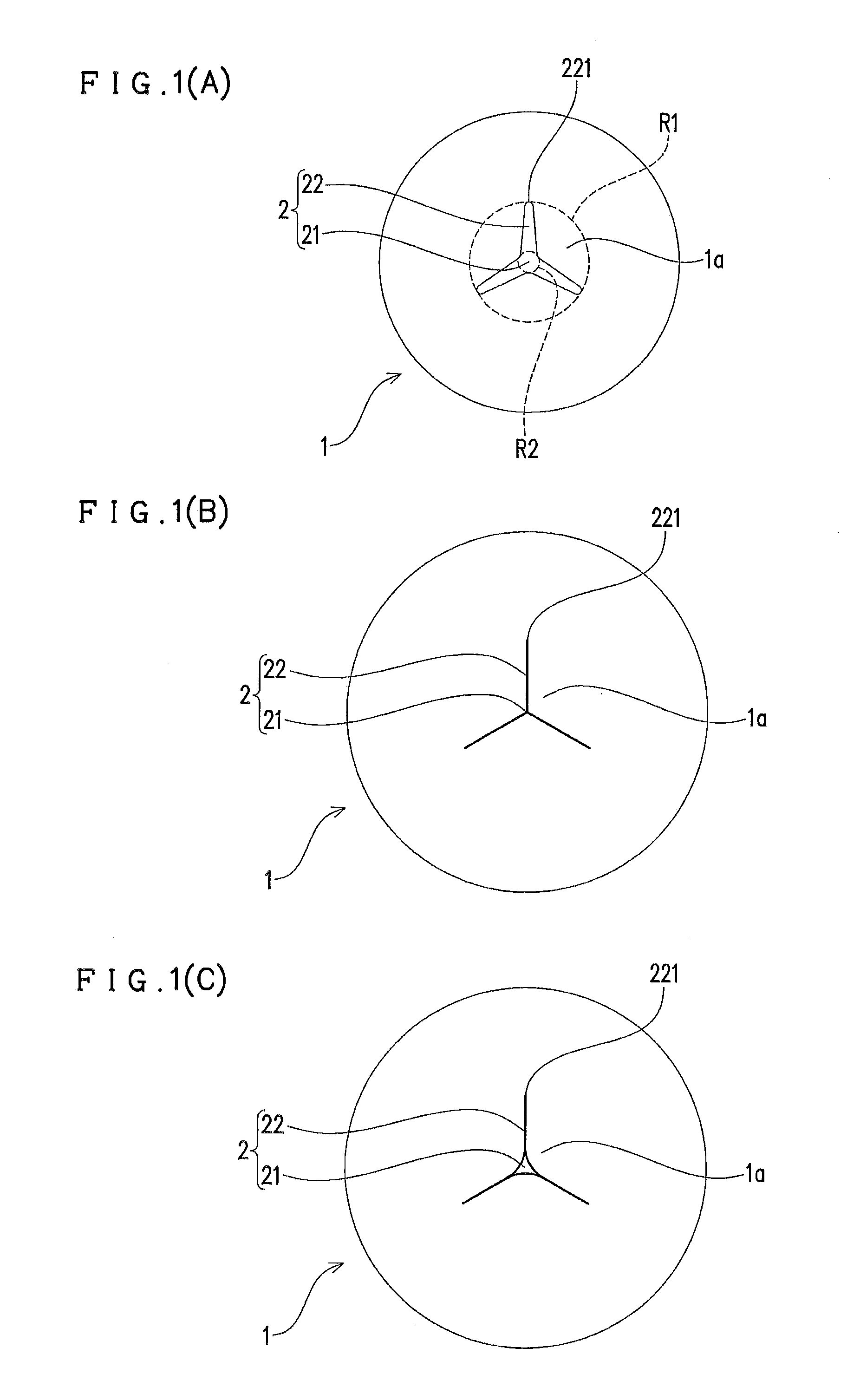

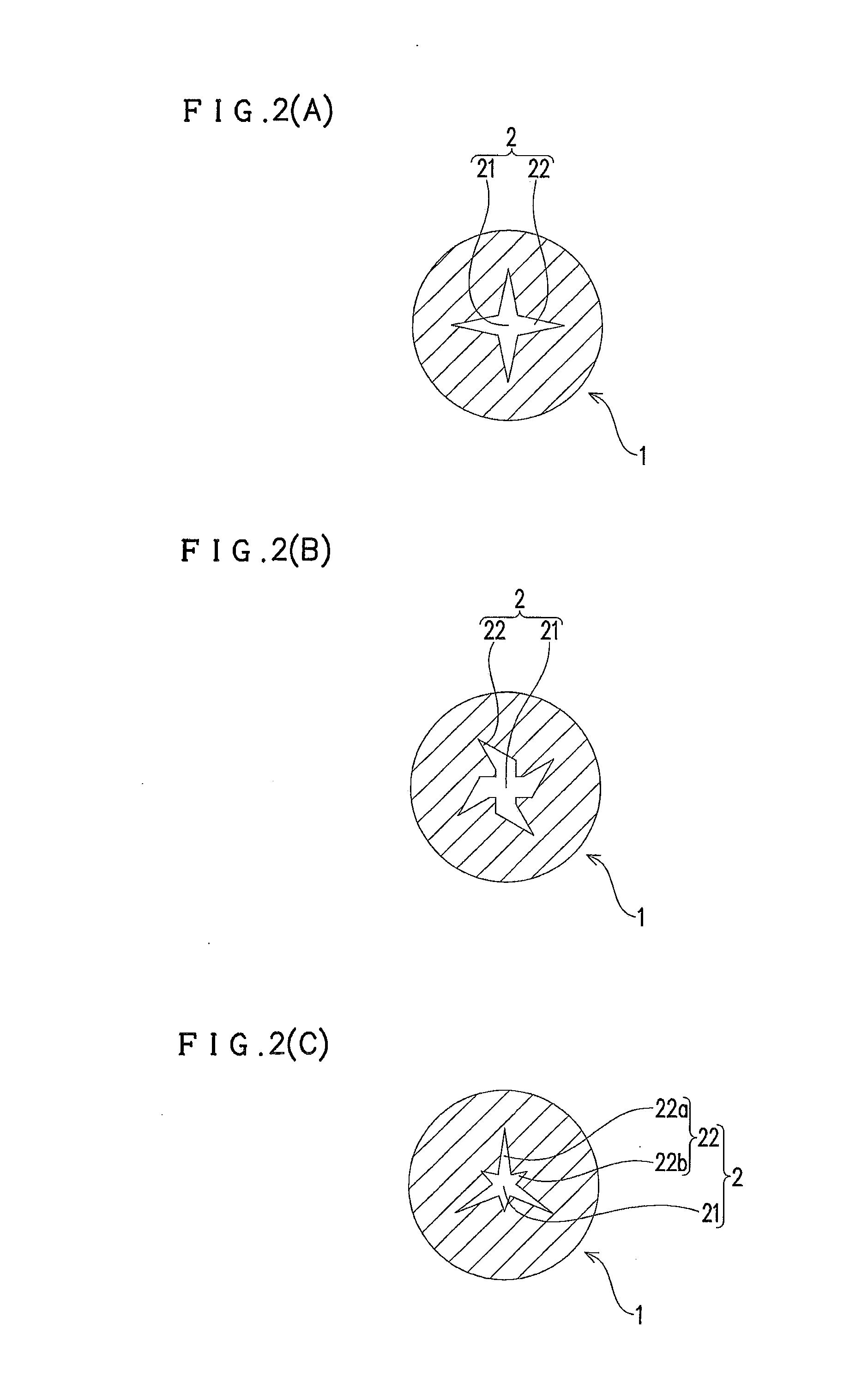

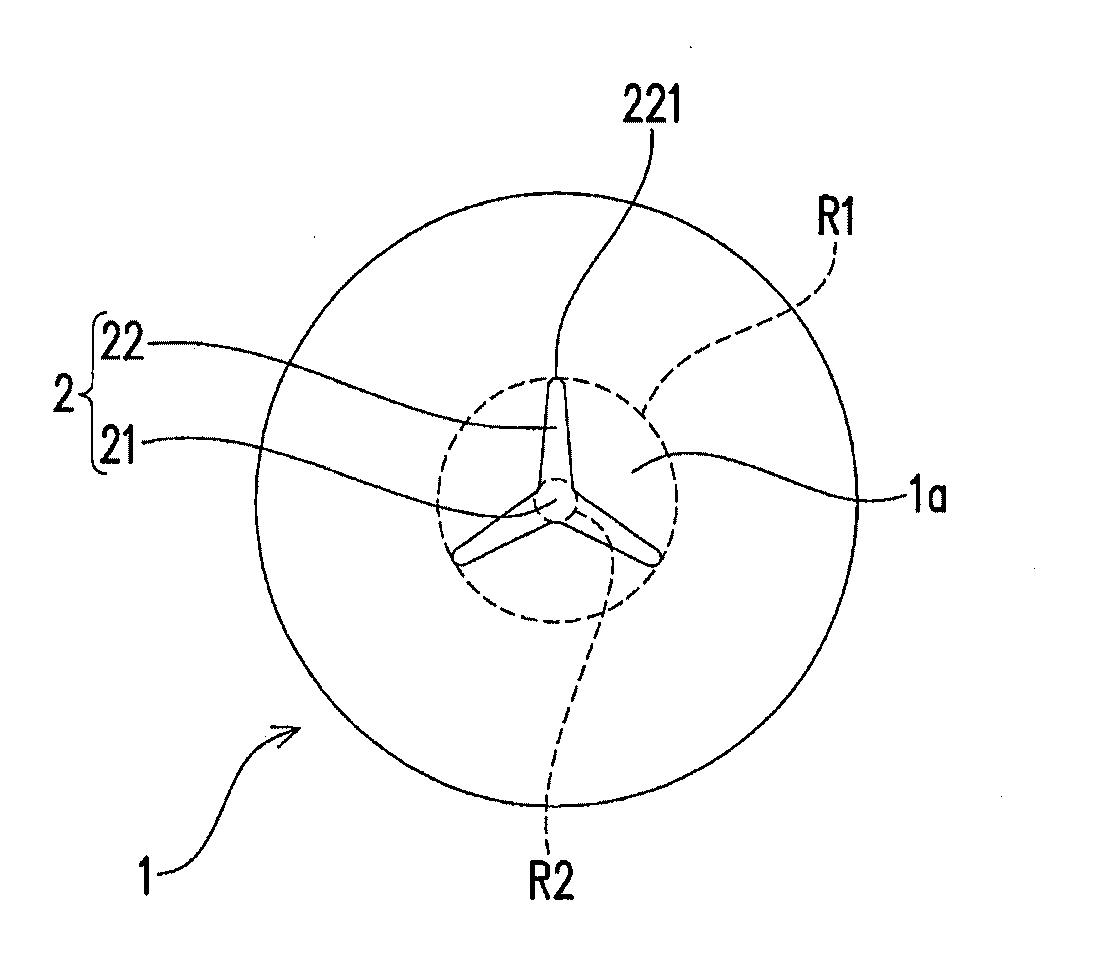

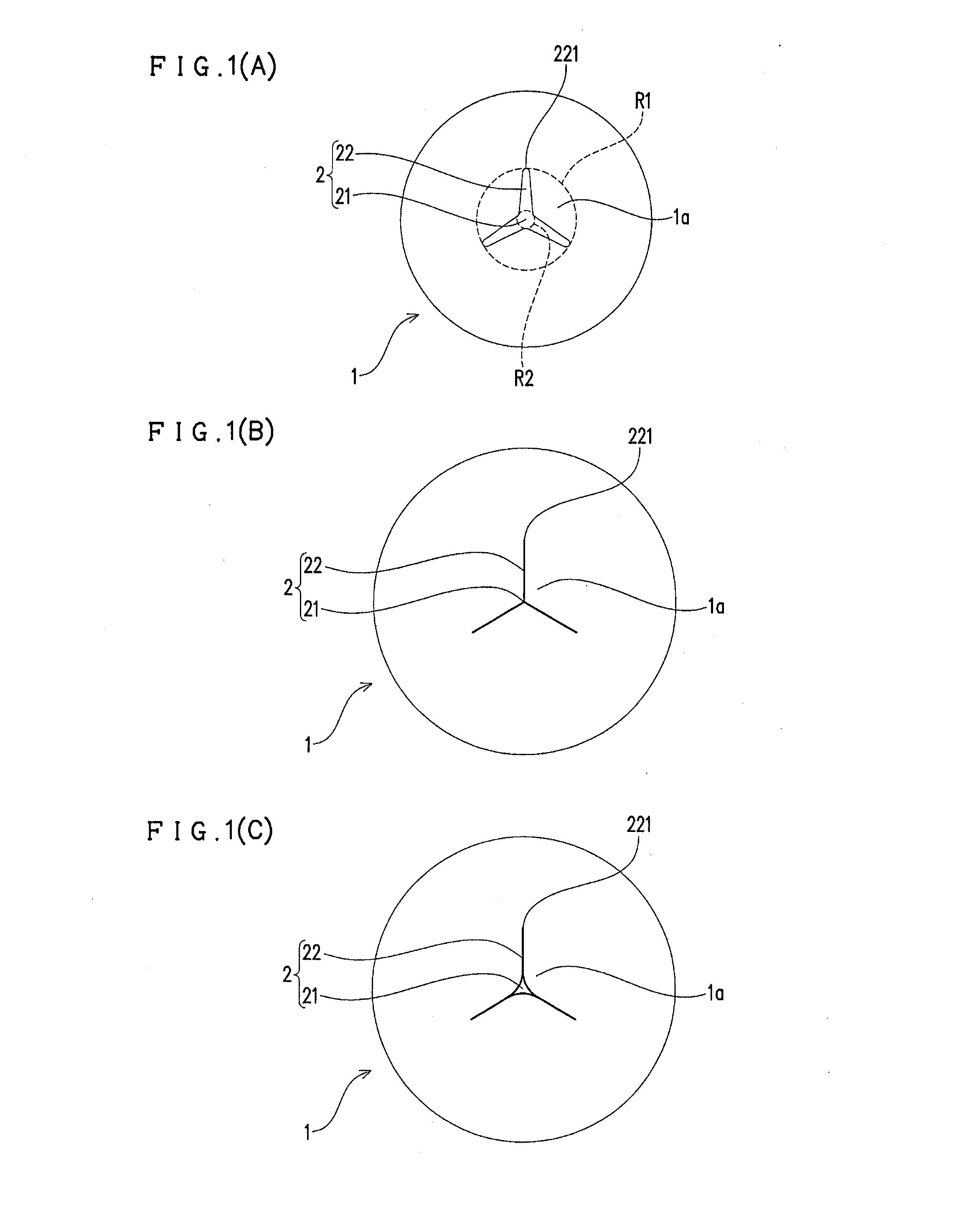

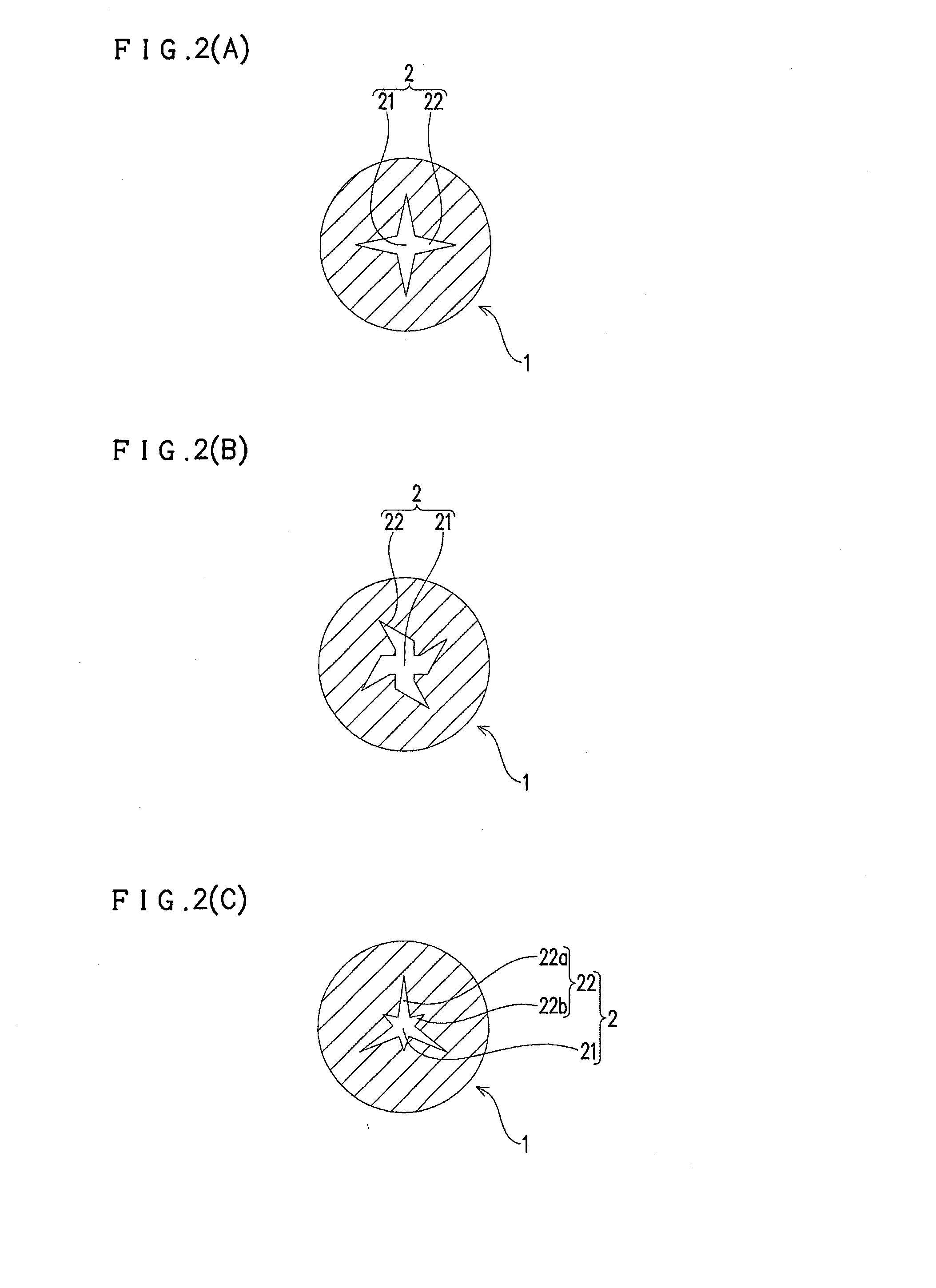

Extruded Noodle and Die Piece for Extruded Noodle

ActiveUS20130302498A1Fast penetrationShorten the boil timeDough treatmentConfectioneryEngineeringMechanical engineering

Owner:NISSIN YORK

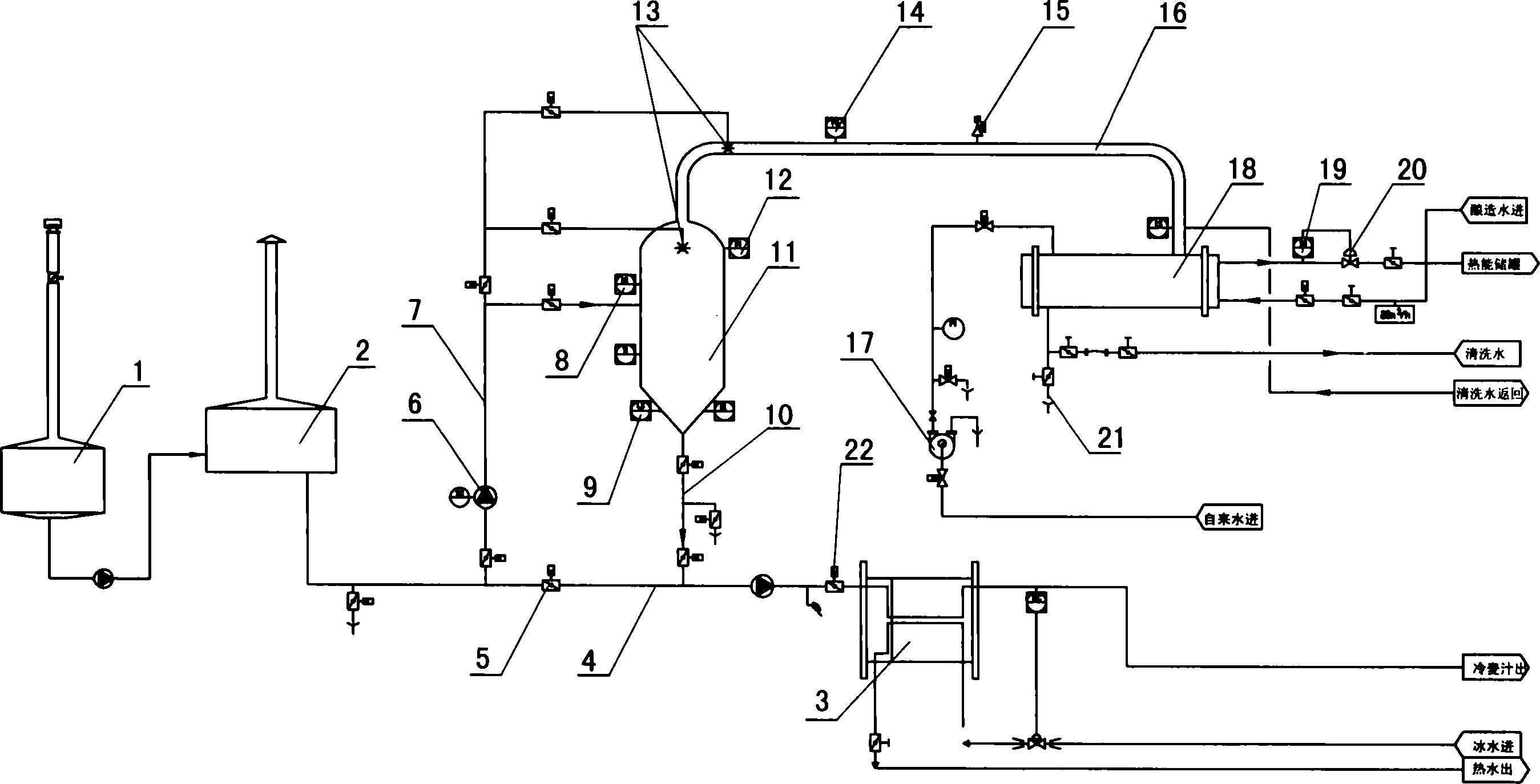

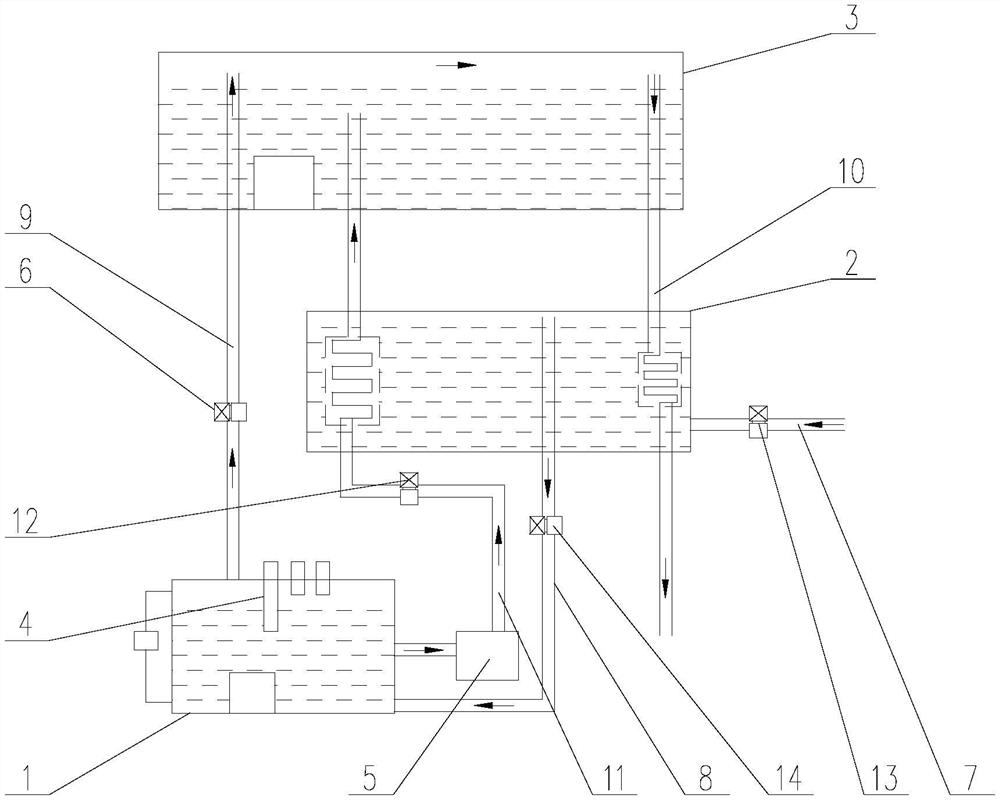

Flash evaporation system for wheat juice

The invention discloses a wheat-liquid flash evaporating system, which comprises the following parts: boiler, cyclotron sediment groove, cooler and flash evaporating chamber with charge and discharge on the upper and lower parts, wherein the discharge of boiler connects the discharge of cyclotron sediment groove through pipe; the charge of flash evaporating chamber connects discharge of cyclotron sediment groove through charge pipe; the discharge of flash evaporating chamber connects liquid material charge of cooler through discharge pipe; the vent hole is opened on the flash evaporating chamber through vent pipe and vacuum pump, which makes pressure in the evaporating chamber lower than saturated vapor pressure of wheat liquid. The invention shortens boiling time, which saves cost and reduces consumption.

Owner:NINGBO LEHUI INT ENG EQUIP CO LTD

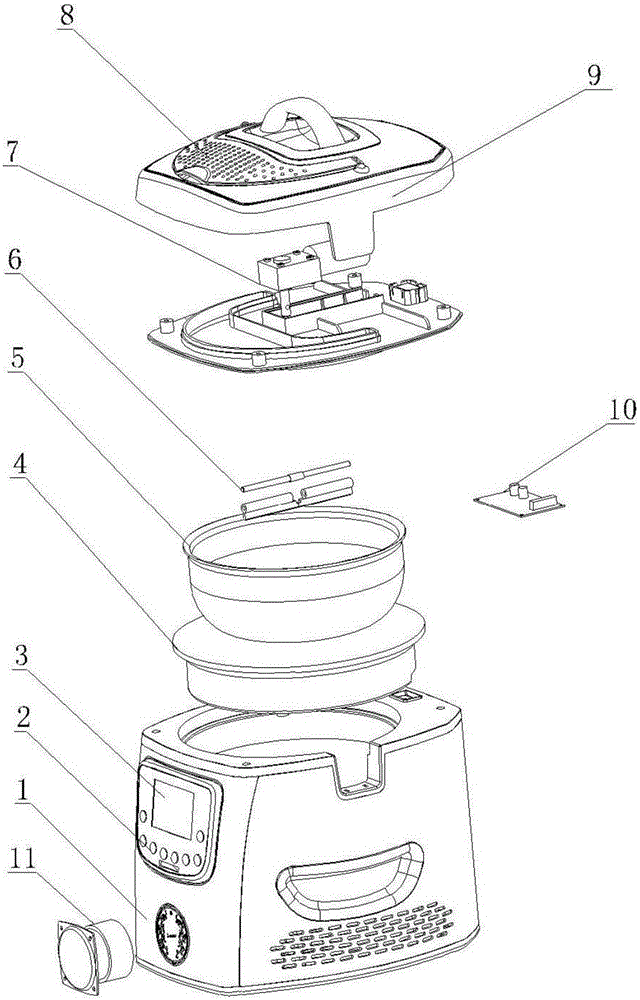

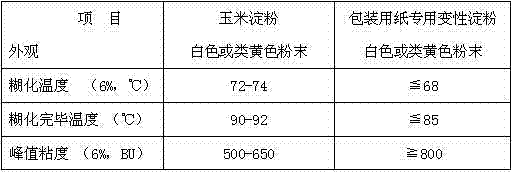

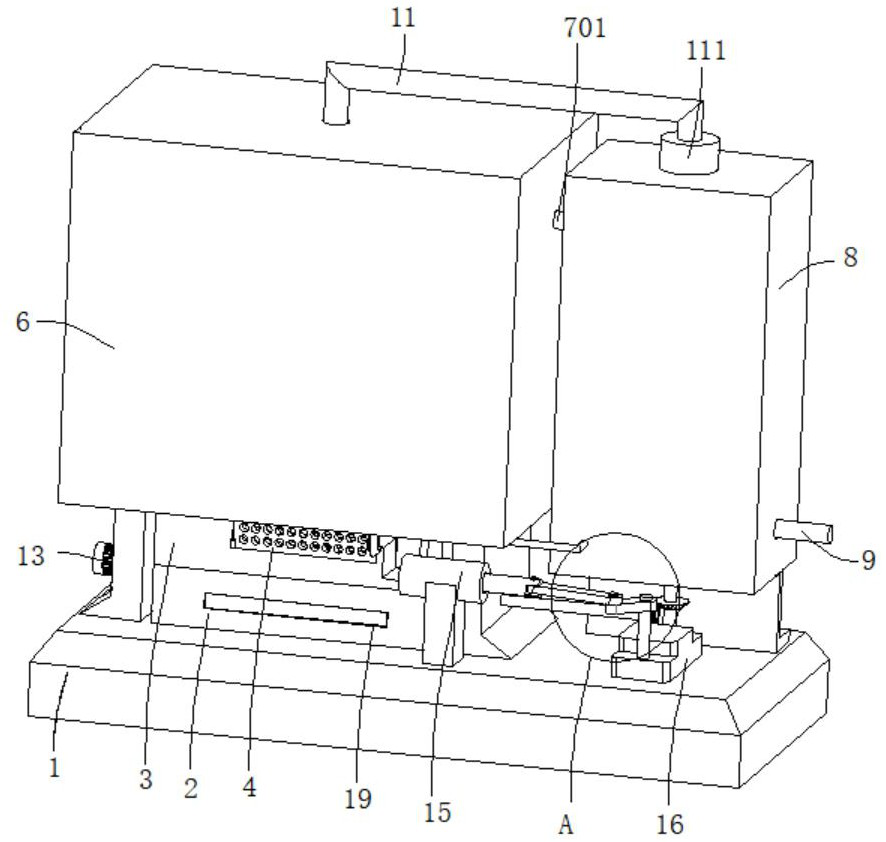

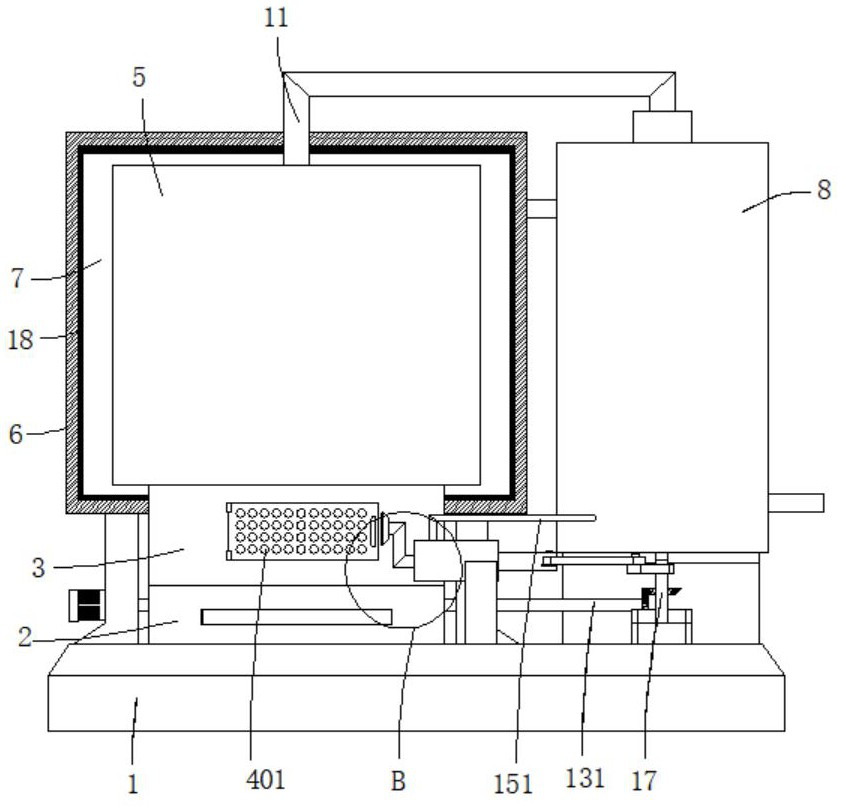

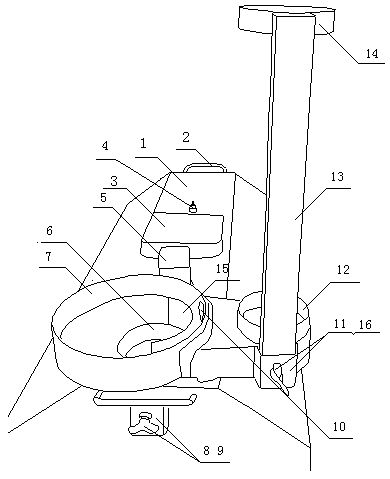

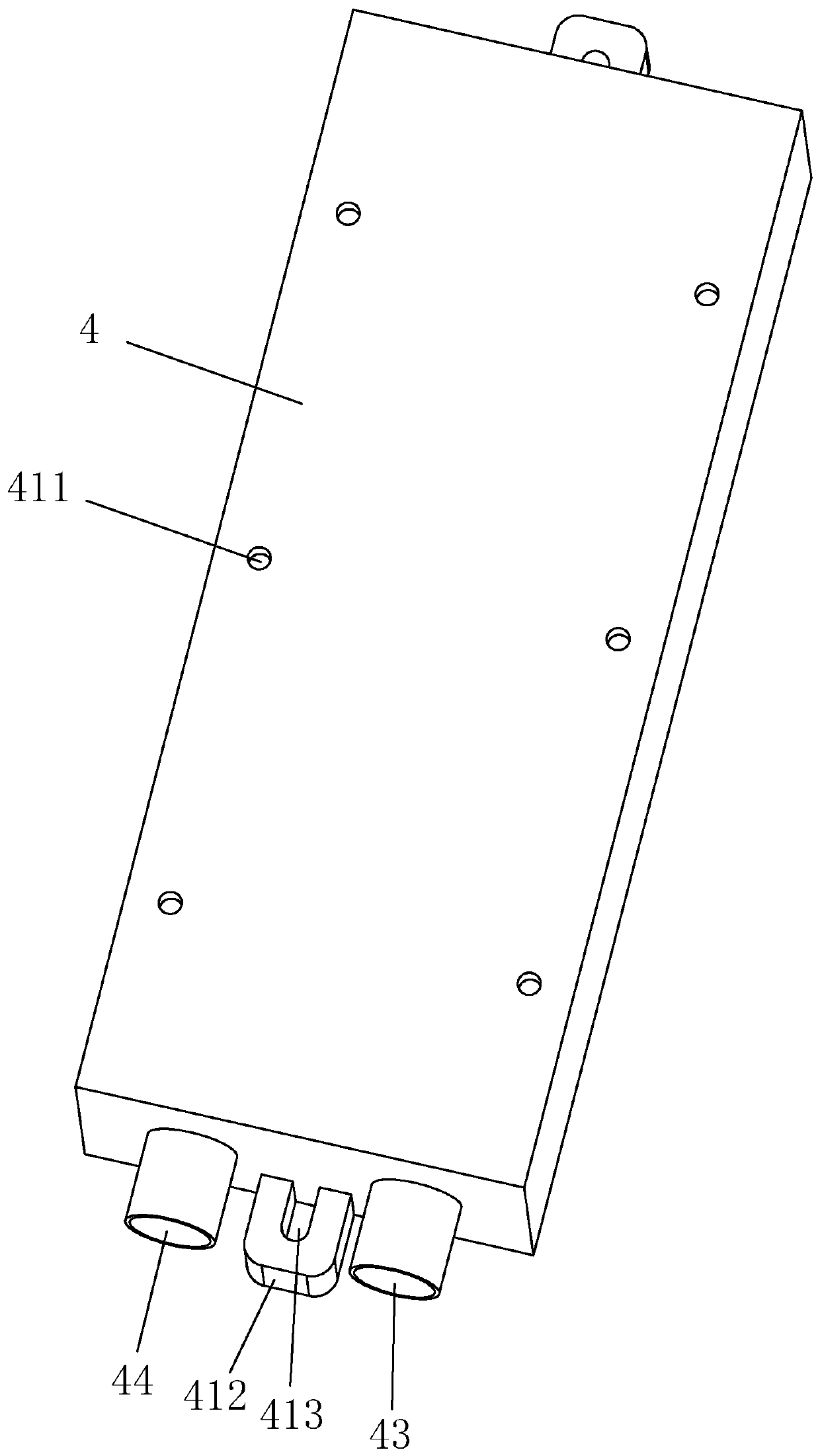

Full-automatic degelatinizing machine and full-automatic degelatinizing method

PendingCN105853229AEasy to operateShorten the boil timePharmaceutical product form changeEngineeringOperability

The invention provides a full-automatic degelatinizing machine. The full-automatic degelatinizing machine comprises a shell, a heating device, a degelatinizing vessel and an upper cover. Meanwhile, the invention also provides a full-automatic degelatinizing method for the full-automatic degelatinizing machine. According to the full-automatic degelatinizing machine and the full-automatic degelatinizing method disclosed by the invention, the degelatinizing time can be shortened, automated boiling is realized, and the operability for degelatinizing operation is improved.

Owner:HIT SMART FACTORY CO LTD

Gas burner apparatus and cooking apparatus including the same

ActiveUS10488051B2Output maximizationIncrease productionDomestic stoves or rangesNon-combustible gases/liquids supplyEngineeringGas burner

Owner:SAMSUNG ELECTRONICS CO LTD

Harvesting and storing method for mung beans

InactiveCN103783150AGuaranteed nutritionSolve the problem of hard teethFood processingFruits/vegetable preservation by freezing/coolingCrack toothPlastic packaging

The invention relates to a harvesting and storing method for mung beans. The harvesting and storing method comprises the following steps: picking mung bean pods which are yellow green and are about to be ripen; stripping to obtain mung bean grains; washing the mung beans and leaching the water; putting the mung beans under sunlight to be aired; keeping 10-15% of water of the mung bean grains; putting the mung bean grains into a plastic packaging bag; extruding surplus air in the packaging bag and sealing; putting the sealed and packaged mung bean grains into a low-temperature environment at a temperature ranging from -25 DEG C to -30 DEG C, and freezing for 1-1.5 hours; and transferring the mung bean grains into a refrigeration storage to be stored at a temperature ranging from 0 DEG C to -4 DEG C. The invention relates to a whole harvesting, processing and storing process of the mung beans; the mung bean grains keep fresh all the time and the nutrition of the mung beans is kept very well; the mung beans are easy to stew and the energy source consumption of the steamed mung beans is saved; the problem that the mung beans are hard and crack teeth is solved.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES

Internal circulation boiling pot

Owner:NINGBO LEHUI INT ENG EQUIP CO LTD

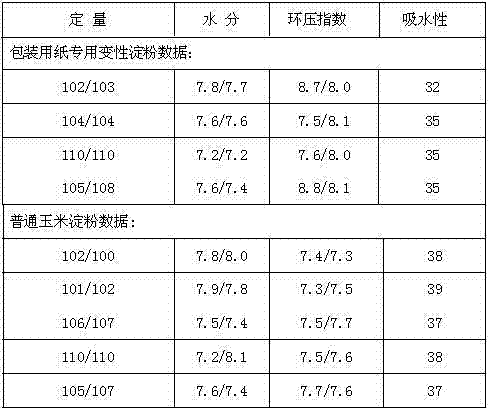

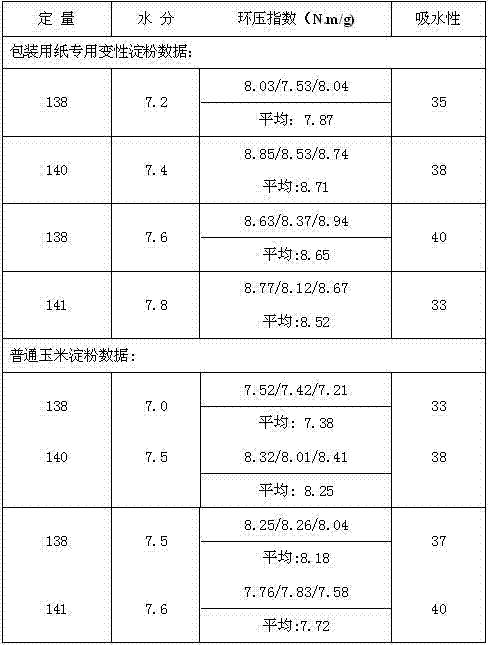

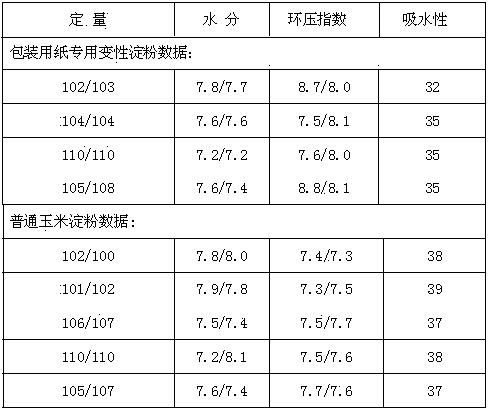

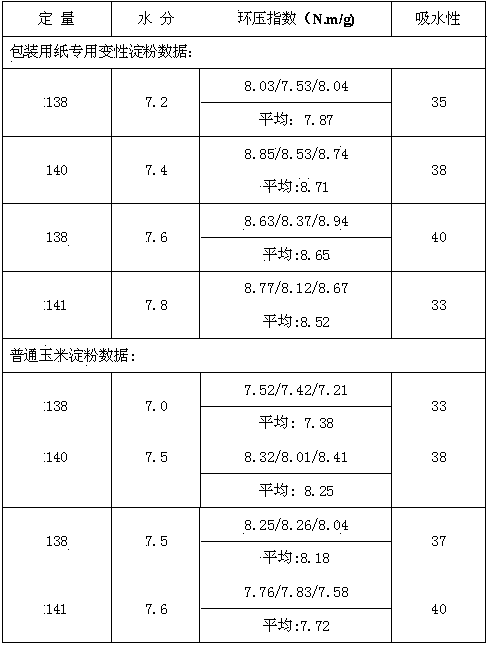

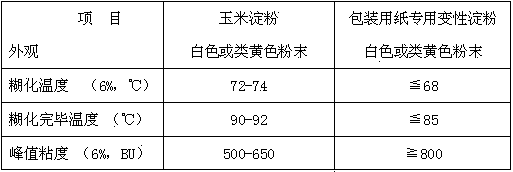

Special modified starch for wrapping paper and production method thereof

ActiveCN102731842AShorten the boil timeEasy to realize the industrialization of special modified starchBiotechnologySODIUM METAPHOSPHATE

The invention provides a special modified starch for wrapping paper and a production method thereof, belonging to the filed of deep processing of maize. The special modified starch is prepared from the following components: in a volume mass ratio, 2250 m<3> to 2750 m<3> of maize starch milk 21Be' ( equivalent to 900 to 1100 Kg of a dry basis), 18 to 22 Kg of sodium tripolyphosphate, 4.5 to 5.5 Kg of sodium trimetaphosphate, 10.8 to 13.2 Kg of urea, 4.5 to 5.5 Kg of sodium hydroxide and 36 to 44 Kg of sodium carbonate. The special modified starch for wrapping paper provided in the invention has the following advantages: the special modified starch is easy to gelatinize and has a low gelatinization temperature and a short gelatinization time; gelatinized liquid has good fluidity, transparency, film forming ability and film strength; and the special modified starch has excellent bonding performance with a variety of fibers and good compatibility with other auxiliary agents.

Owner:JILIN COFCO BIOCHEM

Induction electric kettle

InactiveCN108185815AImprove insulation effectReduce CooldownWater-boiling vesselsEngineeringWater bottle

The invention discloses an induction electric kettle and belongs to the technical field of water heating. The induction electric kettle comprises a housing; a seal cover is arranged at the upper end of the housing and is movably connected with a motor; the output end of the motor is connected with a spindle; the lower end of the spindle is positioned in a partition; the partition divides the housing into an upper chamber and a lower chamber; insulation cotton is arranged between the upper and lower chambers and the housing; a heating rod is arranged in the lower chamber; a base is arranged atthe bottom of the housing. The induction electric kettle can quickly boil water, can effectively prevent scale, has no influence on the quality of drinking water, can effectively remove chlorine ionsin water, and is simple in structure and convenient to operate.

Owner:金华市鸿讯机械工程技术有限公司

Water tank device capable of converting water quality in same vessel

InactiveCN102727097ASolve the problem of purification and conversion of water qualitySave electricityBeverage vesselsWater volumeWater quality

The invention provides a water tank device capable of converting water quality in the same vessel. The water tank device comprises a water tank shell, a purifying handle and a separating plate, wherein the separating plate is positioned in the water tank shell and divides the water tank shell into two cavities, and the separating plate can move in the water tank shell; and a water purifying device is arranged in the purifying handle, and the separating plate moves along with the change of water quantity in the two cavities, thereby realizing the converting of water quality in the same container. The water tank device provided by the invention not only solves the difficulty that the water is purified and the water quality is converted in the same smaller water tank, but also the electric energy is saved more in boiling water by heating, the water boiling time is also shortened, and the use is extremely convenient.

Owner:刘小清

Water boiler for plateau railway vehicle and control method thereof

PendingCN114001342ADoes not take up much spaceIngenious structureSteam generation heating methodsBoiler controlWater storageThermodynamics

The invention relates to a water boiler for a plateau railway vehicle. The water boiler comprises a heating tank, a heat exchange tank and a water storage tank which are sequentially arranged from bottom to top, wherein the heating tank is provided with a heating device, the heat exchange tank is connected with the heating tank through a water replenishing pipe with an electromagnetic valve, the top of the heating tank communicates with the interior of the water storage tank through a steam outlet pipe provided with an electromagnetic valve, the heating tank is connected with the water storage box through a water outlet pipe equipped with with an electromagnetic valve and a water pump, the water outlet pipe is partially arranged in the heat exchange box for heat exchange, a steam exhaust pipe is inserted into the water storage tank, the upper end of the steam exhaust pipe is close to the top of the water storage tank and used for exhausting steam, a part of the steam exhaust pipe is arranged in the heat exchange tank and used for heat exchange, and the lower end of the steam exhaust pipe communicates with the atmosphere. According to the invention, a water boiling point can be increased, continuous water supply can be achieved, occupied space is small, and the problems that an electric heating water boiler for a passenger train in a high-altitude area cannot boil water and sterilization is not thorough are solved.

Owner:CRRC NANJING PUZHEN CO LTD

Flash evaporation system for wheat juice

ActiveCN100398635CQuality improvementImprove stabilityWort preparationEngineeringAtmospheric pressure

The invention discloses a wheat-liquid flash evaporating system, which comprises the following parts: boiler, cyclotron sediment groove, cooler and flash evaporating chamber with charge and discharge on the upper and lower parts, wherein the discharge of boiler connects the discharge of cyclotron sediment groove through pipe; the charge of flash evaporating chamber connects discharge of cyclotron sediment groove through charge pipe; the discharge of flash evaporating chamber connects liquid material charge of cooler through discharge pipe; the vent hole is opened on the flash evaporating chamber through vent pipe and vacuum pump, which makes pressure in the evaporating chamber lower than saturated vapor pressure of wheat liquid. The invention shortens boiling time, which saves cost and reduces consumption.

Owner:NINGBO LEHUI INT ENG EQUIP CO LTD

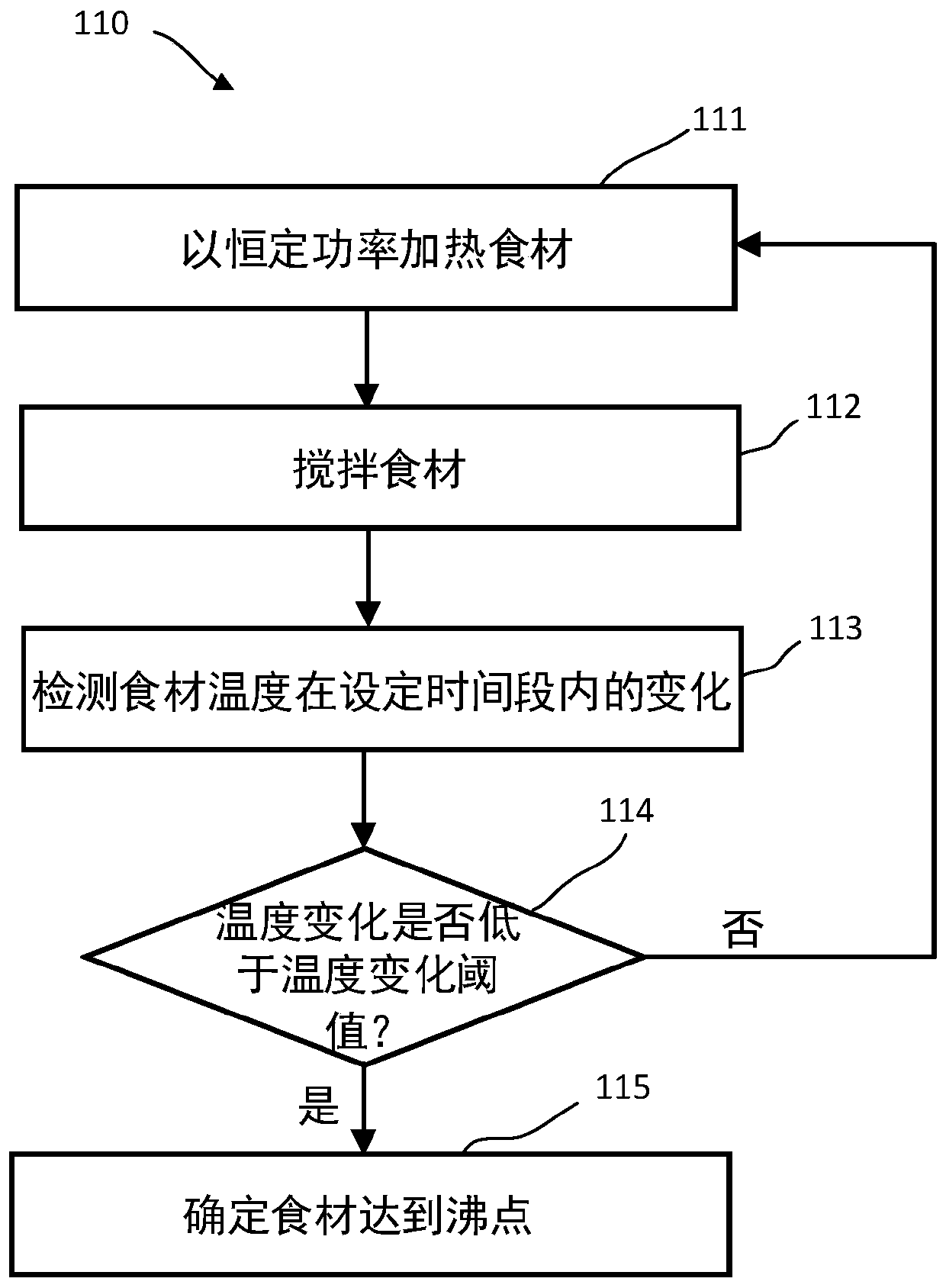

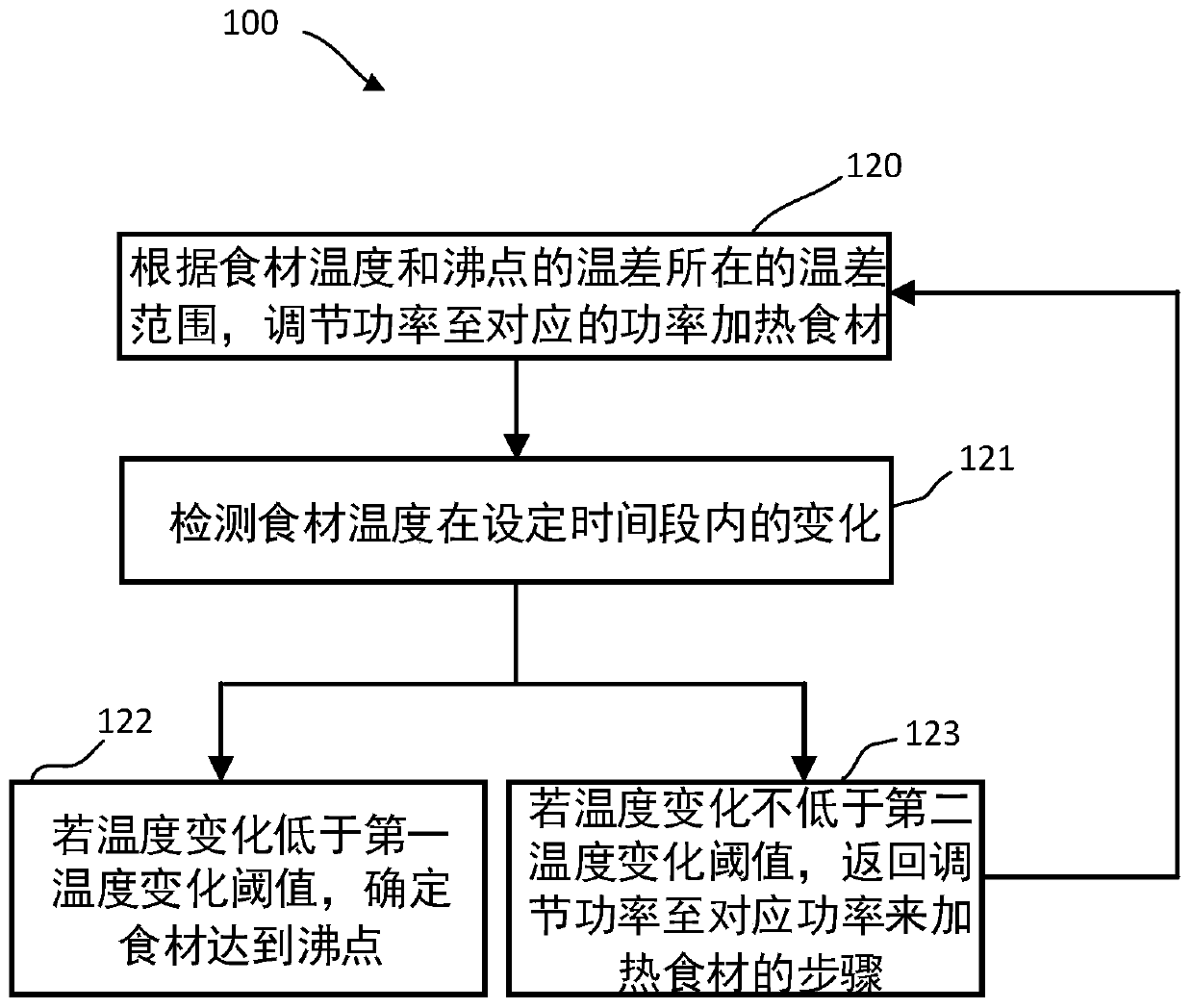

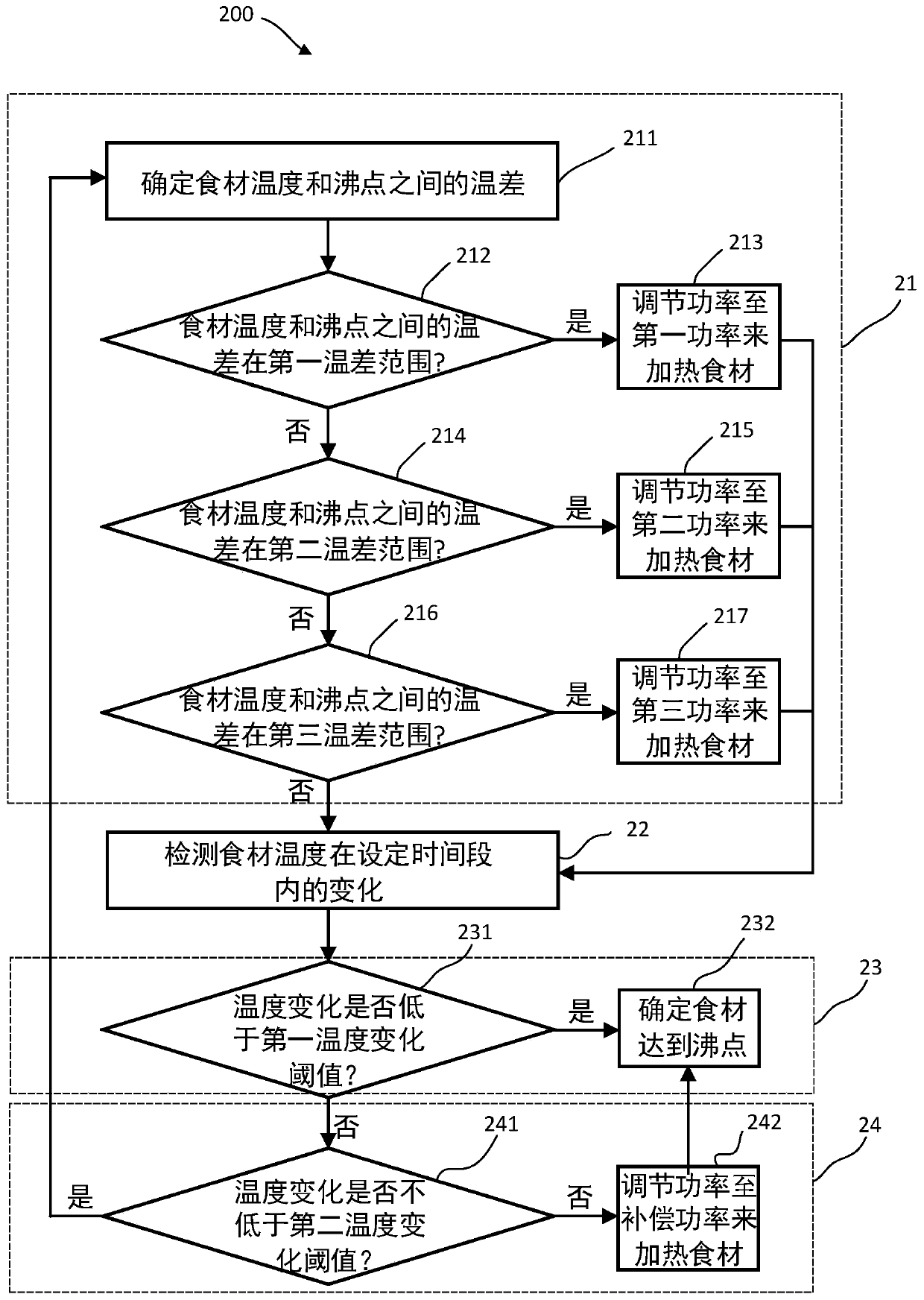

Boiling judgment method, food processer boiling judgment circuit and food processer

InactiveCN111166201AImprove the efficiency of judging boilingShorten the boil timeWarming devicesTime-controlled ignitorsTemperature controlEngineering

The application provides a boiling judgment method, a food processer boiling judgment circuit and a food processer. The boiling judgment method comprises the steps that: when a food material temperature is higher than a temperature threshold value, power is adjusted to corresponding power to heat the food material according to a temperature difference range where the temperature difference betweenthe food material temperature and the boiling point is located; the change of the temperature of the food material in a set time period is detected; if the change of the food material temperature islower than a first temperature change threshold, the food material temperature is determined to reach a boiling point; and if the change of the food material temperature is not lower than a second temperature change threshold value, the step of heating the food material by adjusting the power to the corresponding power according to the temperature difference range where the temperature differencebetween the food material temperature and the boiling point is located is performed again. The food processer boiling judgment circuit comprises a temperature detection circuit and a control circuit,the temperature detection circuit is used for detecting the temperature of a food material, and the control circuit is used for adjusting the heating power of the food material and judging whether thefood material reaches the boiling point or not according to the temperature difference range of the food material temperature and the boiling point. And if the temperature of the food material does not reach the boiling point, the heating assembly is controlled to heat the food material again.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Environment-friendly boiler waste heat recovery device for heat recovery based on heat layering

InactiveCN113757638ABurn fullyShorten the timeSolid fuel combustionCombustion technology mitigationThermodynamicsCombustion chamber

The invention discloses an environment-friendly boiler waste heat recovery device for heat recovery based on heat layering, and belongs to the technical field of heat recovery. The environment-friendly boiler waste heat recovery device for heat recovery based on heat layering comprises a base, wherein the top of the base is connected with a slag chamber, the top of the slag chamber is connected with a combustion chamber, a fuel port is formed in the outer wall of the combustion chamber, a chamber door is arranged on the outer wall of the fuel port, ventilation holes which are uniformly distributed are formed in the outer wall of the chamber door, a material turning mechanism is arranged in the combustion chamber, the end, far away from the slag chamber, of the combustion chamber is connected with a heating water tank, a shell sleeves the outer wall of the heating water tank, a first support is connected between the shell and the base, and a smoke outlet used for discharging smoke is formed in the outer wall of the top of the combustion chamber. According to the environment-friendly boiler waste heat recovery device, fuel can be completely combusted, so that harmful gas in the smoke generated after combustion is reduced, and environmental protection is facilitated; and meanwhile, the heat energy of the smoke after combustion is utilized, preheating is carried out before water body heating, so that the fuel consumption is reduced, the water boiling time is shortened, and the resource utilization rate is improved.

Owner:吕连婷

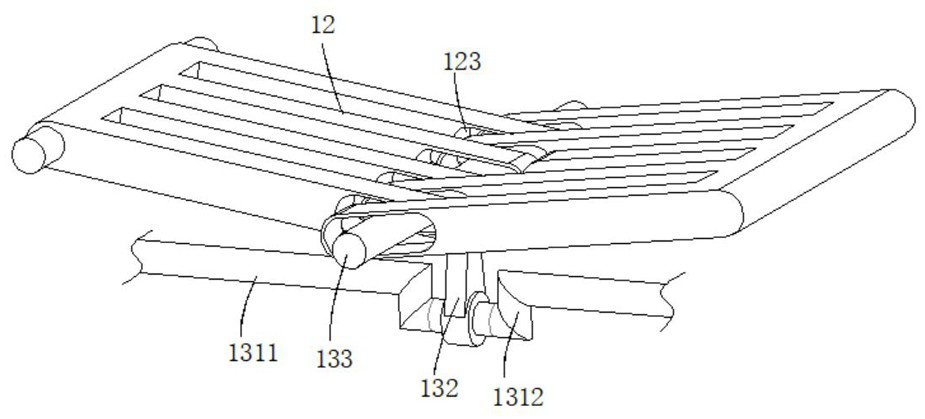

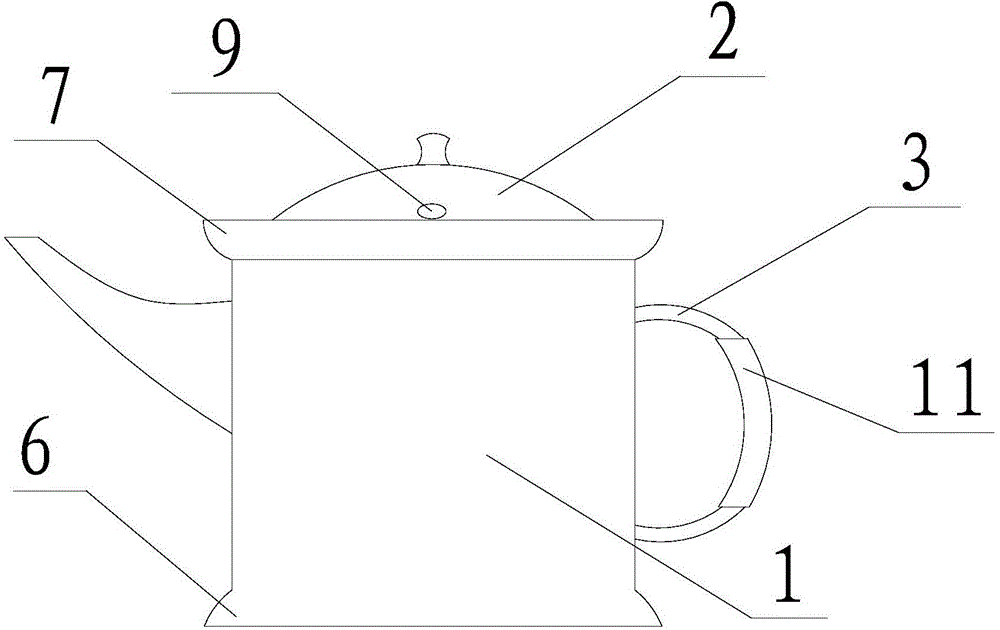

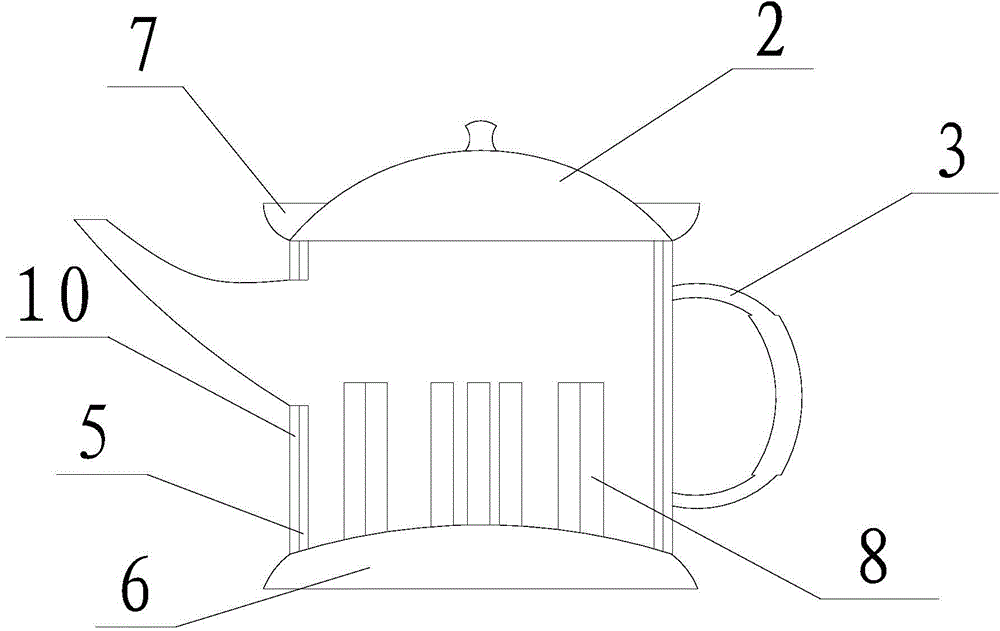

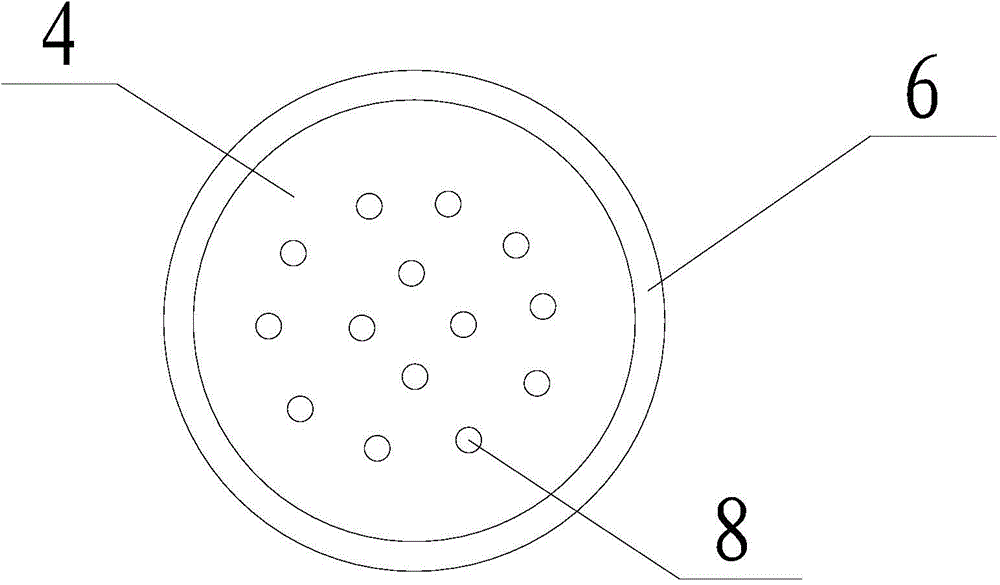

Kettle

InactiveCN104939671AProtection against lossProtection securityWater-boiling vesselsCooking utensils shields/jacketsEngineeringMechanical engineering

The invention discloses a kettle which comprises a kettle body, a kettle lid and a kettle handle. The kettle body comprises a kettle bottom and a kettle wall, wherein the kettle handle is arranged on the kettle wall. A circle of fire baffle obliquely extending outwards is arranged on the lower edge of the kettle wall and arranged obliquely towards the lower portion, and a circle of water baffle obliquely extending outwards is arranged on the upper edge of the kettle wall and arranged obliquely towards the upper portion. The kettle bottom is concaved inwards, the kettle is further provided with heat conduction pipes which are perpendicular to the kettle bottom, one end of each heat conduction pipe is arranged on the kettle bottom and provided with an opening, the other end of each heat conduction pipe is arranged in the kettle body and is sealed, and a heat insulation layer is arranged on the outer side of the kettle wall. The number of the heat conduction pipes is larger than four, the height of the heat conduction pipes is half that of the kettle wall, and the heat conduction pipes are evenly distributed on the kettle bottom. The kettle is simple in structure, the water heating time and water heating fuel can be effectively saved, boiled water is prevented from overflowing form the kettle lid to flow outside, and people can also be protected against scalds.

Owner:吴春兰

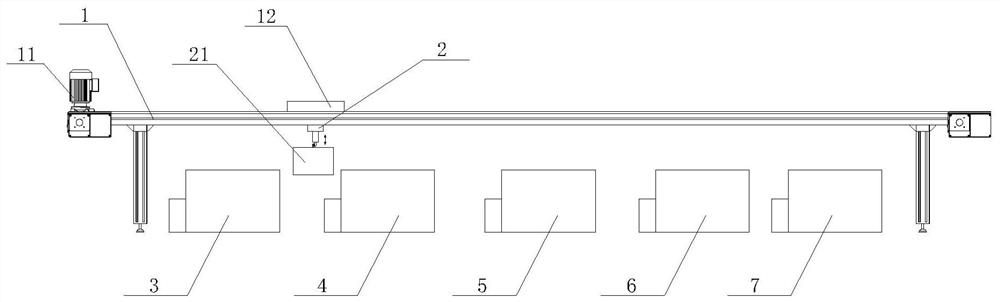

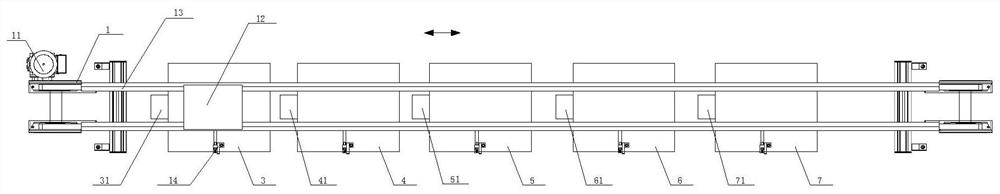

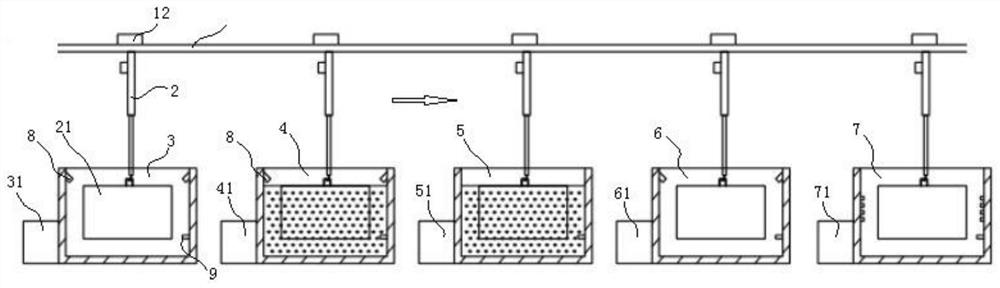

A quartz processing boiling cleaning device

ActiveCN112893265BImprove cleanlinessFull accessDrying gas arrangementsCleaning using liquidsThermodynamicsPhysical chemistry

The invention discloses a quartz processing boiling and cleaning device, which comprises a frame, an electric push rod, a PLC control device, a slide plate, a boiling tank with an infrared sensor arranged in sequence from left to right, an oil removal tank, an ultrasonic cleaning tank, and a moisturizing tank And the drying tank, the lower end of the electric push rod is hung with a material basket, the frame is equipped with an induction switch, the electric push rod is installed at the bottom of the skateboard, and nozzles are installed in the degreasing tank, boiling tank and moisturizing tank, the degreasing tank One side of the , boiling tank, ultrasonic cleaning tank, moisturizing tank and drying tank is respectively equipped with a cleaning liquid supply device, a constant temperature heating device, an ultrasonic generator, a water supply device and a hot blowing device, and the constant temperature heating device can be used for the boiling tank. The water is heated at a constant temperature to keep it in a false boiling state, and the PLC control device controls the working states of each device and electronic components. The invention has the advantages of automatically completing the boiling, washing, drying process of quartz products, stable work, high cleanliness, good control effect and the like.

Owner:NINGBO YUNDE MATERIALS INC

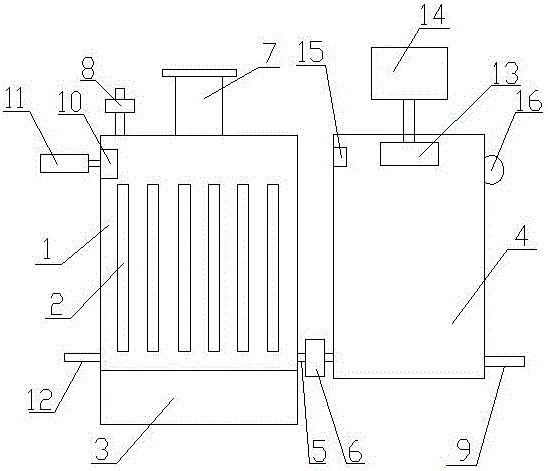

Boiler with water storage device

InactiveCN106052138AShorten production timeShorten the boil timeFluid heatersWater feed controlWater storageEngineering

The invention provides a boiler with a water storage device. The boiler comprises a heating furnace, heating strips are arranged inside the heating furnace, and a heating device is arranged below the heating strips. A water storage furnace is arranged at the right side of the heating furnace and connected with the heating furnace through a water pipe, and the water pipe is provided with a control valve. An exhaust outlet is formed in the upper side of the heating furnace, a water adding opening is arranged at the left side of the exhaust outlet, and a water outlet is arranged on the lower portion of the water storage furnace. The water storage furnace is arranged at the right side of the heating furnace, water heated in the heating furnace can enter the water storage furnace through the water pipe so as to be subjected to heat preservation, the heating furnace can be circularly used, and production time is shortened for enterprises.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

Extruded Noodle and Die Piece for Extruded Noodle

ActiveUS20170013866A1Fast penetrationShorten the boil timeFood shapingDough extruding machinesEngineeringThermal water

Owner:NISSIN YORK

Special modified starch for wrapping paper and production method thereof

ActiveCN102731842BShorten the boil timeEasy to realize the industrialization of special modified starchBiotechnologySODIUM METAPHOSPHATE

The invention provides a special modified starch for wrapping paper and a production method thereof, belonging to the filed of deep processing of maize. The special modified starch is prepared from the following components: in a volume mass ratio, 2250 m<3> to 2750 m<3> of maize starch milk 21Be' ( equivalent to 900 to 1100 Kg of a dry basis), 18 to 22 Kg of sodium tripolyphosphate, 4.5 to 5.5 Kg of sodium trimetaphosphate, 10.8 to 13.2 Kg of urea, 4.5 to 5.5 Kg of sodium hydroxide and 36 to 44 Kg of sodium carbonate. The special modified starch for wrapping paper provided in the invention has the following advantages: the special modified starch is easy to gelatinize and has a low gelatinization temperature and a short gelatinization time; gelatinized liquid has good fluidity, transparency, film forming ability and film strength; and the special modified starch has excellent bonding performance with a variety of fibers and good compatibility with other auxiliary agents.

Owner:JILIN COFCO BIOCHEM

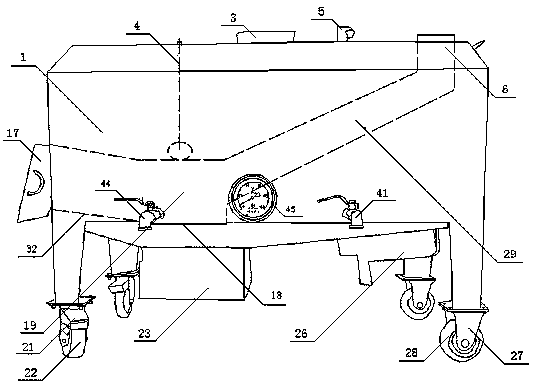

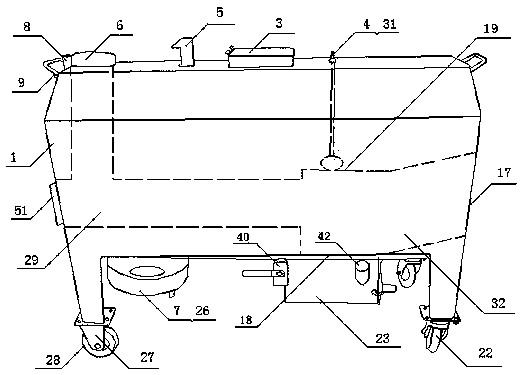

A portable horizontal boiler

The invention relates to the technical field of heating, and particularly relates to a portable and small moveable horizontal boiler. A boiler body water tank is a cuboid water tank; a hearth is arranged at the rear side of a grate; a boiler body chimney opening is arranged at the top part of the rear end of the boiler body water tank; a boiler body flue is obliquely arranged between the hearth and the boiler body chimney opening; a water level float is arranged above the hearth; the water-level float is vertically provided with a float bar; the float bar stretches out of the top part of the boiler body water tank; an observation hole is arranged at the horizontal half part of the top part of the boiler body water tank; an exhaust port is arranged between the observation hole located at the top part of the boiler body water tank and the boiler body chimney opening; handles are respectively arranged at the upper ends of the two sides of the boiler body water tank. The moveable horizontal boiler provided by the invention is simple, scientific and reasonable in structure, high in heat utilization rate, energy saving, complete in function, small in size, light in weight and moveable, and an ideal small moveable horizontal boiler is provided to families, schools and hotels for heating and water supply.

Owner:青海哈三工贸科技开发有限公司

Radiator of energy-saving and high-efficiency electric wall-mounted furnace and production process thereof

PendingCN110848983AExtended service lifeReduce temperature differenceFluid heatersHeat exchange apparatusProcess engineeringElectric consumption

The invention relates to a radiator of an energy-saving and high-efficiency electric wall-mounted furnace and a production process thereof. The radiator comprises a metal body for fixedly mounting a relay and a water pipe arranged in the metal body, wherein the metal body coats on the water pipe; one end of the water pipe extends out of the metal body to form a second water inlet; and the other end of the water pipe extends out of the metal body to form a second water outlet. According to the radiator, the heat conduction technology is adopted, the heat of the relay is absorbed by the metal body to achieve the effect of cooling and radiating, and the heat is transferred to the cold water in the water pipe for primary heating, so that the service life of the relay is effectively prolonged;and the heated water is heated again by the heating body, so that the temperature difference between a third water inlet and a third water outlet is effectively reduced, the time for boiling water iseffectively reduced, and the electricity consumption is reduced.

Owner:中山市冠禧时代电器有限公司

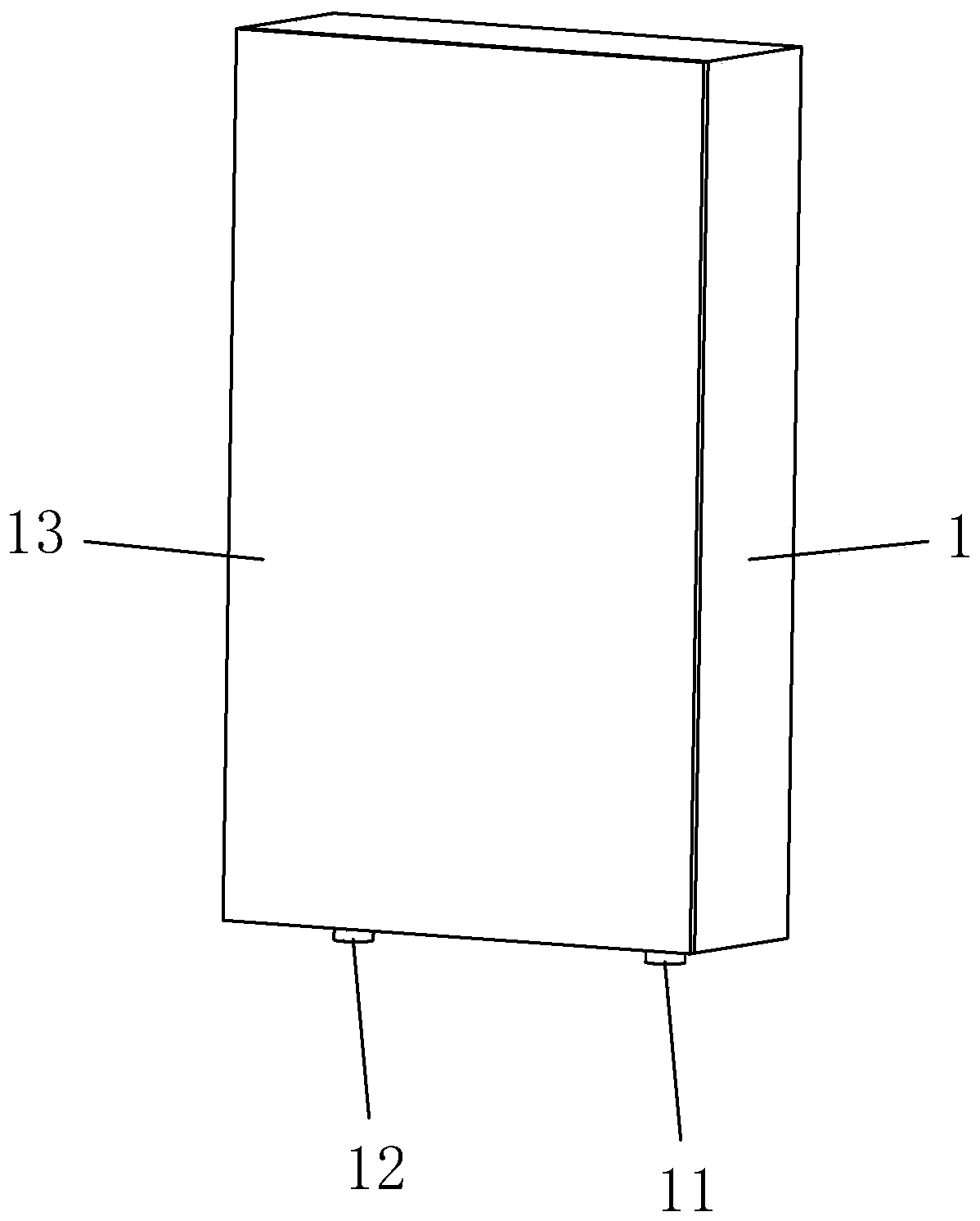

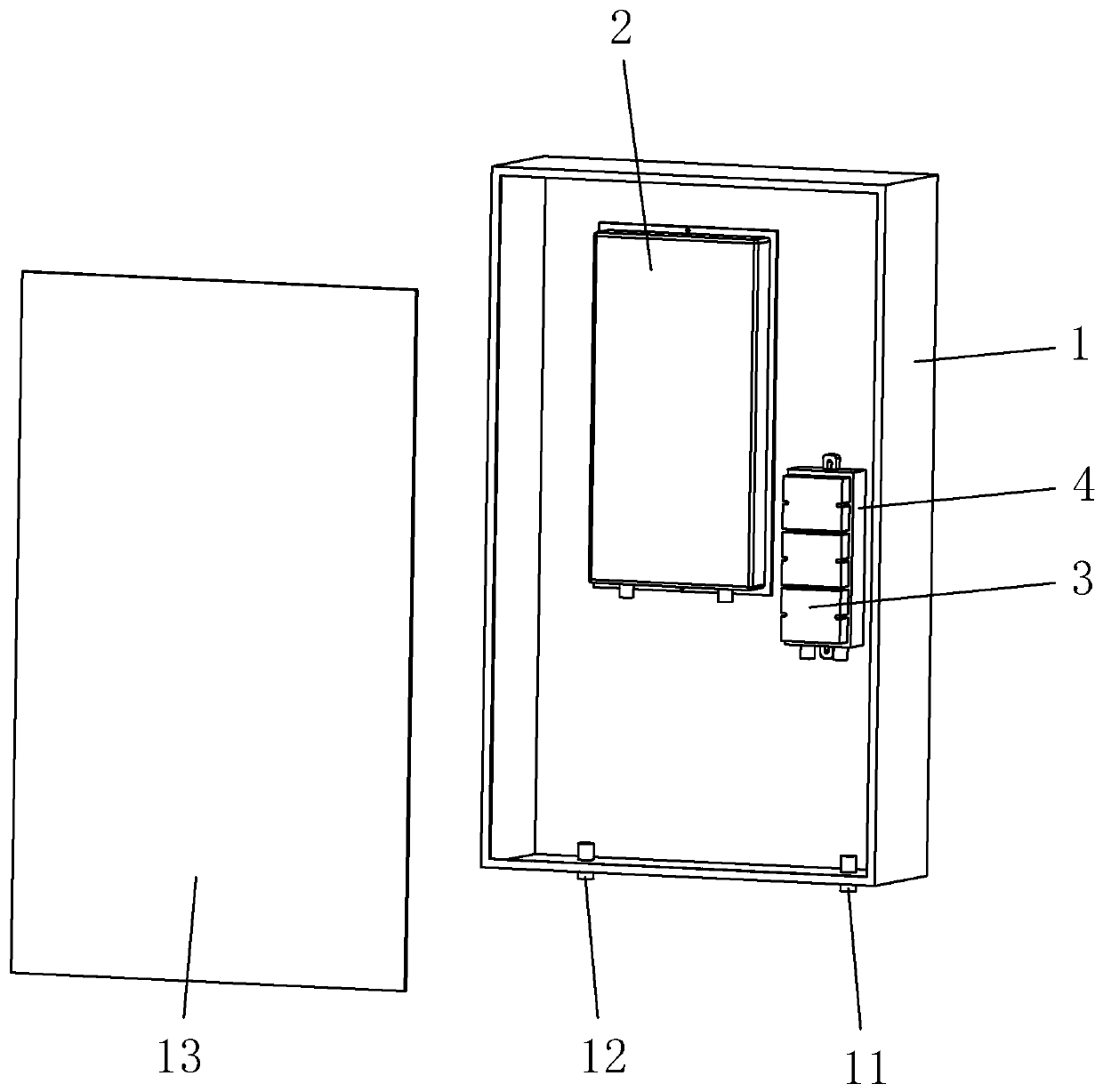

Energy-saving and efficient electric wall-hanging stove

PendingCN110671822AExtended service lifeReduce temperature differenceFluid heatersCooling/ventilation/heating modificationsWater pipeMechanical engineering

The invention relates to an energy-saving efficient electric wall-hanging stove. The electric wall-hanging stove comprises a shell, wherein a heating body, a relay and a radiator are arranged in the shell, the relay is fixedly installed on the radiator, a first water inlet and a first water outlet are formed in the shell, a third water inlet and a third water outlet are formed in the heating body,the radiator comprises a metal body and a water pipe arranged in the metal body, the metal body is coated on the water pipe, one end of the water pipe extends out of the metal body to form a second water inlet of the radiator, and the other end of the water pipe extends out of the metal body to form a second water outlet of the radiator. According to the electric wall-hanging stove, the heat conduction technology is adopted, the heat of the relay is adsorbed through the metal body to achieve the effect of cooling and heat dissipation, the heat is transferred to the cold water in the water pipe for first heating, the service life of the relay is effectively prolonged, the heated water is subjected to secondary heating through the heating body, the temperature difference between the third water inlet and the third water outlet is effectively reduced, the water heating time is effectively reduced, and the electricity consumption is reduced.

Owner:中山市冠禧时代电器有限公司

Water tank device capable of changing water quality in same container

InactiveCN102631135BSolve the problem of purification and conversion of water qualitySave electricityWater-boiling vesselsWater volumeWater quality

The invention provides a water tank device capable of changing water quality in the same container, which comprises a water tank shell, a purification handle and a separation board, wherein the separation board is positioned in the water tank shell, separates the water tank shell into two cavity bodies, and can move in the water tank shell, a water purification device is arranged in the purification handle, the separation board moves along with the variation of the water volumes in the two cavity bodies, and accordingly, the water tank which is used by the same container realizes the water quality changing in the same container. According to the water tank device provided in the invention, not only is the problem of using the same smaller water tank to purify and change the water quality solved, and more electric energy saved when water is heated, but also the water heating time is shortened, and the use is very convenient.

Owner:刘小清

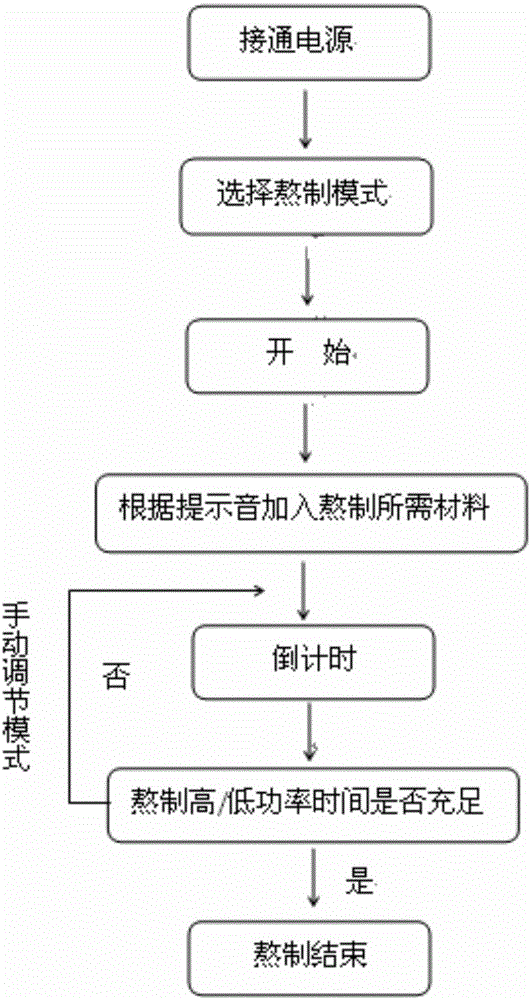

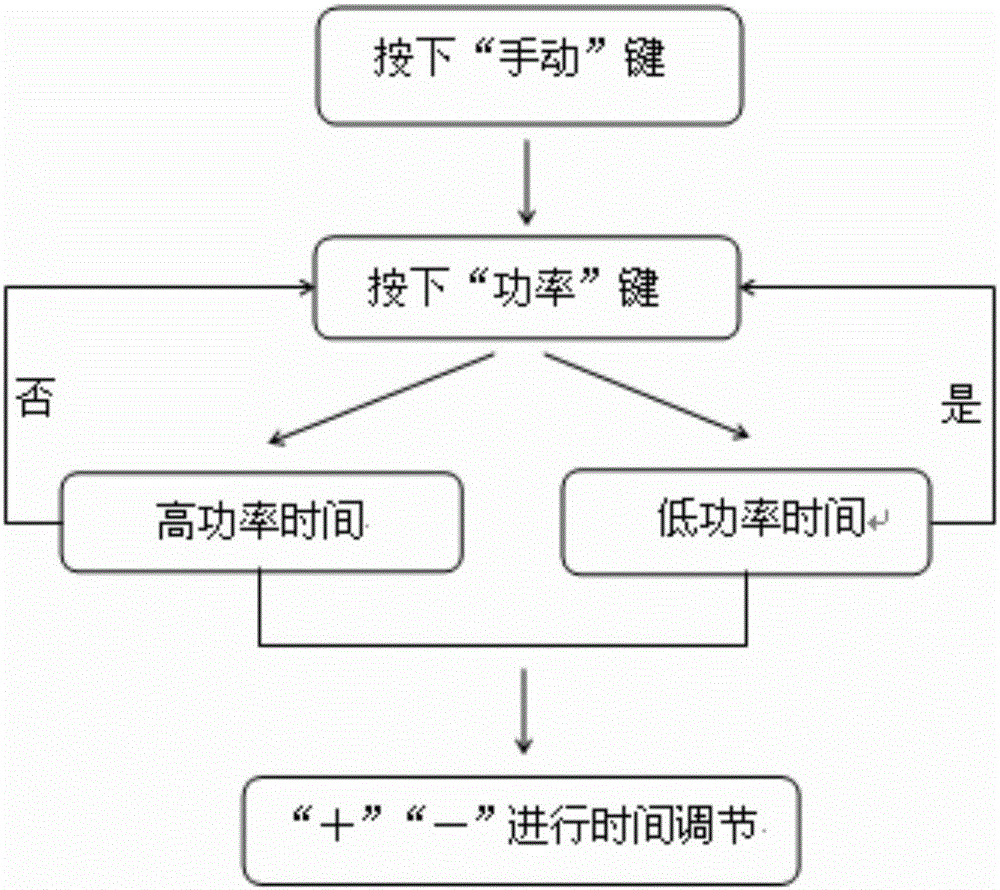

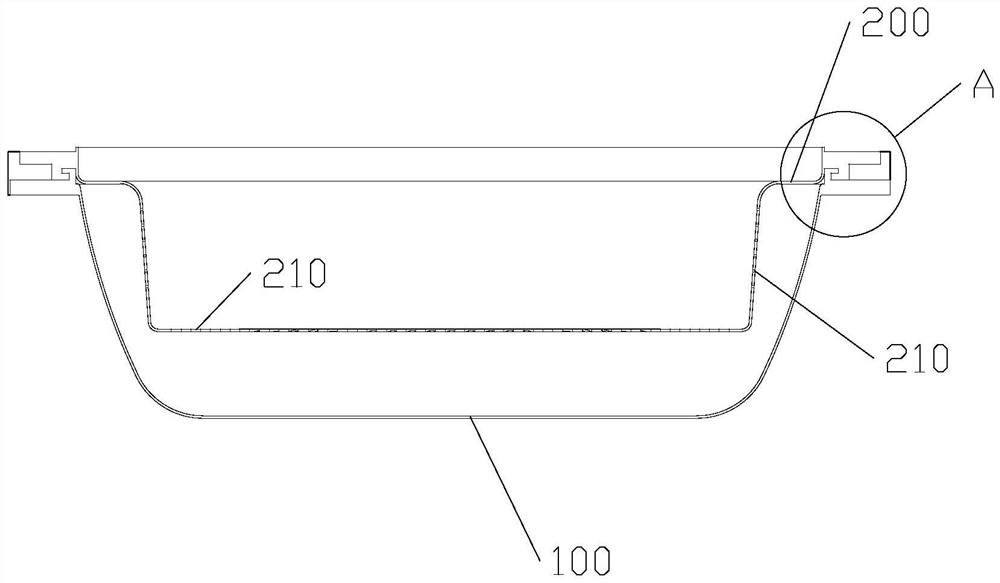

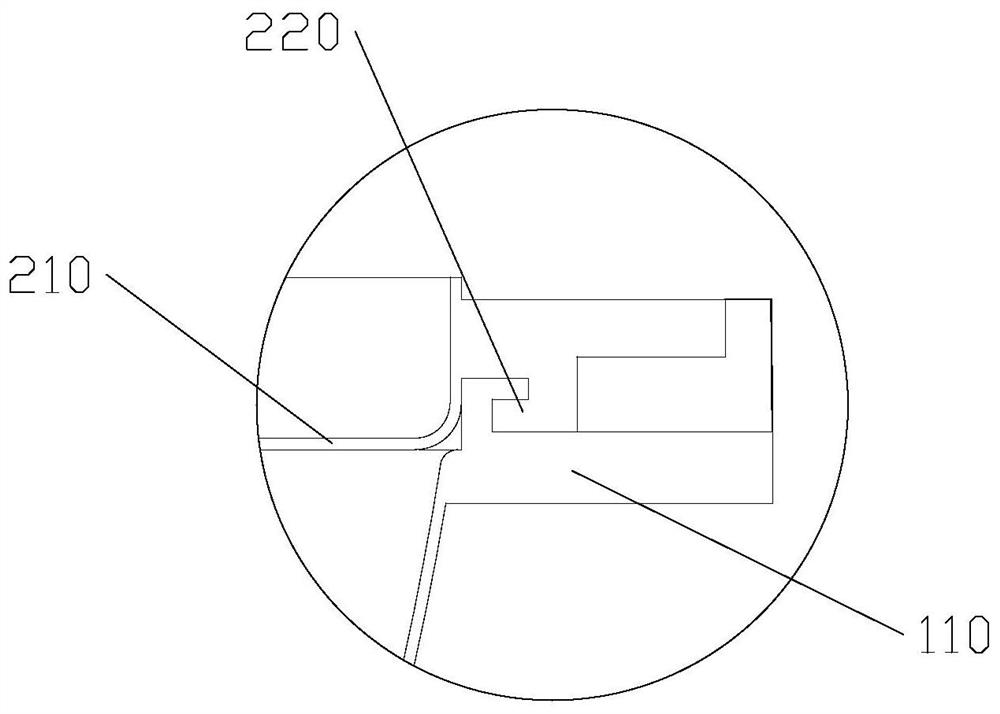

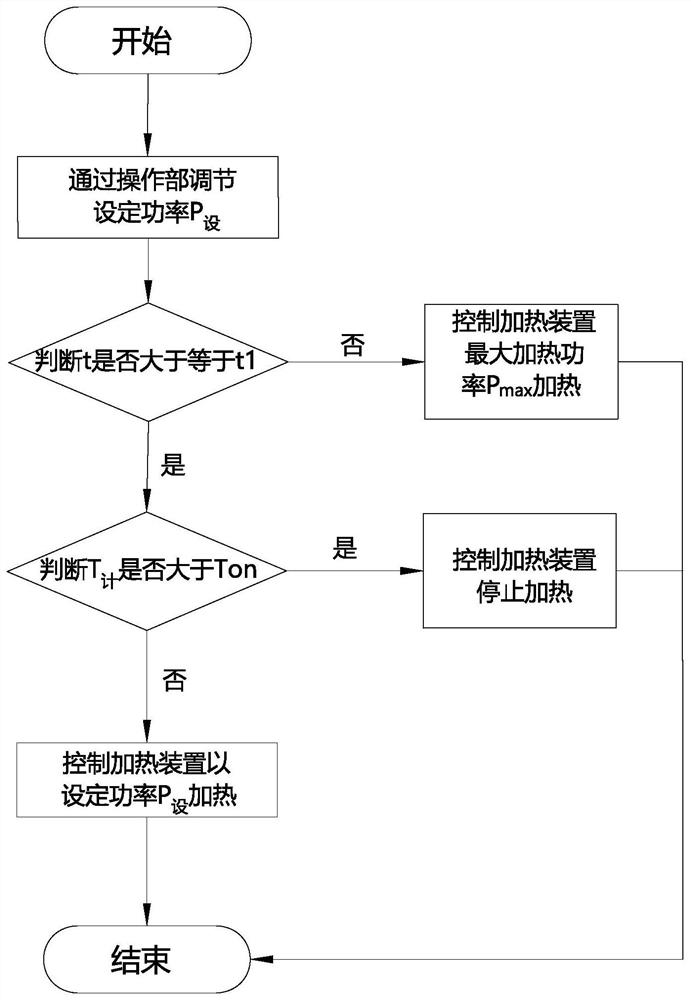

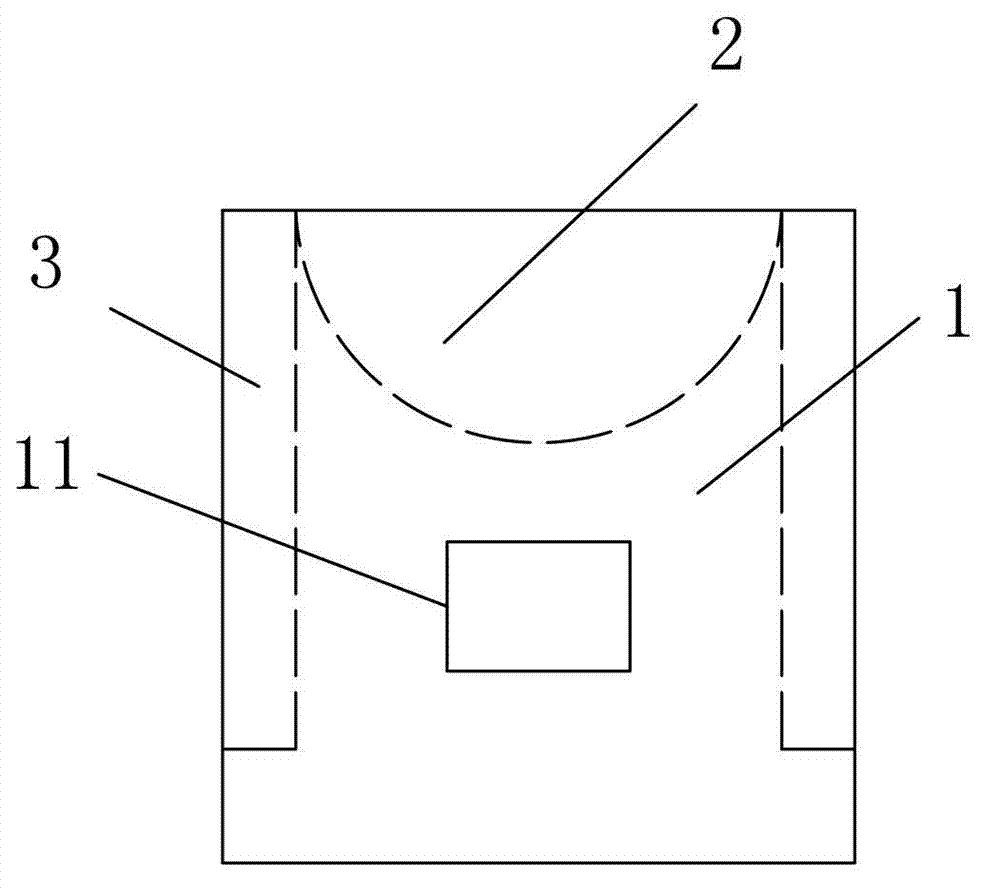

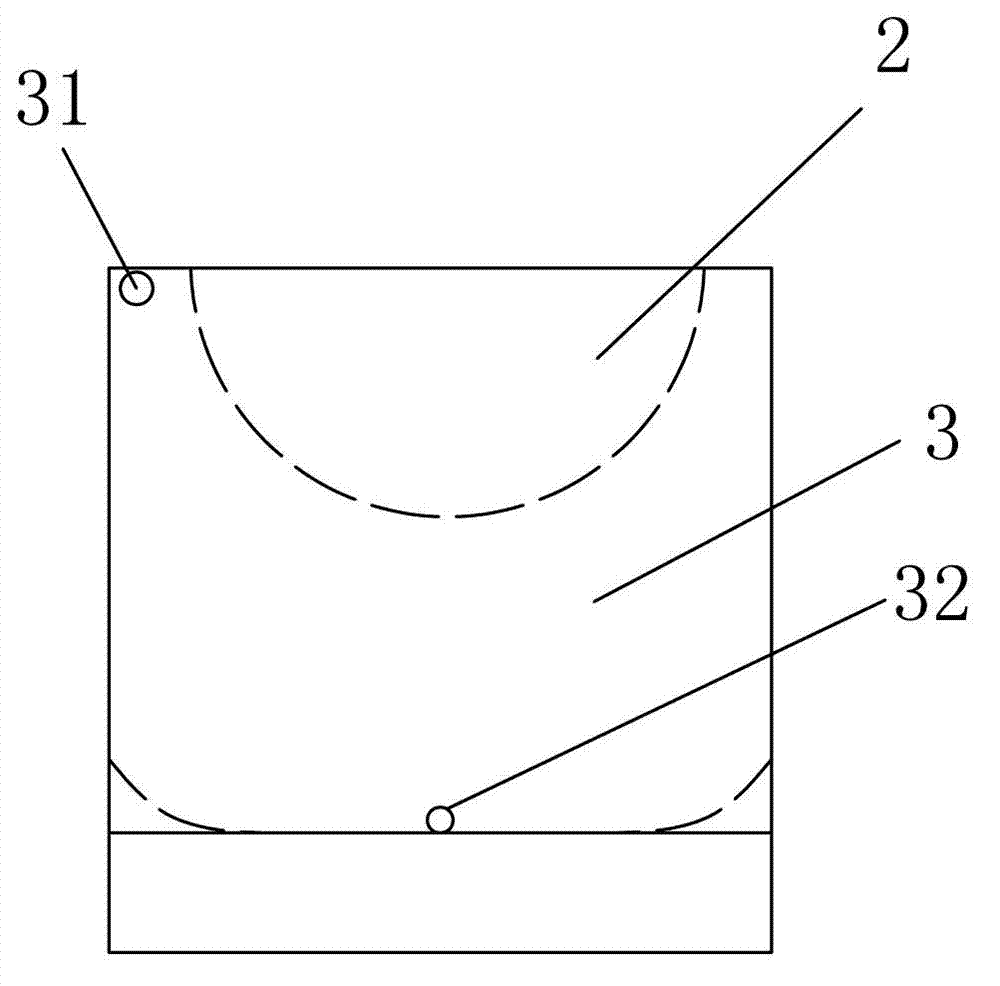

Hot pot control method

ActiveCN111887732AEasy to eatEasy to useWarming devicesTime-controlled ignitorsThermodynamicsProcess engineering

The invention discloses a hot pot control method. The invention belongs to the technical field of chafing dish, and the technical problem that the liquid level cannot be adjusted to achieve differentlifting heights in a hotpot liquid level lifting control method in the prior art is solved. The hot pot comprises a base and a soup pot placed on the base. The base comprises a heating device and a controller, a material tray and soup with the liquid level lower than that of the material tray are placed in the soup pot, a communicating hole allowing the soup to circulate is formed in the bottom wall of the material tray, an operation part connected with the controller to adjust the set power P is arranged on the base, and the hot pot control method comprises the following steps that (1) adjusting the set power P through the operation part; (2) acquiring heating parameters of the soup pot, judging whether to enter an instant-boiling stage or not according to comparison of the heating parameters and preset parameters, and if so, controlling a heating device to perform intermittent heating for multiple times at set power P, so that the liquid level rises and falls alternately for multipletimes; and if not, controlling the heating device to continue heating.

Owner:HONGYANG HOME APPLIANCES

Energy-saving cooking range

InactiveCN102818295ATake advantage ofShorten the boil timeStove/ranges for heating waterProcess engineeringEngineering

The invention mainly discloses an energy-saving cooking range which comprises a hearth and a pot hearth above the hearth. A water storing chamber is arranged in the hearth. Heat in the hearth can be fully utilized, cooking meals and dishes and heating up water can be performed simultaneously, and not only is fuel saved, but also time for heating up the water is saved simultaneously.

Owner:SHAOXING UNIVERSITY

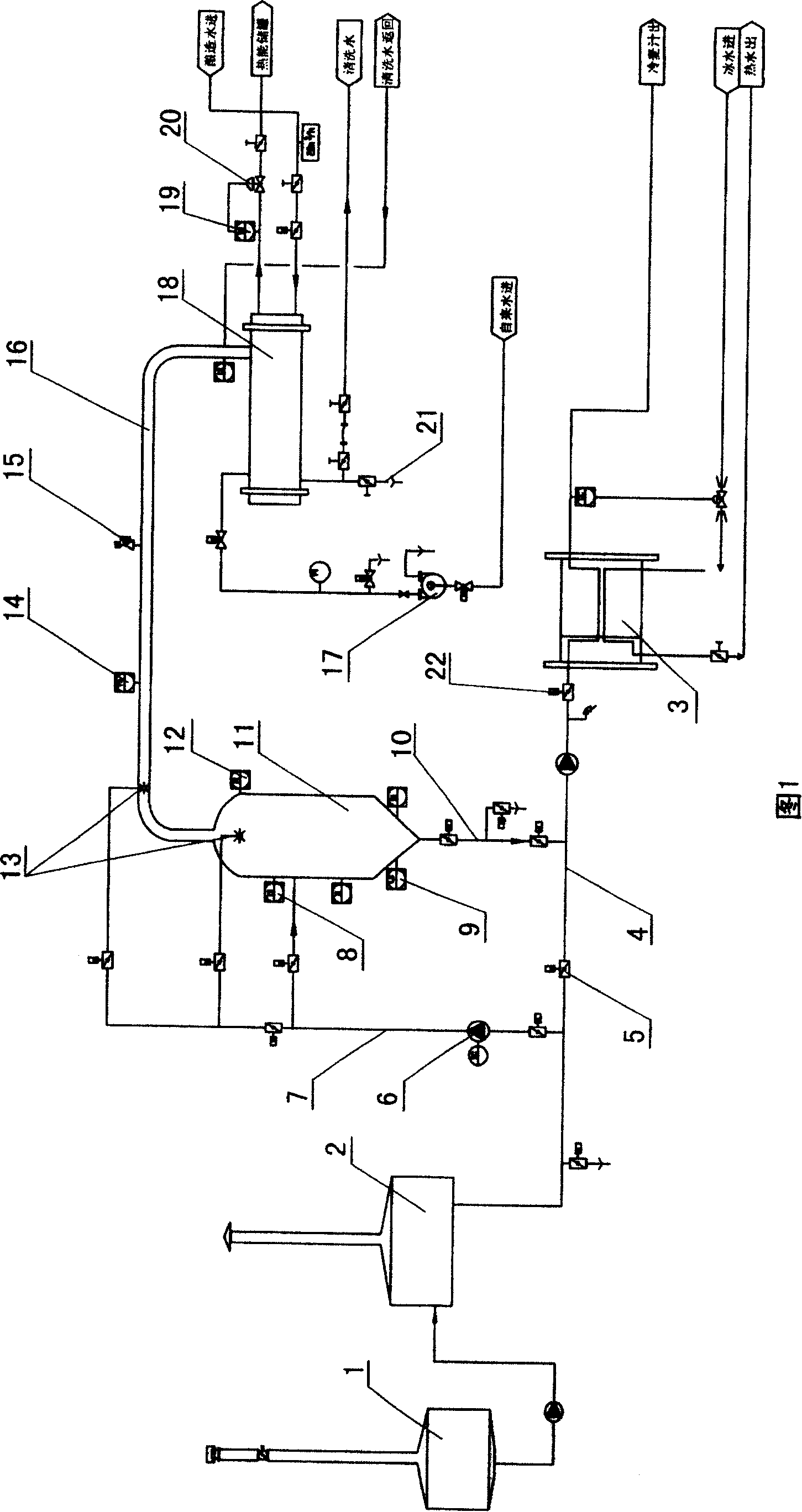

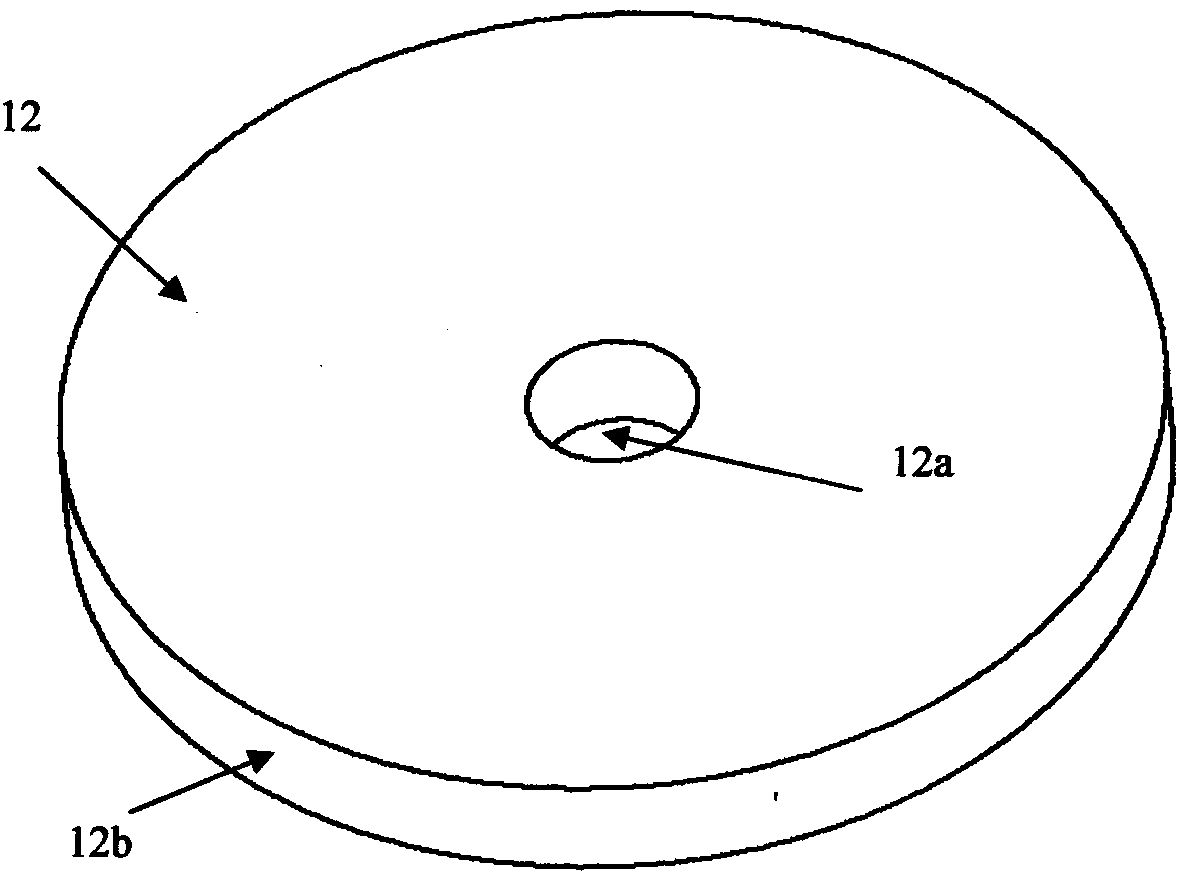

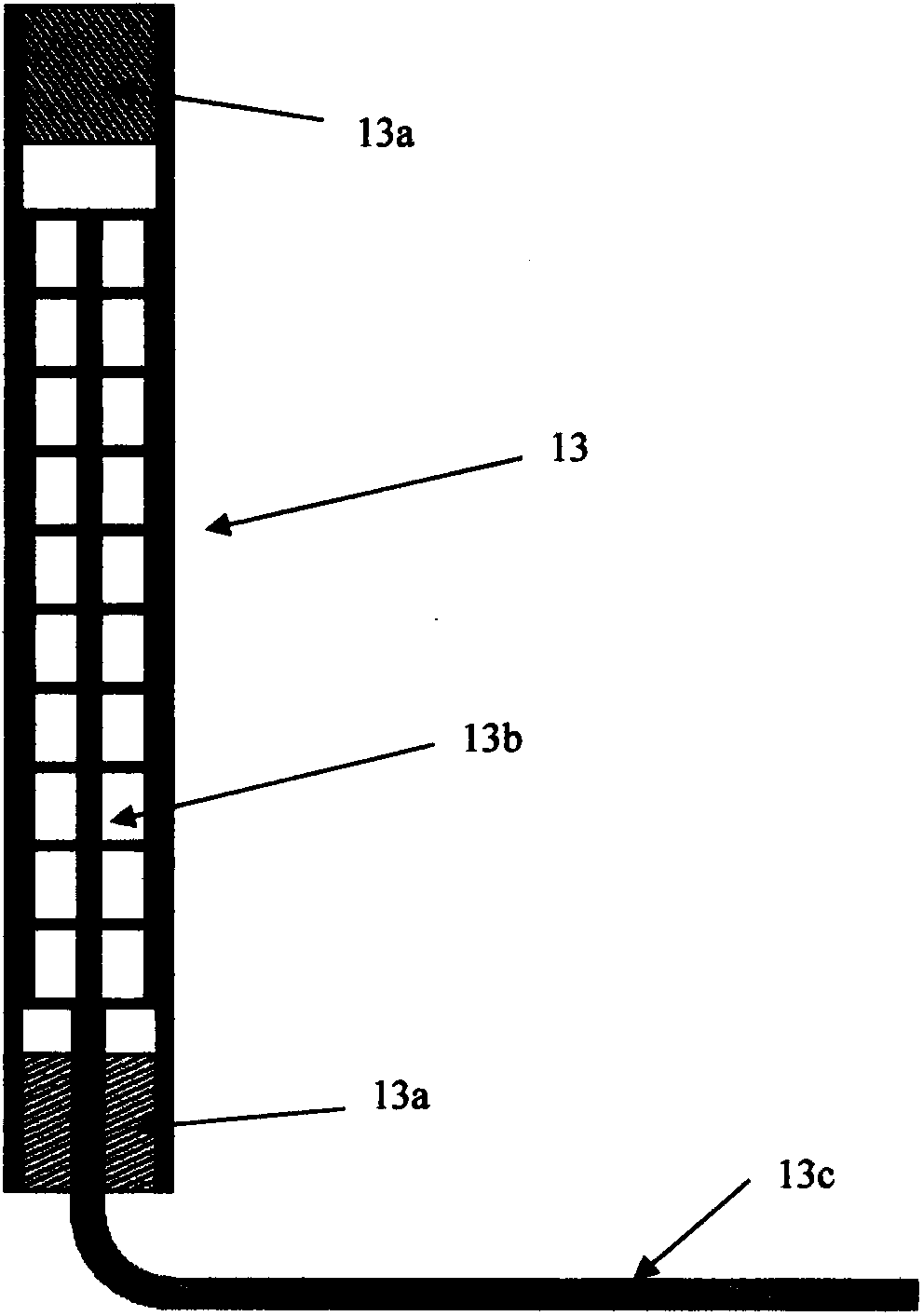

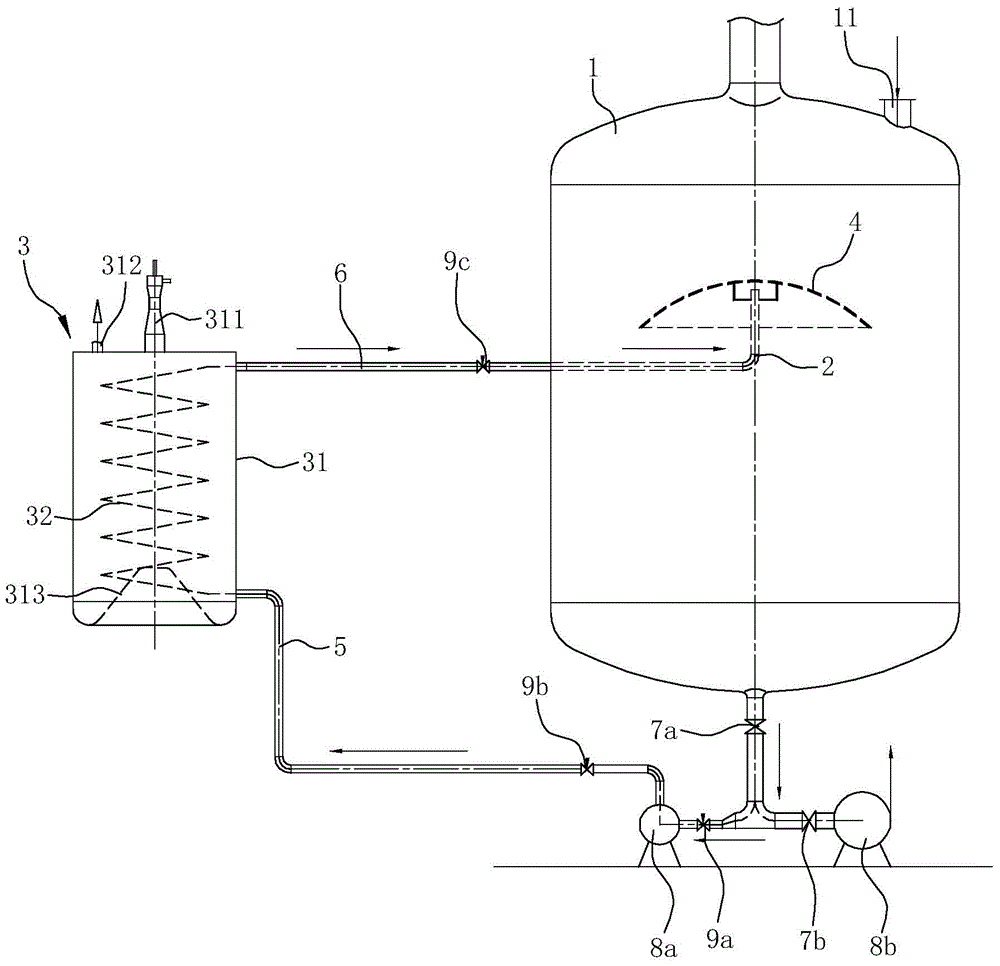

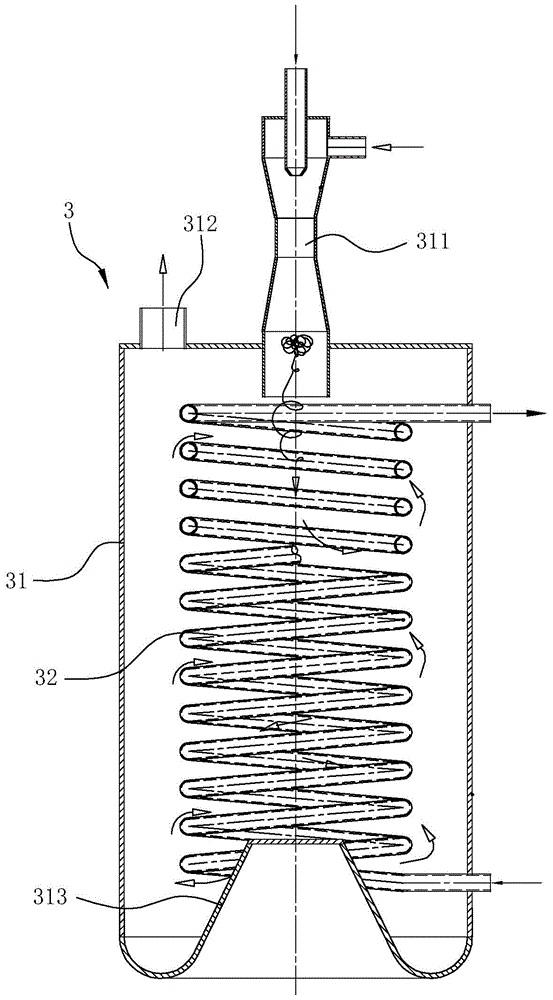

A wort boiling equipment

The invention relates to wort boiling equipment, comprising a boiling pot, and a wort inlet is formed on the boiling pot. The wort boiling equipment is characterized in that an external heating device is arranged at the outside of the boiling pot, the external heating device circularly heats the wort heated by the boiling pot through an external circulation loop, the wort further heated by the external heating device is fed into the boiling pot again, a guide pipe used for receiving the wort further heated by the external heating device is arranged in the boiling pot, a reflecting screen is further arranged in the boiling pot, and the outlet end of the guide pipe is vertically upward and is aligned to the reflecting screen. The equipment conveys the boiled wort to the external heating device, the external heating device heats the wort to a second temperature higher than the boiling temperature, after being continuously ejected to the reflecting screen in a reflux manner, the wort is flashed and evaporated at the upper part of the boiling pot, the concentrated juice flows back to the bottom of the boiling pot, the evaporation rate is improved, the boilng time is shortened, and the necessary flavor properties of the wort are obtained.

Owner:宁波沪港食品机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com